High-altitude automatic downward transporting device for engineering garbage

An automatic descending and garbage technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of low transportation efficiency, difficult to adjust the lower transportation container and connecting mechanism, etc., to reduce labor input, simple structure, guarantee The effect of personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

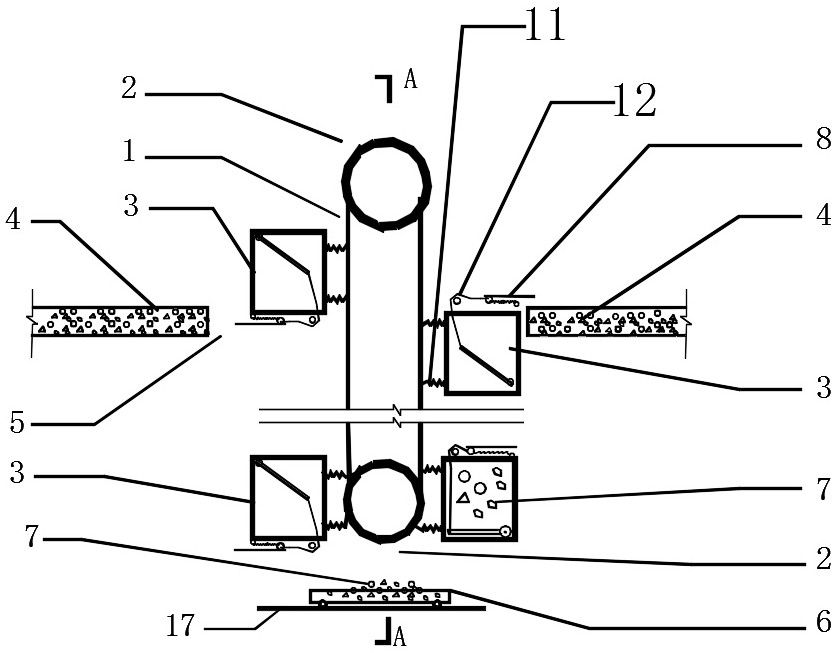

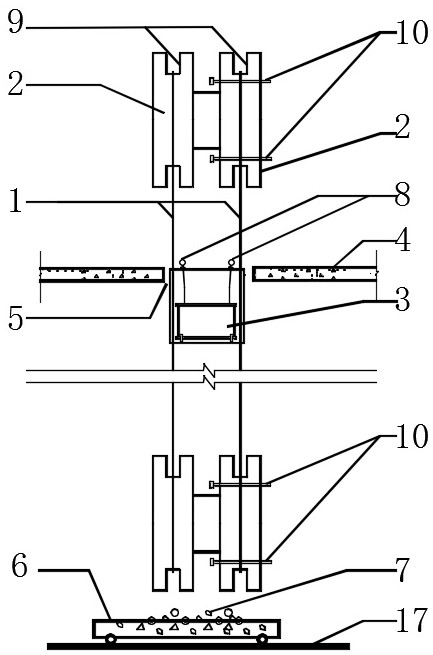

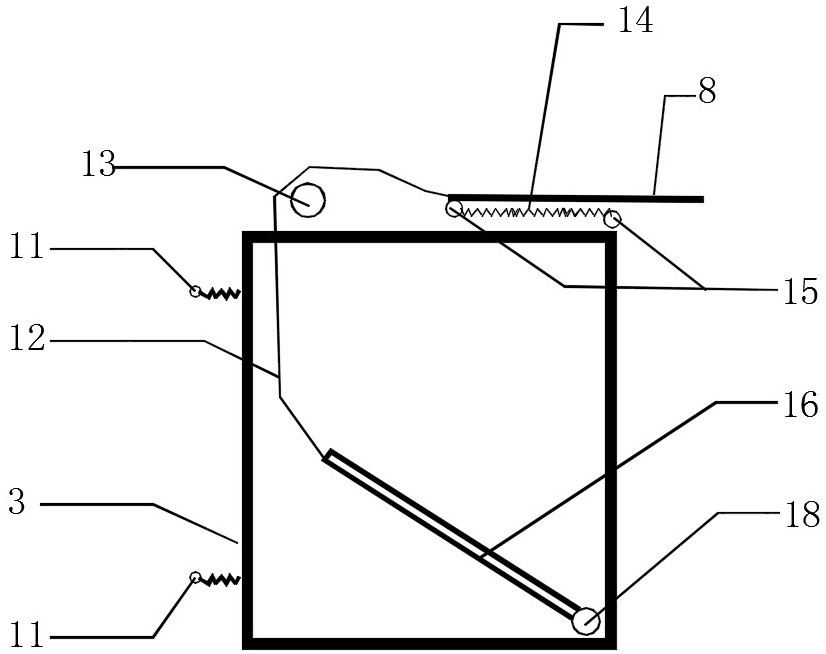

[0017] Such as figure 1 , figure 2 , image 3 Shown is the first embodiment disclosed by the present invention: a high-altitude automatic lowering device for construction waste, including a conveyor belt 1, a runner 2, a hopper 3, a telescopic positioning rod 8, and a movable pallet 16; A groove 9 matching the conveyor belt 1 is provided on the inner side and the outer side respectively; the conveyor belt 1 has two, arranged in parallel in the vertical direction, respectively bypassing the corresponding grooves 9 of the upper and lower two runners to form a closed A continuous ring-shaped overall structure; on the conveyor belt 1, there are several hoppers 3 fixed on each floor, and each hopper 3 utilizes 4 elastic supports 11 to be fixedly connected with the two conveyor belts respectively. When the conveyor belt is pulled to pull the hopper onto the floor panel 4 where the garbage needs to be transported, the hopper is empty at this time, and the telescopic positioning ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com