Integral core head pipe single-pass continuous drawing device

A single pass and drawing device technology for the core pipe material, which is applied in the direction of wire drawing dies, etc., can solve the problems of high mold manufacturing, management and maintenance costs, low production efficiency and equipment utilization, difficult production of tube blanks, etc., and achieve production Improve efficiency and equipment utilization, improve production efficiency, and reduce the number of molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

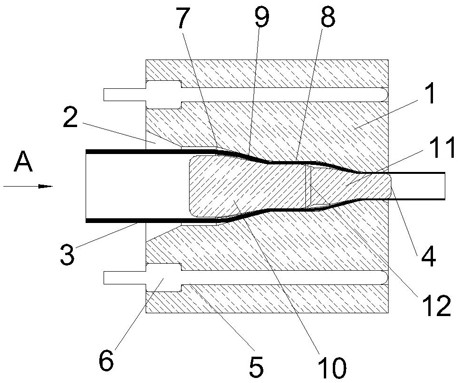

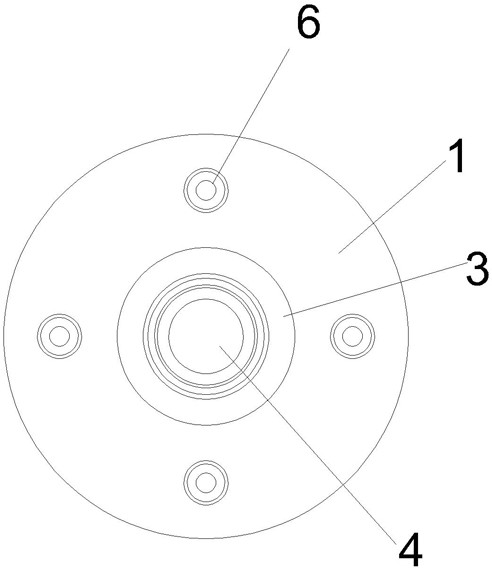

[0016] As shown in the accompanying drawings, this embodiment includes an outer mold 1, which is characterized in that the central axis of the outer mold 1 is provided with a tapered hole 2, the tapered hole 2 includes a first forming section 7 and a second forming section 8, the second The transition between the first forming section 7 and the second forming section 8 is made through the inner curved surface of the tapered hole. The first forming section 7 realizes the first diameter-reducing and wall-reducing deformation of the pipe material 3, and the second forming section 8 realizes the second diameter-reducing and wall-reducing deformation of the pipe material 3, realizing continuous deformation after one drawing.

[0017] The pipe material 3 is arranged in the tapered hole. Since the pipe material 3 with an outer diameter of more than 8mm and a wall thickness of more than 1mm is drawn, the weight of the floating core 4 is relatively large, and it is not easy to balance d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com