A high-strength and low-elongation printing screen and its production process

A technology for printing screen and production process, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of affecting printing quality, consuming a lot of time, and high cost, reducing labor and replacement time, and reducing disassembly and assembly. The tediousness, simplicity and simplicity of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

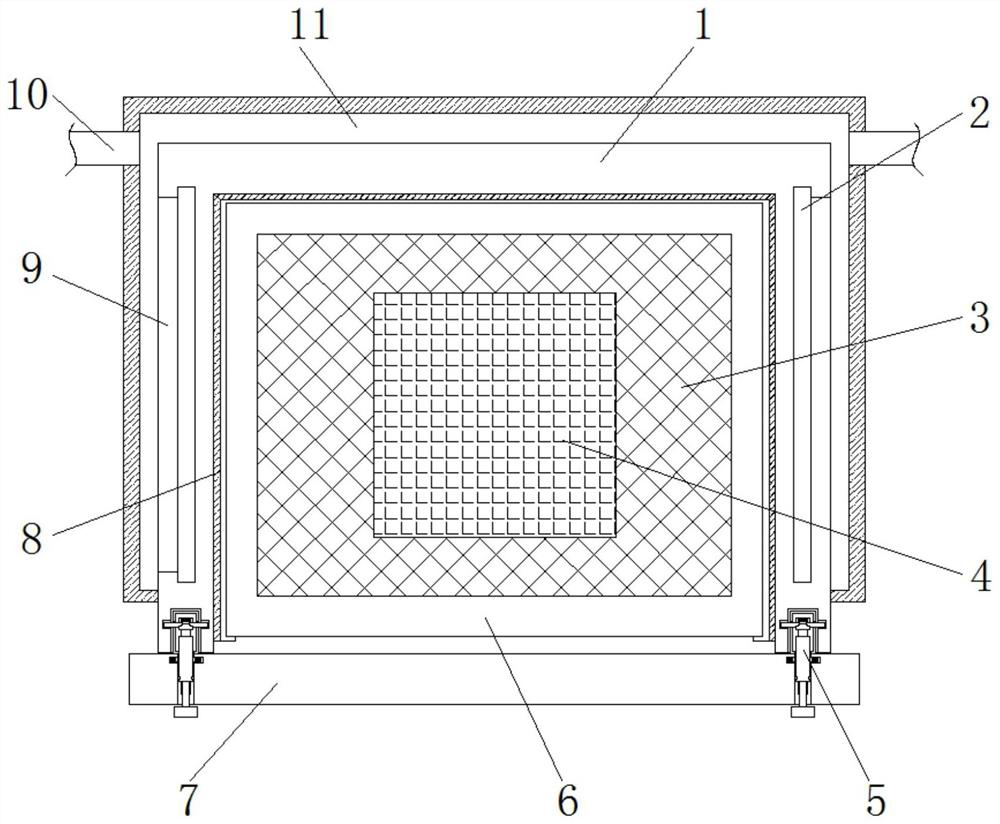

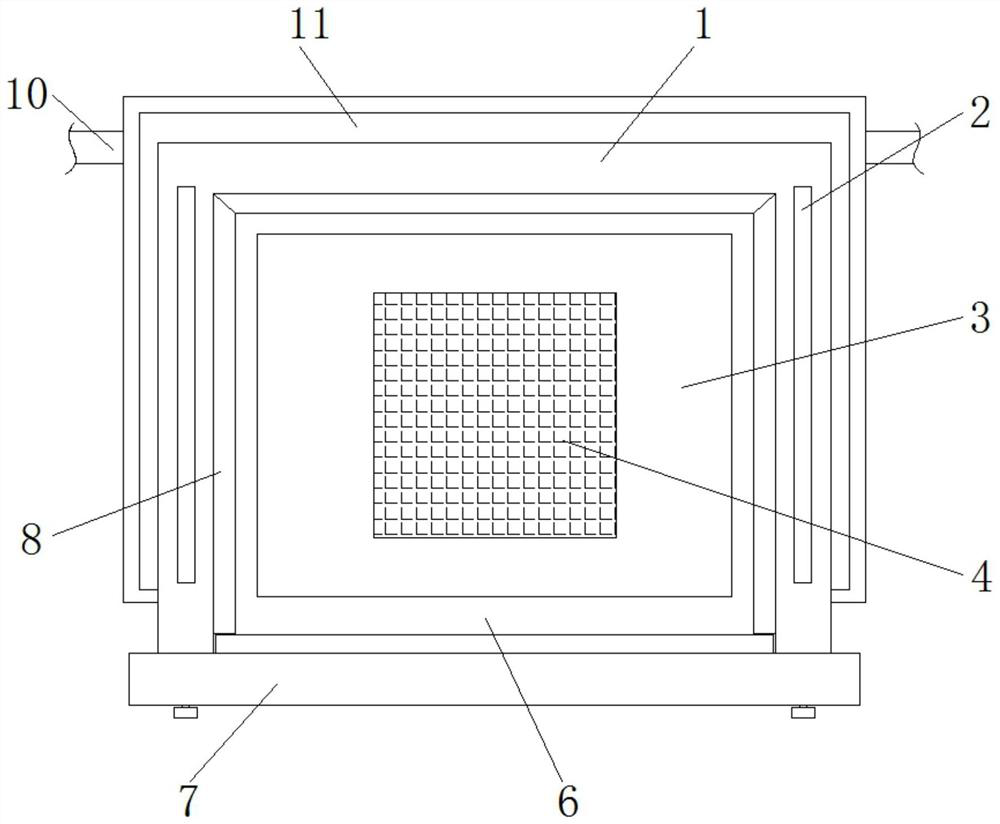

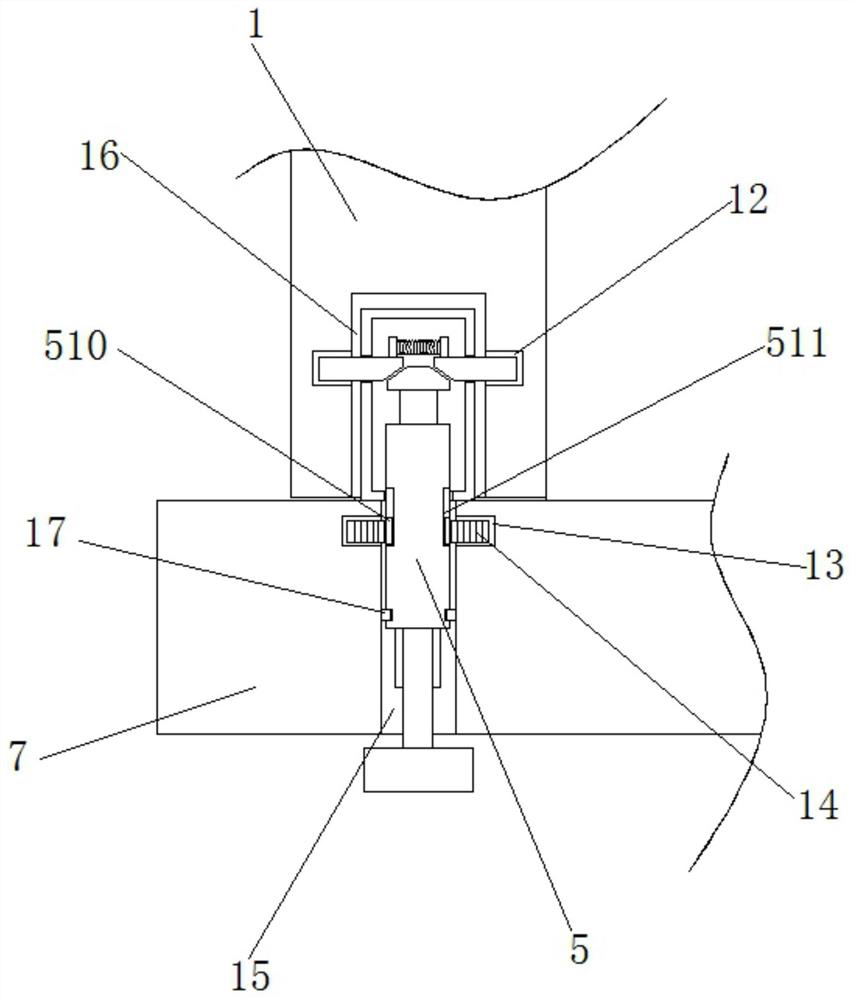

[0036] see Figure 1-7, the present invention provides a technical solution: a high-strength low-stretch printing screen, including a mounting frame 1 and a fixing plate 7, the two sides of the mounting frame 1 and one end of the internal back are provided with mounting slide rails 8, and the mounting frame 1 Both sides of the top are provided with overflow tanks 2, and the sides of the overflow tanks 2 that are far away from each other are provided with connecting grooves 9, and the two sides and one end of the back of the installation frame 1 are provided with ink collecting chambers 11, and the ink collecting chambers 11 are two One end of the back side of the side is provided with a guide tube 10, and the inner sliding sleeve of the three sets of installation slide rails 8 is provided with a printing plate 6, and a printing screen 4 is provided at the middle position inside the printing plate 6, and a printing screen 4 is provided at the edge of the top. There is a metal f...

Embodiment 2

[0038] see Figure 1-7 , the present invention provides a technical solution: a high-strength low-stretch printing screen, including a mounting frame 1 and a fixing plate 7, the two sides of the mounting frame 1 and one end of the internal back are provided with mounting slide rails 8, and the mounting frame 1 Both sides of the top are provided with overflow tanks 2, and the sides of the overflow tanks 2 that are far away from each other are provided with connecting grooves 9, and the two sides and one end of the back of the installation frame 1 are provided with ink collecting chambers 11, and the ink collecting chambers 11 are two One end of the back side of the side is provided with a guide tube 10, and the inner sliding sleeve of the three sets of installation slide rails 8 is provided with a printing plate 6, and a printing screen 4 is provided at the middle position inside the printing plate 6, and a printing screen 4 is provided at the edge of the top. There is a metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com