Plate stamping bending, curling and punching forming equipment

A technology of stamping, bending and hole forming, which is applied in the field of processing machinery and equipment for one-time sequential stamping, bending, curling, punching and forming, which can solve the problems of a large number of machines and equipment, harsh working environment for workers, and large space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to realize the objectives, technical solutions and advantages of the embodiments of the present invention more clearly, the following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

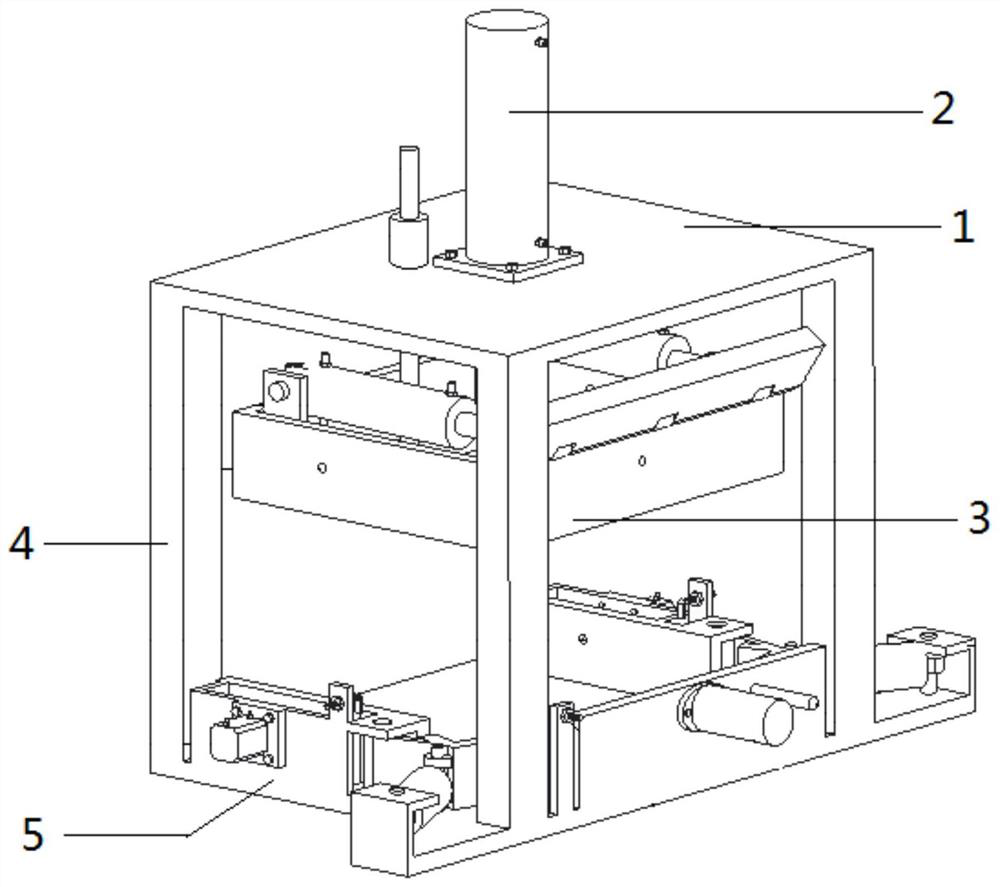

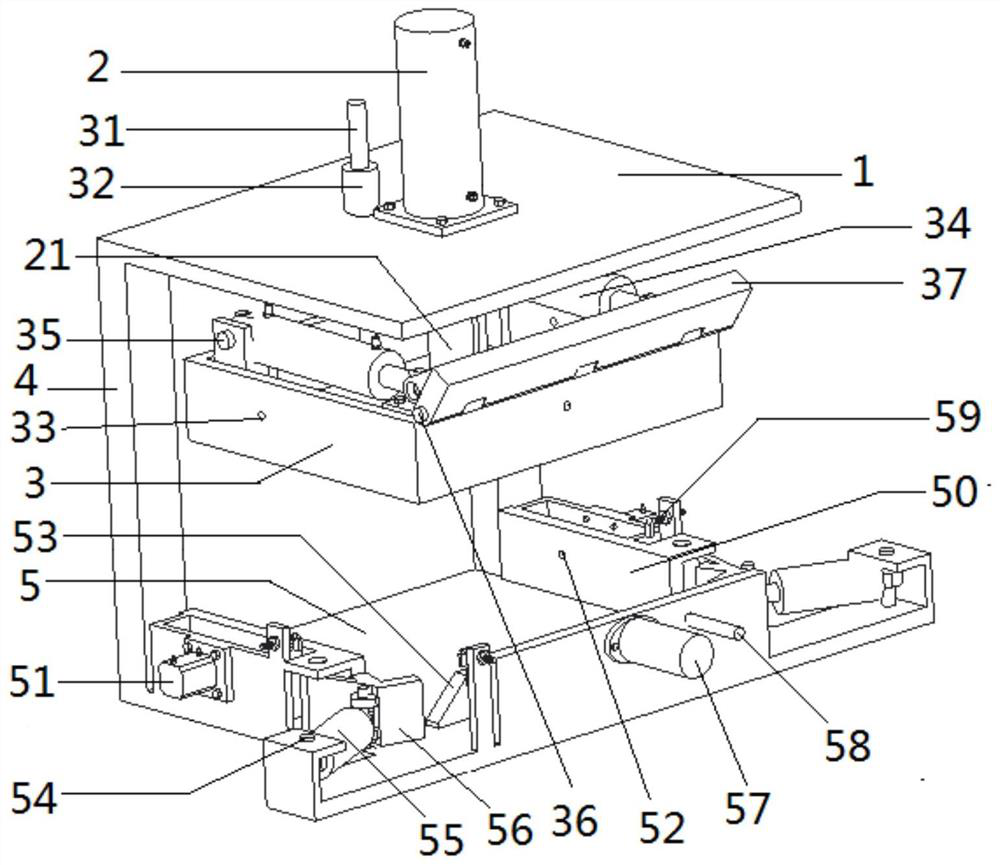

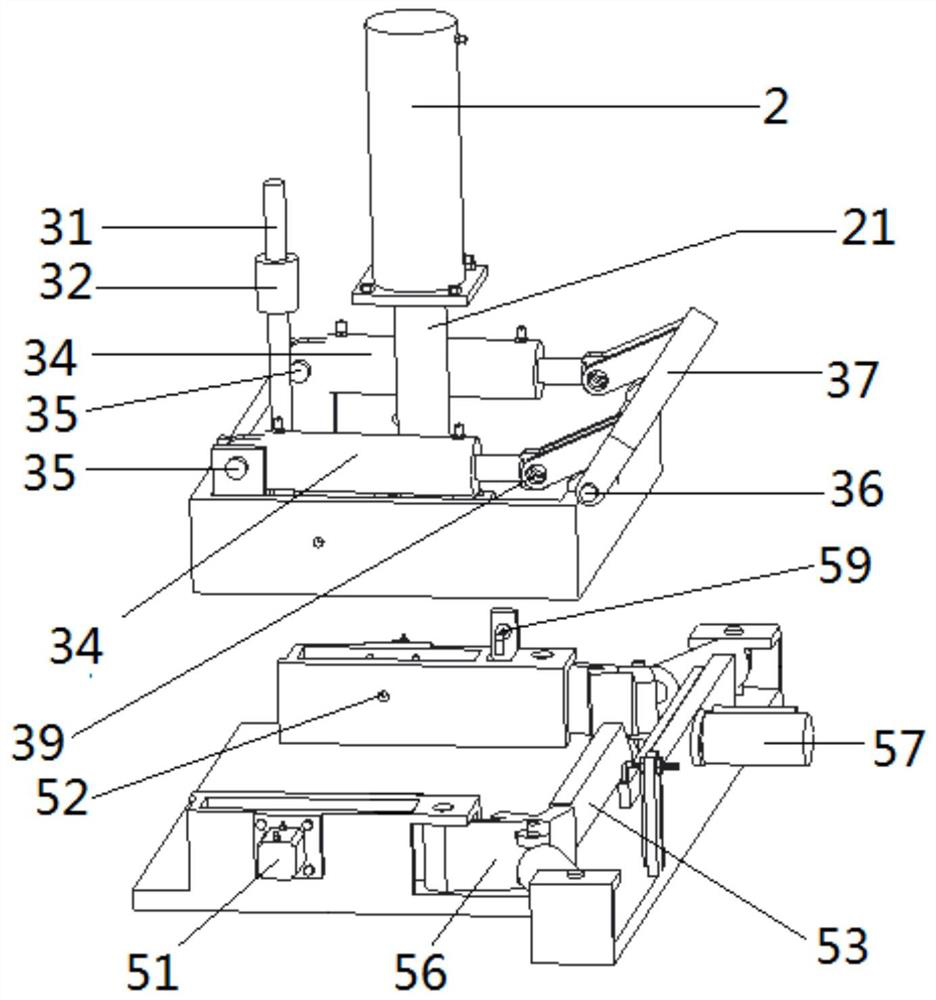

[0030] The embodiment of the present invention provides a plate stamping, bending, hemming, punching and forming equipment, refer to figure 1 , including upper plate 1, upper mold cylinder 2, upper mold 3, column 4, lower mold 5 and electro-hydraulic control system 6, which are composed of six parts.

[0031] Further, refer to figure 1 and 2 , the upper plate 1 is a plate-like structure with a hole perpendicular to the plate surface in the middle, the cylinder body of the upper die cylinder 2 is fixedly connected at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com