Shield tunneling machine rear matching wheel set hydraulic dismounting system and using method

A post-matching and shield machine technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that the wheel set device cannot be effectively fixed, the workpiece is dumped or shifted, and the wheel set pin shaft is rusted, etc., to achieve Simple and efficient preparation, improved safety, and improved maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

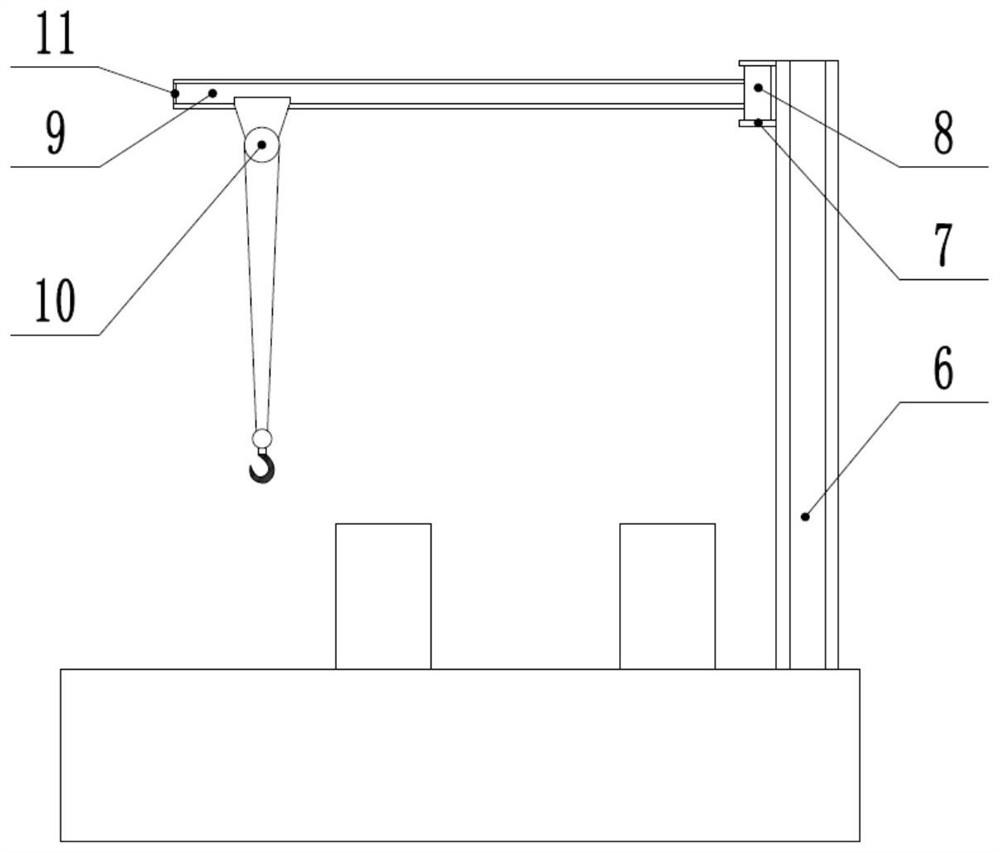

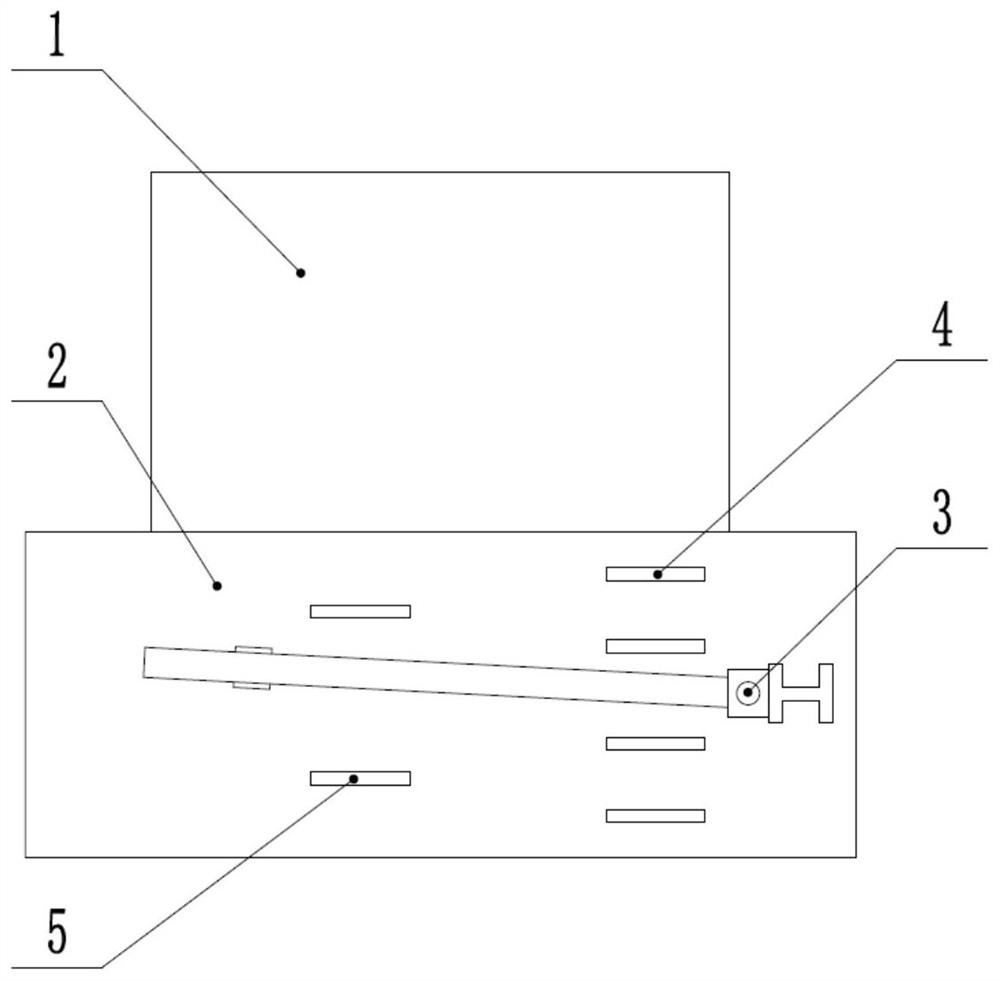

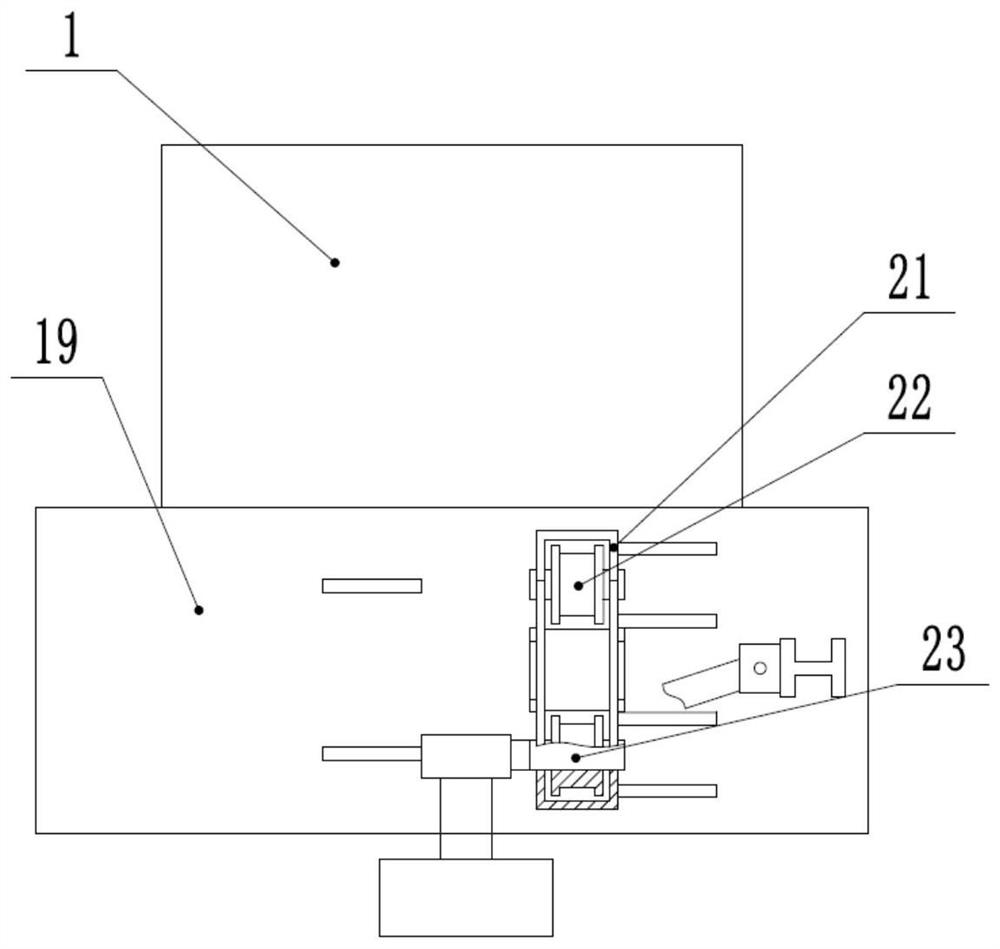

[0026] Such as Figure 1-Figure 5 As shown, the present invention provides a hydraulic dismounting system for the supporting wheel set of the shield machine, including a preparation platform 1, a rubber hose assembly 17, a hydraulic cylinder 18, an operation platform 19 and a pump source device 20, and the operation platform 19 includes a bottom Platform 2, rotary arm pin shaft 3, upright column 6, rotary arm ear seat 7, rotary arm sleeve 8, rotary arm 9, chain hoist 10, limit baffle 11, the preparatory platform 1 is placed on the bottom platform 2 long One side of the side; the upright column 6 is H-shaped steel, welded and fixed on the upper surface of the bottom platform 2 near the center of the narrow side; Welded on the column 6, one is flush with the upper end surface of the column 6, and the other is welded below it, and the space for insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com