Assembly type perforated steel plate rib laminated slab

A technology of perforated steel plate and laminated plate, which is applied to floors, buildings, building components, etc., can solve the problems of low strength and rigidity of laminated plate bottom plate, affect the construction efficiency of laminated plate, and many construction steps, etc., so as to improve the fixing effect and structure. The effect of simplicity and reduced construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

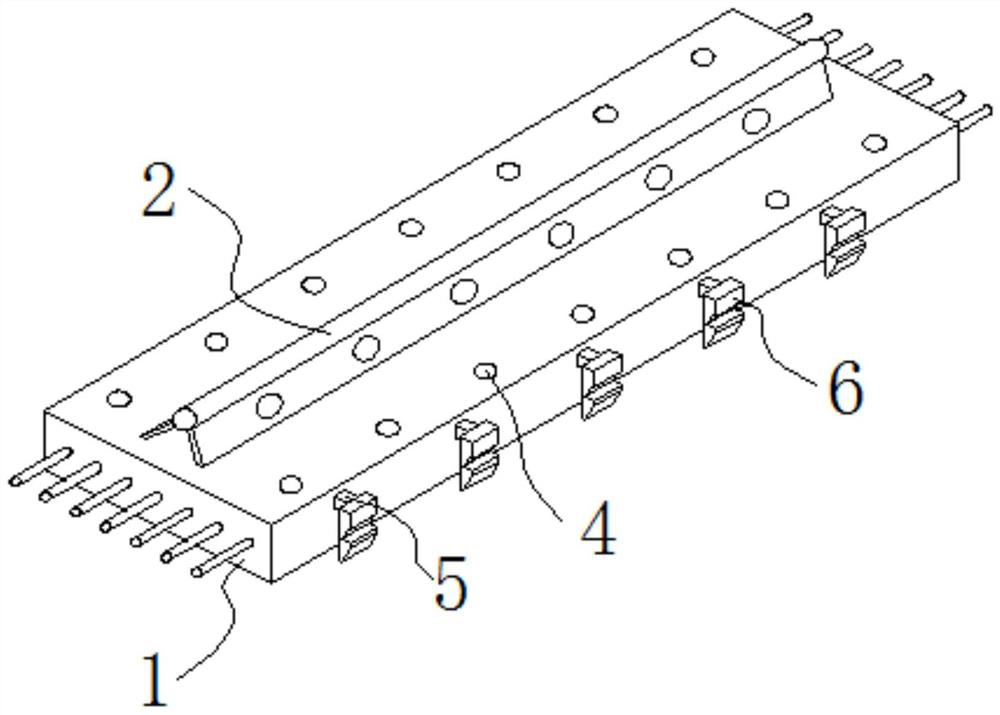

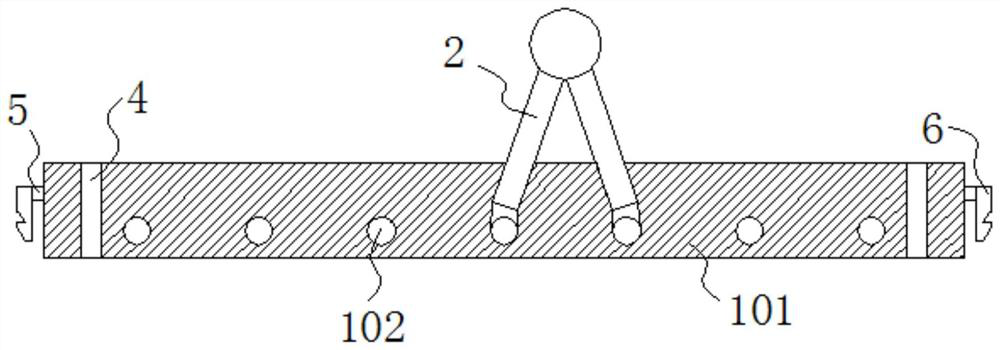

[0063] The invention provides an assembled perforated steel plate rib laminated plate, which comprises a concrete layer 1, steel plate ribs 2 and connectors. Exemplary, such as figure 1 As shown, the main body of the concrete layer 1 is a cuboid structure. Concrete layer 1 is used to support the overall structure.

[0064] The steel plate rib 2 is located on the concrete layer 1 , and the connection structure of the steel plate rib 2 is fixedly installed in the main body of the concrete layer 1 . The steel plate ribs 2 are used to support the building structure above the concrete layer 1 .

[0065] The concrete layer 1 runs through several steel bars in the transverse direction, and several sets of fixing mechanisms of the connectors are arranged symmetrically on both sides of the horizontal steel bars of the concrete layer 1 by welding, and the sets of fixing mechanisms on the same side are arranged at equal intervals.

[0066] The concrete layer 1 includes a laminated sla...

Embodiment 2

[0078] The present invention also provides an assembled perforated steel plate rib laminated plate, which comprises a concrete layer 1, a T-shaped fixing frame 3, steel plate ribs 2 and connectors. like Figure 9 , Figure 10 and Figure 11 As shown, the structures of the concrete layer 1 and the steel plate rib 2 are the same as those of Embodiment 1.

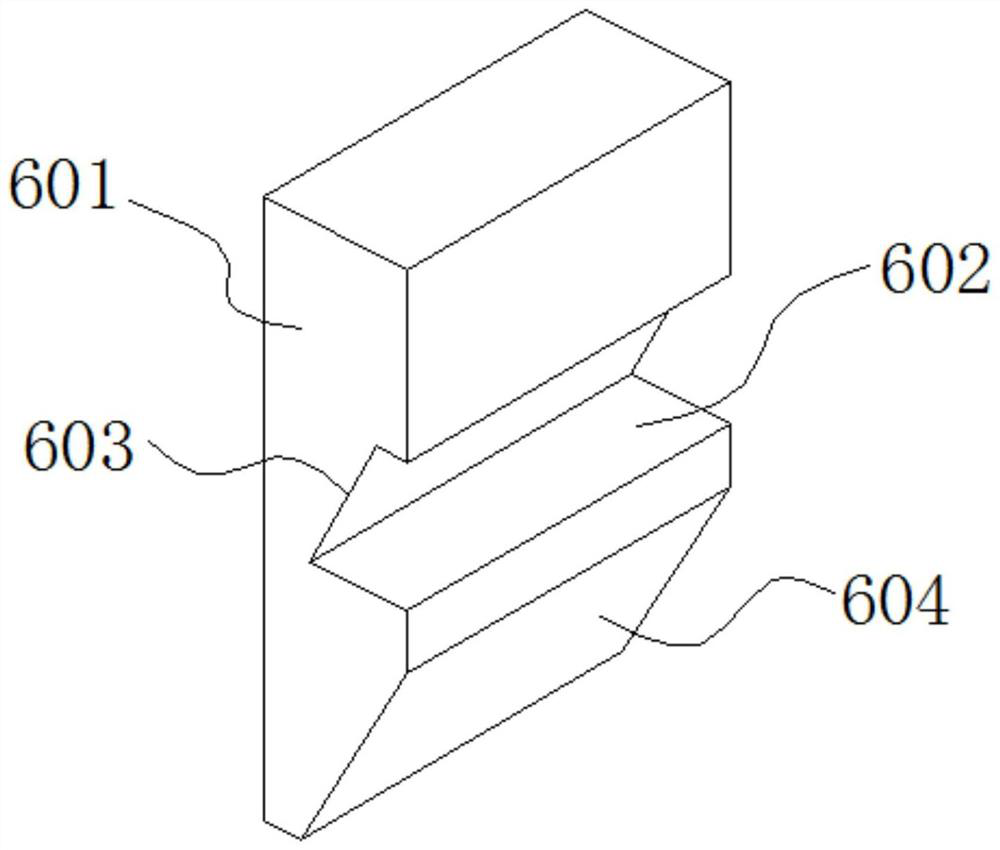

[0079] The connecting piece includes several groups of sliders 8 , several groups of limiting sleeves 11 and several groups of limiting rods 10 . Several groups of sliders 8 are arranged symmetrically at the edges of both sides of the bottom of the laminated board body 101 , and the groups of sliders 8 on the same side are arranged at equal intervals. A group of steel plate limit blocks 9 are fixedly installed at the bottom of each group of slide blocks 8 . The concrete layer 1 runs through a number of steel bars in the transverse direction. Several sets of limit sleeves 11 are welded to the outer wall of the transverse re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com