Method for improving warping of intelligent power semiconductor module product by using mould

A smart power and semiconductor technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., to achieve the effects of improving product warping, avoiding glue overflow, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

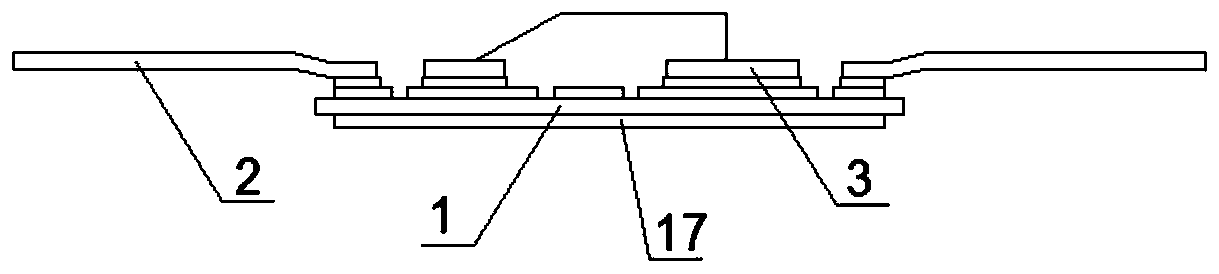

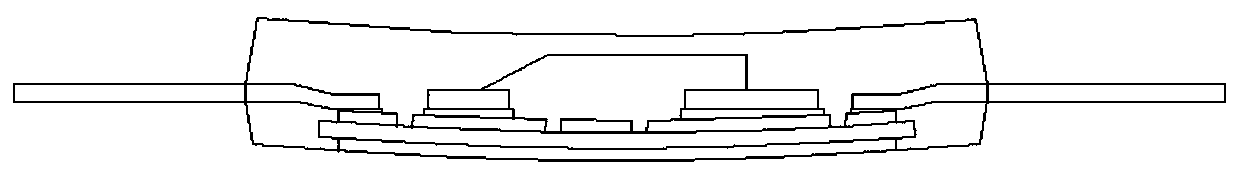

Problems solved by technology

Method used

Image

Examples

Embodiment 1

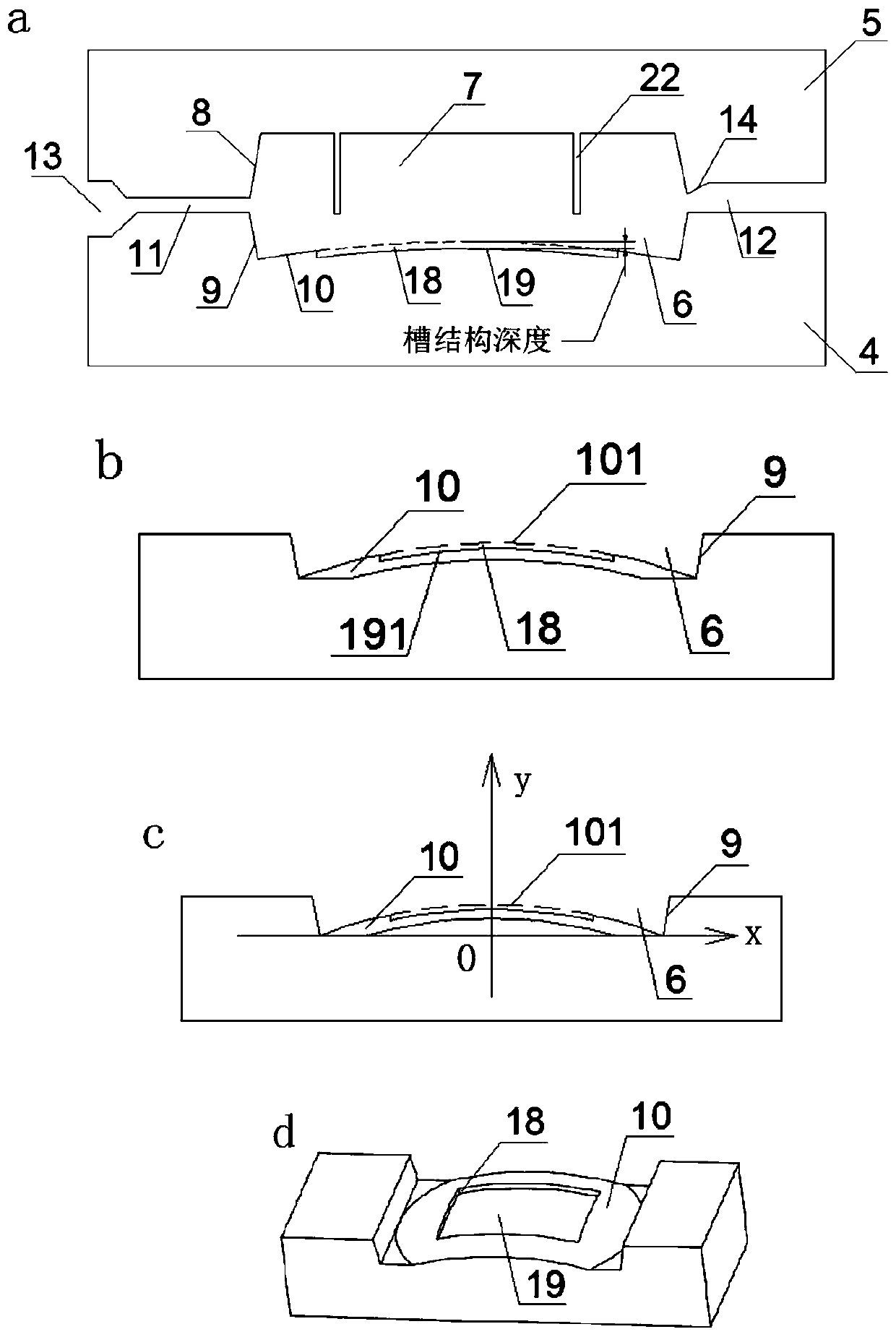

[0041] see attached image 3, where a is a schematic diagram of the structure of the method of using a mold to improve the warpage of an intelligent power semiconductor module product, b is a schematic diagram of the groove structure under the method of using a mold to improve the warpage of an intelligent power semiconductor module product, and c is the use of a mold to improve the warpage of the intelligent power semiconductor module product. Schematic diagram of the groove with coordinate axis structure under the bending method, d is the schematic diagram of the three-dimensional structure of the groove under the method of using molds to improve the warpage of smart power semiconductor module products (for the sake of simplicity and clarity, the funnel-shaped representation is omitted from the left end of b, c, and d. , and the long side of the groove under the lower mold for injection molding is omitted, which does not affect the understanding of those skilled in the art. A...

Embodiment 2

[0046] On the basis of the first embodiment, the bottom surface of the upper groove is designed as an upward spherical surface 15, and the equation of the arc at the junction of the spherical surface 15 and the vertical plane (perpendicular to the horizontal plane) is y=-2.29×10 -4 x 2 +0.22, the midpoint of the line connecting the center points of the two short sides of the bottom surface of the above groove is the coordinate origin, the height of the spherical surface is 0.22 mm, the length is 62 mm consistent with the length of the bottom surface of the upper groove, and the width is the same as the bottom surface of the upper groove. The width is the same as 32 mm; the rest is the same as the first embodiment, see the appendix Figure 8 . According to the existing intelligent power semiconductor modules, the thickness of the lower mold where the heat dissipation substrate is located is smaller than that of the upper mold. First, it is easier to dissipate heat. Second, the...

Embodiment 3

[0049] On the basis of the first embodiment, the bottom surface of the upper groove is designed as a downward spherical surface 16; the equation of the arc at the junction of the spherical surface 16 and the vertical plane (perpendicular to the horizontal plane) is y=1.95×10 -4 x 2 -0.2, the midpoint of the line connecting the center points of the two short sides of the bottom surface of the above groove is the coordinate origin, the height of the spherical surface is 0.2 mm, the length is 64 mm consistent with the bottom surface length of the upper groove, and the width is the same as the bottom surface of the upper groove. The width is uniformly 34 mm; the upper surface of the spherical surface 16 is also provided with a groove structure 20, and the rest are the same as in the first embodiment, see appendix Figure 10 .

[0050] The intelligent power semiconductor module product with double-sided heat dissipation structure obtained by the above mold is shown in the appendix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com