Four-in-one winding machine with forward and reverse winding functions

A winder and functional technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of general tightening effect, general deviation correction effect, and single function, etc., to improve the tightening effect, Increased winding resistance and improved functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

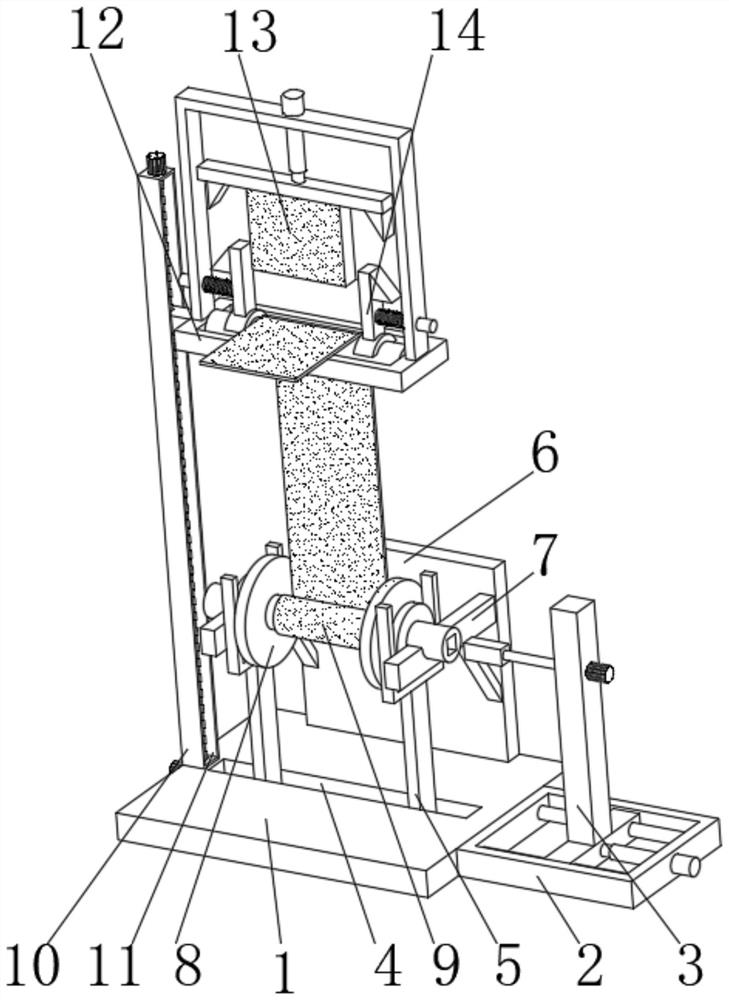

[0036] See Figure 1-8 The technical solutions provided in this embodiment are as follows:

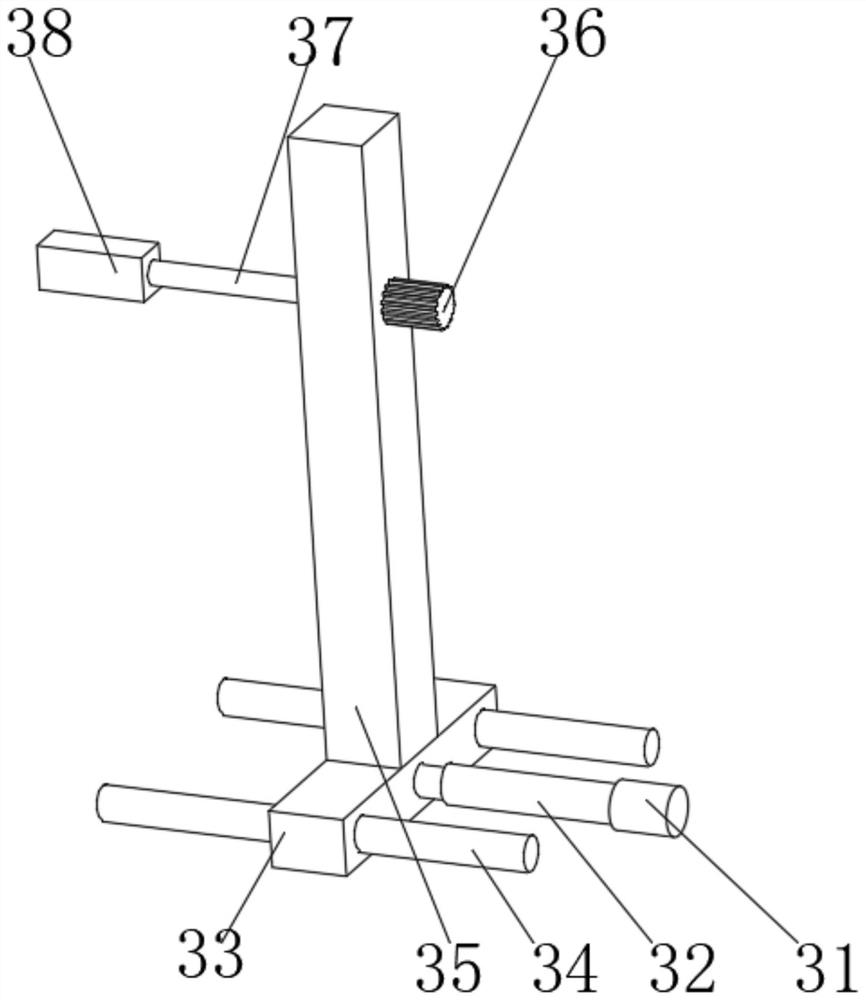

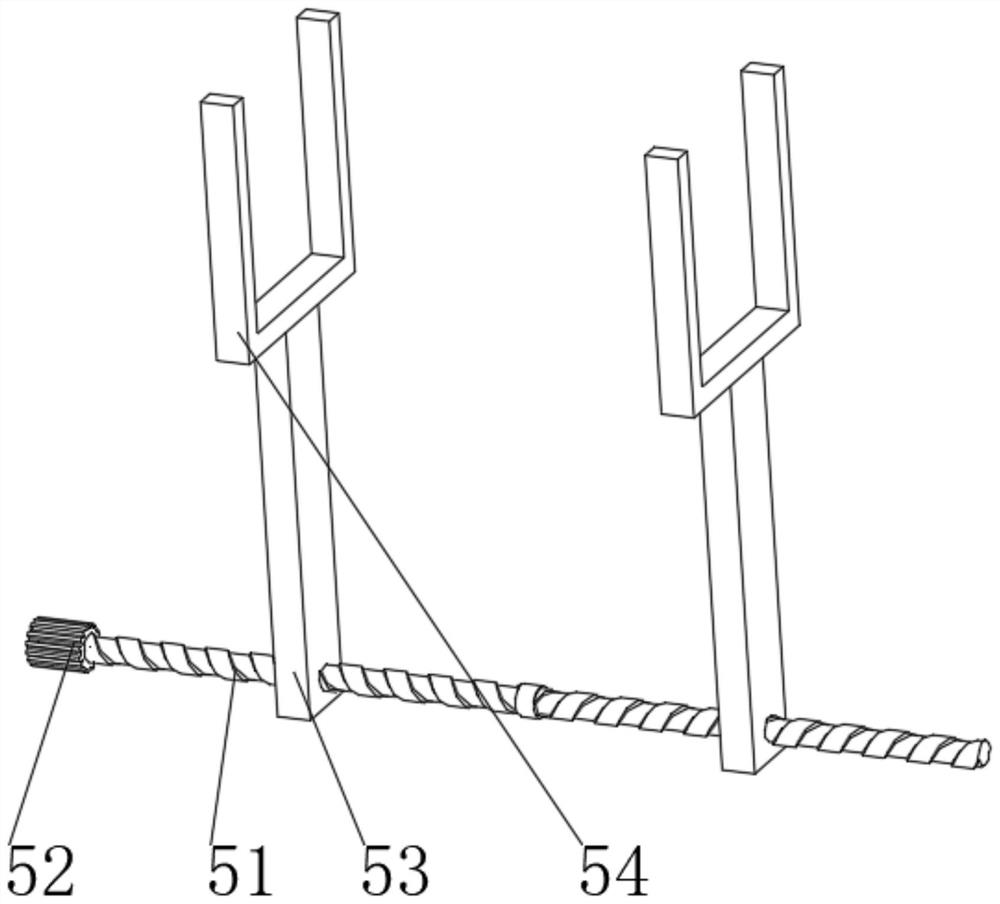

[0037] A four-in-one winding machine having a positive anti-winding function comprising a base 1, and a reticle 2 is attached to the upper right end of the base 1, and the inner cavity of the reticle 2 is provided with a driving device 3, the upper end of the base 1. The groove wall having a groove 4 is provided in the middle, and the slot wall of the groove 4 is provided with a sliding correcting device 5. The upper end of the base 1 is fixedly mounted having a fixing plate 6, and the upper end of the front end of the fixing plate 6 is fixed to the upper left side of the fixed plate, and one support frame 7 is fixedly mounted. The upper end of the two sets of support frames 7 is commonly provided with winding device 8, and the outer surface activity of the winding device 8 is attached to the web 9, and the upper end of the upper end of the base 1 is fixedly mounted, and the plate 10 is opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com