Frequency multiplication method for Hall speed sensor at shaft end

A speed sensor and Hall device technology, which is applied in the field of frequency multiplication of Hall speed sensors at the shaft end, can solve the problems of limited sensor installation space and signal frequency that cannot meet the use requirements, so as to improve the service life and realize the effect of signal induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

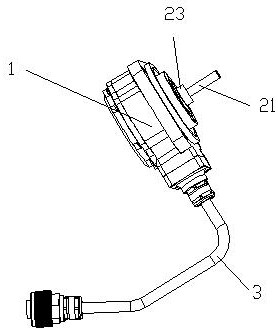

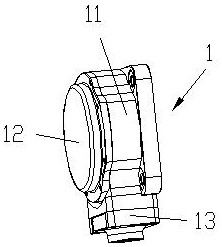

[0033] A frequency doubling method for a shaft-end Hall speed sensor, such as figure 1 As shown, the shaft-end Hall speed sensor includes a housing 1 and a transmission shaft 21, such as figure 2 As shown, the housing 1 includes a mounting base 11, an outer cover 12 and a connecting head 13. The transmission shaft 21 is connected to the mounting base 11 through a bearing 23 as a whole, one end of which is located in the housing 1, and the gear 4 is installed on the transmission shaft 21 in the housing. One end inside the gear 1 rotates synchronously with the drive shaft 21 , and the hall element 511 for receiving induction is arranged on the outer circumference of the gear 4 and is located in the connector 13 , and the induction signal is output through the cable 3 .

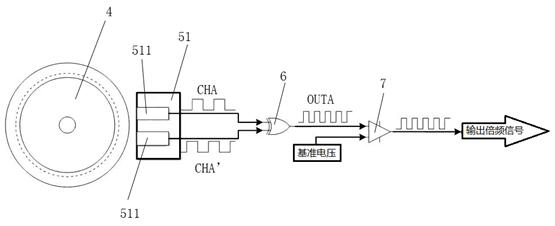

[0034] Due to the limited installation space, the size of the gear 4 is limited, and in order to meet the requirements of the speed sensor, the number of pulses output by each revolution of the gear should not ...

Embodiment 2

[0038] This embodiment is the specific use of the above-mentioned embodiment. In this embodiment, the gear 4 modulus used is 1, that is, the pitch between the teeth is π mm, and the distance between the sensing points of the two Hall elements 511 in the Hall device 51 is Therefore, the position of the Hall device 5 on the outer periphery of the gear 4 is: the angle between the line connecting the sensing points of the Hall element 511 and the rotation direction of the gear 4 is acos((π / 4) / 1.75), which is about 63.346°, at this time, the projected distance of the line between the sensing points on the rotation direction of gear 4 is (π / 4) mm, so that the phase difference between CHA and CHA', and the phase difference between CHB and CHB' are both 90 °. According to the size of the housing 1 and the size of the Hall device 51, the natural number n is selected to be 5, that is, the midpoint line between the respective sensing point lines L1 and L2 in the two Hall devices 51 is ro...

Embodiment 3

[0041] This embodiment is an improvement made on the basis of the above-mentioned embodiments, such as Figure 7 As shown, in order to meet the requirement that the transmission shaft 21 not only transmits the rotational speed but also provides support, a flange 22 is provided at the end where the transmission shaft 21 is connected to the shaft end to form a flange transmission shaft 2, as shown in Figure 8 As shown, the flange transmission shaft 1 is an integral structure of the flange 22 and the transmission shaft 21. Through the connection between the flange 22 and the shaft end, the force bearing area of the transmission shaft 2 is greatly increased and its service life is prolonged.

[0042] like Figure 9 As shown, the gear 4 is arranged at the end of the flange transmission shaft 2 away from the flange 22, and a bearing 23 is provided on the outside of the transmission shaft 21 between the gear 4 and the flange 22 to support the housing 1, so that the gear 4 Relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com