Amplifier partition glass resistant to strong laser radiation sealing installation method

An installation method and an amplifier technology, which are applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve the problems of easily polluting the clean environment of the laser operation, failure of the sealing effect, and easy carbonization of the sealing strip, so as to achieve simple installation, Good effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited accordingly.

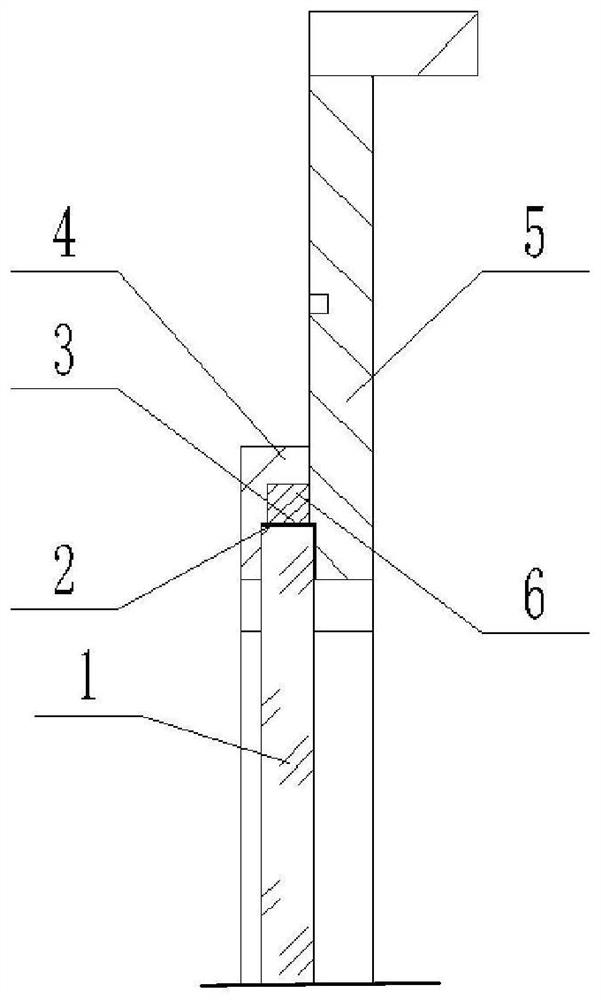

[0030] see Figure 1 to Figure 5 , as can be seen from the figure, the sealing installation method of the amplifier clapboard glass resistant to strong laser radiation of the present invention comprises the following steps:

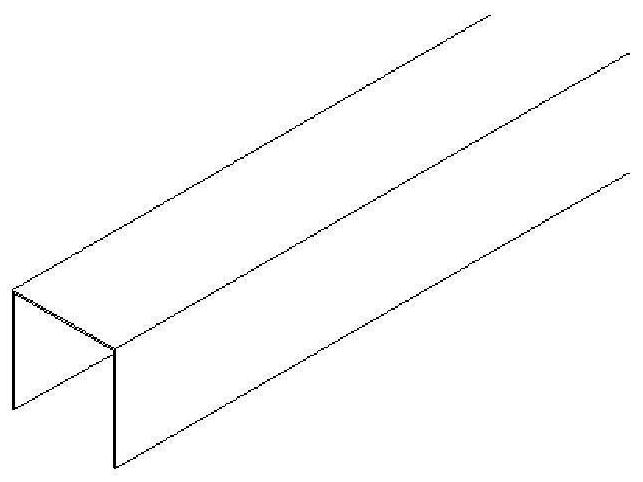

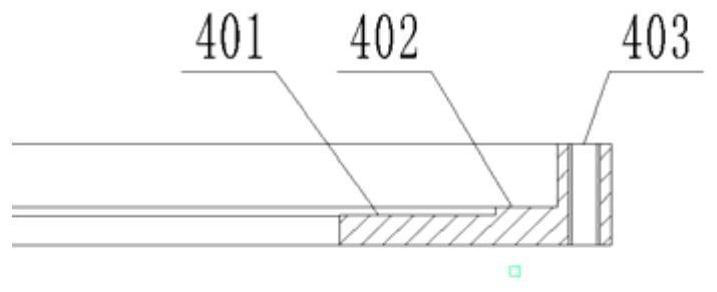

[0031] 1) According to the shape and size of the partition glass 1 to be sealed, prepare the partition glass lower flange 4, the partition glass upper flange 5, the high temperature resistant glue 2, the metal foil 3 and the sealing strip 6:

[0032] Described partition glass 1 is a rectangular or square sheet glass, used for the vacuum sealing window of neodymium glass amplifier;

[0033] The high temperature resistant glue is a kind of glue resistant to more than 600 degrees, and becomes solid glue after solidification;

[0034] The lower flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com