Waste lithium battery recycling device

A waste lithium battery and recycling device technology, applied in garbage collection, household appliances, applications, etc., can solve the problems of waste lithium battery damage, inconvenient garbage sorting and recycling, environmental pollution, etc., to reduce vibration, avoid environmental pollution, and reduce damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

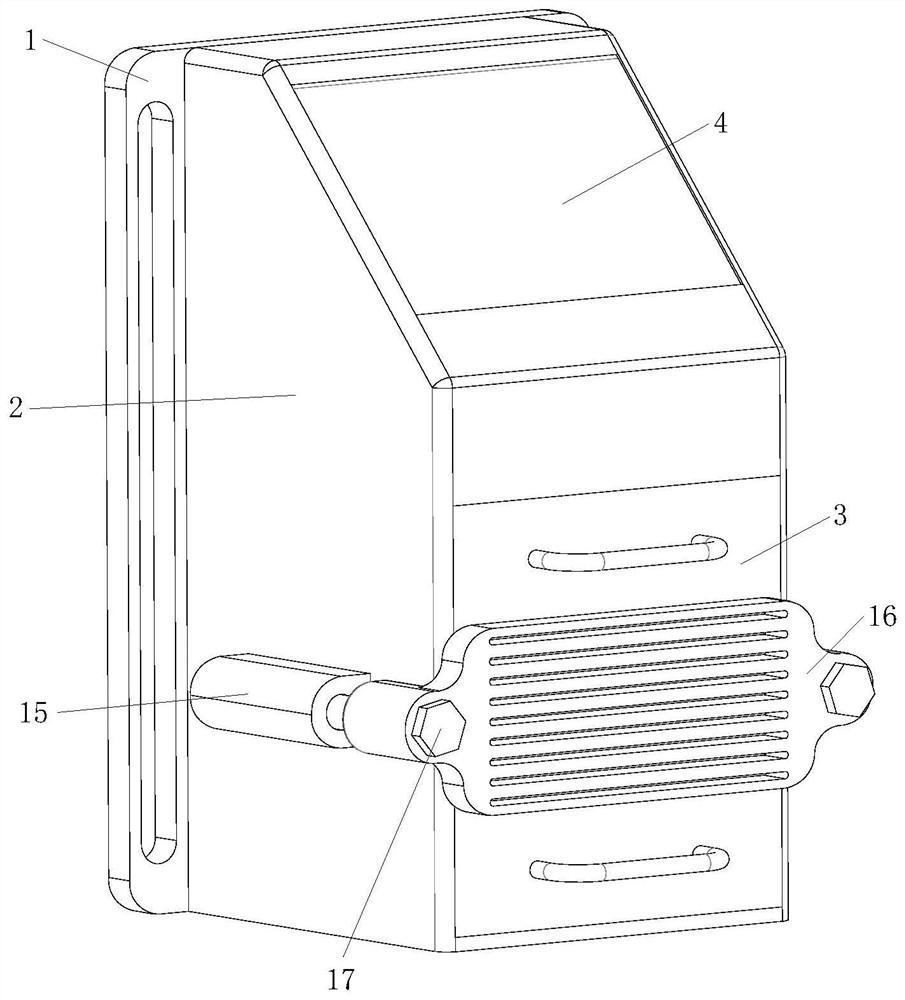

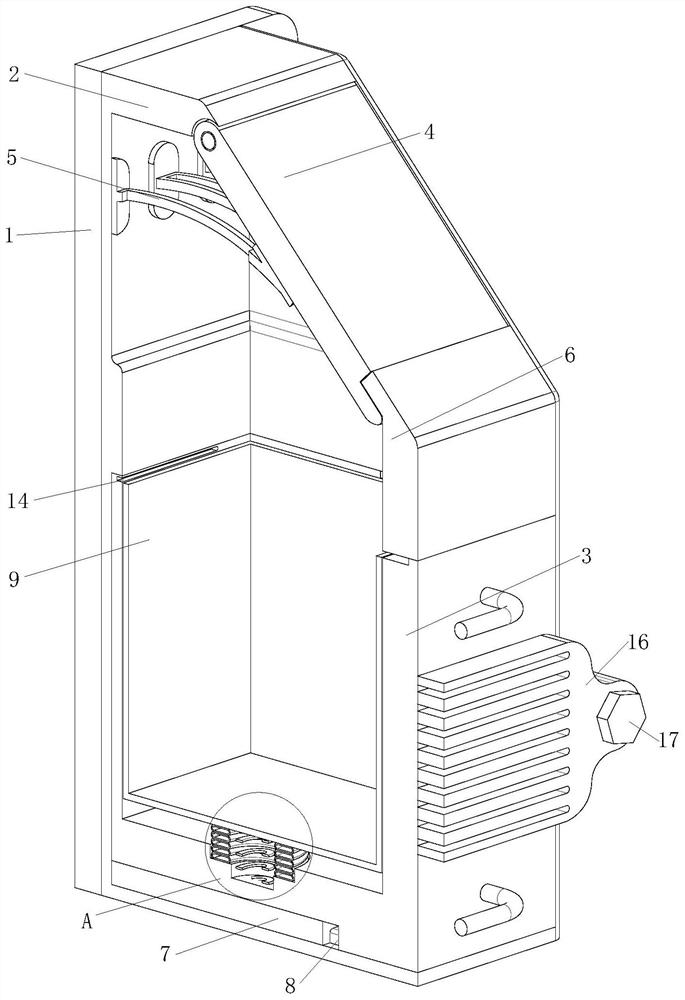

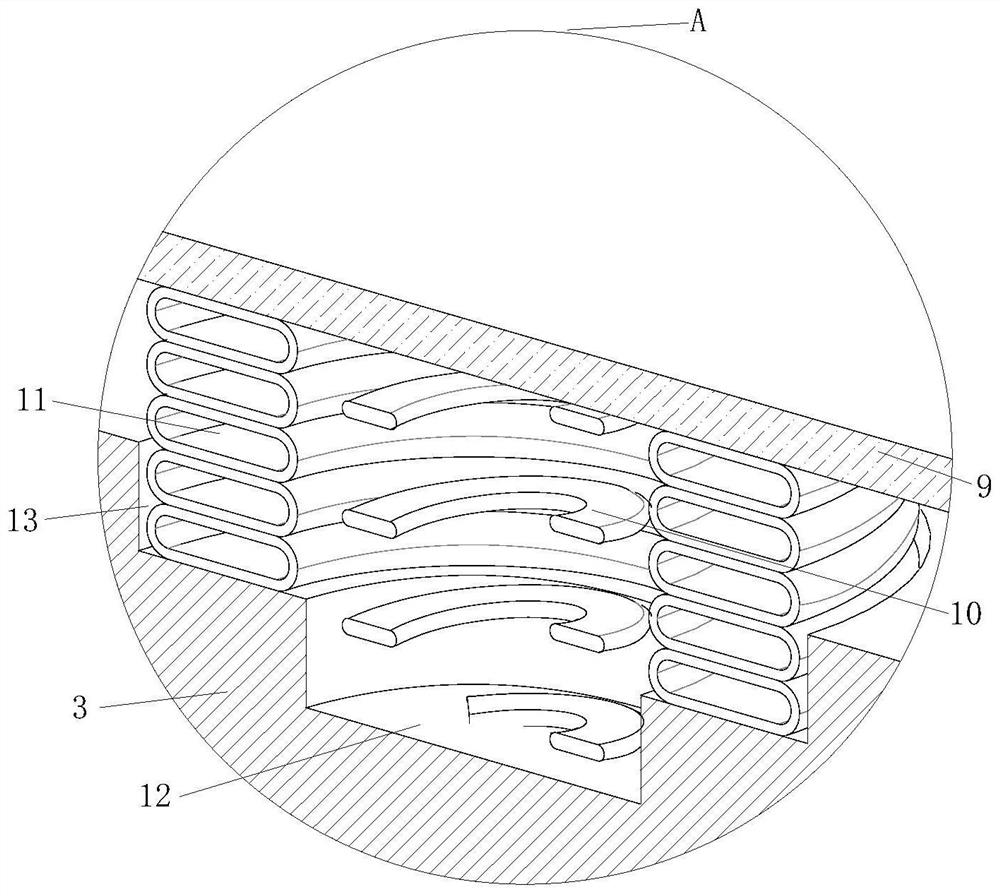

[0024] see Figure 1-3 As shown, a waste lithium battery recovery device includes a fixed plate 1, a recovery box 2 and an inner box 3; the middle part of the fixed plate 1 is fixedly connected to the recovery box 2, and the inner box 3 is slidably installed inside the recovery box 2, The top of the recovery box 2 offers a recovery port, and an isolation assembly is installed inside the recovery port;

[0025] The isolation assembly includes a partition 4 and a reset shrapnel 5; the inner top side of the recovery port is fixed to a rotating shaft, the outer ring of the rotating shaft rotates to install the partition 4, and the top inner wall of the recovery box 2 is installed with multiple reset screws. One end of the shrapnel 5, the other end of the reset shrapnel 5 is screwed to the back of the partition 4; the fixing plate 1 is installed and fixed on the wall of the resident corridor by screws, and the waste lithium battery of the resident is put into the recycling port of ...

Embodiment 2

[0033] see Figure 4 As shown in Comparative Example 1, as another embodiment of the present invention, the top bottom surface of the retaining seat 6 and the bottom of the partition plate 4 are provided with installation grooves 18, and the insides of the installation grooves 18 on the other side are equipped with magnets. 19, the magnets 19 on both sides are attracted to each other; the blocking force of the separator 4 is further improved by the mutual attraction of the magnets 19 on both sides.

[0034] Working principle: Firstly, fix the fixing plate 1 on the wall of the residential building with screws, slide the inner box 3 into the installation opening through the sliding cooperation between the guide rail 7 and the guide groove 8, use the bolt 17 to pass through the through hole, and then screw it in After the threaded hole, the pressing plate 16 presses the inner box 3 into the installation port, and the inner box 3 is fixed and locked;

[0035] Afterwards, the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com