Double-cavity bottle filling technology and filling equipment

A filling and process technology, which is applied in the field of aromatic double-chamber bottle filling process and filling equipment, can solve the problems of liquid leakage and other problems, and achieve the effects of high sanitation and cleanliness, reduced filling process, and high filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

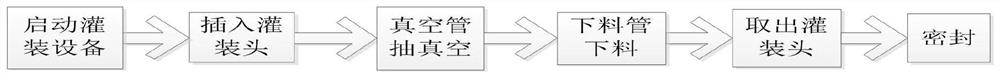

[0037] like Figure 1-3 As shown, the present embodiment provides a double-cavity bottle filling process, comprising the following process steps:

[0038] S1, arrange a plurality of double-chamber bottles 50 horizontally, make the bottle mouths of the double-chamber bottles 50 upward and put them on the conveyor belt;

[0039] S2. Transport the double-chamber bottle to a sterile environment for disinfection and air-drying;

[0040] S3. Move the sterilized and air-dried double-chamber bottle under the double-chamber filling head 10, which is connected with a filling valve 40;

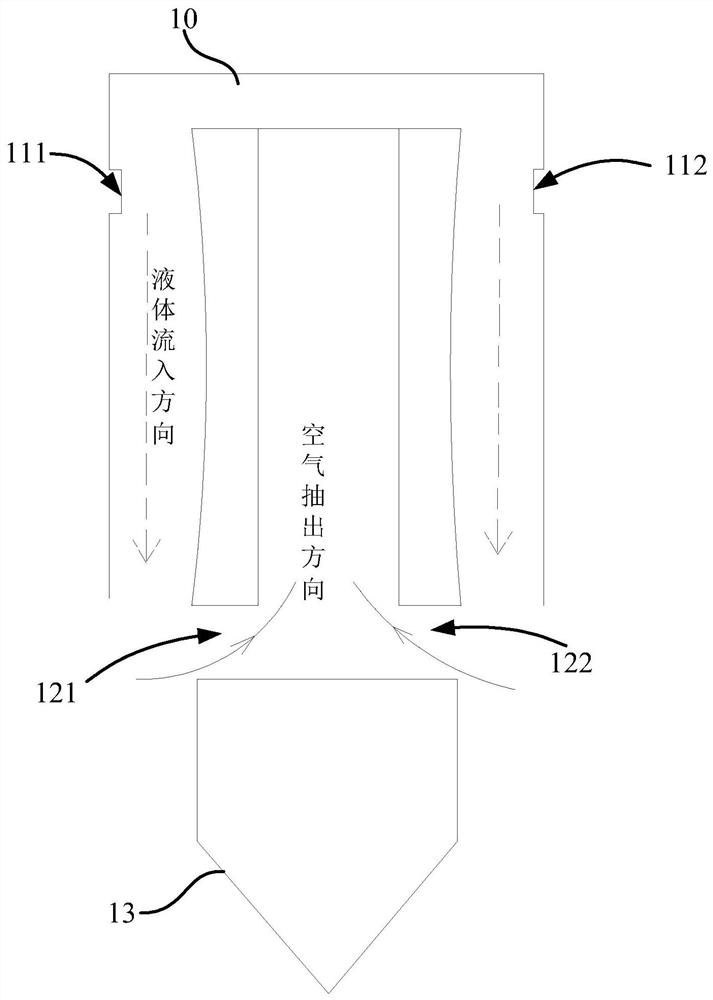

[0041] S4. Insert the filling head 10 into the double-chamber bottle, wherein the filling head 10 includes a feeding tube 11, a vacuum tube 12 and a filler 13, and the vacuum tube 12 is located in the feeding tube 11 and is connected to the lower feeding tube 11. There is a gap between the feed pipes 11, the filler 13 is connected to the bottom of the vacuum pipe 12 and is close to the bottom of the bo...

Embodiment 2

[0058] The present embodiment provides a kind of double-cavity bottle filling process, comprising the following process steps:

[0059] S1. Arrange multiple double-chamber bottles horizontally so that the mouths of the double-chamber bottles go up and put them on the conveyor belt;

[0060] S2. Transport the double-chamber bottle to a sterile environment for disinfection and air-drying;

[0061] S3. Move the sterilized and air-dried double-chamber bottle under the double-chamber filling head 10, which is connected with a filling valve 40;

[0062] S4. Insert the filling head 10 into the double-chamber bottle, wherein the filling head 10 includes a feeding tube 11, a vacuum tube 12 and a filler 13, and the vacuum tube 12 is located in the feeding tube 11 and is connected to the lower feeding tube 11. There is a gap between the feed pipes 11, the filler 13 is connected to the bottom of the vacuum pipe 12 and is close to the bottom of the bottle, the side of the feed pipe 11 is ...

Embodiment 3

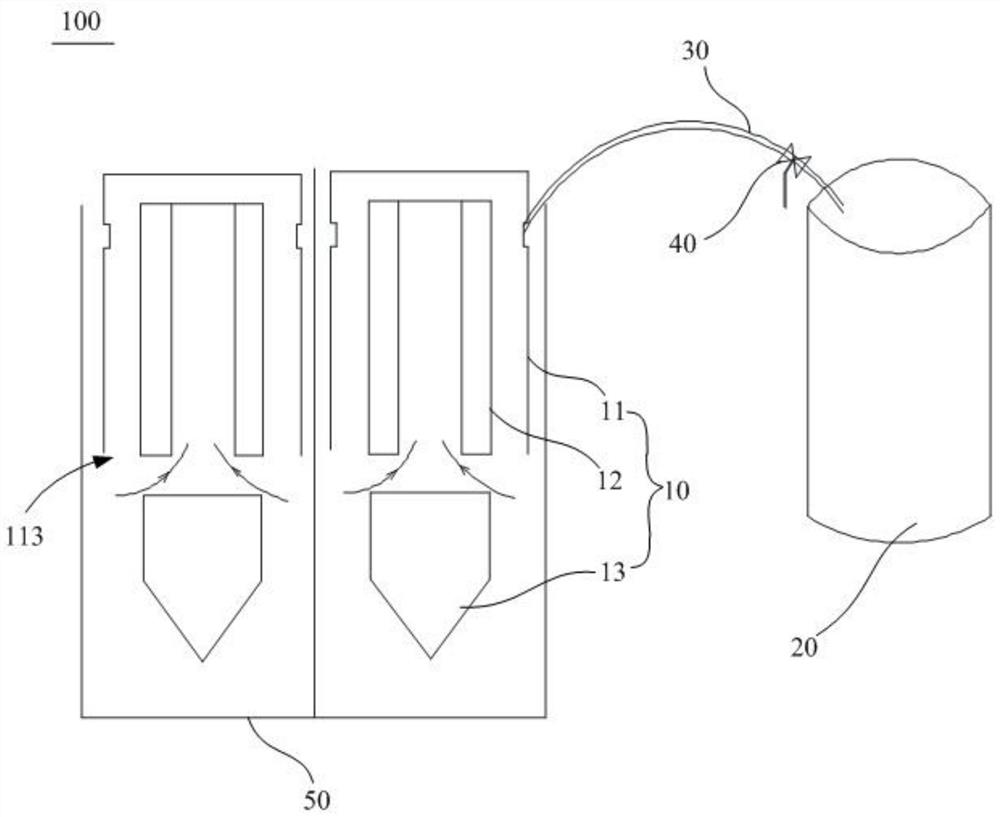

[0079] like Figures 2 to 3 As shown, this embodiment provides a double-chamber bottle filling equipment 100, which is applied to the double-chamber bottle filling process, including a liquid storage tank 20 and the following process steps:

[0080] S1, arrange a plurality of double-chamber bottles horizontally, make the bottle mouth of the double-chamber bottle 50 upward and put it on the conveyor belt;

[0081] S2. Transport the double-chamber bottle to a sterile environment for disinfection and air-drying;

[0082] S3. Move the sterilized and air-dried double-chamber bottle under the double-chamber filling head 10, which is connected with a filling valve 40;

[0083] S4. Insert the filling head 10 into the double-chamber bottle, wherein the filling head 10 includes a feeding tube 11, a vacuum tube 12 and a filler 13, and the vacuum tube 12 is located in the feeding tube 11 and is connected to the lower feeding tube 11. There is a gap between the feed pipes 11, the filler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com