Multifunctional loading and unloading integrated robot

A robot and multi-functional technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low loading and unloading efficiency, single function, inconvenient adjustment and use, etc., to achieve the effect of improving functionality and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

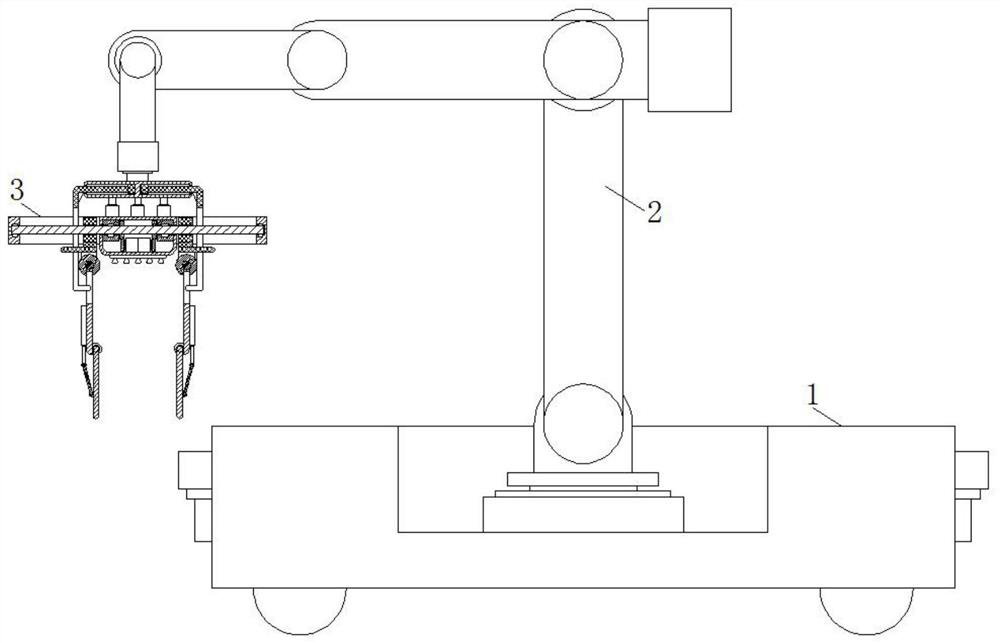

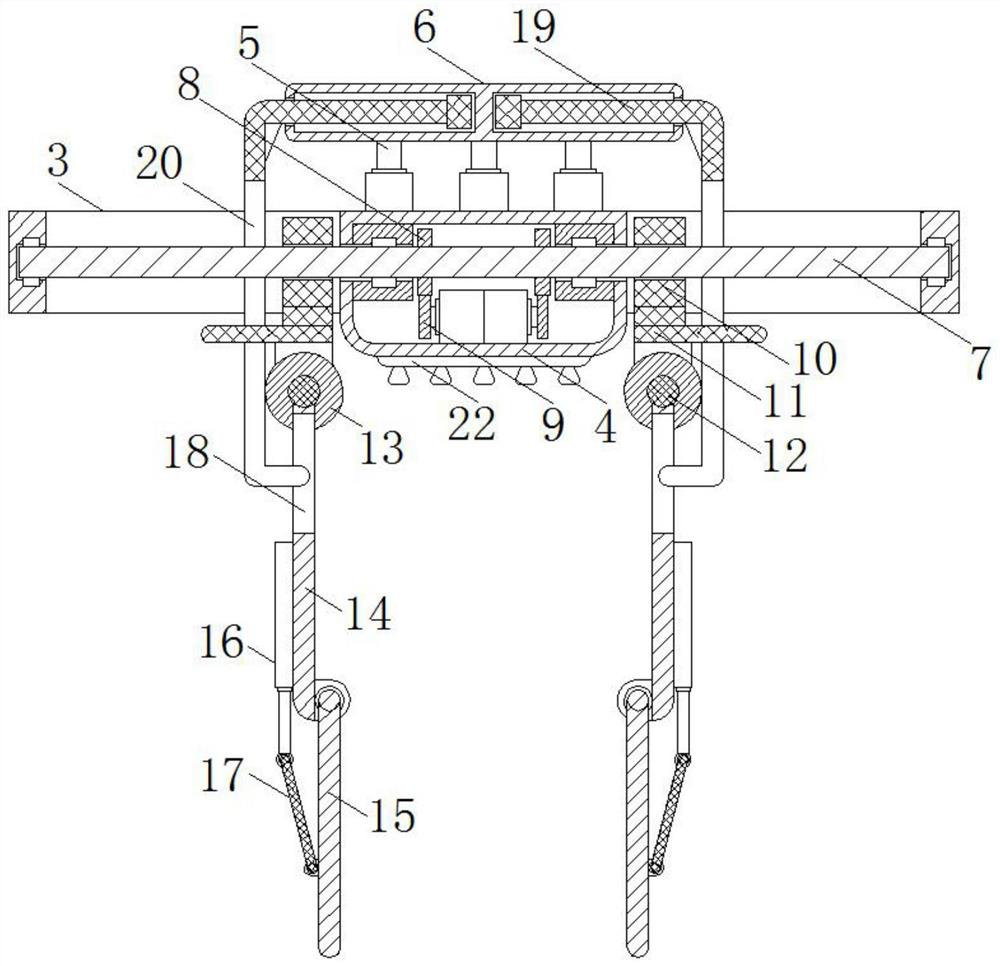

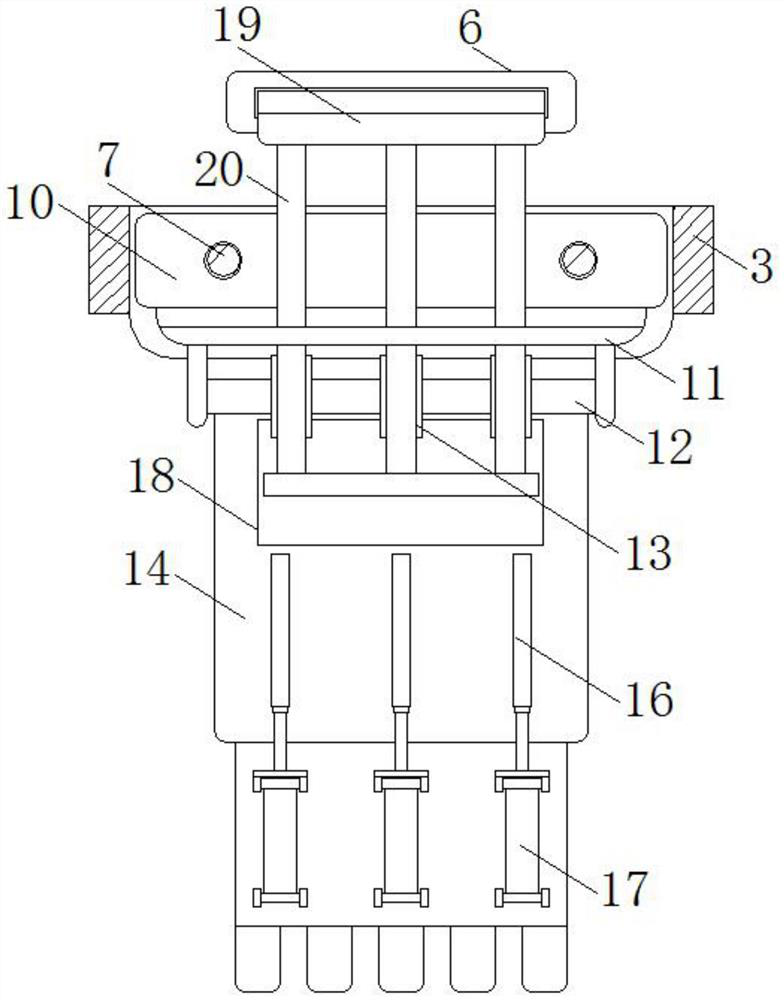

[0028] refer to Figure 1-3 As shown, a multifunctional loading and unloading integrated robot includes an omnidirectional vehicle platform 1, a six-axis mechanical arm 2, and a square frame 3. An equipment compartment 4 is fixedly connected between the front and rear inner walls of the square frame 3. The upper part of the equipment compartment 4 A push rod motor 5 is fixedly mounted on the end face array, and the upper end of the push rod motor 5 is fixedly connected to the limit cylinder 6, and the lower end face of the equipment compartment 4 is fixedly mounted with a suction cup 22, which is characterized in that the front and rear sides of the square frame 3 A screw rod 7 is rotatably connected between the left and right inner walls, and the screw rod 7 passes through the equipment box 4 and is fixedly fitted with a first gear 8 on the surface of the equipment compartment 4. The lower inner wall of the equipment compartment 4 is fixedly equipped with a first motor and a s...

Embodiment 2

[0030] refer to Figure 1-3 As shown, under the condition that the other parts are the same as those in Embodiment 1, the difference between this embodiment and Embodiment 1 is that the two ends of the limit slide rods 19 on both sides that are close to each other are respectively slid to be arranged on the two ends of the limit cylinder 6. The sides of the third gears 13 on both sides that are far away from each other extend on the side where the sliders 10 on both sides are far away from each other, and the lower end of each rack 20 extends below the mounting plate 11 through the slideway opening 21, The racks 20 on both sides are respectively arranged on the side where the third gears 13 on both sides are away from each other and meshed with the third gear 13. The lower end of each rack 20 is movably arranged in the opening 18 on the respective side, and then The push rod motor can drive the limit cylinder 6 to move up relative to the square frame, so that the limit slide rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com