Comprehensive control box of towel rapier loom

A rapier loom and comprehensive control technology, which is applied in the field of control boxes, can solve the problems of affecting the heat dissipation effect of the control box and the blockage of the filter mesh.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

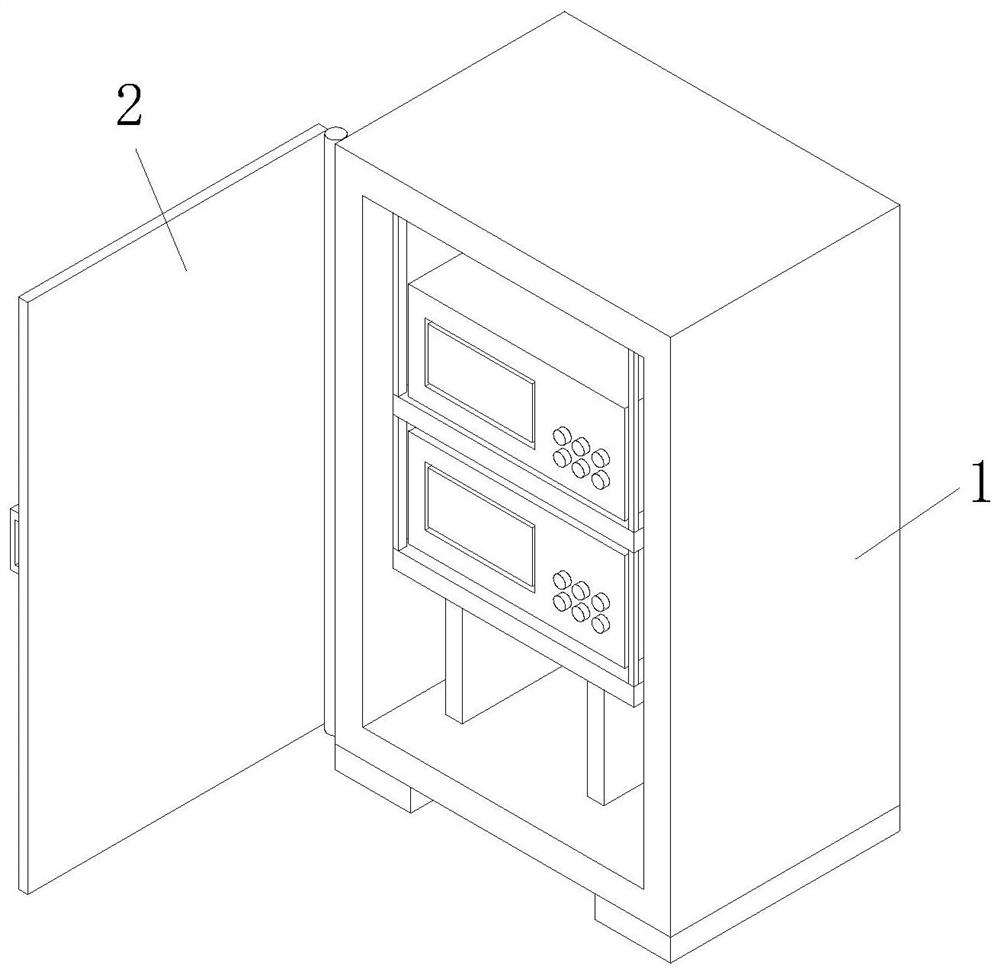

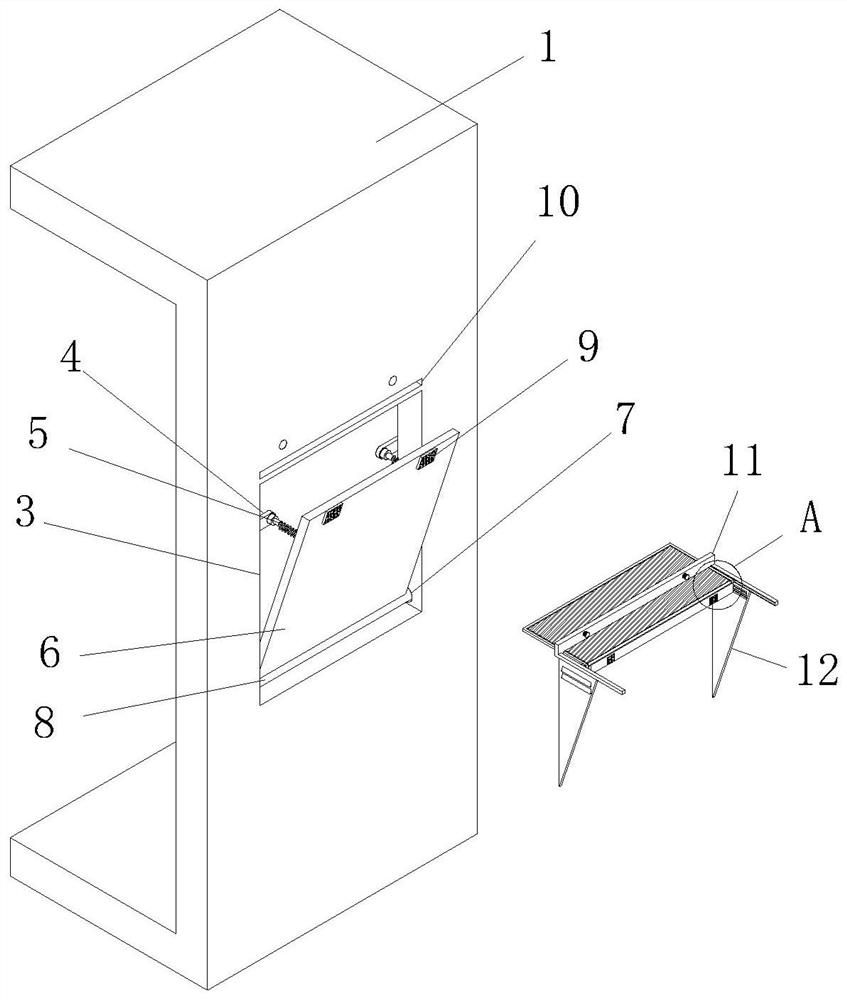

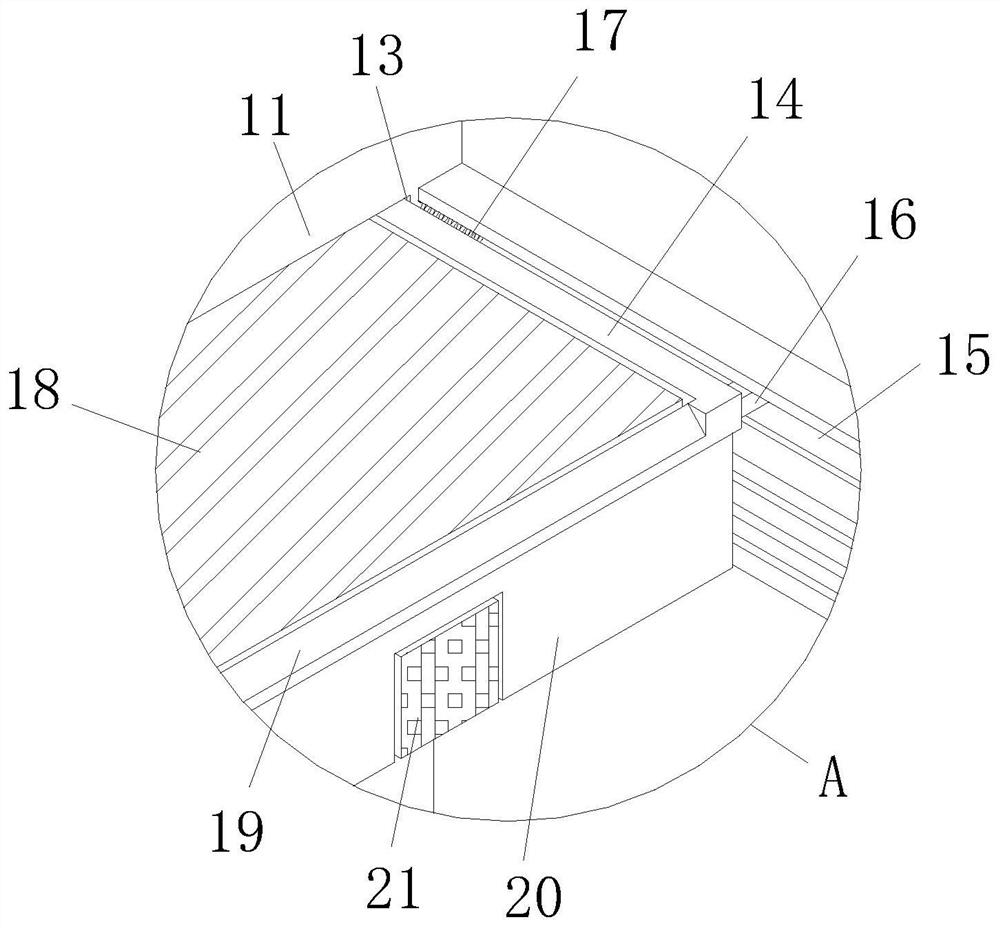

[0032] Example 1: Please refer to Figure 1-3, a comprehensive control box for a towel rapier loom, comprising a control box 1, the control box 1 is a rectangular hollow structure, the outer wall of the control box 1 is movably connected with a sliding door 2 through a hinge, the sliding door 2 is a rectangular structure, and the control box 1 There are two heat dissipation holes 3 on the outer wall of the control box 1, and the heat dissipation holes 3 are rectangular through holes. The outer wall of the control box 1 is provided with two through grooves 10, which are rectangular through holes. , the inner wall of the control box 1 is fixedly installed with four fixed blocks 4 at the positions corresponding to the two heat dissipation holes 3, and the inside of the fixed block 4 is fixedly equipped with an electric telescopic rod 5, which is an existing structure, and will not be described here. To repeat, there is a rotatable baffle 6 inside the heat dissipation hole 3, the ...

Embodiment 2

[0034] Embodiment two: on the basis of embodiment one, as Figure 6 The outer wall of the side plate 12 is provided with two side holes 28, the side holes 28 are rectangular through holes, the inside of the side hole 28 is fixedly equipped with a shroud 29, the shroud 29 is a rectangular inclined plate, and the shroud 29 is in a downwardly inclined state .

[0035] Working principle: through the side hole 28 is fixedly installed with the hood 29, the hood 29 is in a downward sloping state, part of the heat inside the control box 1 can flow out through the side hole 28, and at the same time, when the side plate 12 is used to block When the gaps on both sides of the board 6 are blocked, the downwardly inclined shutter 29 prevents external dust from entering the inside of the control box 1 through the side hole 28 .

Embodiment 3

[0036] Embodiment three: on the basis of embodiment one, as Figure 4 , The bottom of the slide block 16 is provided with a draw-in groove 22, the draw-in groove 22 is a three-quarter spherical groove, and the inside of the draw-in groove 22 is movable with a ball 23, and the ball 23 is a spherical structure.

[0037] Working principle: Balls 23 are movably installed inside the card slot 22, and the slider 16 slides inside the chute 15 to drive the screen frame 14 to slide. When the slider 16 slides inside the chute 15, the balls 23 can slide Friction is converted into rolling friction, which reduces the frictional force, thereby facilitating the sliding of the screen frame 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com