A connection structure and method for corners of plastic-steel doors and windows

A corner joint, plastic-steel door and window technology, applied to corner joints/edge joints, windows/doors, building components, etc., can solve the problems of reducing the service life of the overall doors and windows, loose corner structures, poor corner stability, etc., to achieve Good mutual sealing, enhanced stability, avoiding cracking and loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of this patent will be further described in detail below in conjunction with specific embodiments.

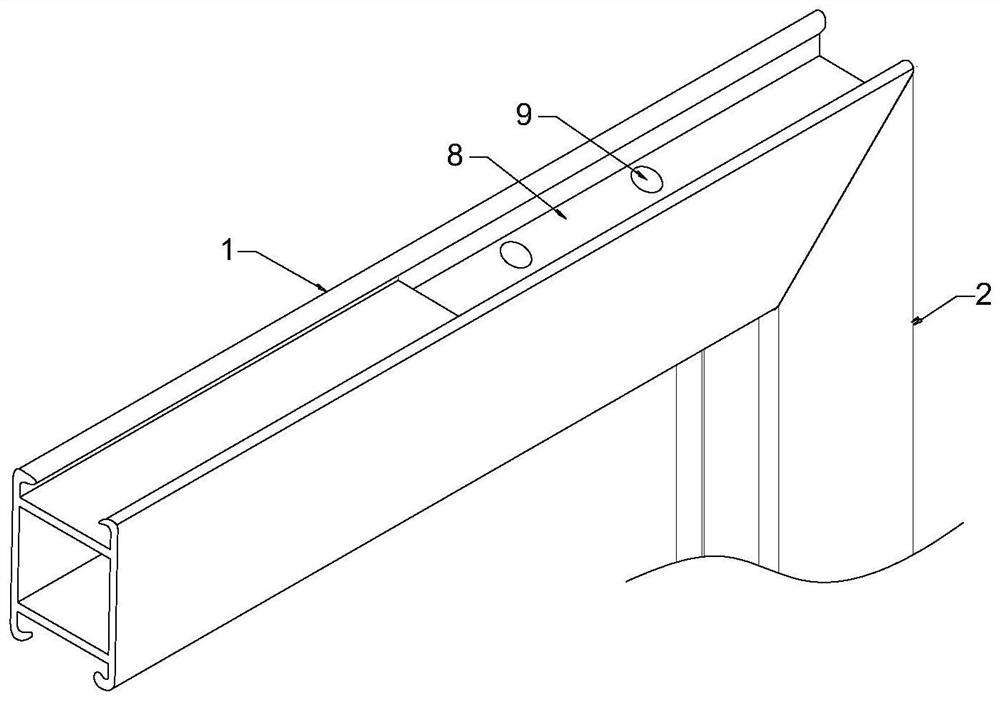

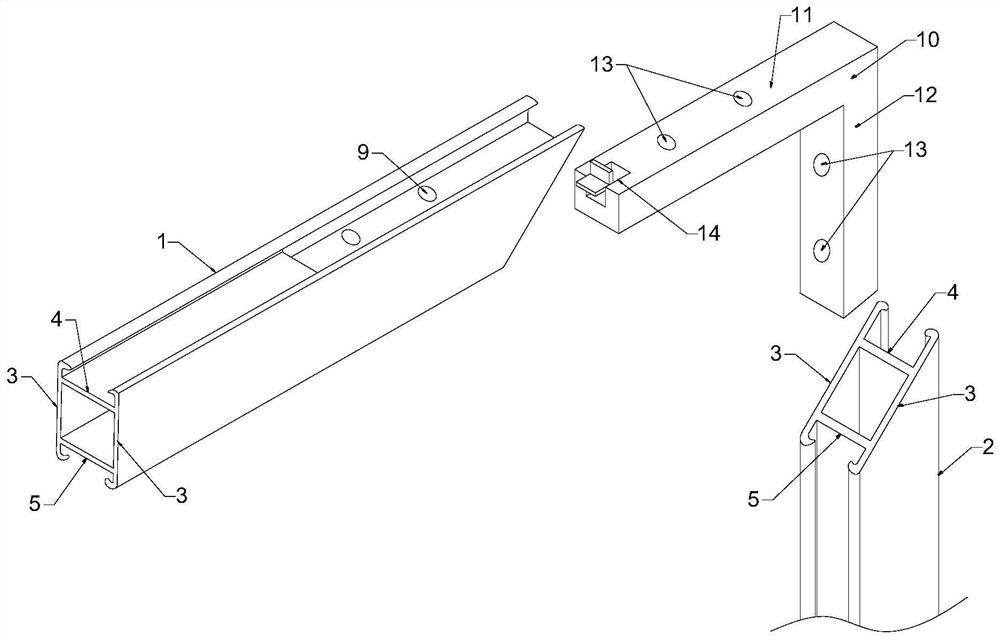

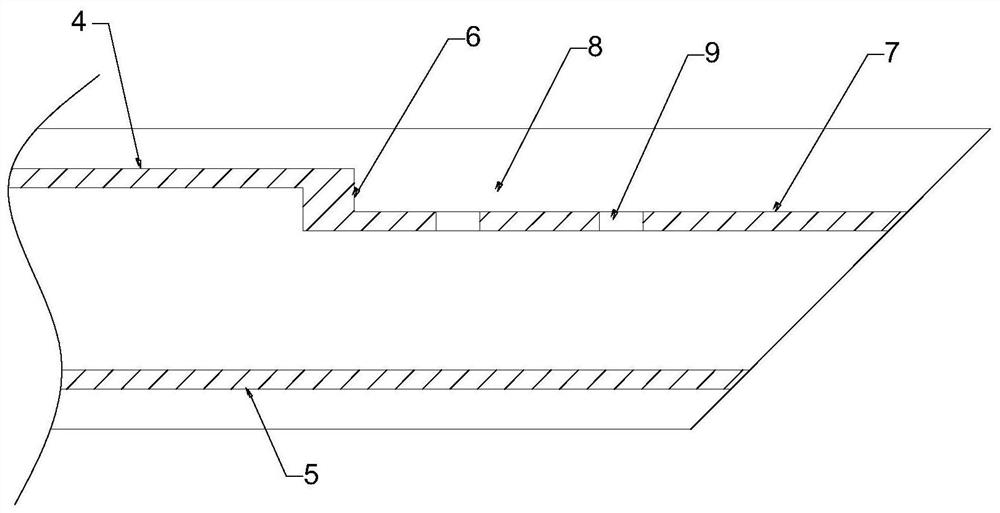

[0034] See Figure 1-9 A plastic steel door-to-corner connection structure, including the lateral frame rod 1 and the vertical frame rod 2, the lateral frame rod 1 is connected to the vertical frame rod 2 and forms a vertical angle in two connecting ends, the lateral frame rod 1 and vertical The frame rod 2 is a hollow rod member, and the lateral frame rod 1 and the vertical frame rod 2 each include two side walls 3, and the two side walls 3 are connected by one wall 4 and the second wall 5, two The side wall 3 is formed between the first wall 4 and the No. 1 wall 4; all of which are existing techniques, in the present invention, the first wall 4 is adjacent to the interior of the cavity to form a corner. The segment 6 and continues to extend forming a wall mounting section 7 and forms a mounting chamber 8 on a wall mounting section 7, which is conside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com