Instrument shell supporting assembly for automobile

A technology for supporting components and instrument cases, which is applied to vehicle parts, transportation and packaging, etc., can solve problems such as difficult adjustment, excessive adjustment, excessive force, etc., and achieve the effect of preventing sundries from entering and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

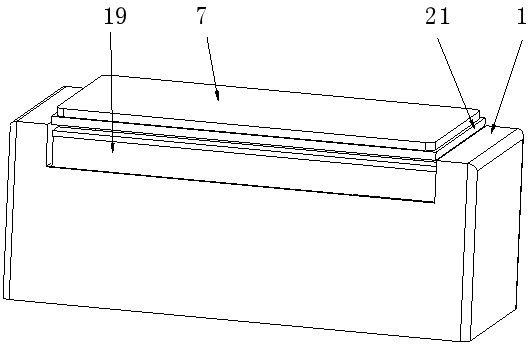

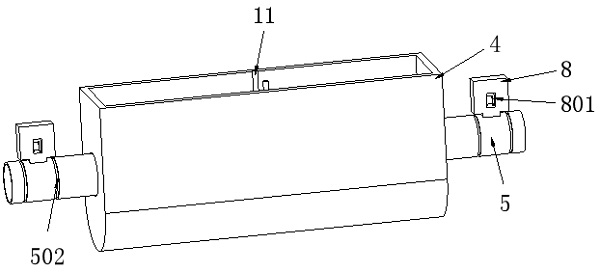

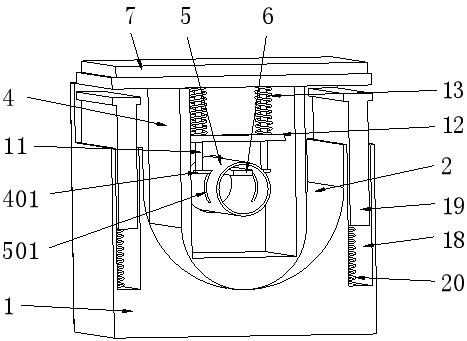

[0027] see Figure 1-6 , an instrument case support assembly for automobiles, comprising a housing 1, a first fixing groove 2 is provided in the middle of the housing 1, and a second fixing groove 3 is provided at both ends of the housing 1, and the upper end of the first fixing groove 2 An opening is provided, and a movable seat 4 is provided in the first fixed groove 2, a fixed shaft 5 is provided in the middle of the movable seat 4, and a movable plate 6 is provided in the fixed shaft 5, and the end of the fixed shaft 5 extends into the second In the fixed groove 3, it is rotatably connected with the second fixed groove 3 by a damping rotating shaft. The two ends of the fixed shaft 5 are provided with a sealing assembly, and the upper end of the movable seat 4 is provided with a fixed frame 21, and the upper end of the fixed frame 21 is provided with a display screen. 7. The lower side of the fixed frame 21 is provided with a connecting component.

[0028] The sealing asse...

Embodiment 2

[0032] see Figure 1-5, this embodiment is a further improvement on Embodiment 1, the fixed shaft 5 is a hollow structure, and the middle part of the fixed shaft 5 is symmetrically provided with two hollow openings 501, and the fixed shaft 5 is fixedly connected with the movable seat 4. The movable plate 6 is slidably connected with the fixed shaft 5 through the guide rod 10 , and the middle part of the movable plate 6 is provided with two fixed protrusions 601 , and the positions of the fixed protrusions 601 correspond to the hollow openings 501 one by one. The connecting assembly includes a connecting rod 11 and a support plate 12, the supporting plate 12 is fixedly connected with the movable seat 4, one end of the connecting rod 11 is fixedly connected with the fixed frame 21, and the other end of the connecting rod 11 passes through the supporting plate 12 and is connected with the fixed protrusion 601 is fixedly connected, and the connecting rod 11 is elastically connecte...

Embodiment 3

[0036] see figure 1 , 5 and 6, this embodiment is a further improvement to embodiment 1, the cross section of the second fixing groove 3 is circular, and the second fixing groove 3 is provided with a second limiting plate 14, the second limiting plate The upper end of 14 is provided with top block 15, and the bottom end of top block 15 is elastically connected with second limiting plate 14 by connecting spring 16, and the upper end of top block 15 is provided with the arc groove that fits with fixed shaft 5. Both ends of the fixed shaft 5 are provided with a set of O-rings 17 , the O-rings 17 are sleeved on the fixed shaft 5 , and the O-rings 17 are arranged symmetrically on both sides of the top block 15 . Both ends of the fixed shaft 5 are provided with limiting grooves 502 for fixing the O-ring 17 .

[0037] The second limiting plate 14, together with the fixed shaft 5 and the limiting block 8, together play a sealing effect on the second fixing groove 3, wherein the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com