Closed foam water spraying system

A water spray and foam technology, applied in fire rescue and other directions, can solve problems such as pipe corrosion, lack of cleaning after use of spray pipes, and limited storage of foam stock solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is not limited to this embodiment, and other embodiments may also belong to the scope of the present invention as long as they conform to the gist of the present invention.

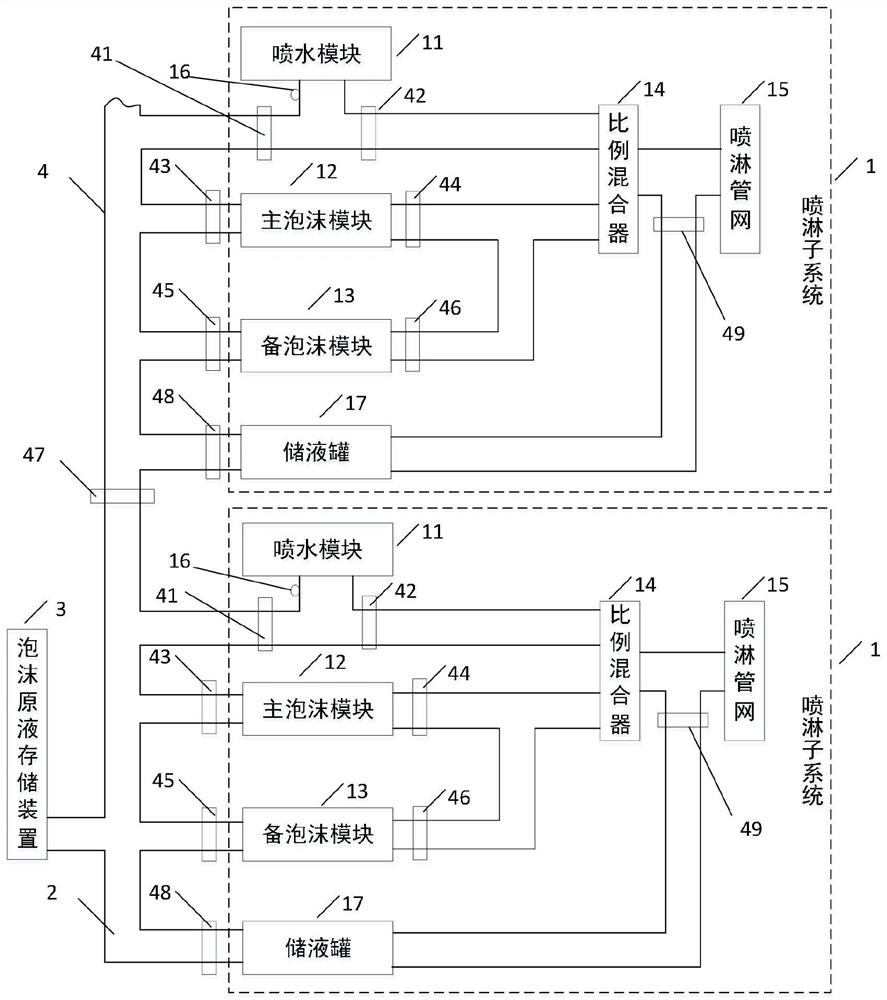

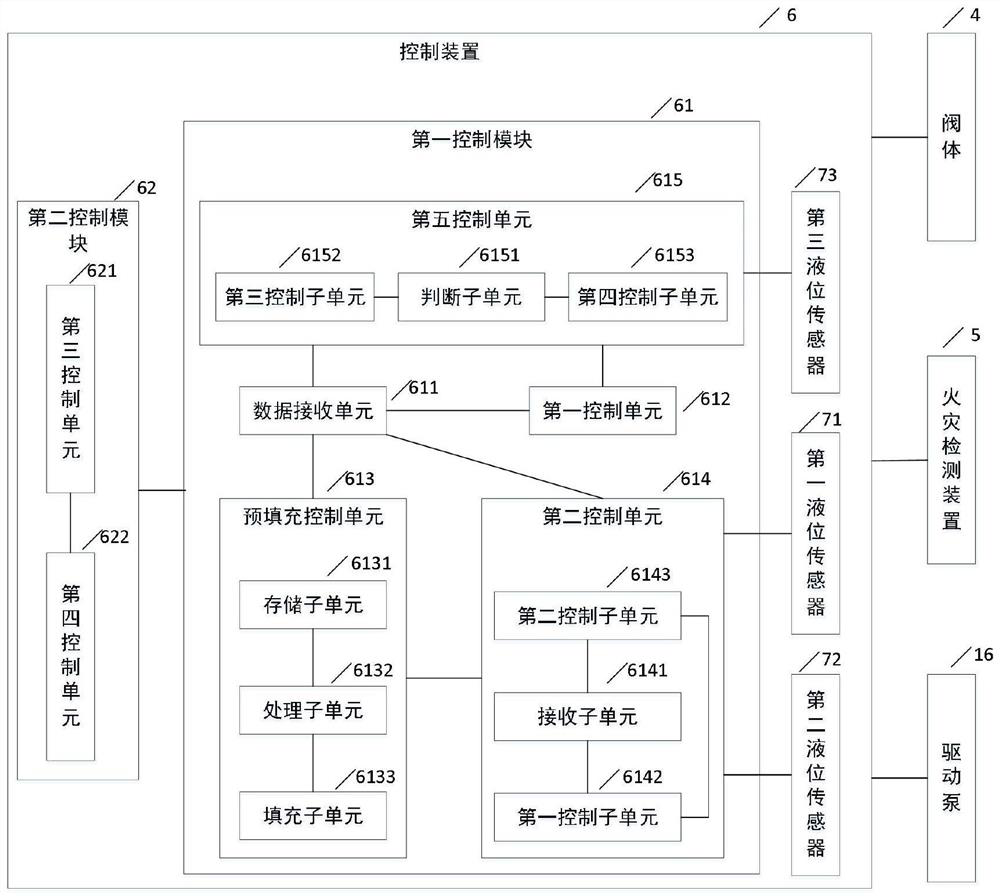

[0049] In a preferred embodiment of the present invention, based on the above-mentioned problems existing in the prior art, a closed foam water spray system is now provided, such as figure 1 with figure 2 shown, including:

[0050] Multiple sets of spray subsystems 1, each set of spray subsystem 1 includes a water spray module 11, a main foam module 12 and a standby foam module 13, the output of the water spray module 11, the main foam module 12 and the standby foam module 13 The liquid ports are respectively connected to the liquid inlet of a proportional mixer 14, the liquid outlet of the proportional mixer 14 is connected to a spray pipe network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com