Automatic refueling device

A technology of automatic oiling and oiling device, applied in the field of automation, can solve the problems of low oiling work efficiency, huge structure, complex oil gun maintenance cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

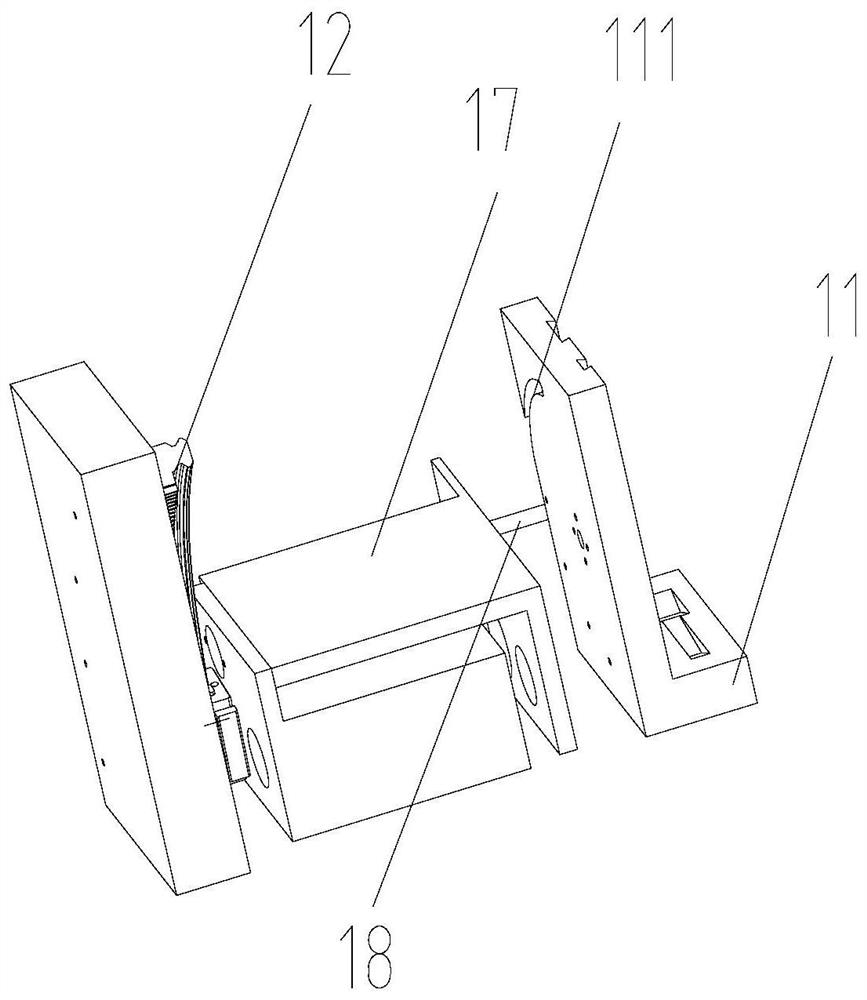

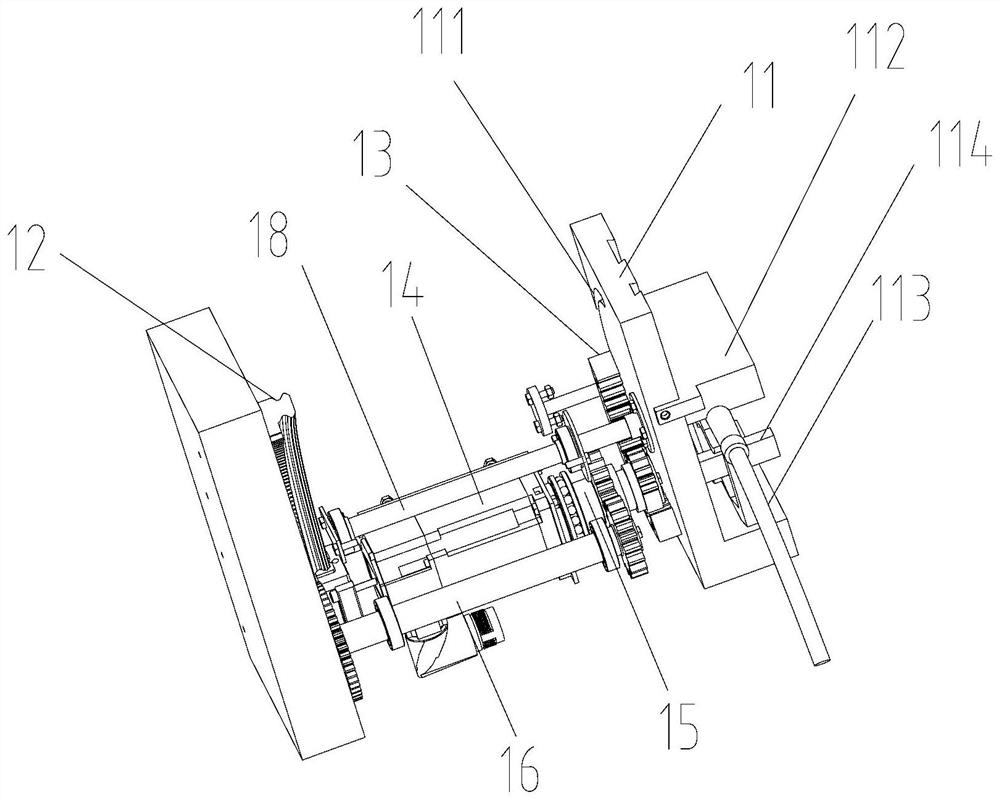

[0051] The main purpose of the present invention is to realize the automatic refueling of automobiles. In order to prevent the oil gun from colliding with the outer wall of the automobile when it enters the automobile refueling process, multiple structures are designed to realize the staged operation of the oil guns, thereby realizing the oil refueling process. The gun does not collide on its way into the filler port.

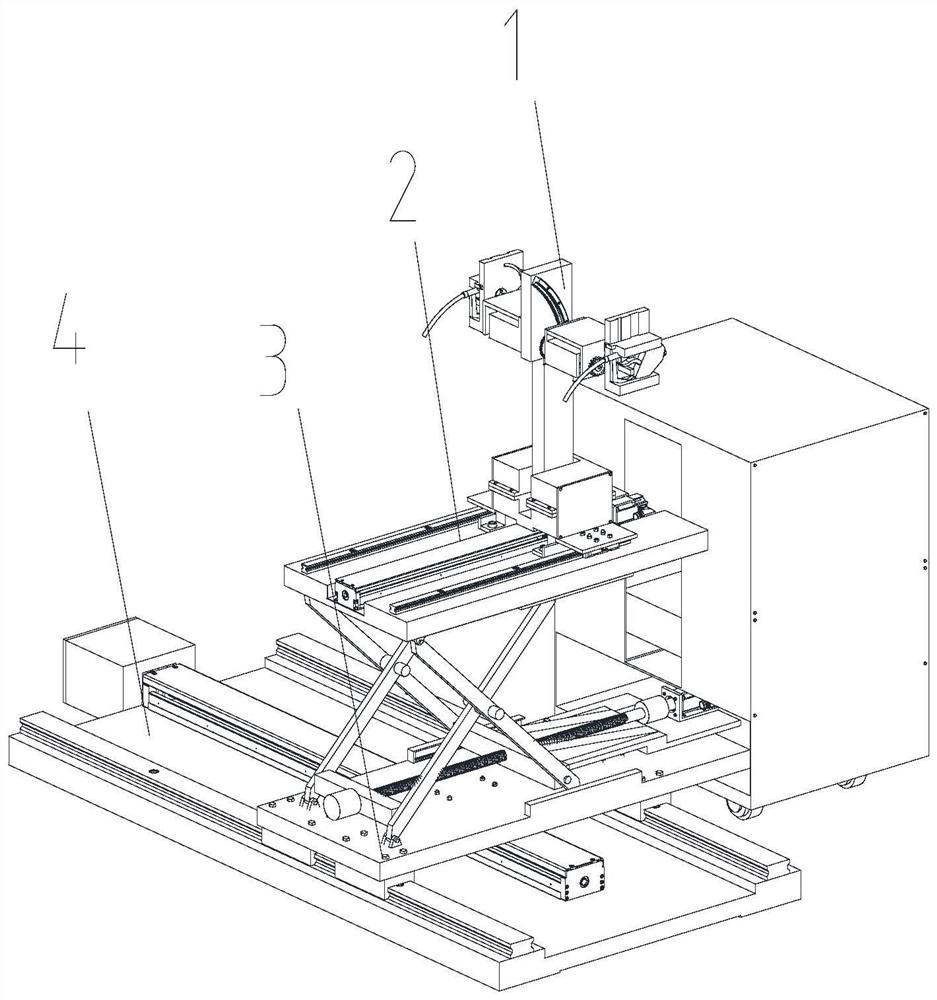

[0052] like figure 1 The shown automatic oiling device includes a differential oiling device 1 for adjusting the position of the nozzle of the oil gun, a swing device 2 for adjusting the position of the oil gun in cooperation with the differential oiling device 1, and a swing device 2 for adjusting the position of the differential oiling device 1 The height lifting device 3, the lateral moving device 4 for adjusting the horizontal position of the differential oil injection device 1, and the central control system. The central control system is used to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com