Brushless direct current motor rotor positioning method and brushless direct current motor

A technology of brushed DC motor and positioning method, which is applied in the direction of electronic commutation motor control, electrical components, control system, etc., can solve the problems of failure to start, easy to fail to start, difficult to accurately judge the rotor, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

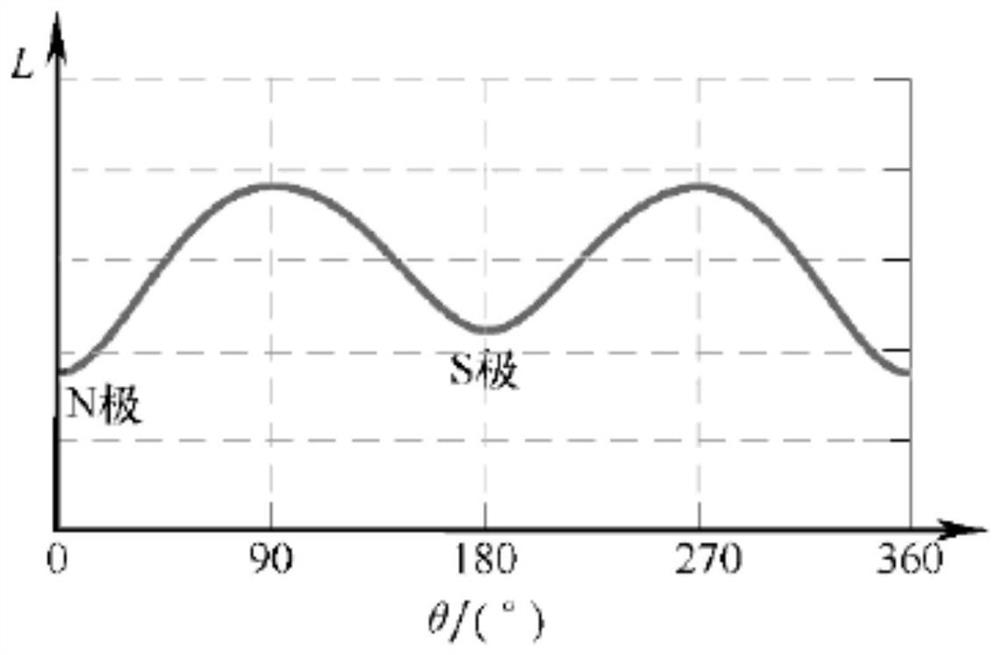

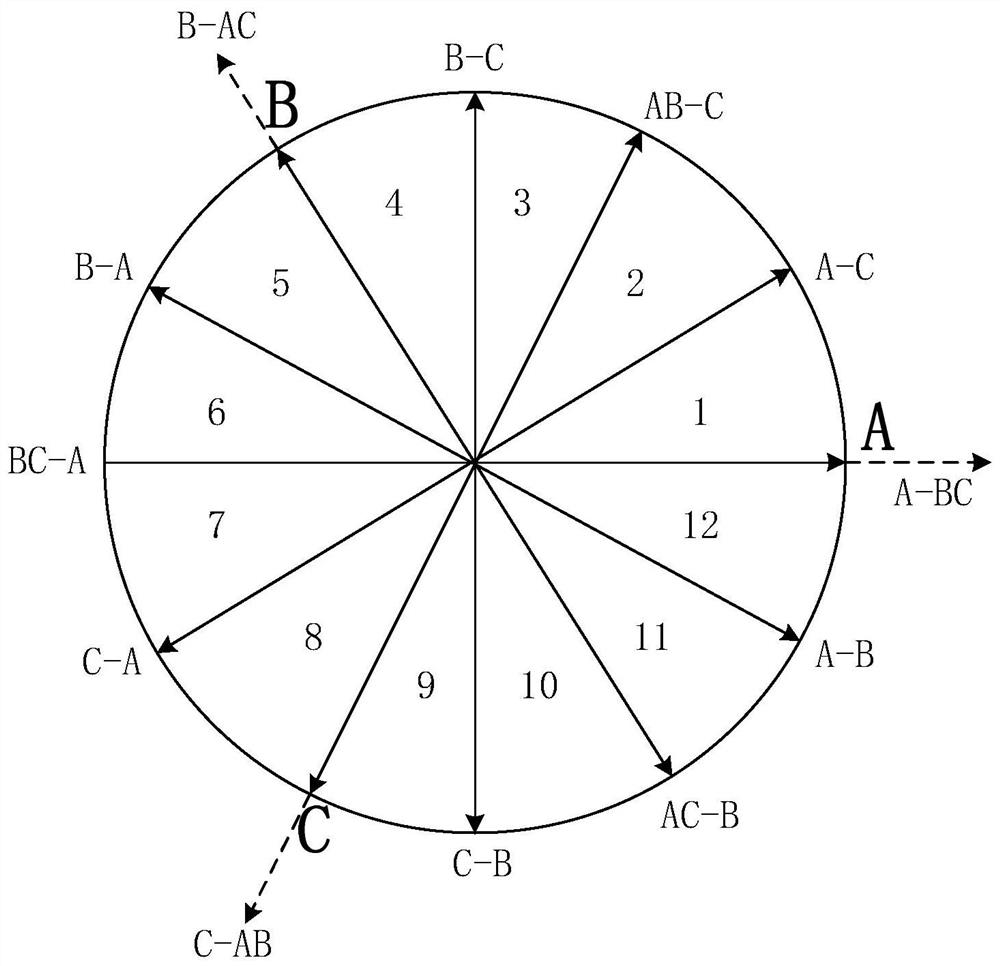

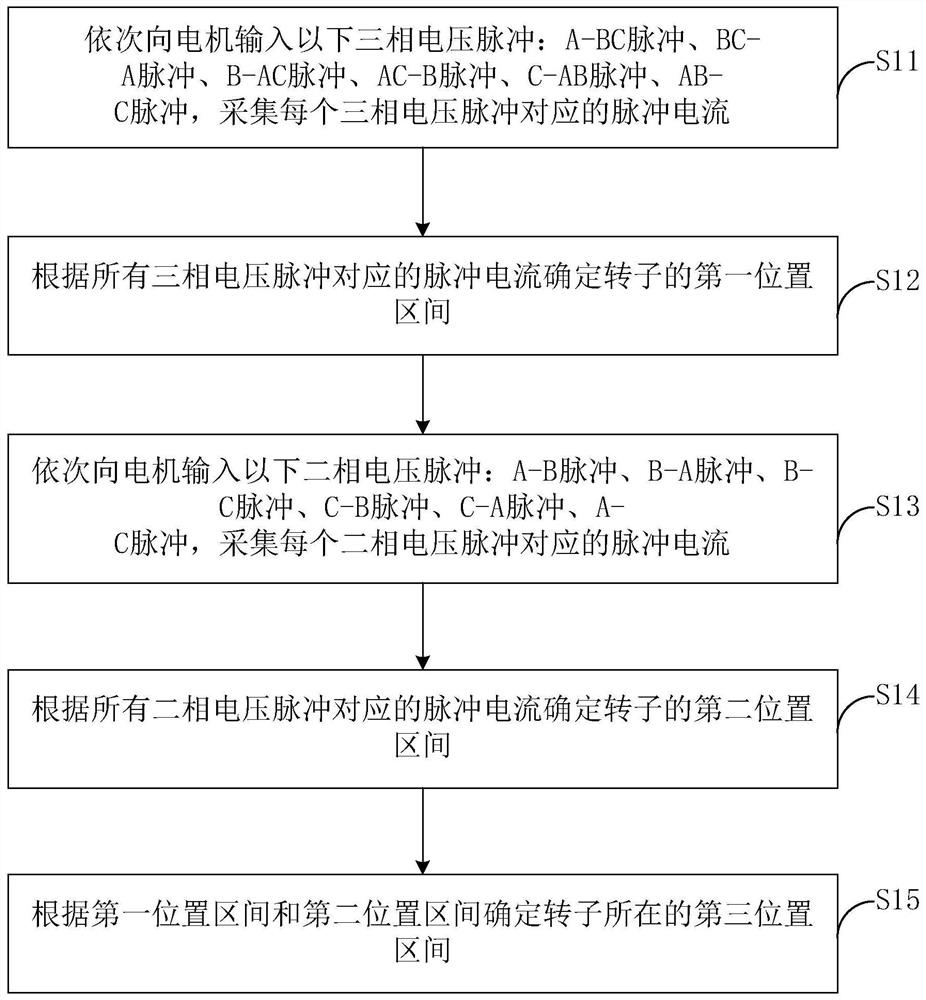

[0067] In a preferred embodiment, refer to Figure 1 to Figure 3 , The brushless DC motor rotor positioning method of this embodiment is applied to the brushless DC motor, the brushless DC motor includes A phase, B phase and C phase, and the A phase, B phase and C phase are separated by 120°. The brushless DC motor has the saturation effect of the stator core, which leads to a certain correspondence between the inductance of the motor winding and the position of the rotor. Therefore, the initial position of the rotor can be obtained indirectly by detecting the inductance of the stator winding. When a short-term voltage detection pulse with the same pulse width is applied to the stator winding, the rising speed of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com