Winch cable take-up and pay-off wiring frame for drilling radar detector

A technology of drilling radar and winch, which is applied in the field of wiring racks, can solve the problems of uneven and troublesome cable winding, and achieve the effect of avoiding uneven winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

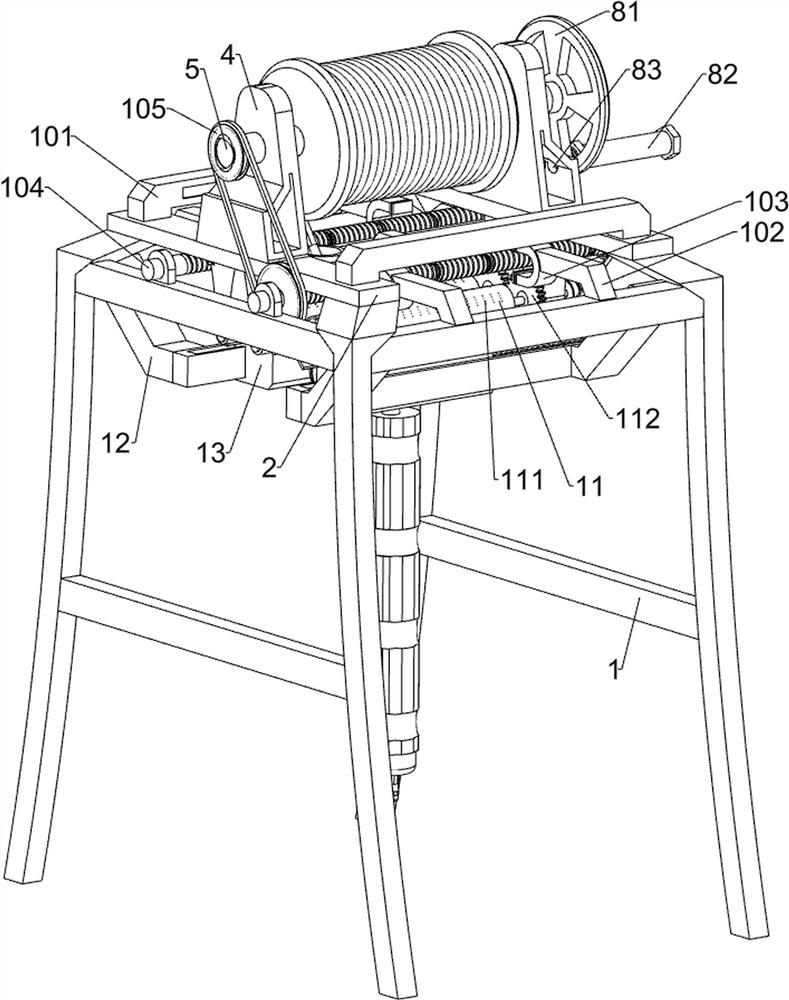

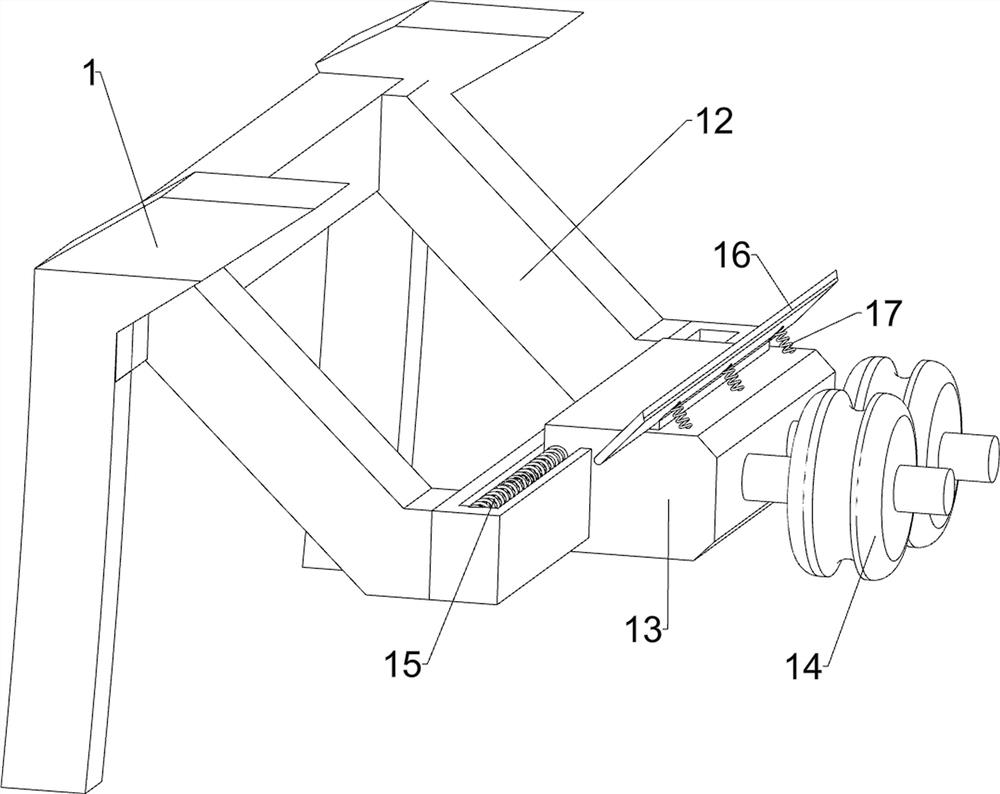

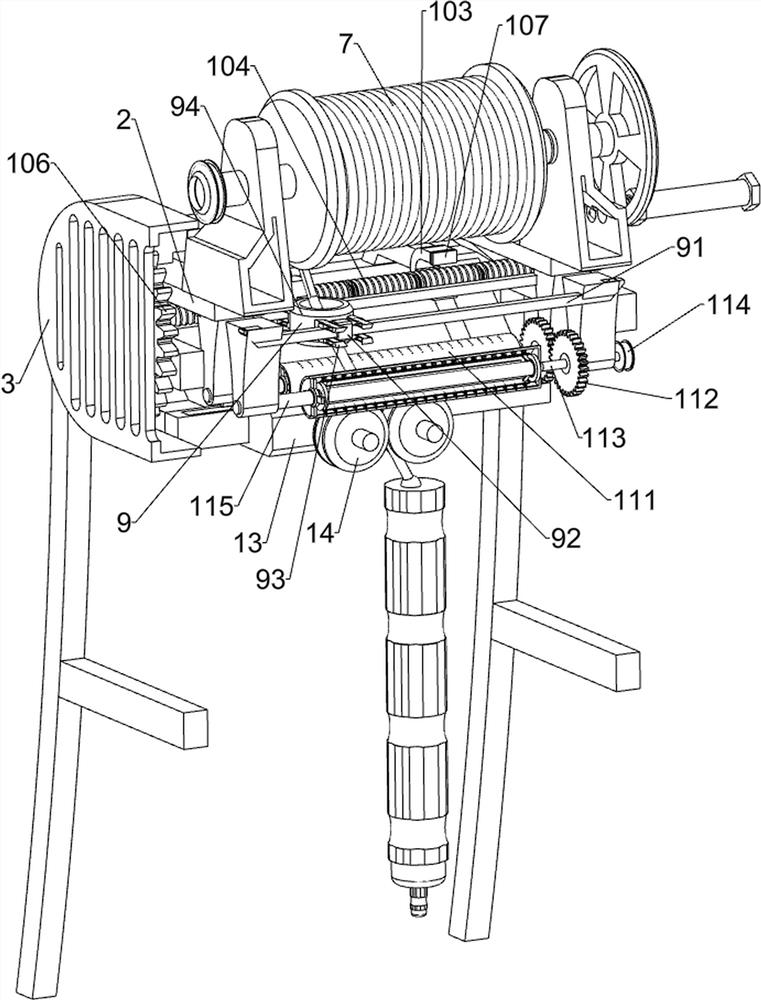

[0029] Embodiment: A cable retractable wiring frame for a winch of a borehole radar detector.

[0030] refer to Figure 1-Figure 4 As shown, it includes a mounting frame 1, a fixed plate 2, a protective shell 3, a vertical plate 4, a rotating shaft 5, a hoist 6, a cable 7, a driving mechanism 8 and a guiding mechanism 9, and the two ends on the left side of the top of the mounting frame 1 are connected to the The fixed plate 2 is fixedly connected between the two ends on the right side, and a guide mechanism 9 is arranged between the bottoms of the fixed plate 2 on the left and right sides. The rotary type is connected with a rotating shaft 5, and a winch 6 is fixedly connected between the inner ends of the left and right rotating shafts 5, and a cable 7 is wound on the hoisting machine 6, and the tail end of the cable 7 passes through the guide mechanism 9 to cooperate with it, and the right rotating shaft 5 A driving mechanism 8 is provided between the right end and the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com