High-strength wear-resistant hard alloy glass cutter drilling tool

A technology of cemented carbide and glass cutters, applied in the direction of manufacturing tools, stone processing tools, work accessories, etc., can solve the problems of increased replacement costs, inconvenient use, and poor drilling flexibility, so as to save replacement costs and facilitate drilling , Flexible and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

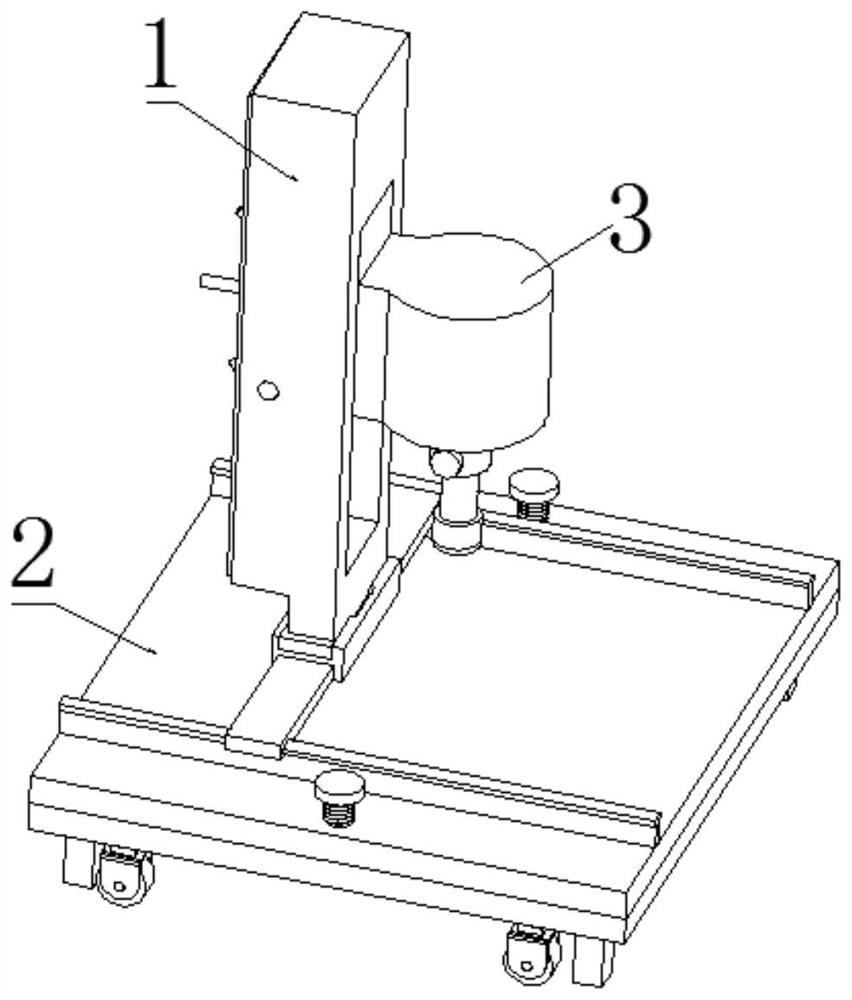

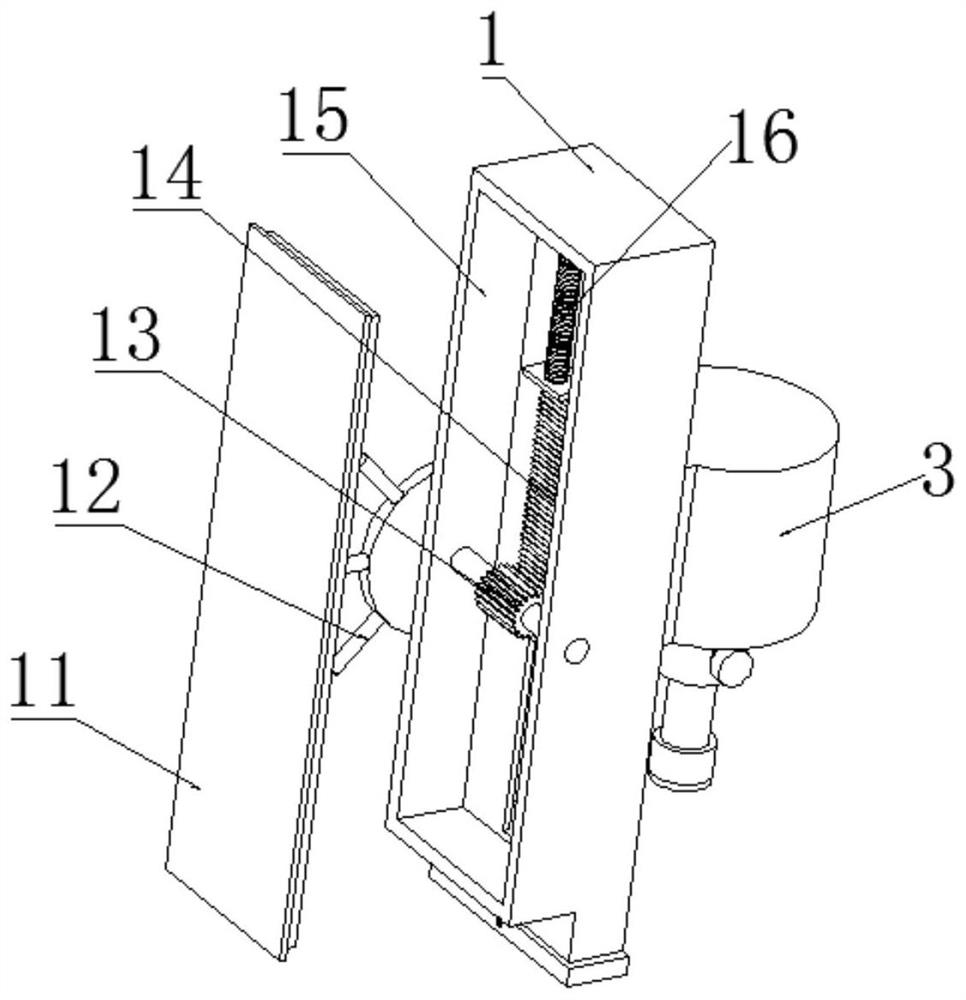

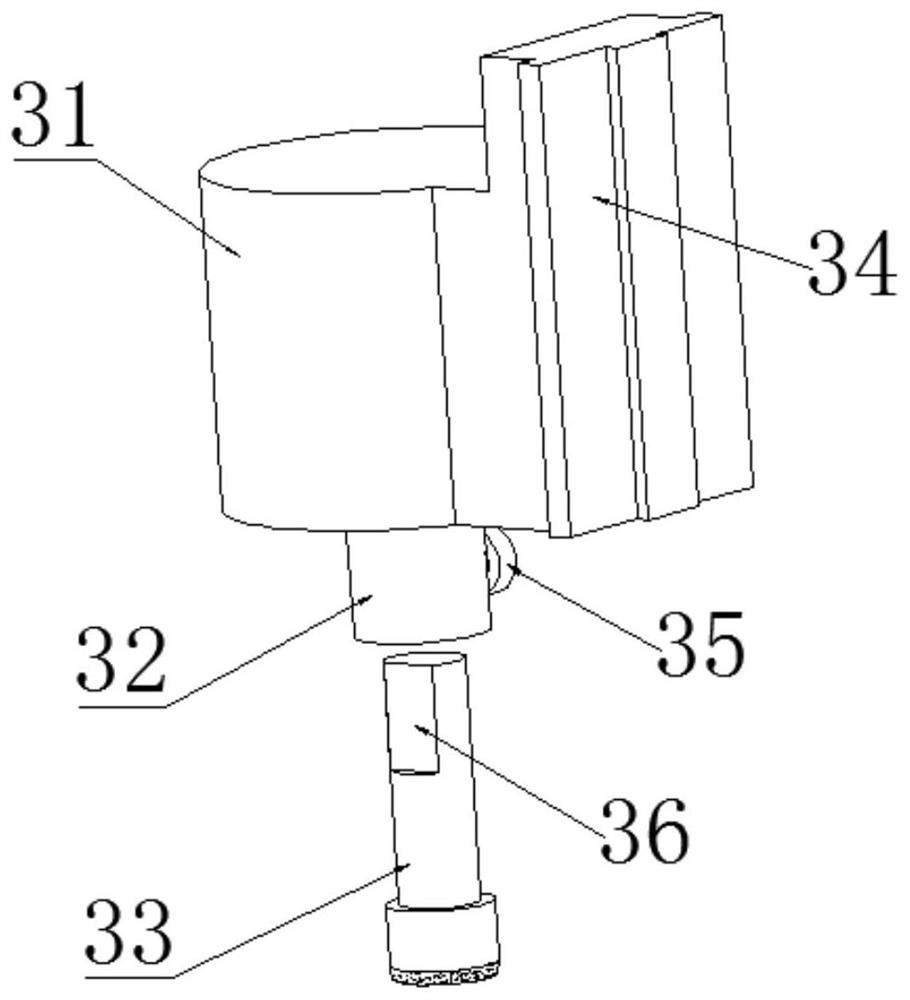

[0030] Example 1, please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a high-strength wear-resistant hard alloy glass cutter drilling tool includes a support column 1, and one side of the support column 1 is provided with a drilling mechanism 3 that can be adjusted up and down, and the lower end of the support column 1 is detachably fixed on the The base 2, the left side of the support column 1 is provided with an installation cavity 15, and the inside of the installation cavity 15 is provided with a vertical rack 14, the drilling mechanism 3 includes a motor 31, the left end of the motor 31 passes through the support column 1 and the rack 14 is fixedly connected, and the rack 14 is meshed with a tooth column 13, the upper end of the rack 14 is connected with a tension spring 16 fixedly connected to the inner top of the installation cavity 15, and one end of the central axis of the tooth column 13 passes through the side wall of the installat...

Embodiment 2

[0032] Example 2, please refer to Figure 7 and Figure 8 As shown, a high-strength wear-resistant cemented carbide glass cutter drilling tool includes a support column 1, the lower end of which is fixed on a fixed seat 4, and the fixed seat 4 is fixedly arranged near the four corners to carry out on the glass. Adsorption fixed adsorption mechanism 43, and the middle part of the right side of the fixed seat 4 is provided with a relief opening 44 for the drill bit 33 to make way, and the adsorption mechanism 43 is adsorbed on the surface of the larger glass to realize the attachment of the fixed seat 4 on the glass. Fixed so as to facilitate the drilling of the drilling mechanism 3 on the glass, so that the drilling mechanism 3 can be fixedly drilled at any position on the larger glass, and the drilling process of the larger glass is more flexible and convenient. The upper surface is provided with an installation groove 42 that cooperates with the fixed block 19, and the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com