LED driving lamp strip

A technology of light strips and lamp sockets, which is applied in the direction of motor vehicles, road vehicles, vehicle parts, etc., can solve the problems of limited fixing method and installation angle, flexible light strips cannot adjust the lighting angle, and hard light strips are inconvenient to bend, etc. , to achieve the effect of convenient adjustment, improved disassembly efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

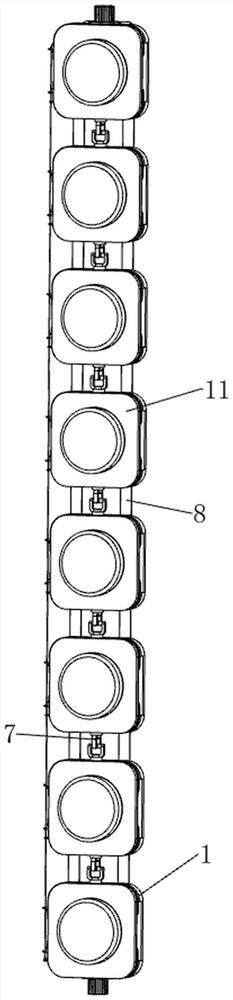

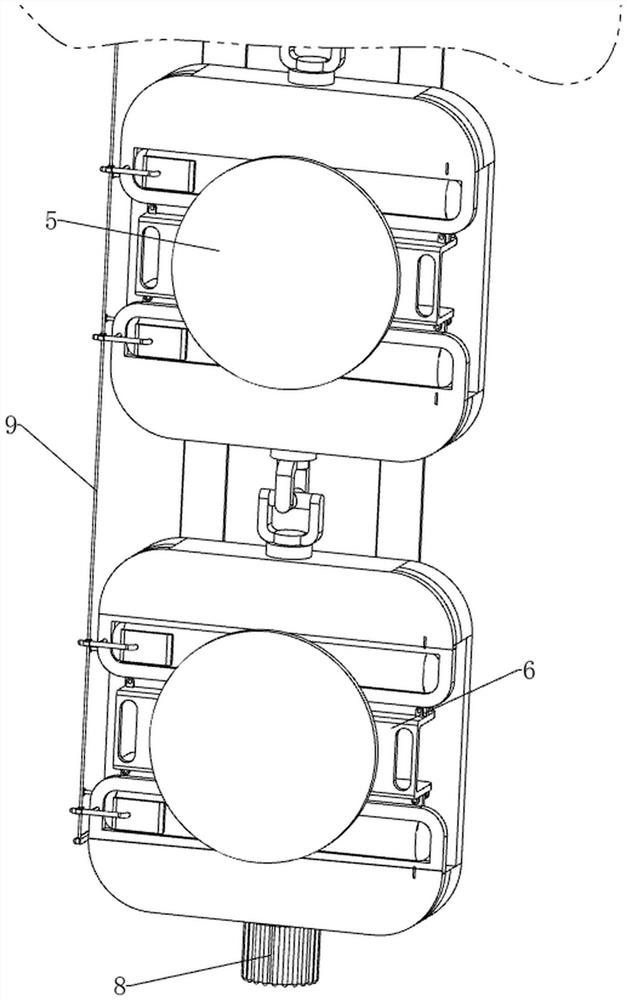

[0037] A LED running light strip, such as Figure 1-8 As shown, it includes a lamp holder 1, a limit slot plate 3, a first power supply seat 4, a lamp bead 5, a clamping assembly 6 and a movable connection assembly 7. There are eight lamp holders 1, and the eight lamp holders 1 are arranged from above It is evenly distributed in a straight line from the bottom to the bottom. There is a movable connection assembly 7 connected between each two adjacent lamp holders 1. There are installation grooves 2 on the front sides of multiple lamp holders 1. The installation grooves 2 are square. The lamp holders The middle part of the installation groove 2 of 1 is connected with the first power supply seat 4 by means of screw connection, and the upper and lower sides of the front end of the lamp holder 1 are integrally formed with a limiting slot plate 3, and two limiting slot plates 3 of each lamp holder 1 A clamping assembly 6 is clamped and connected between them, and a lamp bead 5 is i...

Embodiment 2

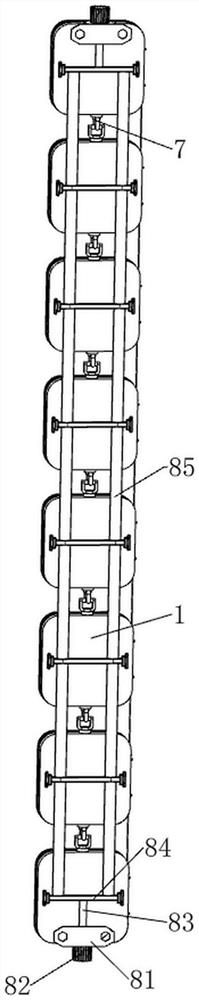

[0044] On the basis of Example 1, such as figure 1 , figure 2 , Figure 9 , Figure 10 , Figure 11 , Figure 12 and Figure 13 As shown, an adjustment assembly 8 is also included. The adjustment assembly 8 includes a connecting plate 81, a handle 82, a connecting shaft 83, a first connecting rod 84 and a rope 85. A connecting shaft 83 is connected in a screw connection, and a connecting plate 81 is rotatably connected to the connecting shaft 83. The connecting plate 81 is sleeved on the outside of the connecting shaft 83, and the end of the connecting shaft 83 is connected with a handle 82 through a key connection. The middle part of the rear end surface of each lamp holder 1 is connected horizontally with a first connecting rod 84, the upper connecting shaft 83 is welded to the middle of the uppermost first connecting rod 84, and the lower connecting shaft 83 is connected to the lowermost first connecting rod 84. The middle part is welded and connected, and there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com