Rail alignment and limit device for maintenance lifts

A limit device and elevator technology, which is applied in elevators, transportation and packaging, etc., can solve the problems of high machining accuracy and installation errors, scratches on trolleys, and difficult alignment of rails, etc., and achieve compact and reasonable structure, cost saving, and easy to use The effect of small frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below according to the drawings.

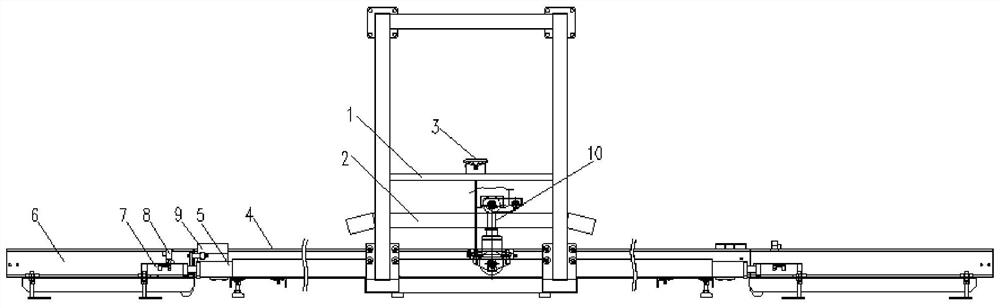

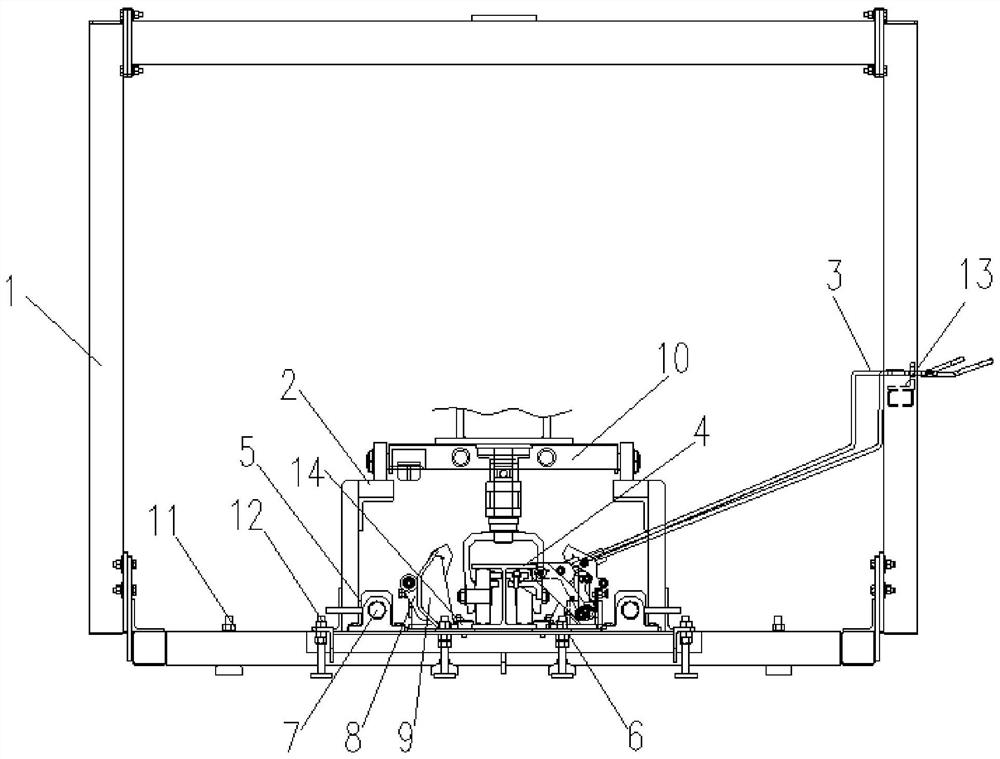

[0018] like Figure 1-4 As shown in the figure, the rail alignment and limit device used for the maintenance of the elevator includes a carriage 1, a righting rail 2, a limit component 3, a movable rail 4, a positioning pin cylinder 5, a rail alignment mechanism 6 and a cage 9. The movable rail The track 4 is fixed on the carriage 1, the limiting assembly 3 is fixed on the movable track 4, and a rail alignment mechanism 6 is respectively provided on both sides of the carriage 1, and the rail alignment mechanism 6 includes a positioning assembly 7 and The stopper 8 , the centralizing rail 2 , the positioning pin cylinder 5 and the holder 9 are screwed on the carriage 1 respectively.

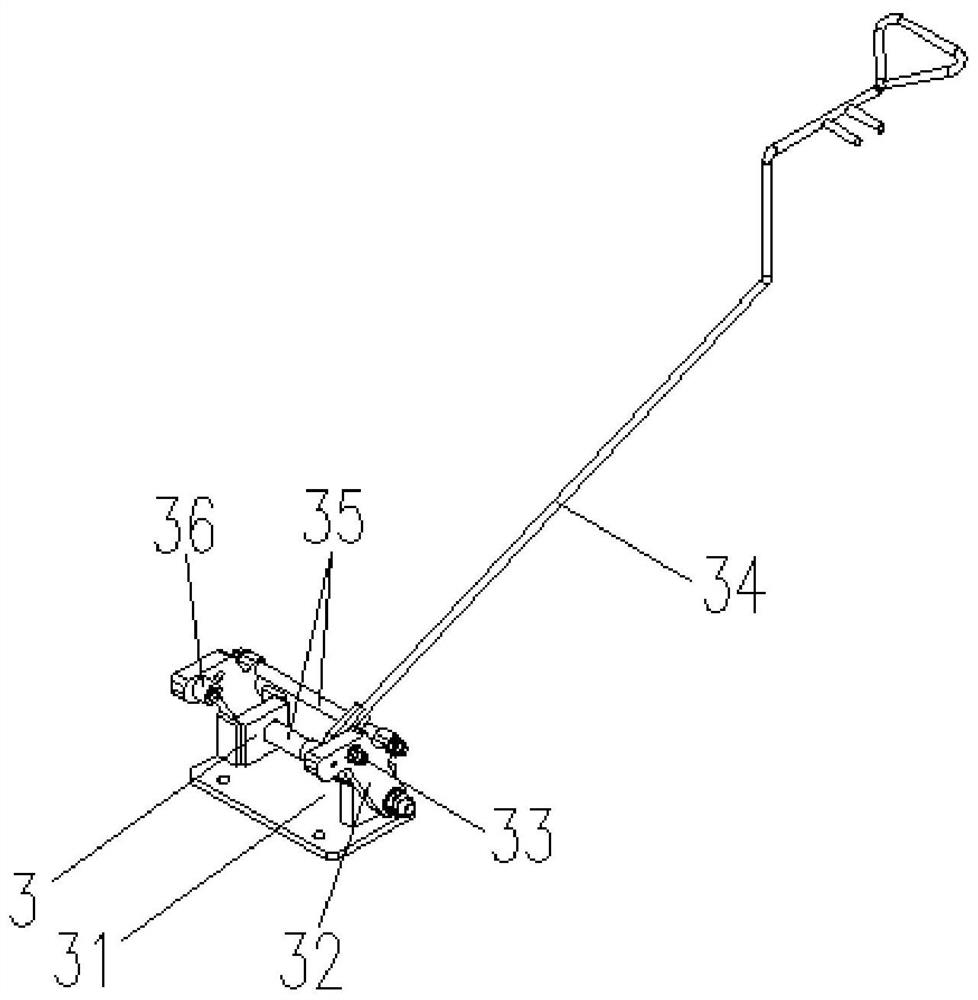

[0019] like image 3 As shown, the bottom of the limit assembly 3 is the base 31, the limit blocks 32 on both sides are fixed on the base 31 through the connecting rod 35, the pull rod 34 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com