Spatial bidirectional open-web truss structure system and construction method thereof

A technology of hollow truss and truss, which is applied in the space two-way hollow truss structure system and its construction field, and can solve the problems of difficult positioning of diagonal members and low accuracy of diagonal members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

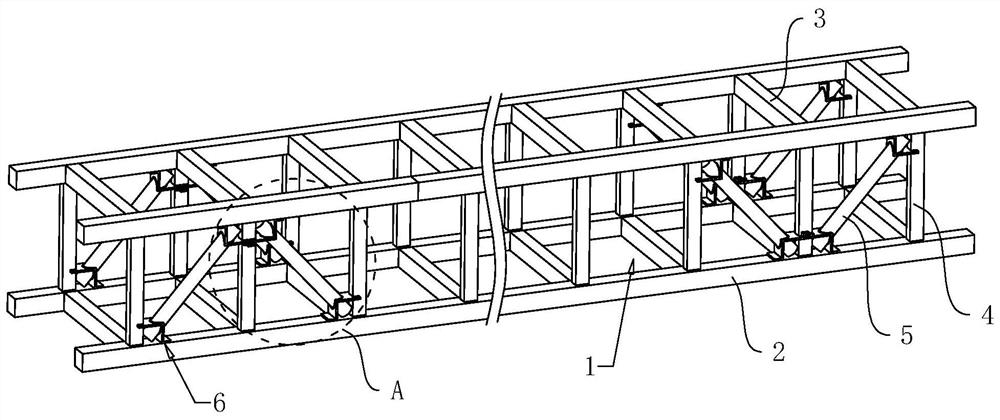

[0042] This embodiment discloses a space two-way vierendeel truss structure system, such as figure 1 As shown, a space two-way vierendeel truss structure system is manufactured by the following construction methods:

[0043] S1. Manufacture the main body of the truss.

[0044] Take four chords 2, take multiple vertical bars 4 and multiple cross bars 3, and fix the chords 2, vertical bars 4 and cross bars 3 to each other to form a truss body containing multiple truss grids 1.

[0045] The chords 2 are all arranged horizontally, the vertical bars 4 are all vertically arranged, and the cross bars 3 are all arranged horizontally. A truss grid 1 is formed between a cross bar 3 and two chords 2, so that a plurality of truss grids 1 are formed in the length direction of the truss main body.

[0046] S2. Put the diagonal rods 5 into the corresponding truss grids 1 .

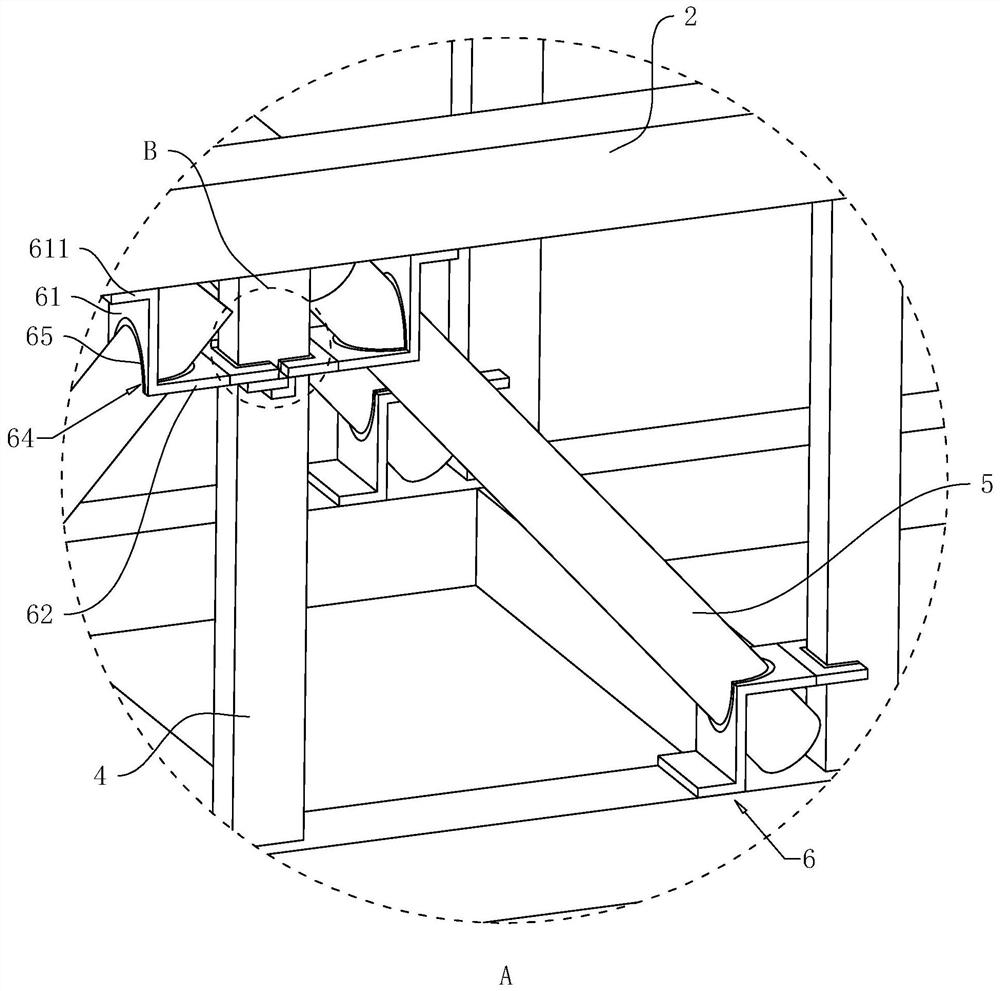

[0047] Put the two positioning frames 6 into the two ends of the diagonal rods 5 respectively, and then put the dia...

Embodiment 2

[0060] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, the truss main body of this embodiment is assembled from two prefabricated truss main bodies 7 .

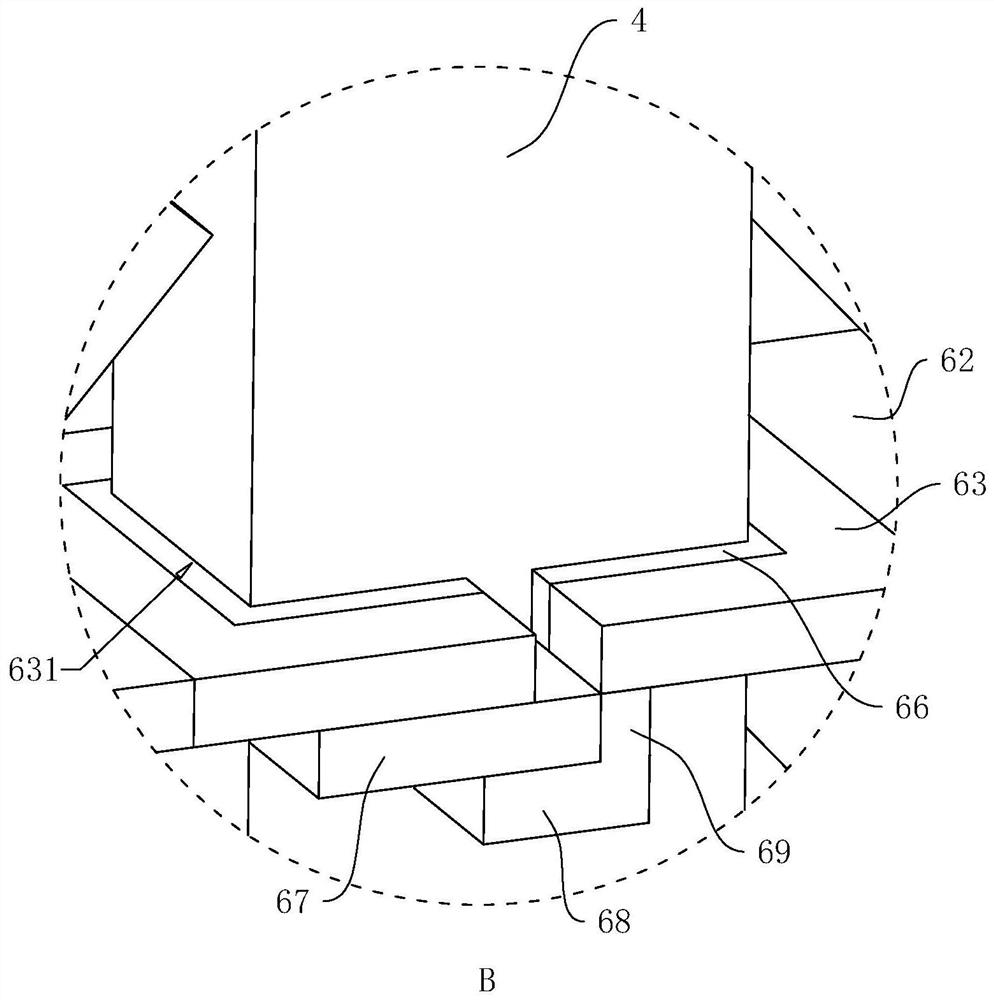

[0061] Such as Figure 4 and Figure 5 As shown, the two prefabricated truss bodies 7 are connected end to end, and the ends of the two prefabricated truss bodies 7 that are close to each other omit the installation of vertical bars 4 and cross bars 3. Install the diagonal rod 5 in the center, first fix the positioning frame 6 at one end of the diagonal rod 5 with the chord 2 and the vertical rod 4, and fix the first positioning plate 61 in the positioning frame 6 at the other end of the diagonal rod 5 with the chord 2 , the connecting plate 63 of the positioning frame 6 is not processed, and then one end of the diagonal web bar 5 is fixed with the chord bar 2 and the vertical bar 4, and the other end of the diagonal web bar 5 is fixed with the chord bar 2.

[0062] Put the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com