A compound film glazing heat energy recovery unit

A light-heat and unit technology, which is applied in the direction of printing machines, lighting and heating equipment, and general parts of printing machinery, can solve the problems of energy waste, unfavorable energy saving and consumption reduction of enterprises, and inability to reduce cost expenditures, so as to reduce costs and prevent The effect of heat dissipation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

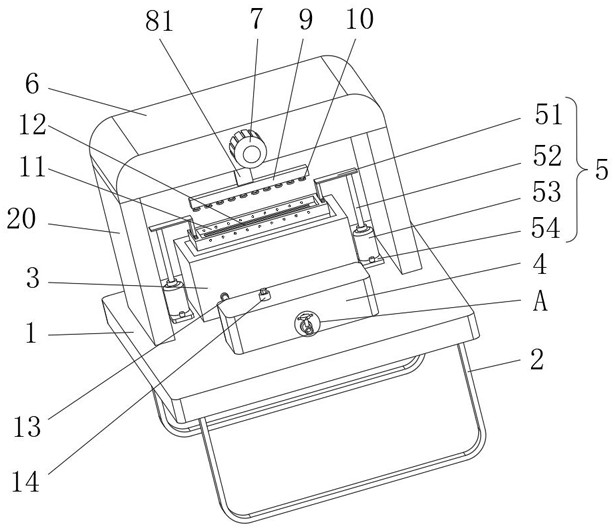

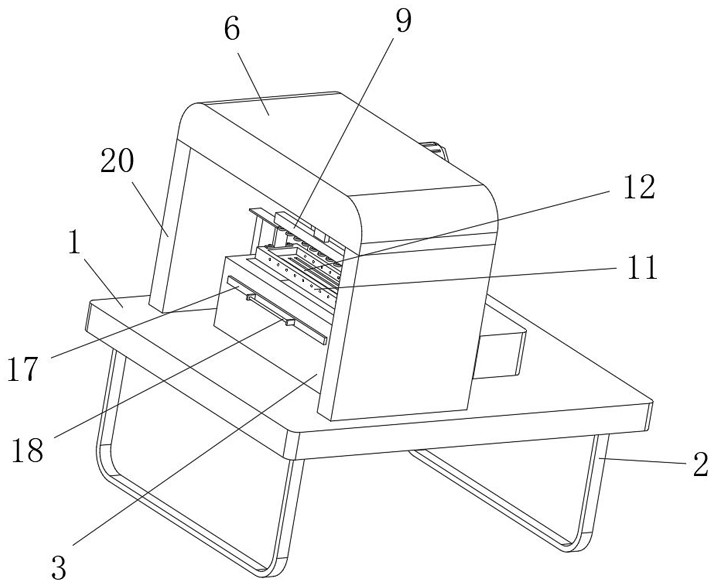

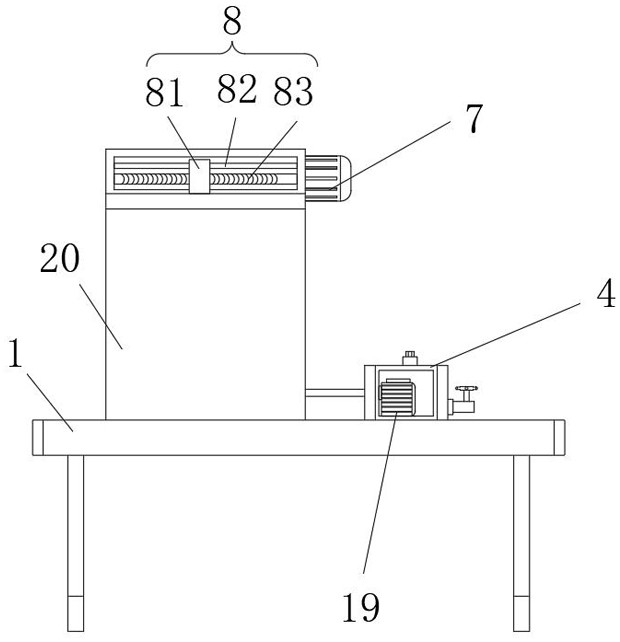

[0028] Such as Figure 1-6 As shown, the embodiment of the present invention provides a light and heat energy recovery unit for laminating coating, including a support plate 1, and two symmetrically arranged support legs 2 are fixedly connected to the lower side wall of the support plate 1. The support legs 2 are U-shaped, and the support legs 2 Hollowing treatment, and the support leg 2 is made of stainless steel die-casting, the surface of the support leg 2 is treated by coating the nano-varnish anti-oxidation film coating process, the upper side wall of the support plate 1 is fixedly connected with two vertical plates 20 arranged symmetrically at the front and rear , and the upper end of the riser 20 is fixedly connected with the top plate 6, the interior of the top plate 6 is provided with a moving cavity, the side wall of the top plate 6 is fixedly connected with the motor 7, the output end of the motor 7 penetrates into the interior of the top plate 6 and is connected wit...

Embodiment 2

[0033] The difference between the second embodiment and the first embodiment is that the motor 7, the threaded rod 83, and the threaded bar 81 are changed into electric telescopic rods, and the electric telescopic rods are connected with the placement frame 11, so that the movement in the horizontal direction can also be realized, and the automatic upward movement can be realized. light work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com