Device capable of replacing and recovering steel wire rope anchor rod and recovering method

A technology of steel wire rope and wire rope sleeve, which is applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of cumbersome operation process, low recovery value and high production cost, and achieves efficient operation, easy preservation and management, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

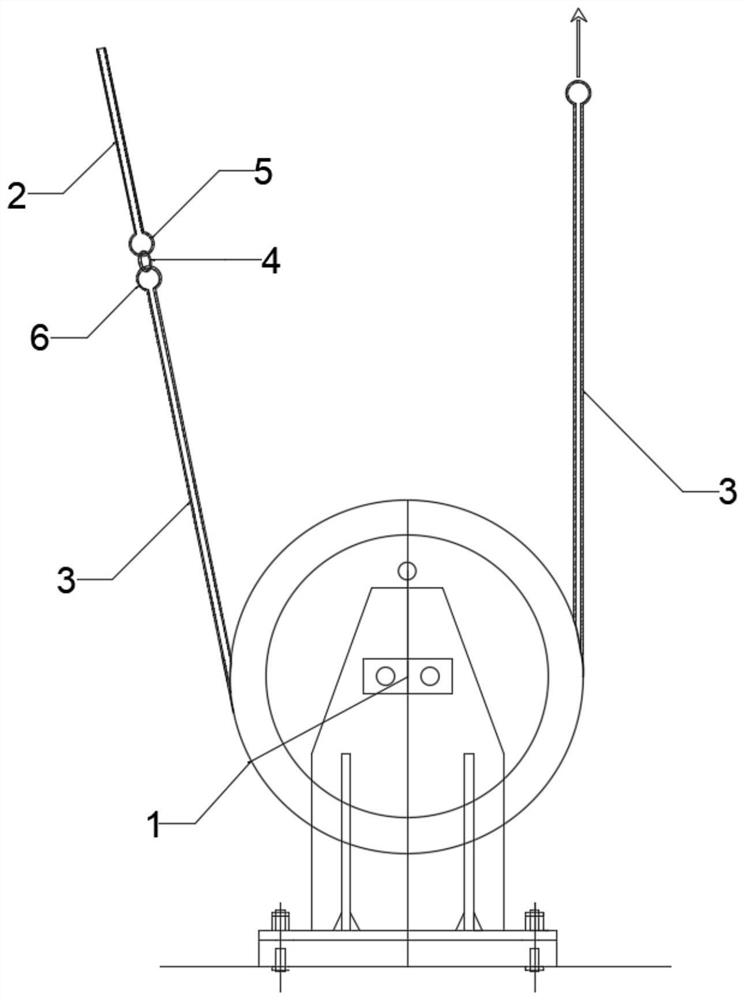

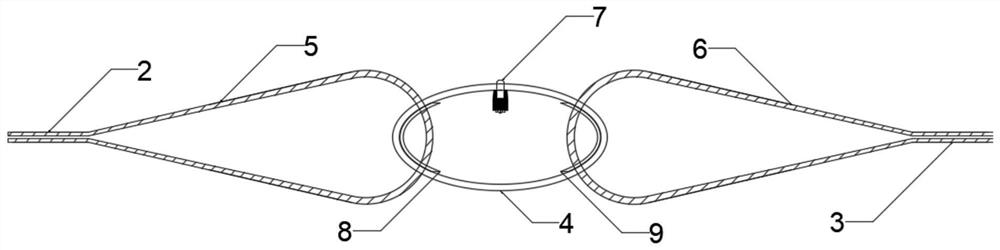

[0026] Such as Figure 1 to Figure 2 As shown, the device of the present invention that can replace and reclaim the wire rope anchor, the components include a static pulley 1, a new wire rope anchor 2, an old wire rope anchor 3, a wire rope collar 4, a bolt 7, a left gasket 8 and The right gasket 9, the specific structure and connection relationship of the components are:

[0027] The static pulley 1 is fixed on the rock mass, and the new wire rope anchor 2 and the old wire rope anchor 3 are supported by the static pulley 1 to play the role of pulling support. The heart ring 5 of the new wire rope anchor 2 is connected with the heart ring 6 of the old wire rope anchor 3 through the wire rope collar 4, so as to realize the connection between the new and old wire rope anchors. Same as the wire rope anchors on the market, the heart ring is a structure embedded in the bend of the wire rope and fixed with a rope clip or an aluminum alloy fastening sleeve. Wire rope collar 4 insid...

Embodiment 2

[0031] A recovery method suitable for a device capable of replacing and recovering a wire rope anchor, comprising the steps of:

[0032] (1) When the old steel wire rope 3 needs to be replaced due to reasons such as corrosion and metal fatigue, first remove the bolt 7 of the steel wire rope collar 4, and remove the heart ring 6 on one side of the old steel wire rope anchor rod 3 from the supporting structure, and put the It and the heart ring 5 on one side of the new wire rope anchor rod 2 are respectively placed on the left gasket 8 and the right gasket 9 of the wire rope collar 4, and then the bolt 7 of the wire rope collar 4 is tightened;

[0033] (2) Put the heart ring 5 and the heart ring 6 at both ends of the new wire rope anchor 2 and the old wire rope anchor 3 into the two ends of the wire rope collar 4 respectively, so that the new steel rope anchor 2 and the old wire rope The anchor rods 3 are connected to each other; in this process, the other end of the old wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com