Automatic vamp pressure maintaining device

A pressure-holding device and shoe upper technology, which is applied to footwear, adhesive shoe parts, shoe-making machinery, etc., can solve the problems of worker injury, low efficiency, and high labor intensity, and achieve improved safety, precise control, and Guarantee the effect of safe boot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

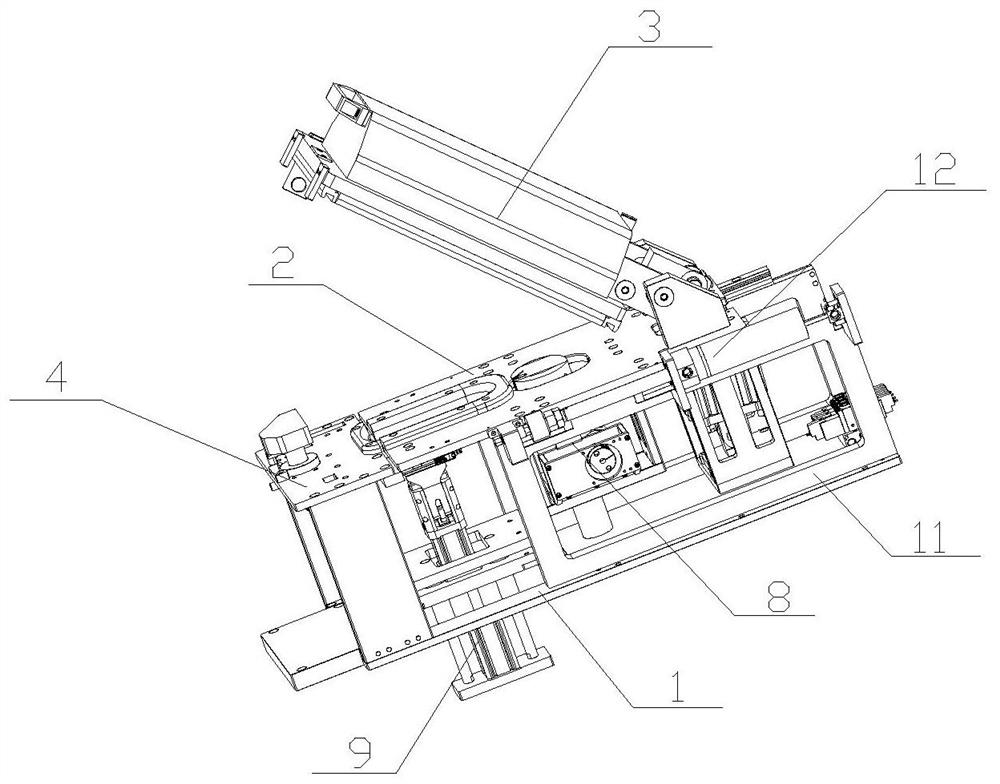

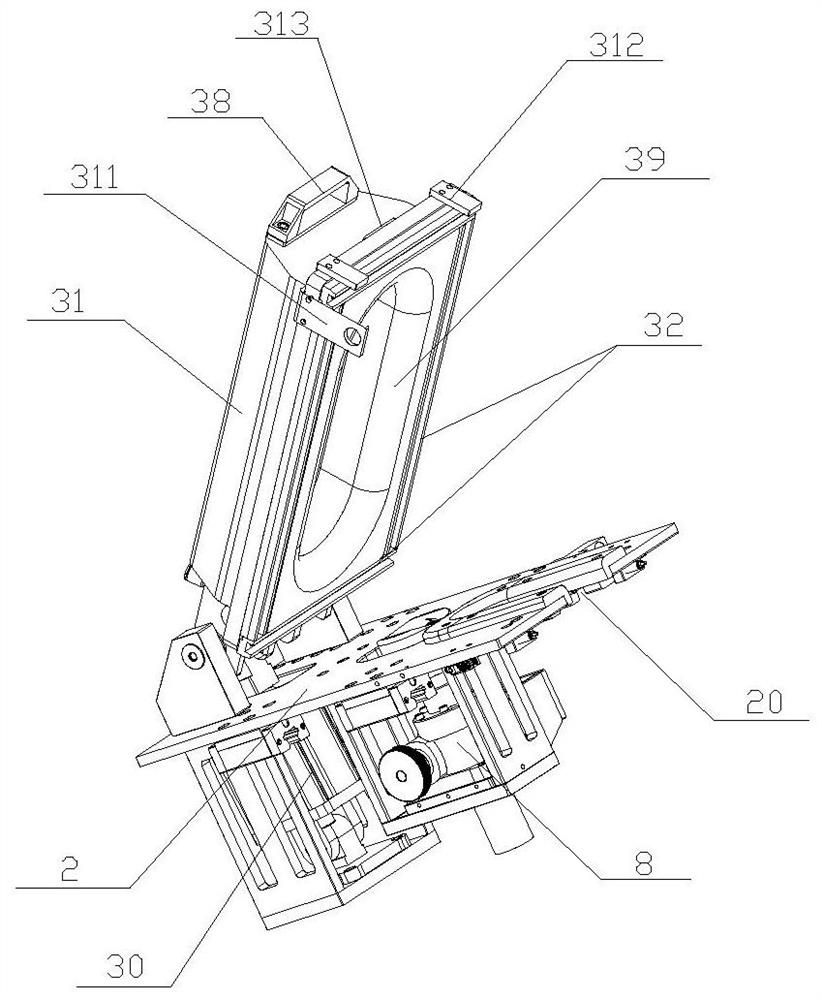

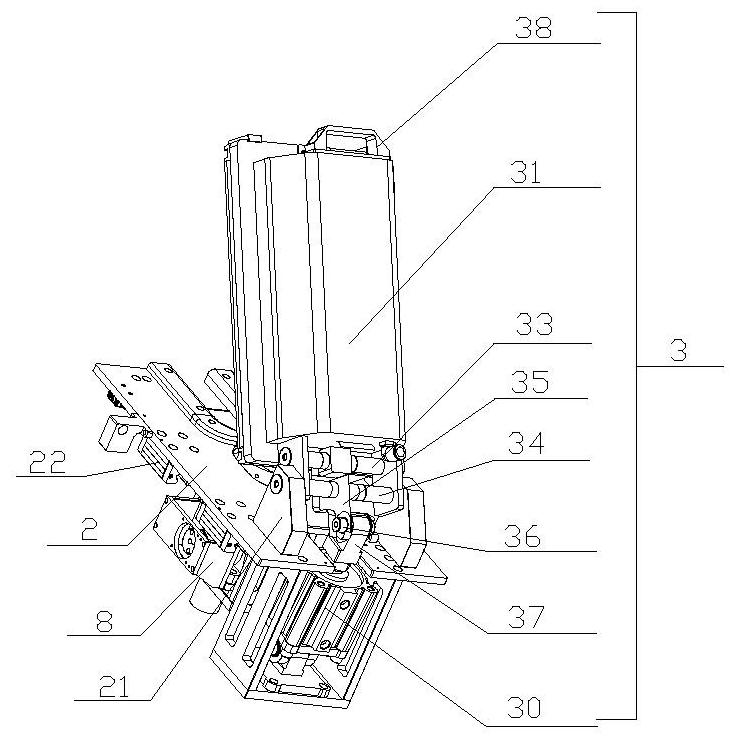

[0032] refer to Figure 1 to Figure 9 , the present embodiment provides an automatic vamp pressure maintaining device, comprising:

[0033] Bottom plate 1, the top of the bottom plate 1 is equipped with a shoe upper limit unit and a gland fastening unit 4;

[0034] The upper limit unit, the upper limit unit includes a pressure bearing plate 2, the pressure bearing plate 2 is provided with a first upper limit groove 20 for limiting the upper, and the pressure bearing plate 2 is parallel to the bottom plate 1 Install;

[0035] Flip cover pressure-holding unit 3, and flip cover pressure-holding unit 3 comprises flip control device 30, gland 31, the air bag 39 that is adapted to be installed on gland 31 inwalls, and gland 31 is provided with the inflation joint that communicates with air bag 39, and inflation joint is connected with air bag 39. Connected with the air source, the lower end of the gland 31 is rotated and installed on the pressure plate 2 and its rotation is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com