Damping double suction pump with angle adjusting function

An angle-adjusting, double-suction pump technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problems of inability to change the installation angle, damage to parts, and vibration of the double-suction pump. Simple structure, avoid damage to parts, and prevent stress collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

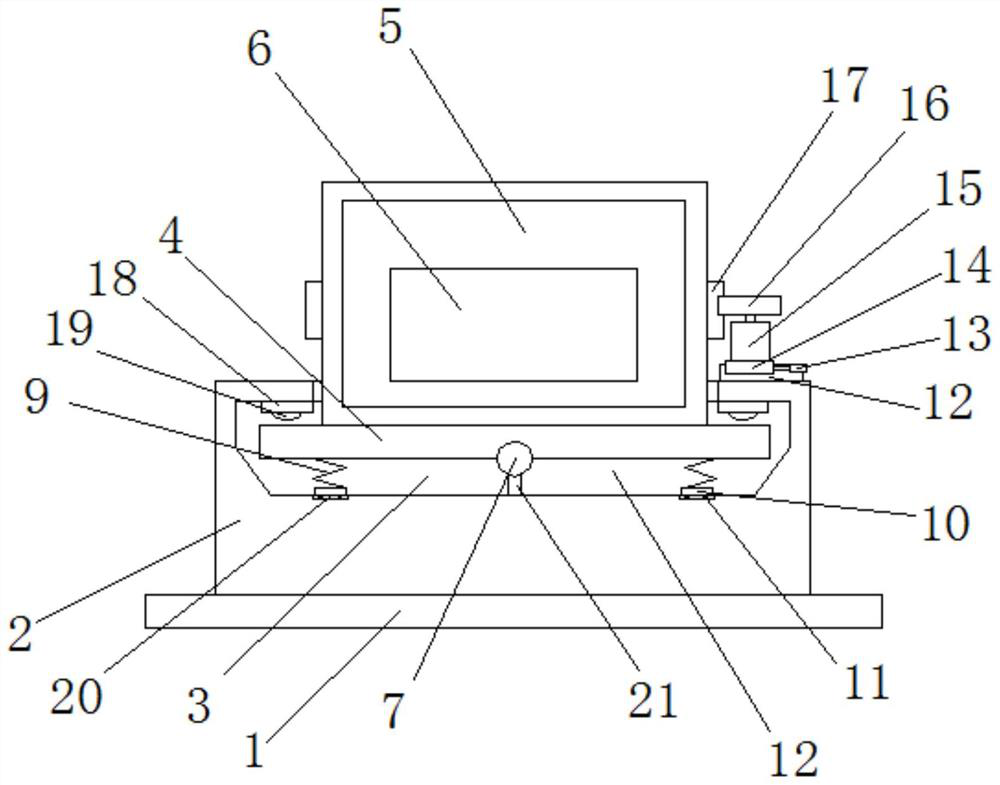

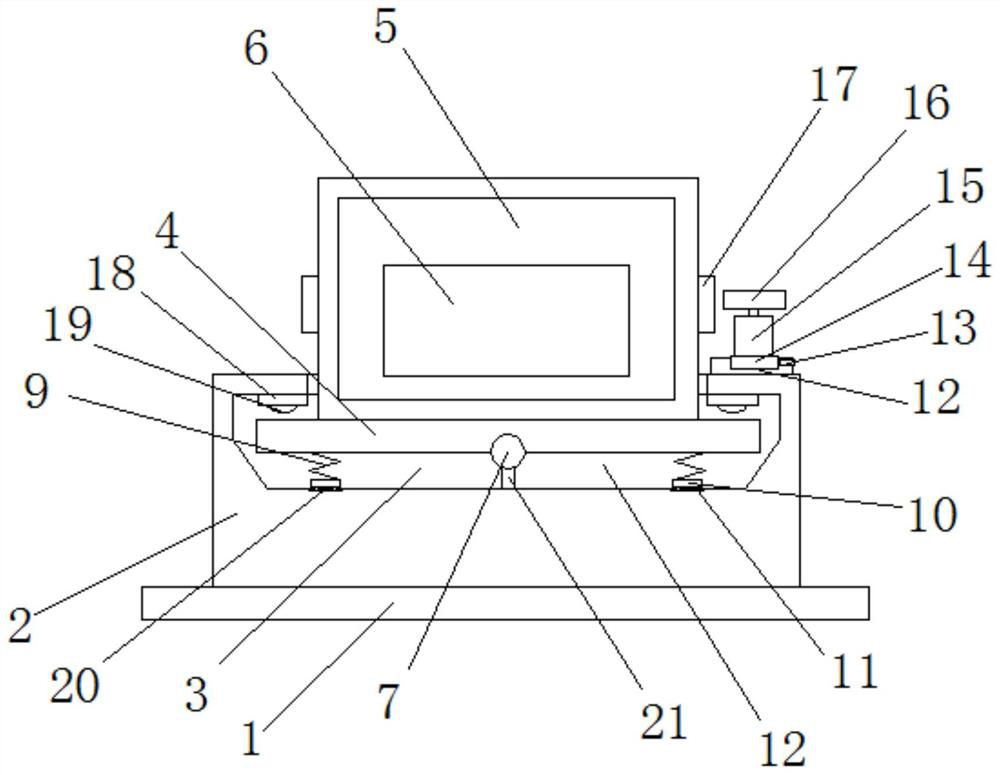

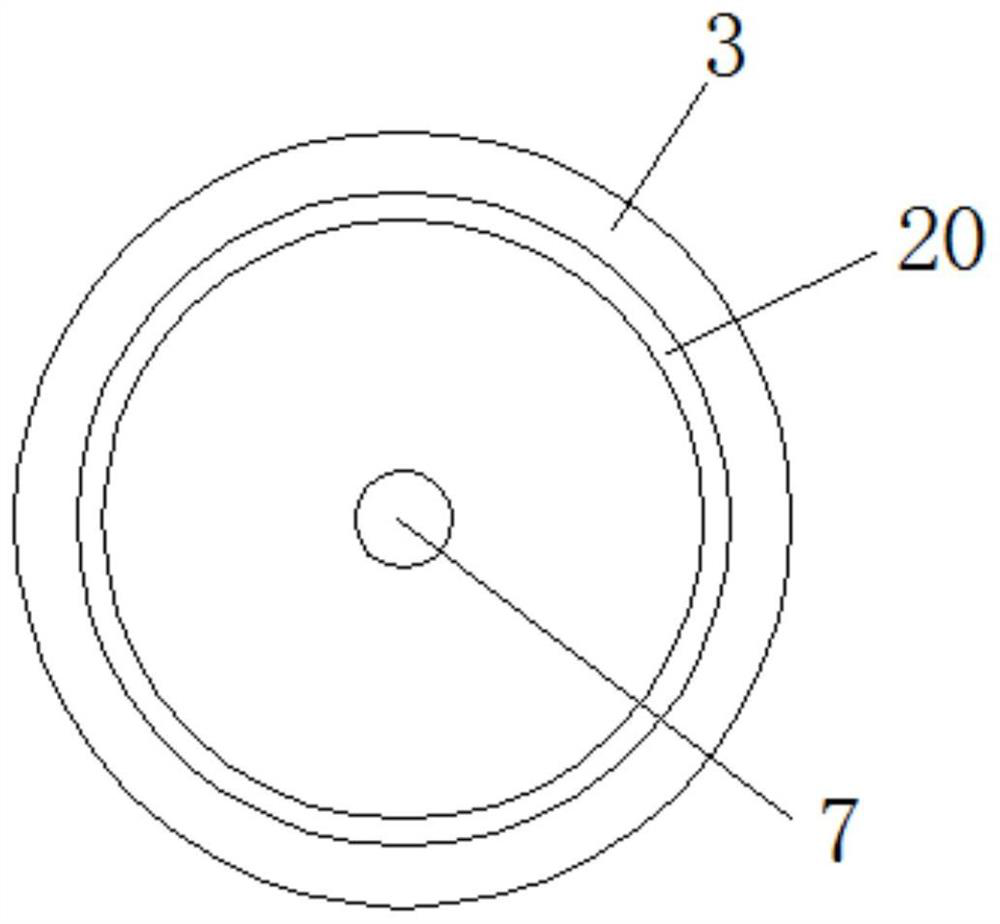

[0021] Embodiment 1: as Figure 1-5 As shown, a shock-absorbing double-suction pump with angle adjustment function includes a flange 1, the top of the flange 1 is fixedly installed with a mounting seat 2, and the top side of the mounting seat 2 is provided with a shock-absorbing cavity 3, A disc 4 is clamped inside the cushioning cavity 3, and the top side of the disc 4 is fixedly connected with a sound-absorbing box 5, and a pump body 6 is fixedly installed inside the sound-absorbing box 5;

[0022] A bracket 21 is fixedly installed at the bottom center of the inner cavity of the cushioning chamber 3, and a clamping ball 7 is fixedly installed on the top side of the bracket 21, and a clamping groove 8 is provided at the bottom side of the center of the disc 4, and the clamping ball 7 and the The draw-in slot 8 is movably clamped, and the bottom side of the disc 4 is fixedly equipped with a number of springs 9, which are distributed with the draw-in slot 8 as the center of the...

Embodiment 2

[0029] Embodiment 2: as Figure 1-5 As shown, a shock-absorbing double-suction pump with angle adjustment function includes a flange 1, the top of the flange 1 is fixedly installed with a mounting seat 2, and the top side of the mounting seat 2 is provided with a shock-absorbing cavity 3, A disc 4 is clamped inside the cushioning cavity 3, and the top side of the disc 4 is fixedly connected with a sound-absorbing box 5, and a pump body 6 is fixedly installed inside the sound-absorbing box 5;

[0030] A bracket 21 is fixedly installed at the bottom center of the inner cavity of the cushioning chamber 3, and a clamping ball 7 is fixedly installed on the top side of the bracket 21, and a clamping groove 8 is provided at the bottom side of the center of the disc 4, and the clamping ball 7 and the The draw-in slot 8 is movably clamped, and the bottom side of the disc 4 is fixedly equipped with a number of springs 9, which are distributed with the draw-in slot 8 as the center of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap