Maintenance platform convenient for fixing motor

A technology for maintenance stations and driving motors, which is applied in the manufacture of motor generators, workbenches, electrical components, etc. It can solve the problems of affecting the maintenance efficiency of motors and the time-consuming and laborious adjustment of motor positions, so as to enhance the effect of melting and dropping, and improve the practicality. Effects, Effectively Collected Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

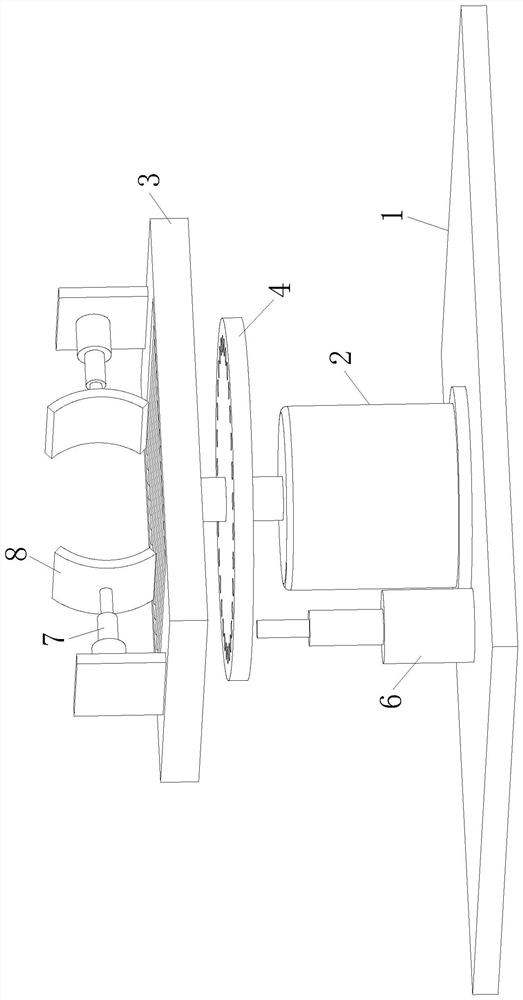

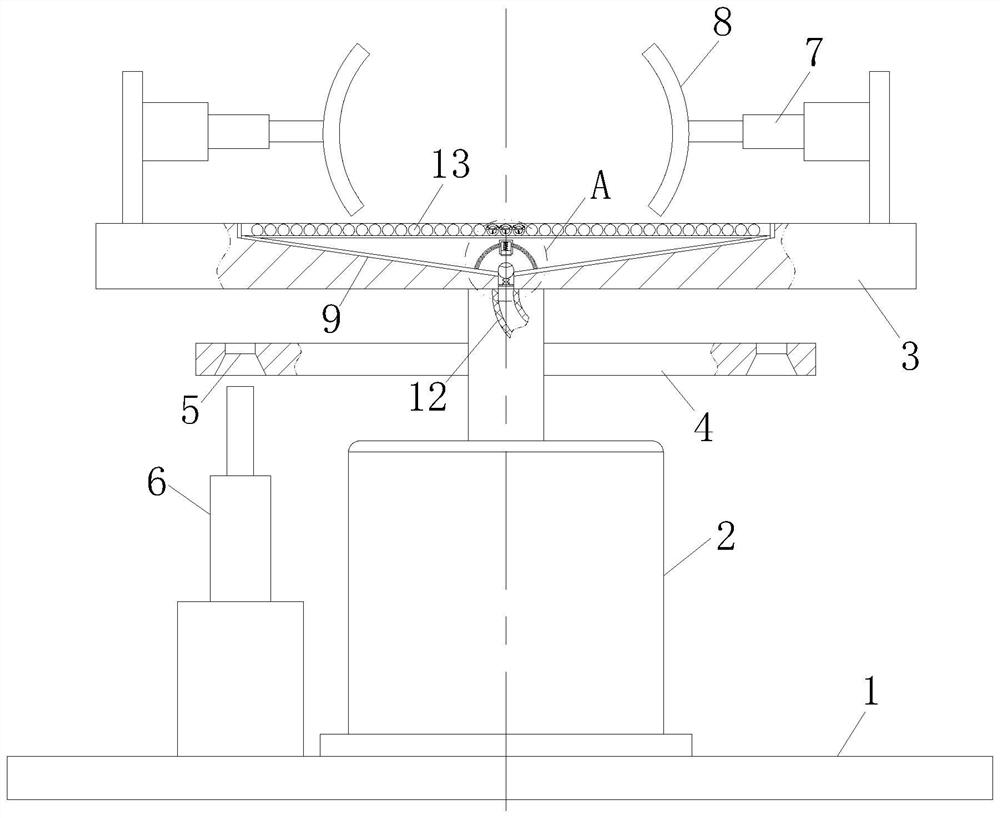

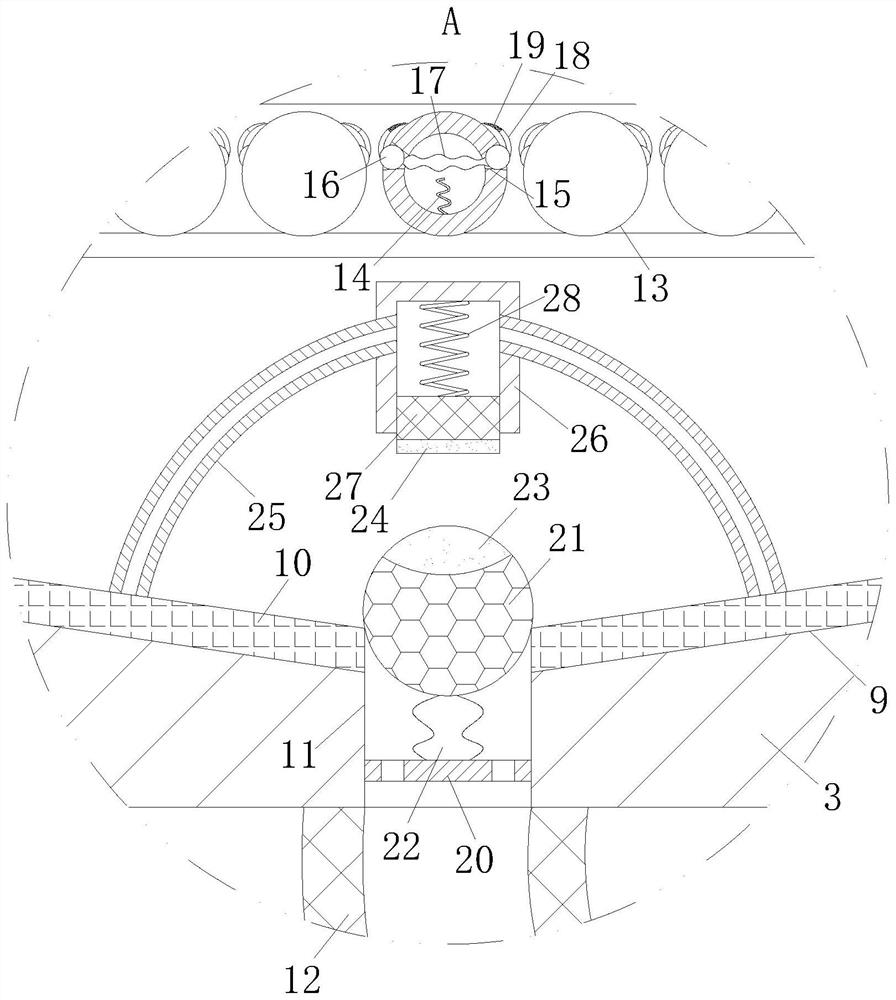

[0029] see Figure 1-4 As shown, a kind of maintenance station convenient for fixing a motor according to the present invention includes a base 1; a driving motor 2 is installed on the top of the base 1, and a maintenance board 3 is connected to the top of the driving motor 2 through a rotating shaft. A turntable 4 is fixedly connected to the side wall of the rotating shaft, and a group of annular evenly distributed draw-in slots 5 are provided on the bottom surface of the turntable 4. The openings at the bottom of the draw-in slots 5 gradually increase from top to bottom, and two adjacent draw-in slots 5 The outer edges of the opening at the bottom of the bottom end are attached to each other, the base 1 corresponding to the bottom end of the card slot 5 is equipped with a No. No. 2 push rod 7, the end of described No. 2 push rod 7 is connected with arc-shaped pressing plate 8; During work, when the maintenance stand of fixed motor in the prior art is in use, by the transmiss...

Embodiment 2

[0039] see Figure 5 As shown, the bottom end of the floating ball 21 is connected with a filter cavity 29 made of a filter mesh, the filter cavity 29 is arranged in a bowl shape, and the top side wall of the filter cavity 29 is in contact with the side wall of the oil leakage tank 11. fit; during work, when the floating ball 21 moves upwards and makes the oil leakage groove 11 in an open state, the floating ball 21 can drive the side wall of the filter chamber 29 to move to the top of the oil leakage groove 11, thereby being able to clean the motor oil. It is also convenient for the staff to clean up the impurities collected in the filter cavity 29, which greatly improves the purity of the motor oil when it is recovered.

[0040]Working principle: place the motor to be repaired on the maintenance board 3, and then the second push rod 7 can clamp and fix the motor through the two pressure plates 8 when it is working. When the position of the motor needs to be adjusted, the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com