Masonry dry-mixed mortar paving device and paving method thereof

A dry powder mortar and slurry technology, which is applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve problems such as difficulty in ensuring that the amount of dry powder mortar is fully filled, bricks and bricks are empty, and the use effect is not good. , to achieve the effect of good connection effect, stable connection position and improved stacking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

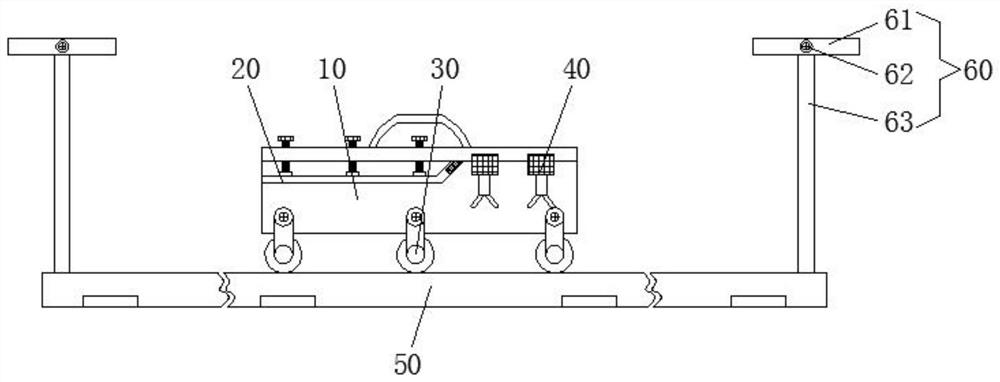

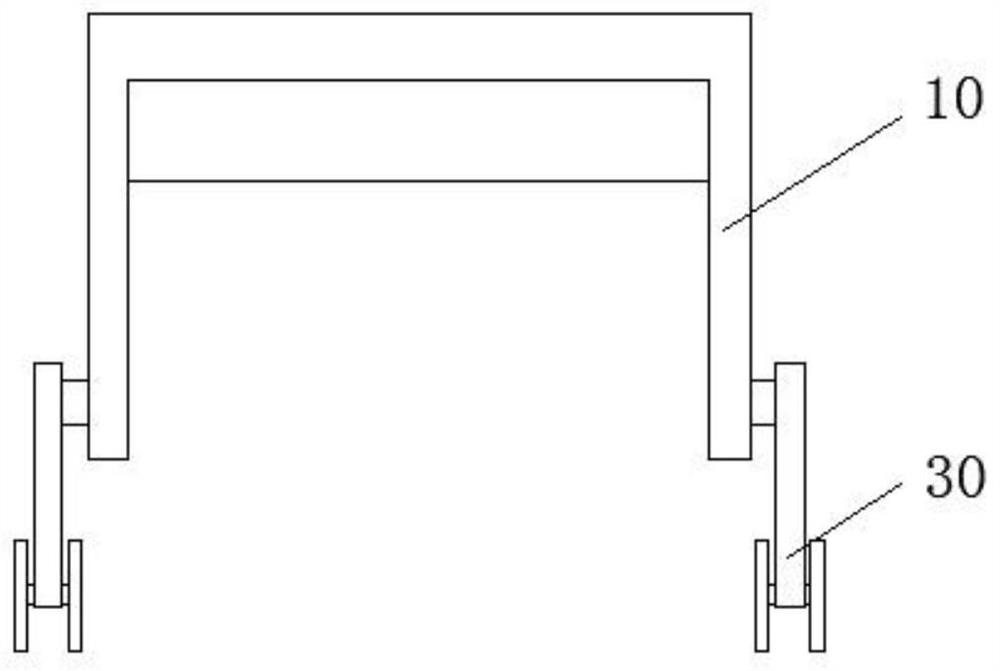

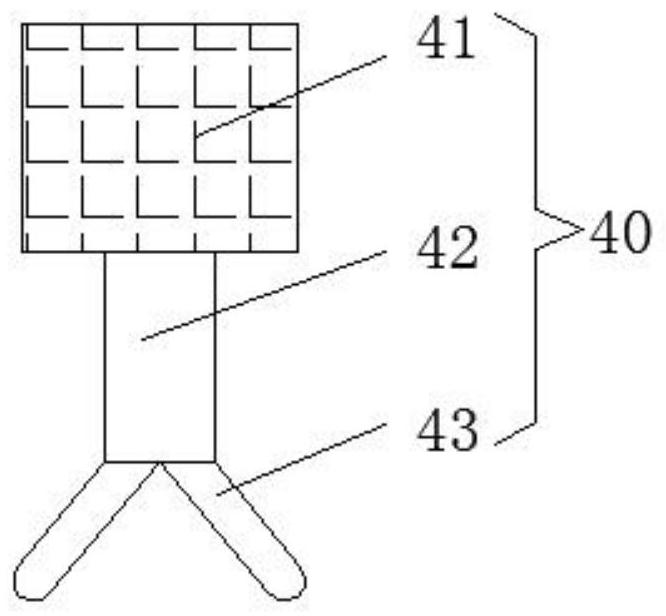

[0030] like Figure 1-2 As shown, a masonry dry powder mortar paving device described in this embodiment includes a paving bin 10, a leveling mechanism 20, a sliding limit mechanism 30, a stirring mechanism 40, and a horizontal conveying mechanism 50. The paving bin 10 The bottom is an open structure. One side of the paving bin 10 is equipped with a mixing mechanism 40 with uniform dry powder mortar located on the top of the wall. The leveling mechanism 20 tiles the dry powder mortar on the top of the wall, and the outer wall of the paving bin 10 is evenly provided with a plurality of sliding limit mechanisms 30 near the bottom, and the sliding limit mechanisms 30 are located on the horizontal conveying mechanism. 50 for sliding, and the horizontal conveying mechanism 50 is fixed on both sides of the wall.

[0031] The interior of the paving bin 10 is provided with a stirring mechanism 40. By rotating the stirring mechanism 40, the dry powder mortar placed on the top of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com