A kind of high-strength bamboo composite reconstituted material and its manufacturing method

A manufacturing method and technology for reconstituting timber, which can be applied in the fields of manufacturing tools, wood impregnation, and wood treatment, etc., which can solve the problems of low material utilization rate and board strength-to-weight ratio, high glue consumption and production cost, and restricting the market competitiveness of bamboo materials. , to achieve the effect of increasing the strength-to-weight ratio, increasing the strength-to-weight ratio, and prolonging the ignition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

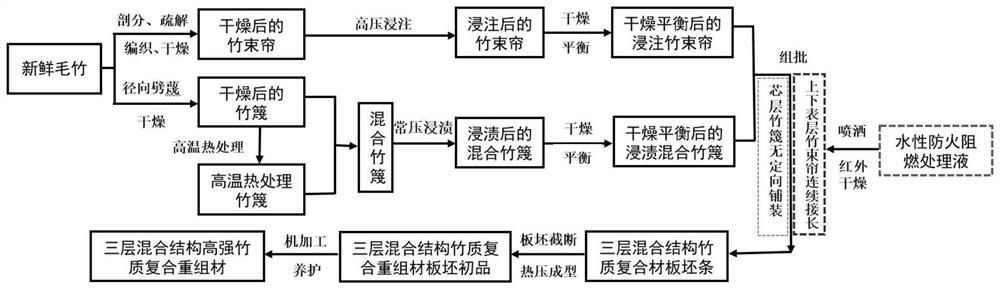

[0042] like figure 1 As shown, the manufacturing method of the high-strength bamboo composite reconstituted material of a three-layer hybrid structure of the present embodiment specifically includes the following steps:

[0043] (1) Preparation of radial bamboo strips: sawing fresh moso bamboo into bamboo tubes with a length of 1.5 m, and after removing green and yellow, the bamboo tubes were processed into radial bamboo strips with a thickness of 1.5 mm using a radial breaking machine.

[0044] (2) Bamboo bundle preparation: sawing fresh moso bamboo into a bamboo tube with a length of 1.5m, using a bamboo dispersing machine to split the bamboo tube into bamboo pieces with a width of 30mm, removing the bamboo green and then using a decompression machine to decompose it into horizontal loose, Longitudinal bamboo bundles.

[0045] In this application, the size of the bamboo bundle is inconsistent with the bamboo strip, and there is no specific requirement for the thickness. Be...

Embodiment 2

[0064] like figure 1 As shown, the manufacturing method of the high-strength bamboo composite reconstituted material of a three-layer hybrid structure of the present embodiment specifically includes the following steps:

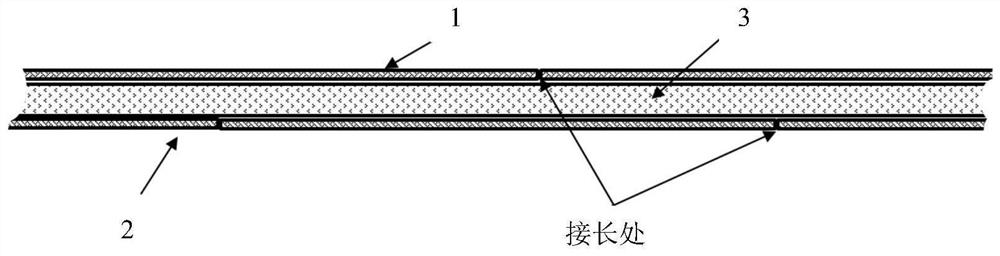

[0065] (1) Bamboo bundle curtain preparation: cutting fresh moso bamboo into a bamboo tube with a length of 2.0m, using a bamboo dispersing machine to split the bamboo tube into bamboo pieces with a width of 25mm, removing the green bamboo and using a decompressor to roll it into horizontal looseness, After the longitudinally connected bamboo bundles are loosened, the bamboo bundles are woven into curtains in parallel with a weaving machine. The distance between adjacent bamboo bundles is not greater than 2mm, and the distance between adjacent sutures is 0.4m, resulting in a length of 1.5m and a width of 2.0 m bamboo beam curtain.

[0066] When using bamboo bundles to weave bamboo curtains, the size of the bamboo bundles only needs to be evenly matched, no s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com