Co-rotating vertical take-off and landing membrane wing aircraft

A vertical take-off and landing, co-rotation technology, applied in the direction of vertical take-off and landing aircraft, aircraft parts, wings, etc., can solve the problems of increased resistance, difficult switching operation, and difficulty in further increasing the speed, so as to reduce the demand for torque , Improve the flight speed and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

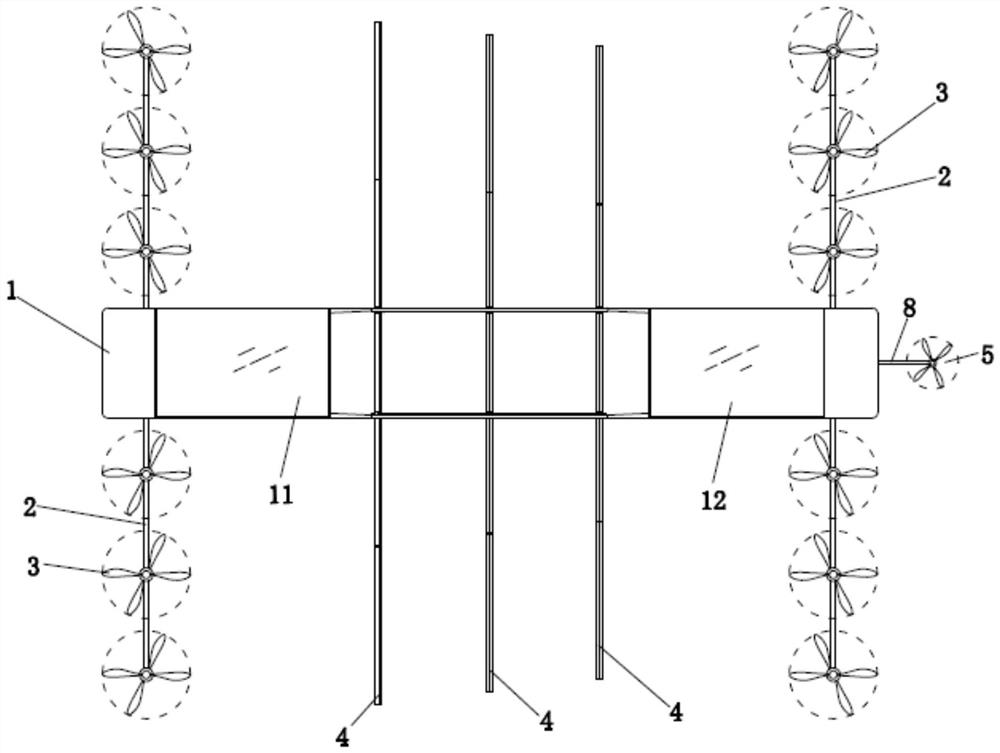

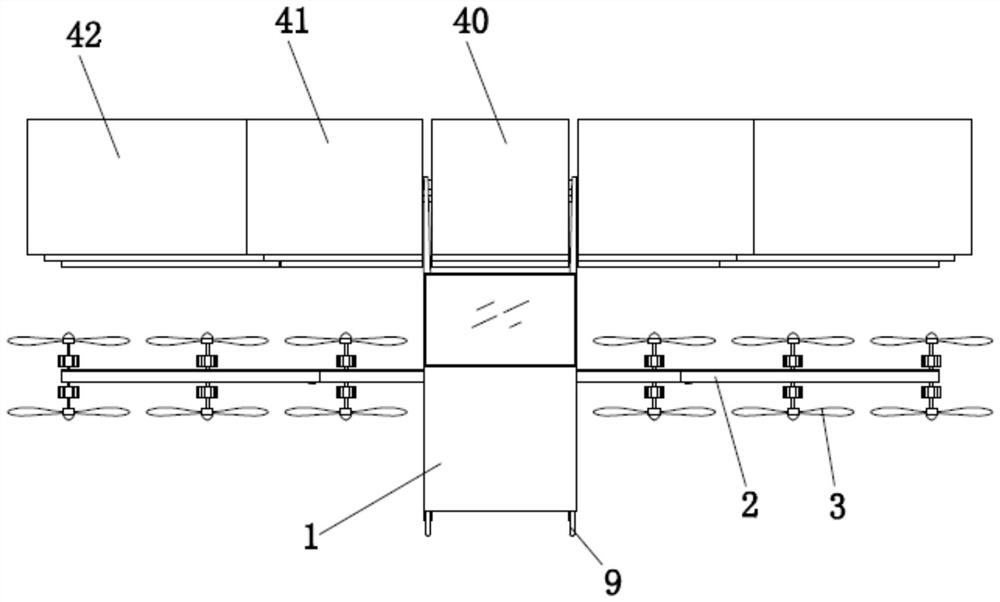

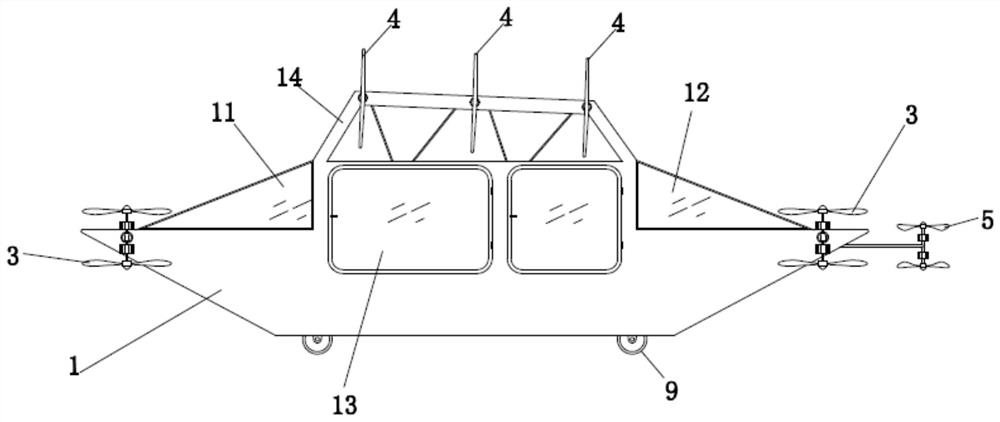

[0055] The specific embodiment of the present invention is as Figure 1 to Figure 20 As shown, a co-rotating vertical take-off and landing membrane wing aircraft includes a fuselage 1 with an aluminum alloy shell, at least two rows of power spars 2 are rotatably connected to the fuselage 1, and propellers 3 are installed on each row of power spars 2 . A membrane wing 4 rotatably connected to the fuselage 1 is arranged between adjacent power spars 2 . The middle part of the membrane wing 4 is provided with a folding angle adjusting mechanism 6 . The fuselage 1 is provided with a linkage operation device 7 for synchronously rotating the membrane wing 4 and the power spar 2 relative to the fuselage 1 . The fuselage 1 is provided with a front windshield glass 11, a rear windshield glass 12 and a plexiglass door 13. The fuselage 1 includes a wing support 14 , and each membrane wing 4 is rotatably connected with the wing support 14 . A high-energy battery providing power is hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com