Method and system for weakly coherent optical detection of lens internal deformation

An optical detection and weak coherence technology, which is applied in the direction of optical instrument testing, machine/structural component testing, and optical performance testing, can solve problems such as hindering lens surface recognition and failing to meet the resolution requirements of lens accuracy, so as to avoid artifacts effect, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, which form a part of this document. It should be noted that these descriptions and examples are illustrative only, and should not be construed as limiting the scope of the present invention. The protection scope of the present invention is defined by the appended claims, and any changes based on the claims of the present invention All are protection scope of the present invention.

[0082] In order to facilitate the understanding of the embodiments of the present invention, each operation is described as a plurality of discrete operations, but the order of description does not represent the order of implementing the operations.

[0083] The implementation of the inventive method is as follows:

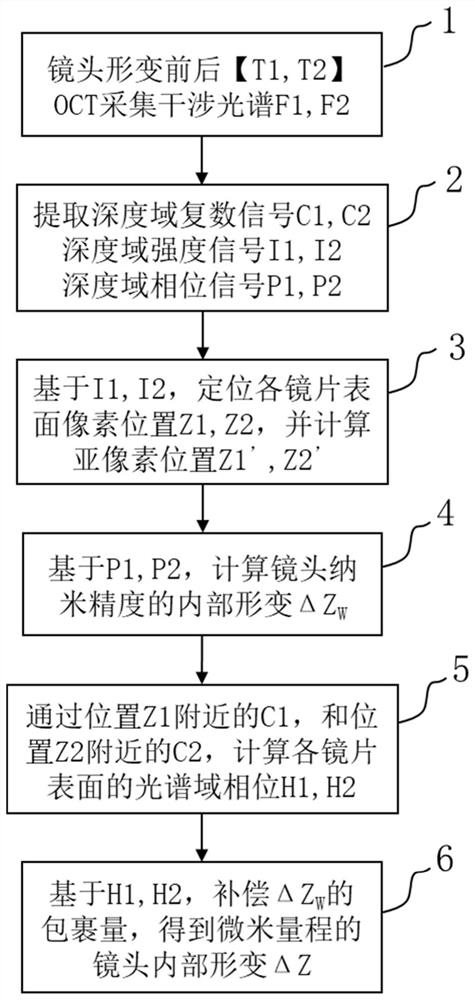

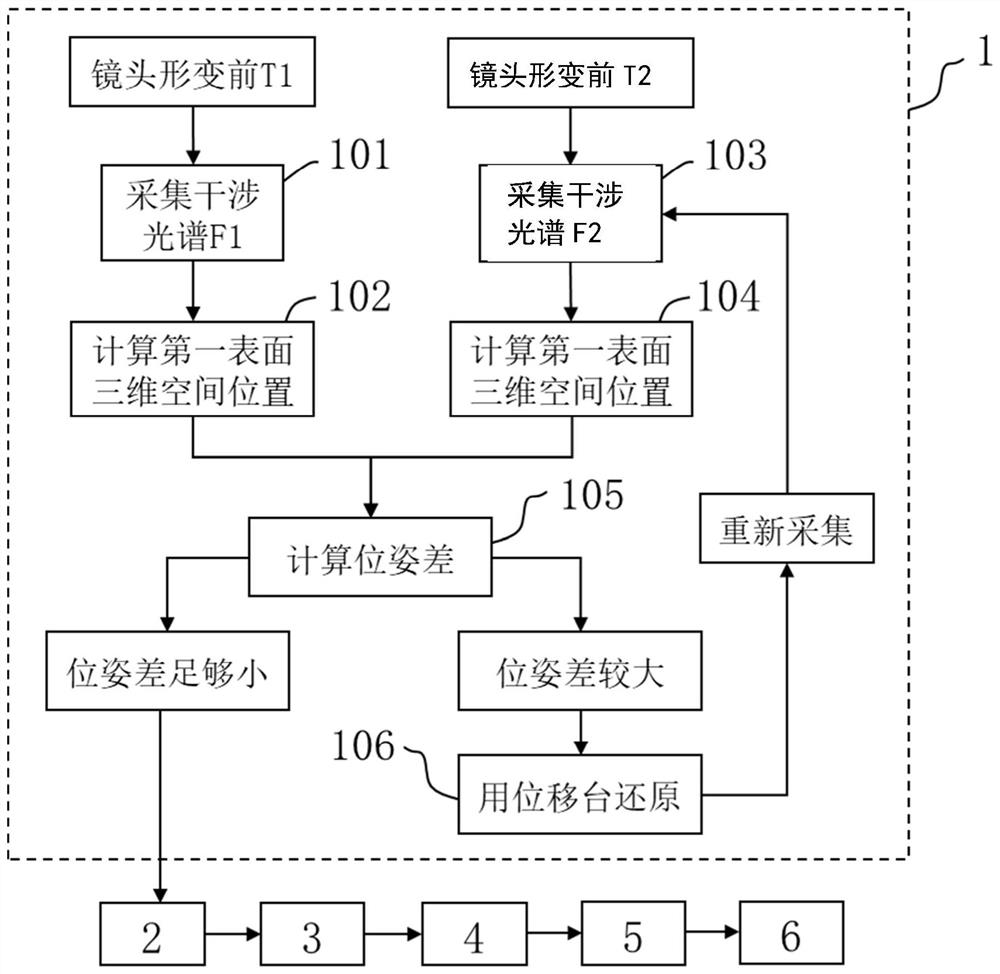

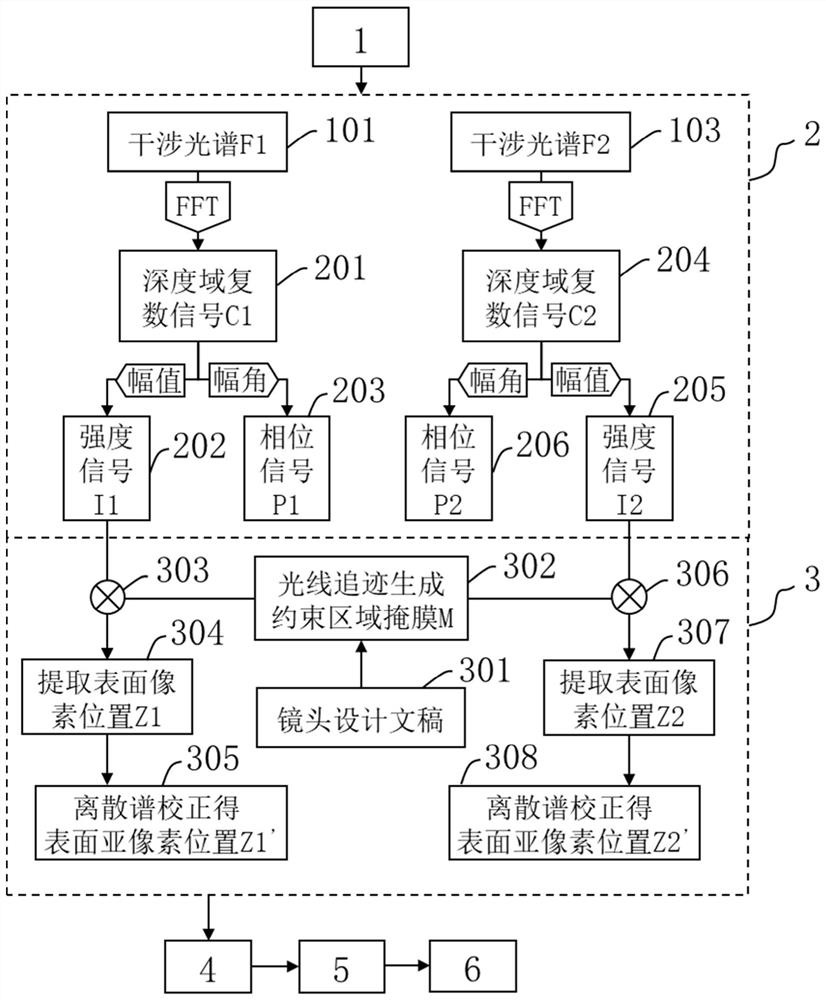

[0084] The present invention as figure 1 As shown, it includes several steps: OCT acquisition of interference spectrum before and after lens deformat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com