Rotary transformer

A rotary transformer and rotary shaft technology, applied in transformers, inductors, magnetic circuit rotating parts and other directions, can solve the problems of low yield of steel workpieces, heavy rotor weight, and it is not easy to achieve lightweight rotary transformers, so as to prevent leakage. The effect of improving the magnetism and transformation ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments will be listed, and the resolver according to the present invention will be described in detail with reference to the drawings.

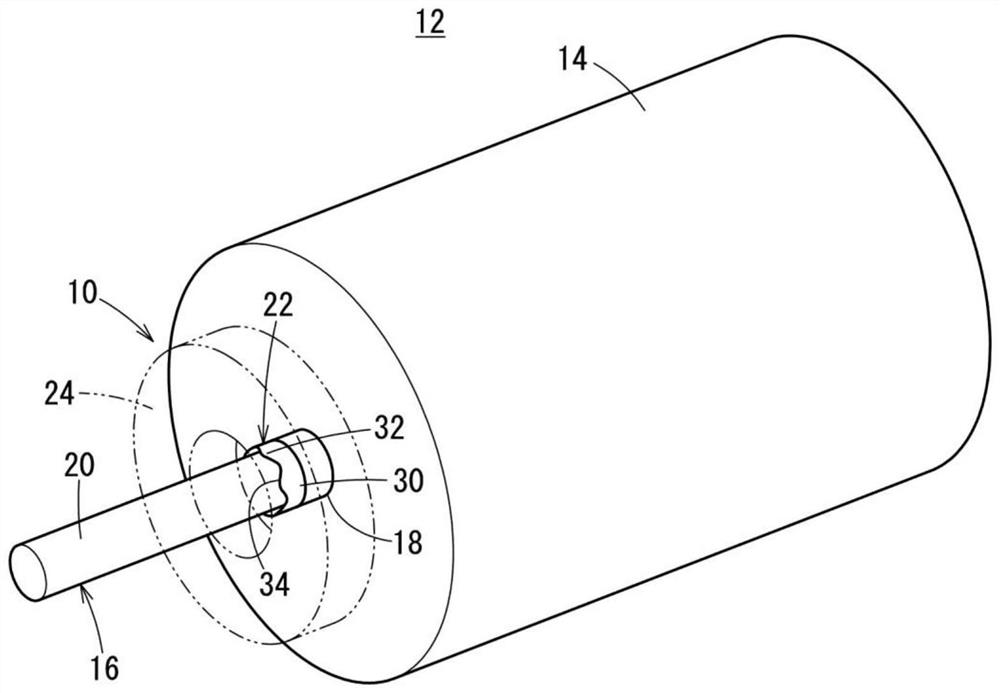

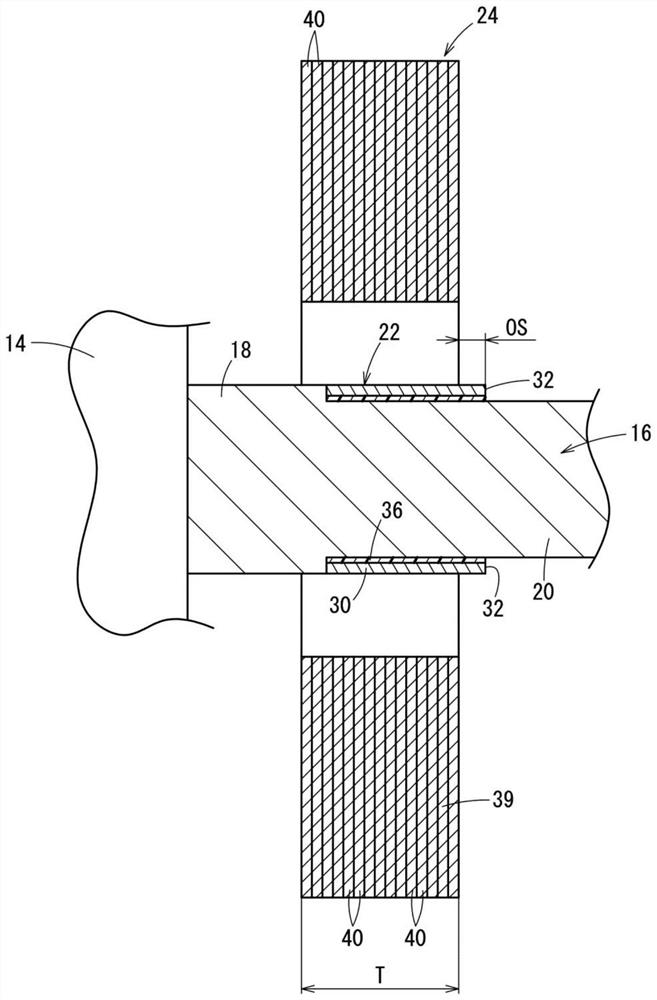

[0018] figure 1 is a schematic perspective view of main parts of a rotating electric machine 12 including the resolver 10 according to the present embodiment, figure 2 It is a schematic side sectional view of main parts of the resolver 10 . In this case, the rotary electric machine 12 is configured to include the resolver 10 and the motor 14 .

[0019] The rotary electric machine 12 includes a rotary shaft 16 as a structural component of the resolver 10 . The rotating shaft 16 has a short large-diameter portion 18 and a small-diameter portion 20 longer than the large-diameter portion 18 and smaller in diameter.

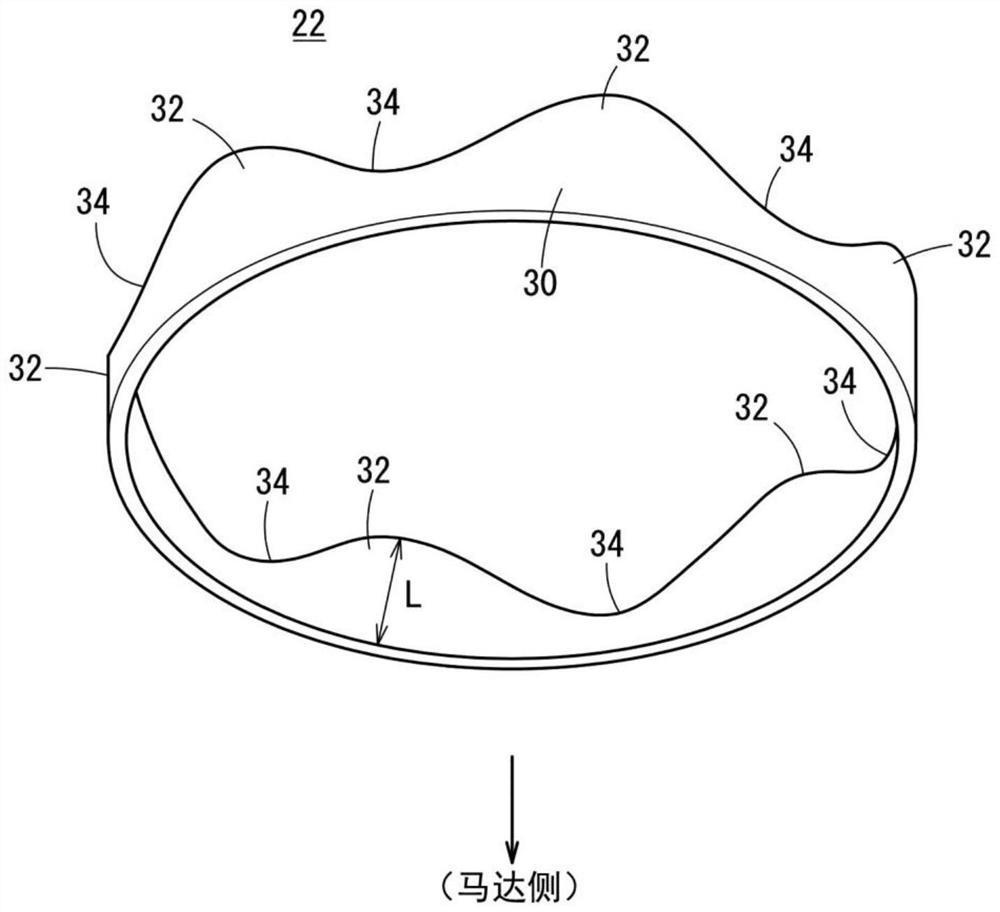

[0020] In addition, the resolver 10 has a resolver rotor 22 (rotor) assembled to the rotary shaft 16 , and a resolver stator 24 (stator) surrounding the resolver rotor 22 . The small-diameter p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com