Composite structure, method for manufacturing the composite structure, and hybrid composite structure

一种复合结构、压缩模制的技术,应用在化学仪器和方法、合成树脂层状产品、其他家里用具等方向,能够解决不能充分地加强接合处、增加制造成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] Clause 1. A method of manufacturing a composite structure, the method comprising:

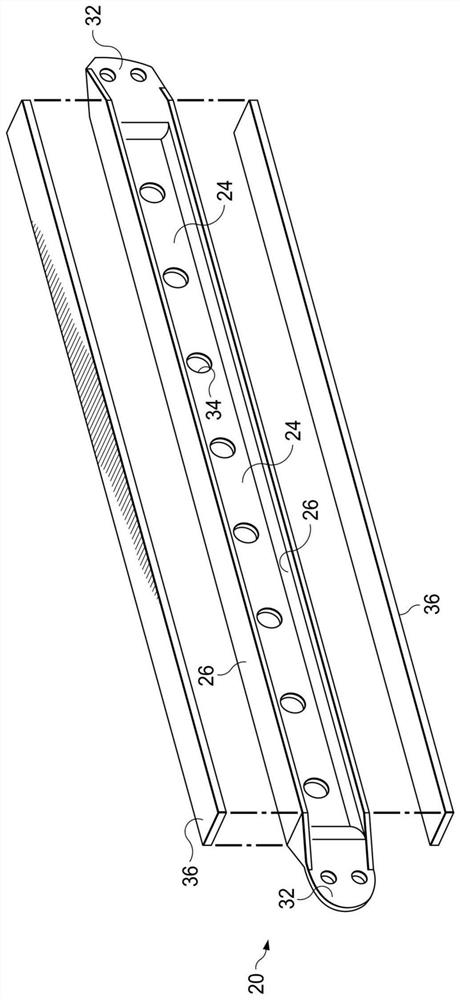

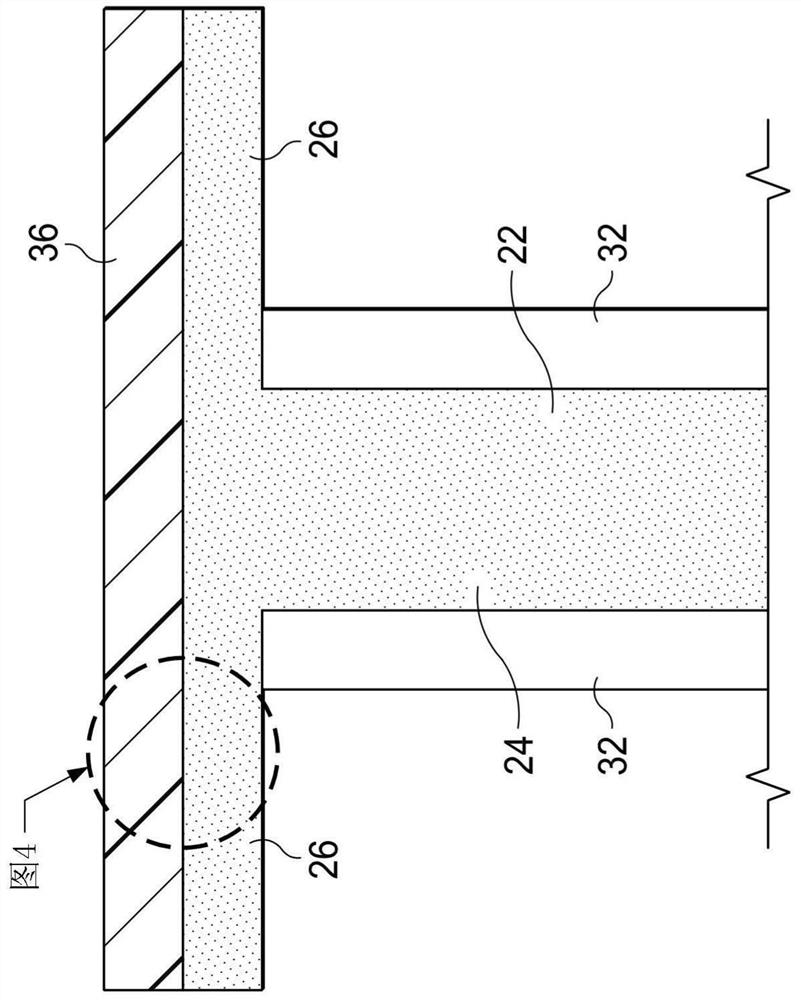

[0053] molding a thermoplastic resin first part reinforced with discontinuous fibers;

[0054] laying down a second part of thermoplastic resin reinforced by substantially continuous fibers; and

[0055] The thermoplastic resin first member and the thermoplastic resin second member are co-welded.

[0056] Clause 2. The method of clause 1, wherein molding the thermoplastic resin first part is performed by compression molding a flowable mixture of thermoplastic resin and discontinuous, randomly oriented fibers.

[0057] Clause 3. The method of clause 2, wherein said compression molding comprises:

[0058] placing a certain load of thermoplastic prepreg in the mold;

[0059] forming a flowable mixture of resin and fibers by melting a thermoplastic resin in the prepreg; and

[0060] The flowable mixture within the mold is compressed.

[0061] Clause 4. The method of clause 3, wherein: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com