Floor drain device capable of automatically and circularly removing dirt

An automatic circulation and floor drain technology, which is applied to water supply devices, waterway systems, drainage structures, etc., can solve the problems of limited installation space of floor drain devices, difficulty in installation and construction, and loss of parts, etc., to achieve simple structure, ensure installation efficiency, The effect of preventing clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

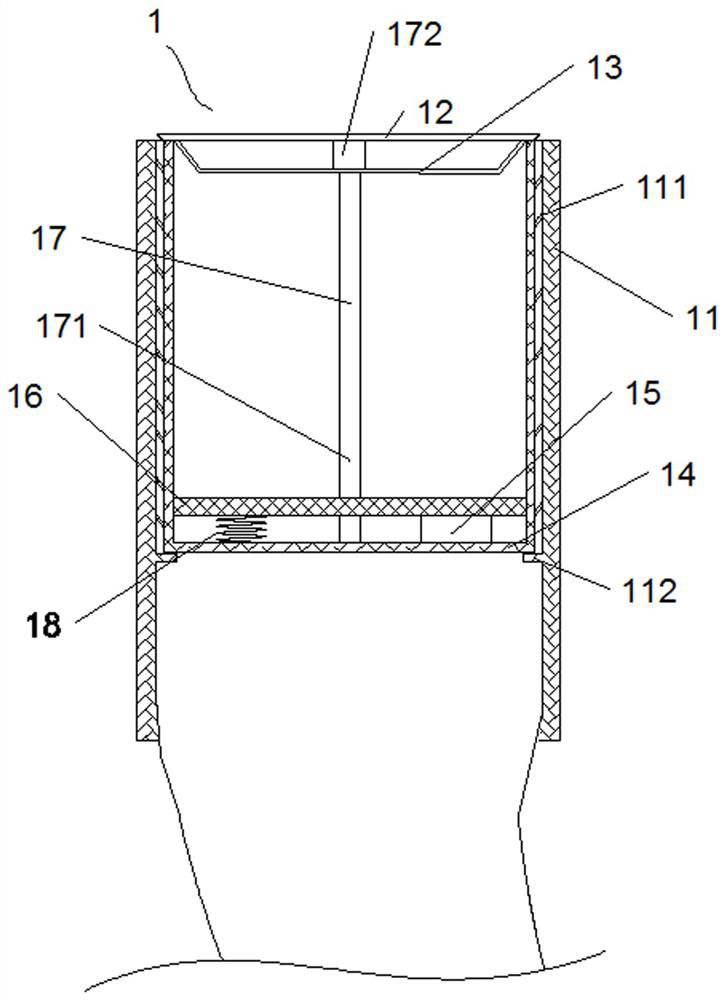

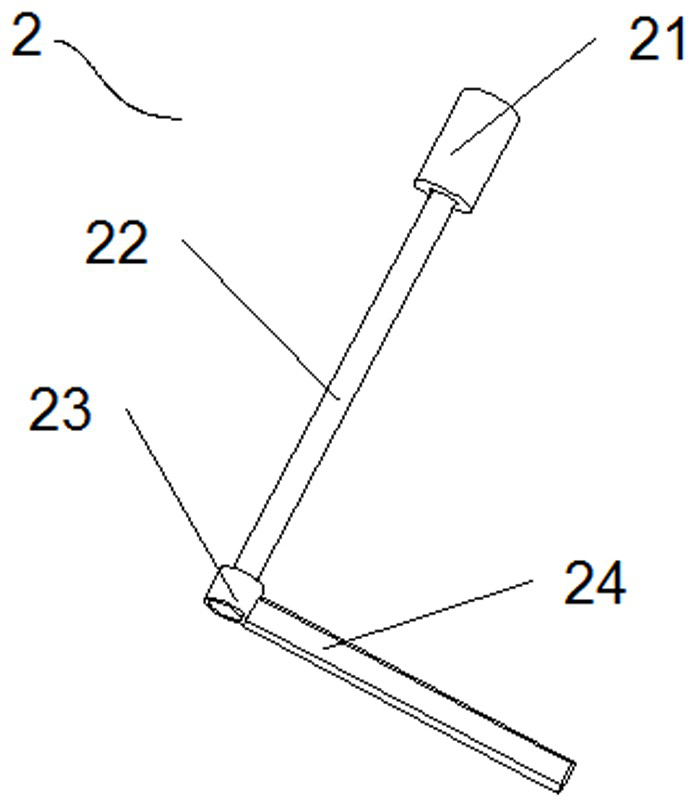

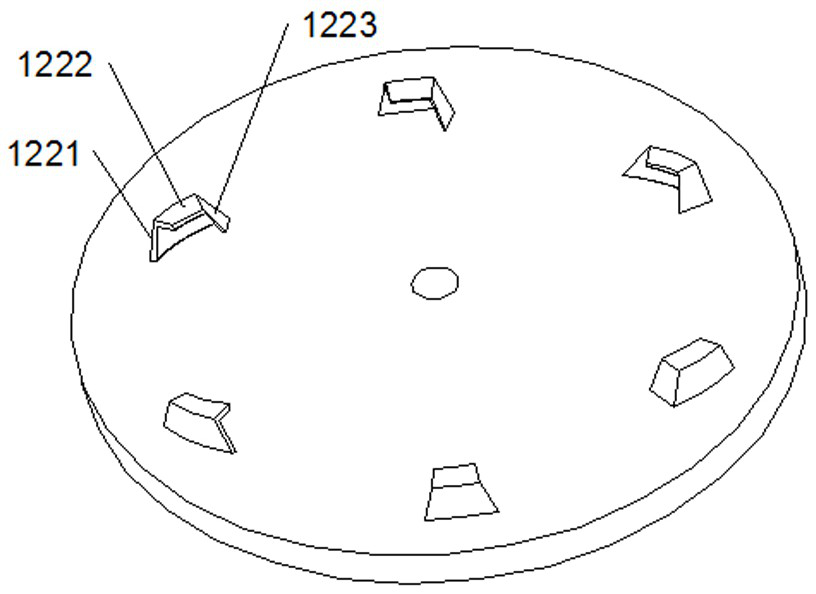

[0033] A floor drain device diagram for automatic cycle decontamination, including a debris collection mechanism 1 and a debris cleaning mechanism 2; 1 is a schematic diagram of the debris collection mechanism, figure 2 Schematic diagram for debris cleaning mechanism, such as figure 1 and figure 2As shown, the debris collection mechanism 1 includes a casing 11 arranged in the drainage pipe, a floor drain cover 12 arranged at the water inlet of the casing 11, a floor drain cover 12 arranged at the bottom of the floor drain cover 12 and connected to the The filter screen 13 connected to the floor drain cover 12, the filter cartridge 14 arranged in the casing 11, the gravity sensor 15 arranged at the bottom of the filter cartridge 14, and the filter plate 16 arranged above the gravity sensor 15 And one end is rotationally connected with the bottom of the filter cartridge 14, and the other end is connected with the central rotating shaft 17 of the floor drain cover 12; the debr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap