Air pressure line control brake master cylinder of commercial vehicle

A technology for air pressure lines and commercial vehicles, which is applied to hydraulic brake transmission devices, brakes, brake transmission devices, etc., can solve the problem of inability to meet the requirements of manual operation comfort, stability, consistency, and mutual compatibility of intelligent network-connected commercial vehicles. and other problems, to achieve the effect of convenient switching between each other and satisfying the effect of wire-controlled and intelligent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

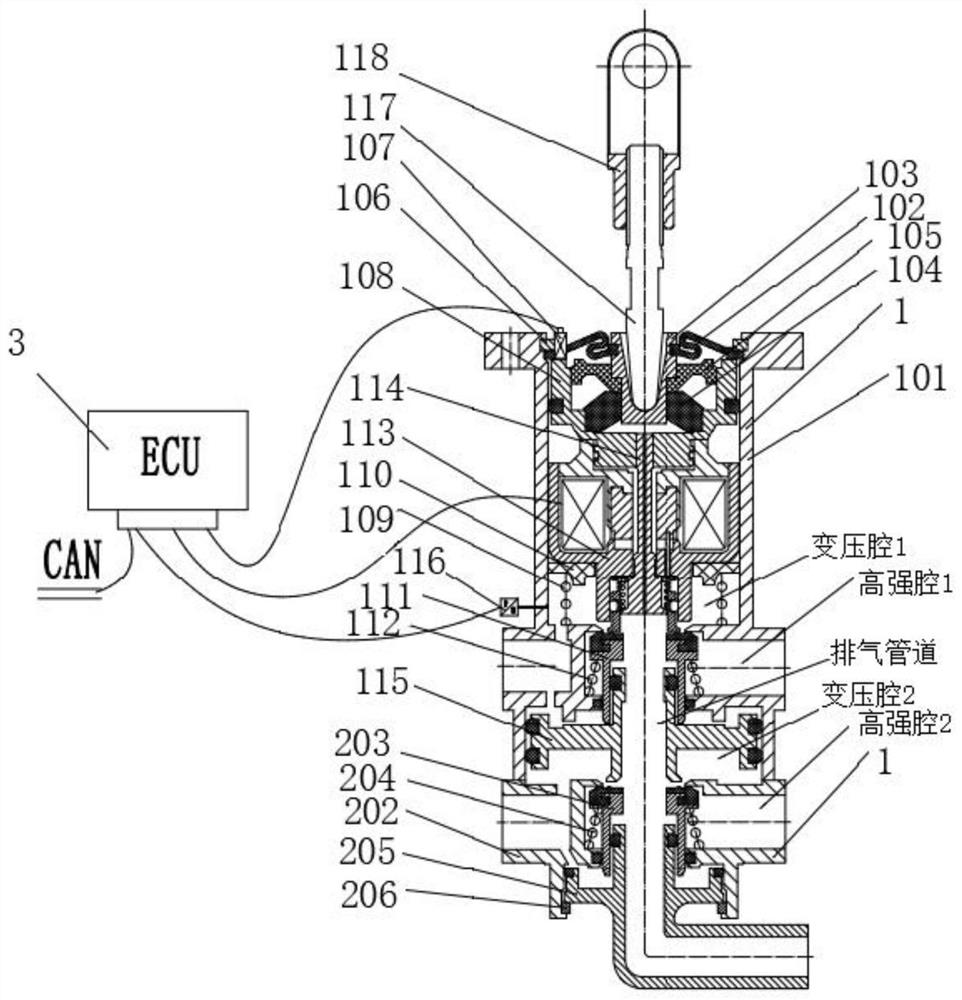

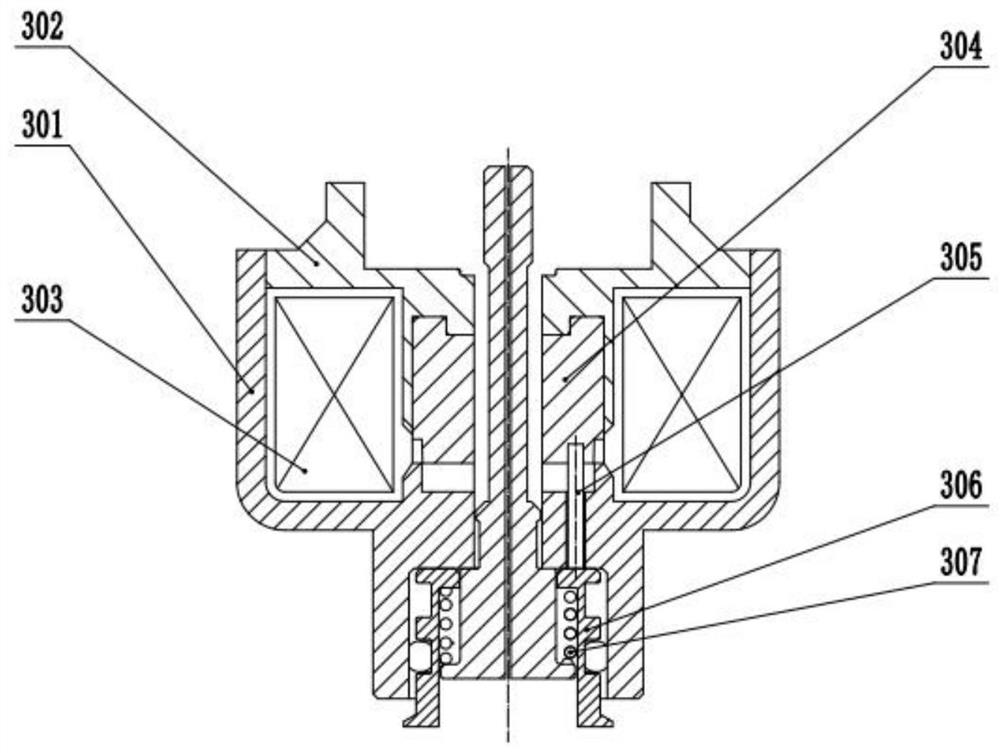

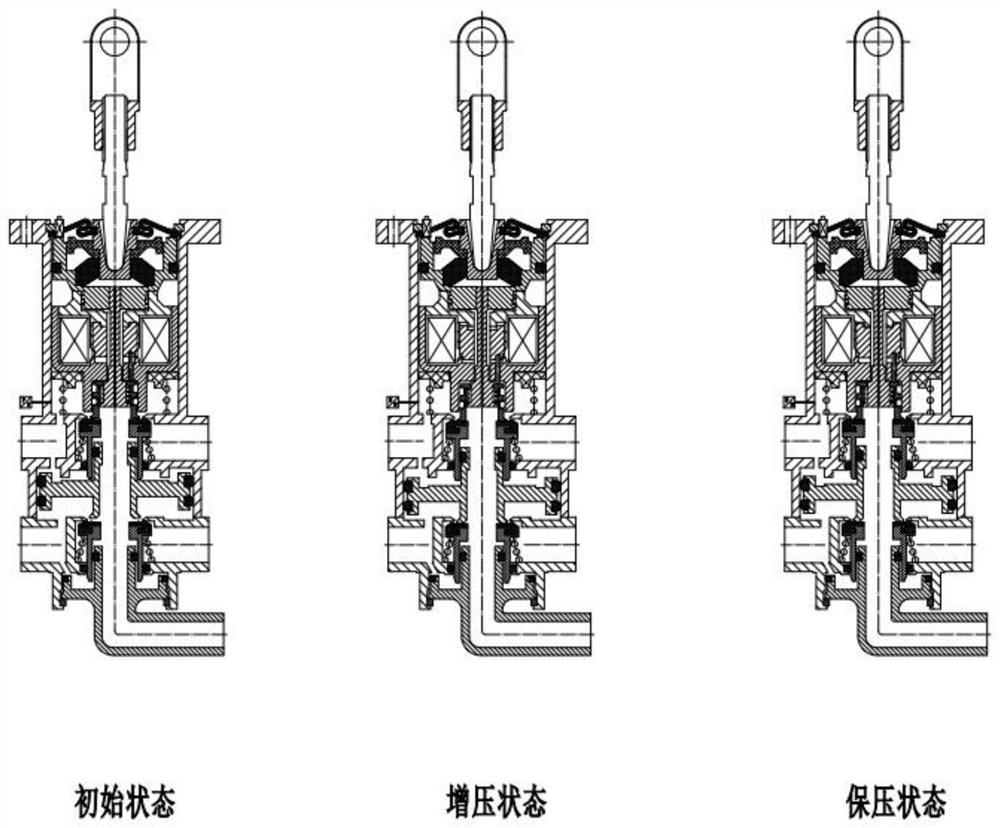

[0032] A commercial vehicle air pressure brake-by-wire master cylinder of the present invention is installed in the engine compartment in front of the driver through the flange hole on the valve body, the adjustment fork is connected with the brake pedal in the driver compartment, and the air intake hole on the valve body is connected with the brake pedal in the driver compartment. The pipeline connection of the brake air storage tank is connected with the air outlet of the variable pressure chamber on the valve body and the brake pipeline leading to the brake. The harness connector on the valve body is used to connect the internal solenoid valve assembly circuit and the external embedded system controller. The pressure sensor installed on the valve body is connected with the embedded system controller by wires. The circuit pins of the micro switch are connected with the embedded system controller by wires. The embedded system controller is installed in the cockpit and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com