Granular composition comprising sugar alcohol and method for preparing same

A composition and granule technology, applied in food science, food forming, application, etc., can solve the problems of flying powder, choking sensitivity, etc., and achieve the effect of excellent granule quality, excellent reliability, and excellent cooling feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Process for the preparation of granular compositions comprising sugar alcohols

[0067] In addition, it may be that the present invention relates to a method for preparing a granular composition comprising sugar alcohol, which may include: (a) combining (i) xylitol and (ii) erythritol and More than one sugar alcohol in mannitol; and the step of mixing the combination liquid; and (b) putting the mixture obtained in the (a) step into a compression molding granulator to form a granule step, the The sugar alcohol is 70% to 90% by weight based on the overall weight of the granular composition, and the content of (i) is larger than the content of (ii). In addition, after the step (b), it may further include: (c) the step of drying and finely sieving the granules obtained in the step (b).

[0068] Hereinafter, the present invention will be described in more detail according to each step.

[0069] In the present invention, in the step (a), sugar alcohols containing one or mor...

Embodiment 1

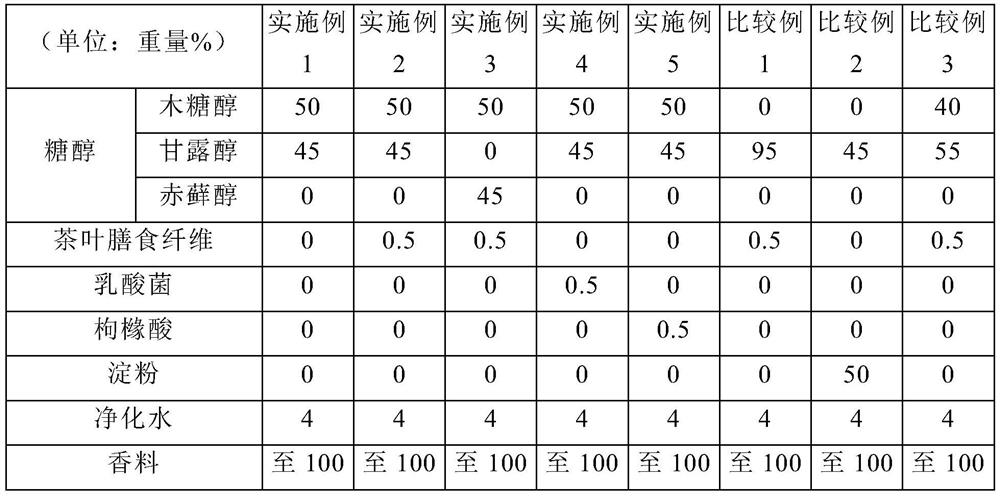

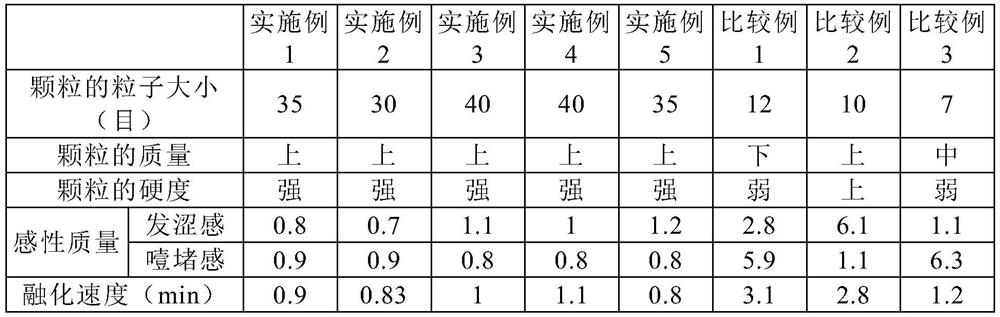

[0099] According to the components described in Table 1 below, a granular composition was prepared by the following method.

[0100] Xylitol and mannitol which are sugar alcohols were put into a mixer (high shear mix, Nara Co.), and then mixed to obtain a mixture. At this time, purified water was added and mixed together as a combined solution.

[0101] Put the mixed solution into a compression molding granulator (Dalton company) to form granules, put it into a fine sieve device (SEOWON ENG company), after the particle size is evenly finely sieved, dry at room temperature for 30 minutes to prepare a granule combination things.

[0102] 【Table 1】

[0103]

Embodiment 2

[0105] A granule composition was prepared by the same method as in Example 1, except that the tea dietary fiber was further mixed with the sugar alcohol.

[0106] As the tea dietary fiber, the tea dietary fiber produced by the following method was used.

[0107] 100 g of tea leaves were extracted once at 50° C. for 2 hours with 1,500 g of 50% alcohol, and then extracted at 90° C. for 3 hours with 1,500 g of purified water.

[0108] After the first and second extractions, 70 g of tea leaves remaining (moisture removed) were immersed in 1050 g of 0.5 M sodium hydroxide aqueous solution at 90° C. for 2 hours for extraction and solid-liquid separation to obtain an alkali extraction residue.

[0109] The residual alkali extract in the alkali extraction residue is washed with drinking water to remove residual alkali. Then, 500 g of a 0.2 M aqueous acetic acid solution was added to 50 g of the obtained solid alkali extraction residue to neutralize.

[0110] The neutralized extract ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com