Patents

Literature

54results about How to "Avoid synchronous rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

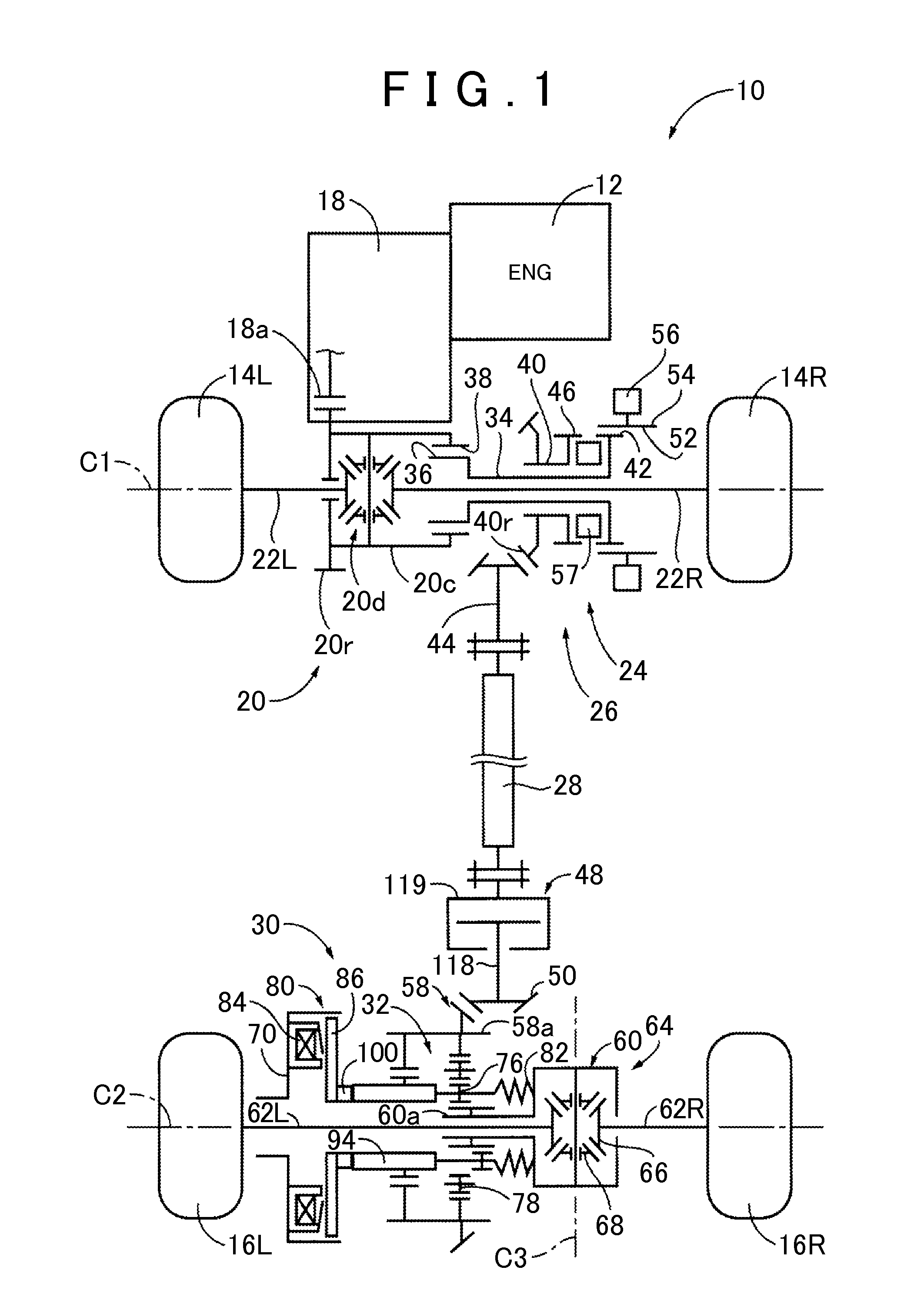

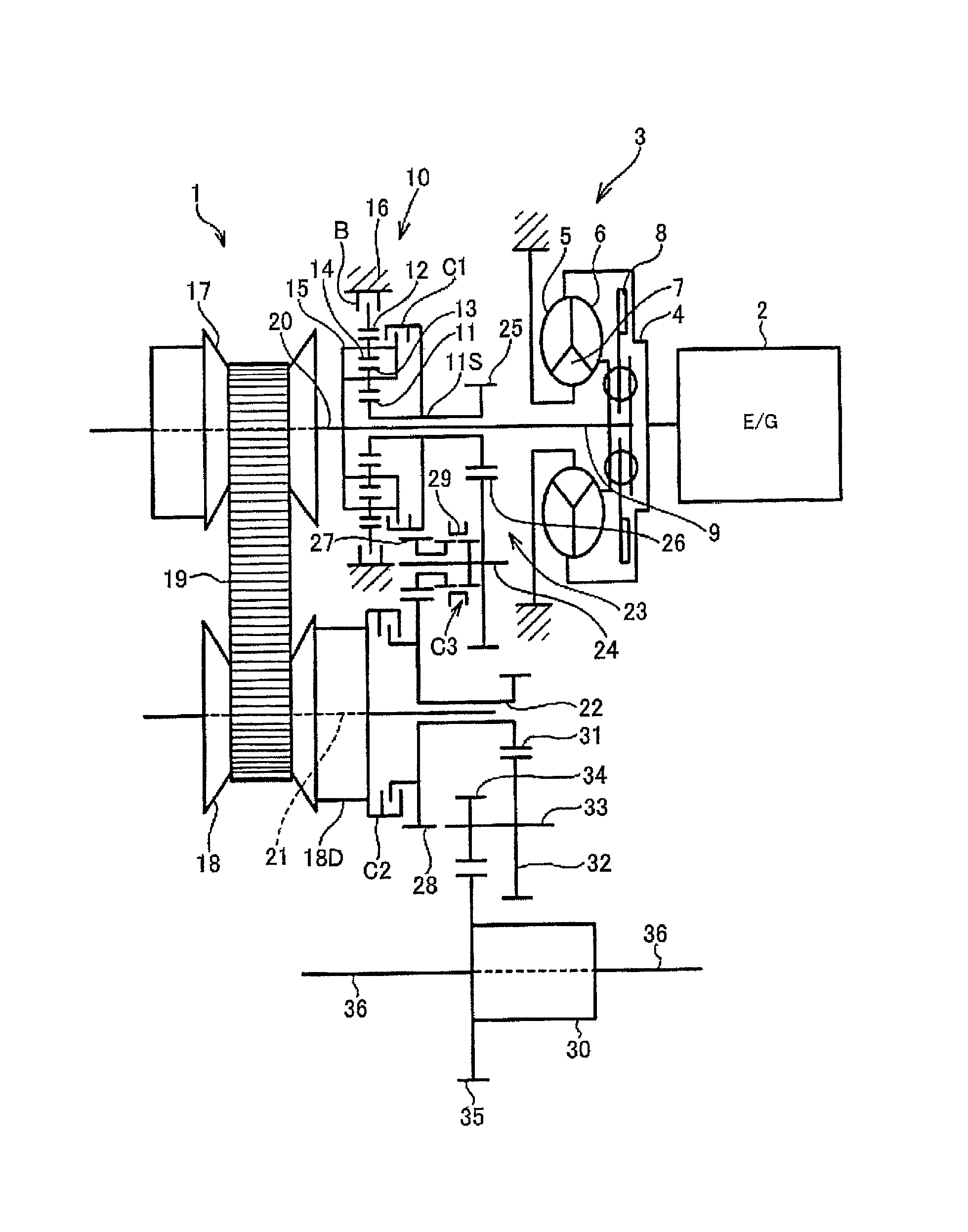

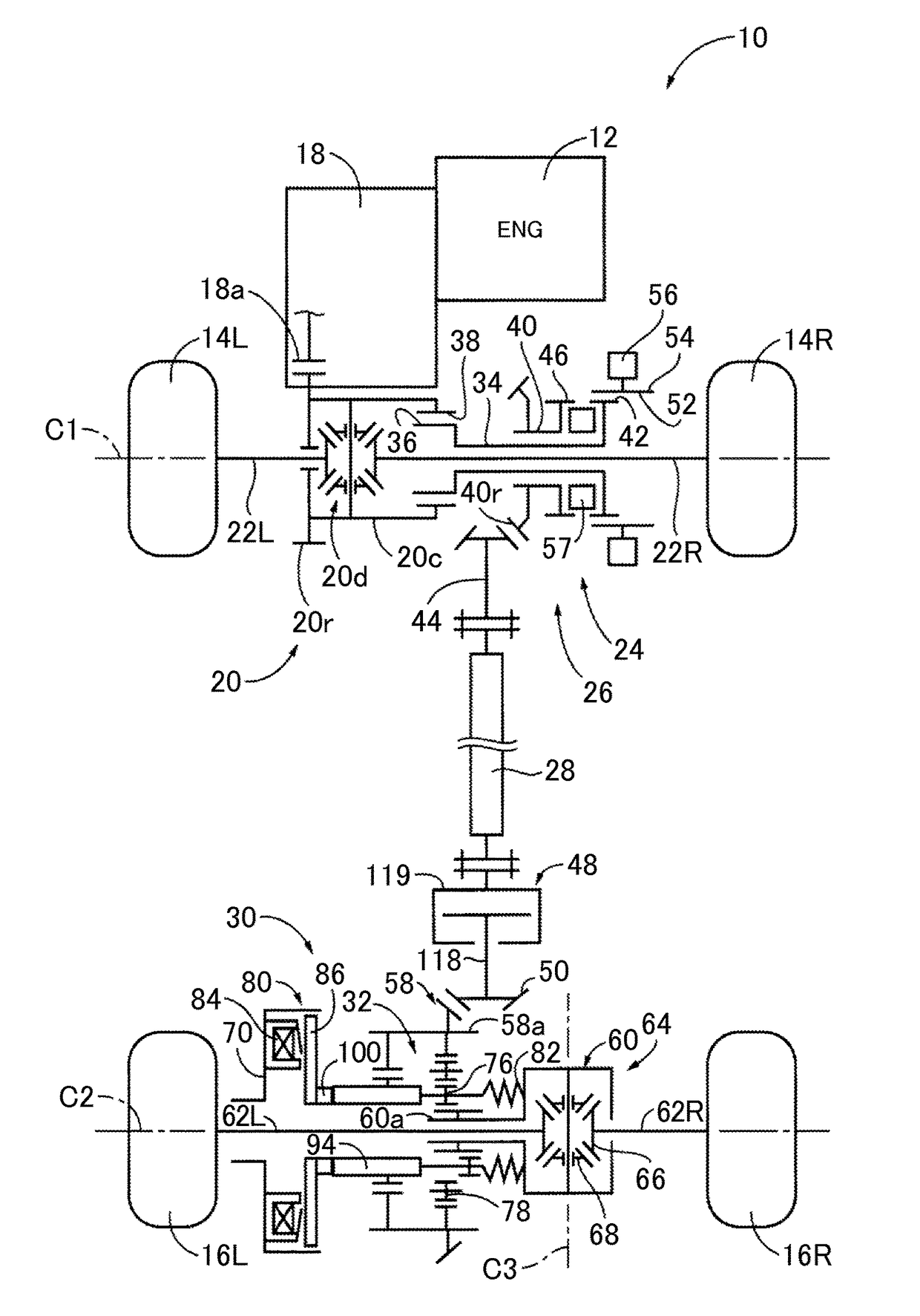

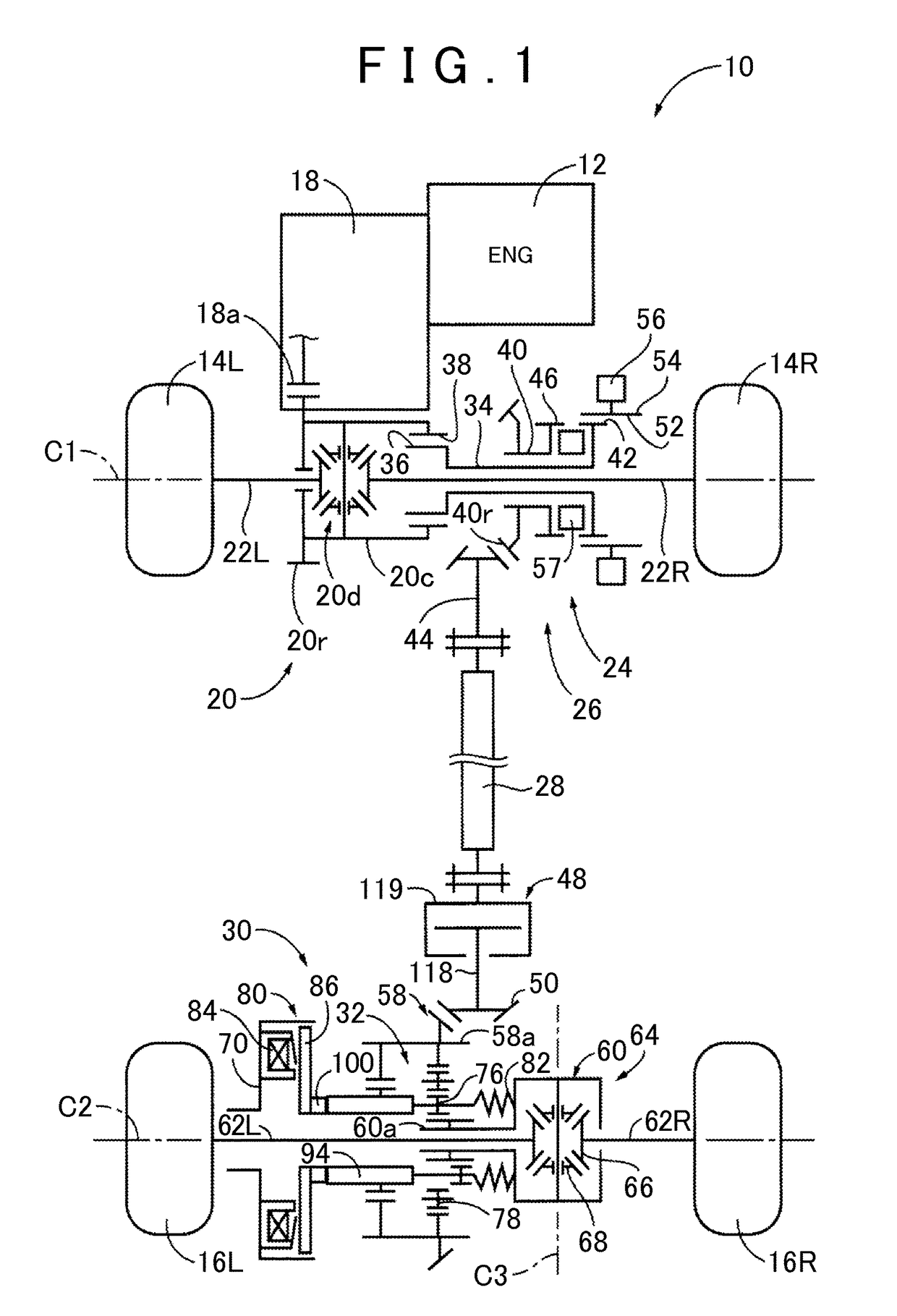

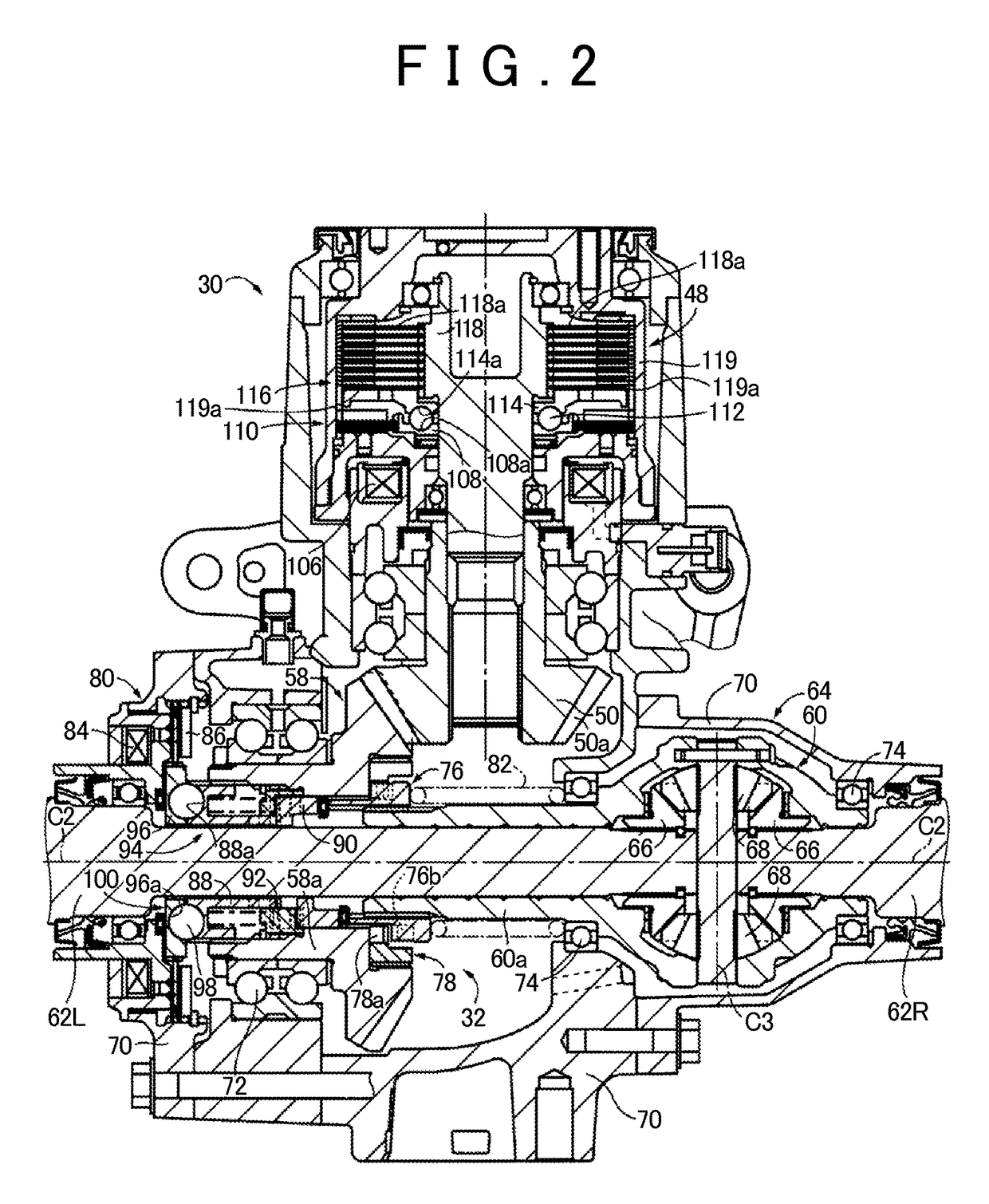

Vehicle power transmission device

ActiveUS20150087463A1Easy to reduce in sizeIncreased durabilityGearingTransmission elementsTorque transmissionGear train

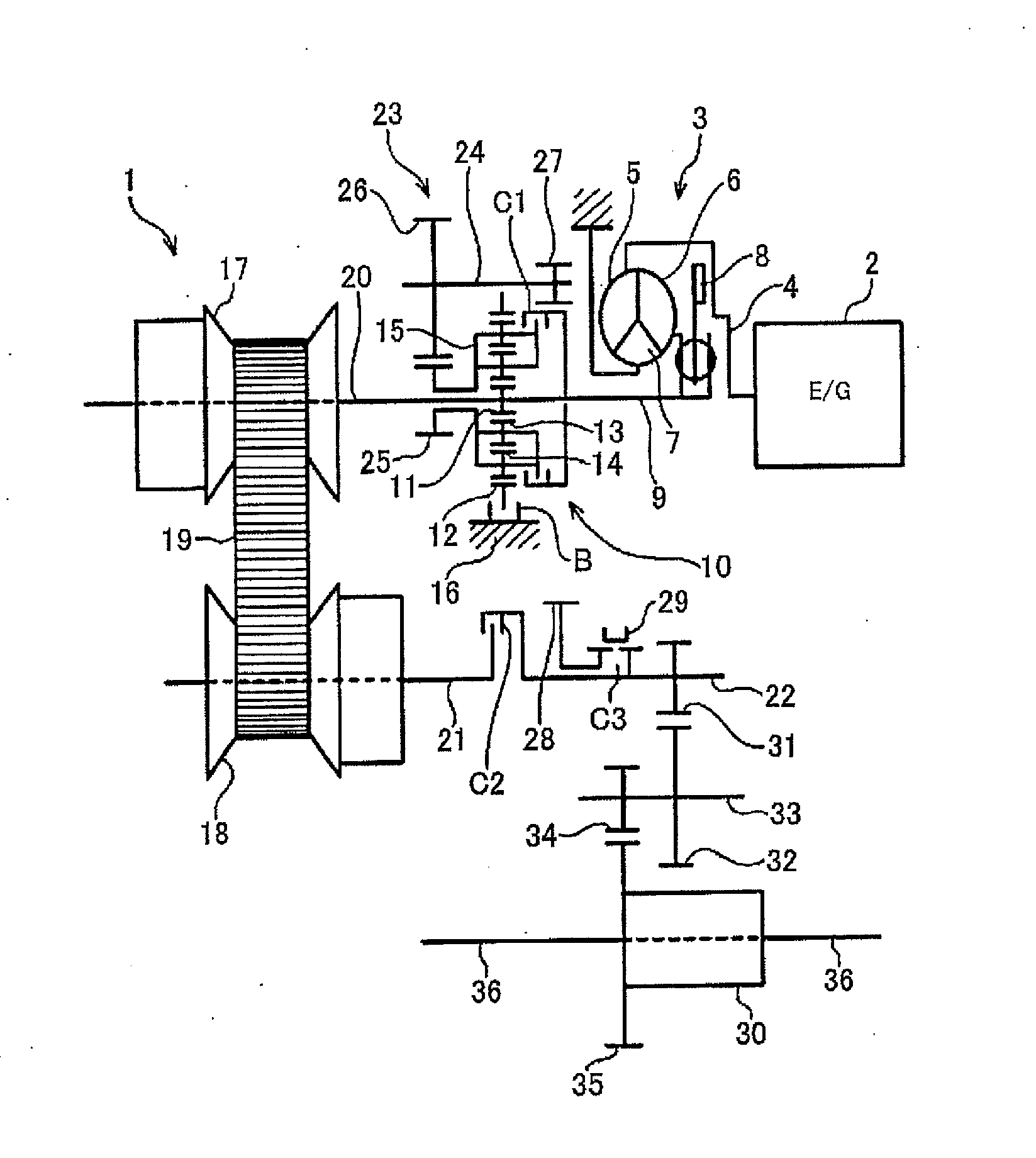

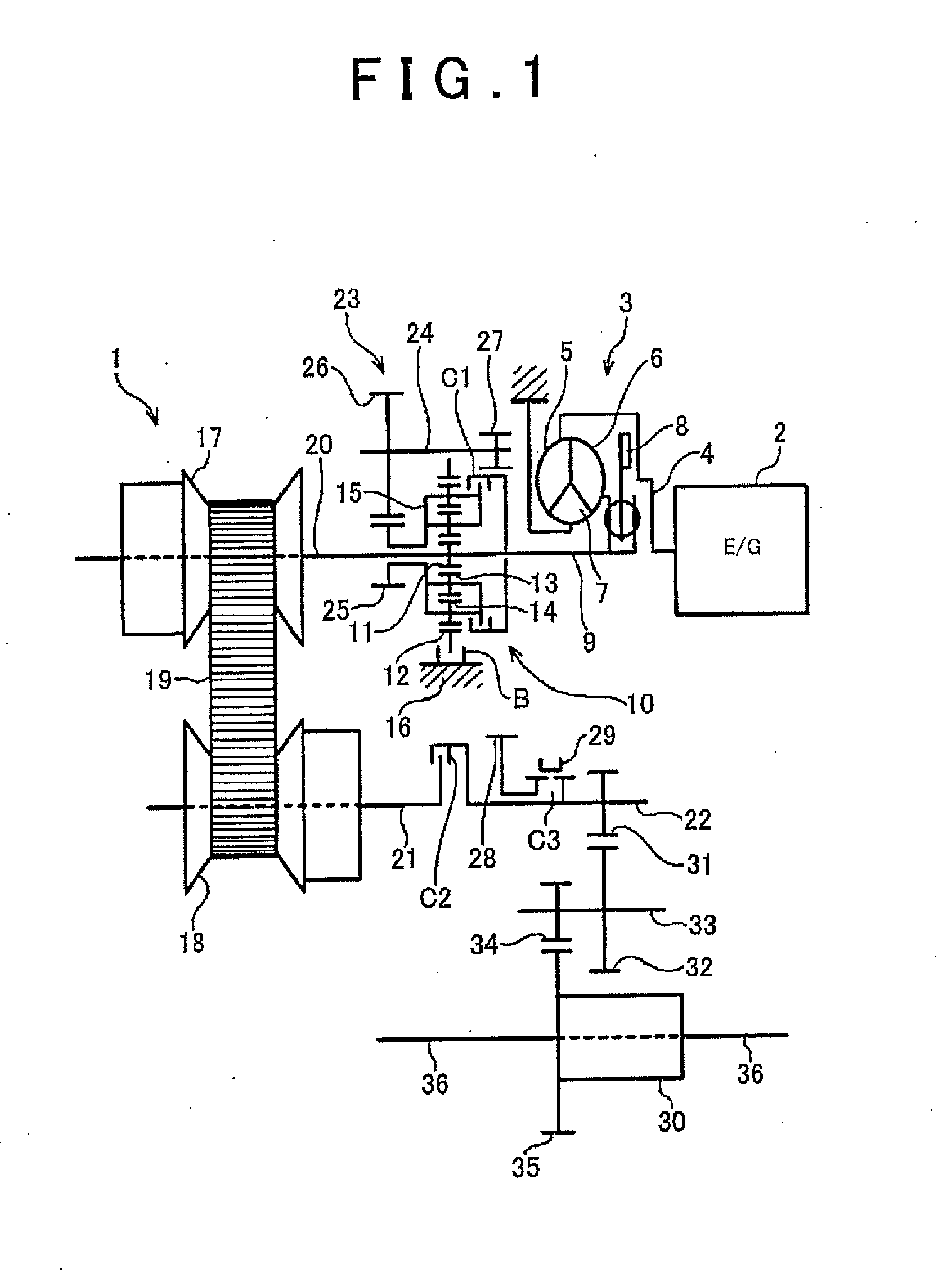

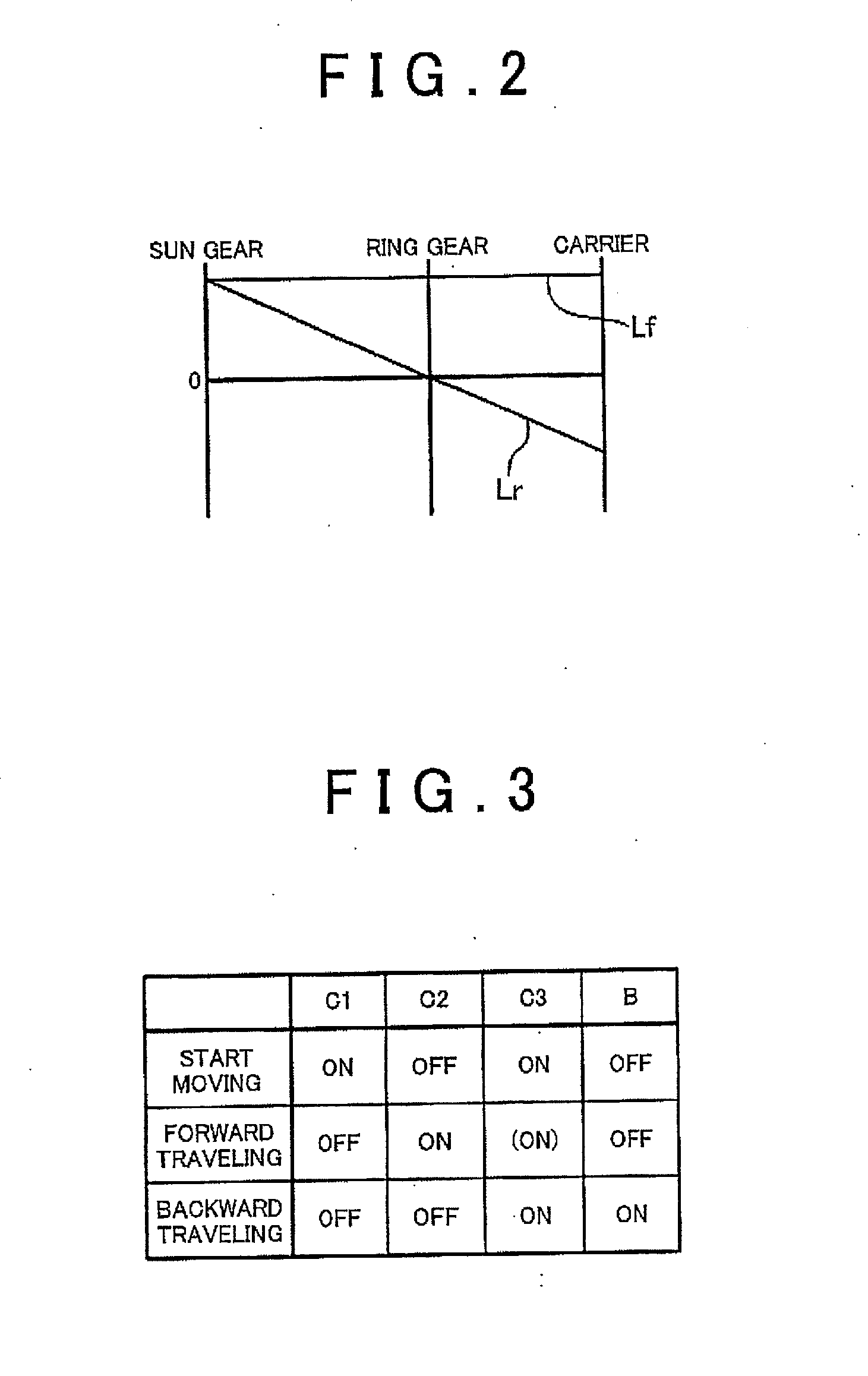

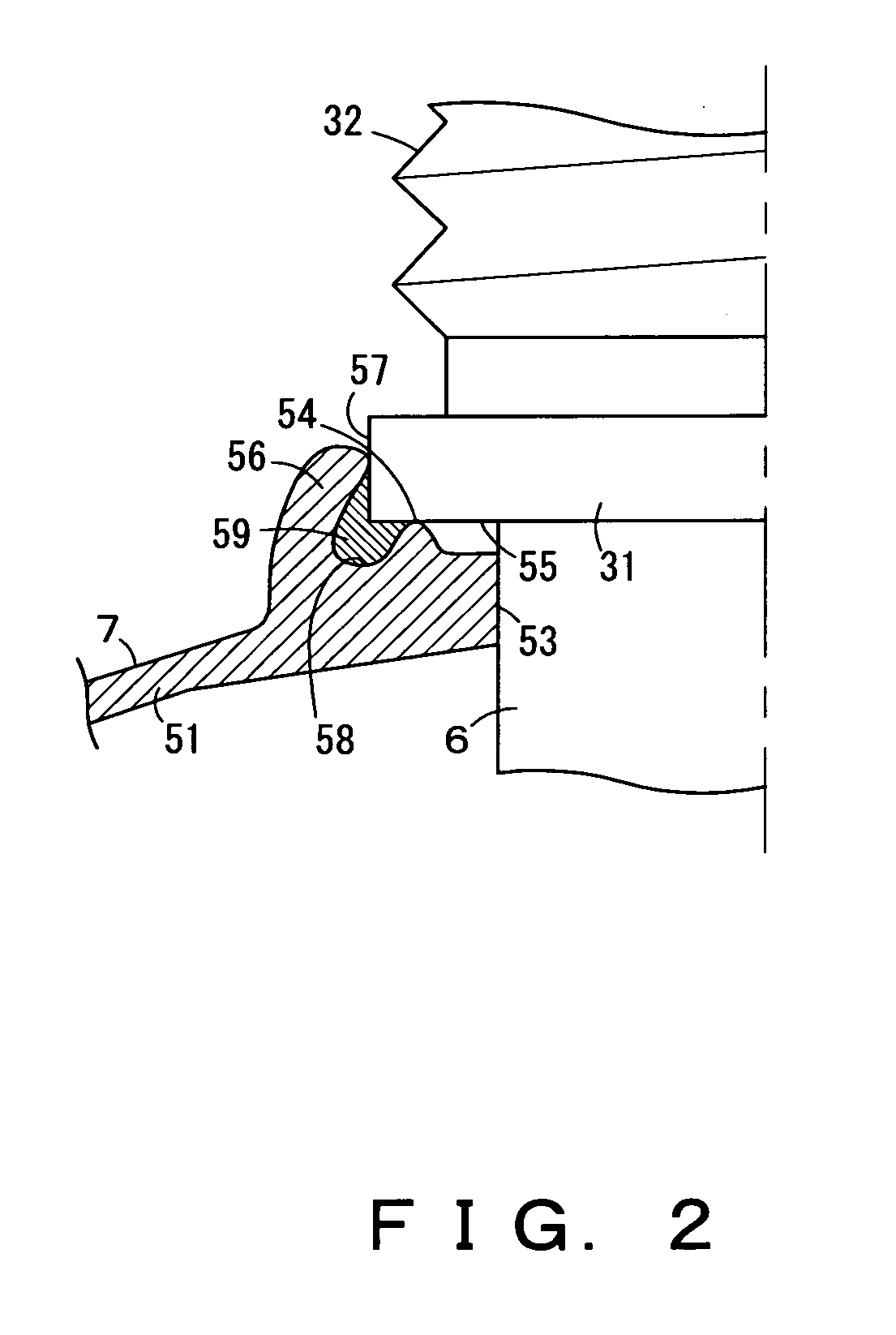

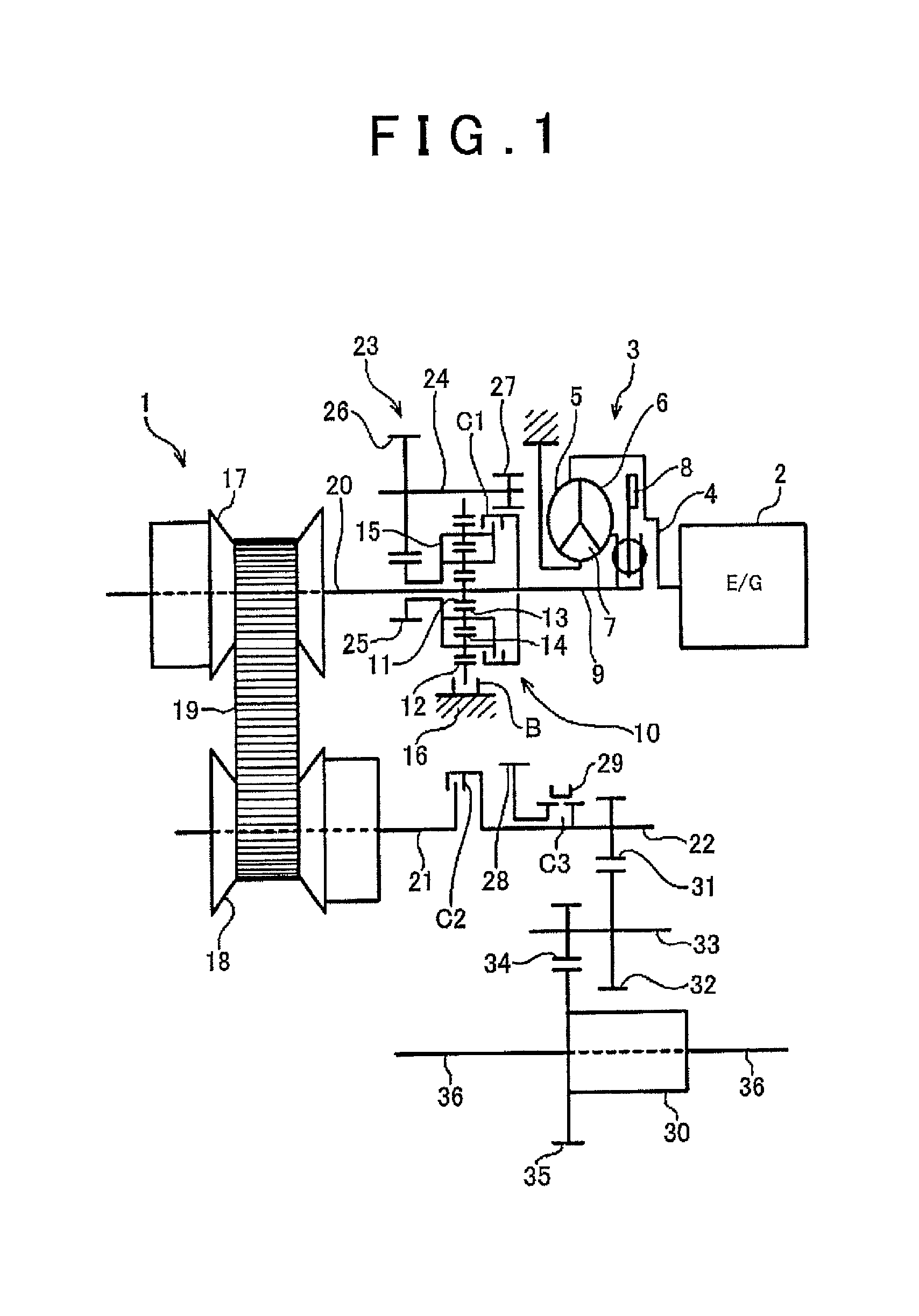

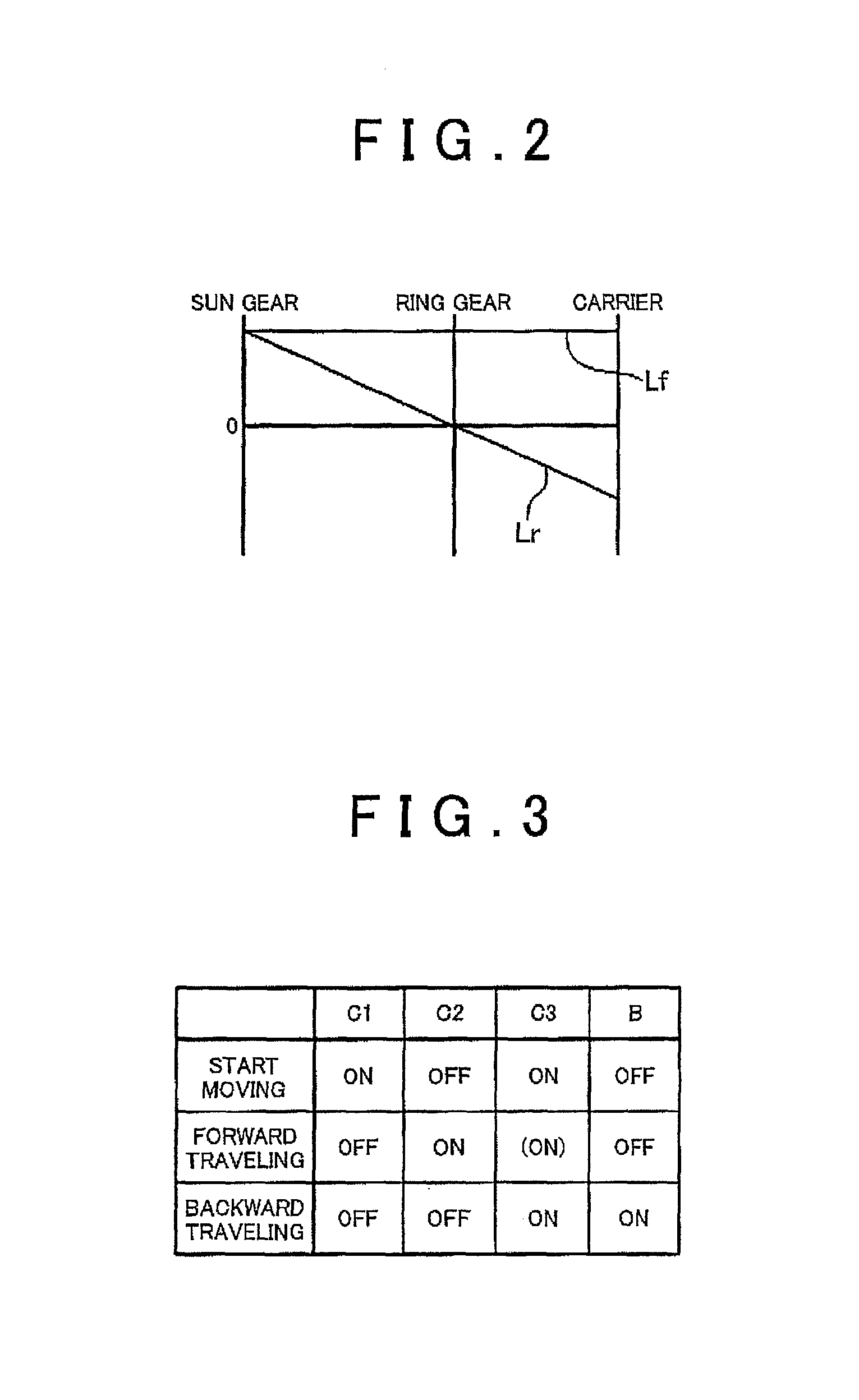

There is a vehicle power transmission device in which a continuously variable transmission and a gear train are provided between an input shaft and an output shaft so as to be able to transmit torque between the input shaft and the output shaft, the gear train has at least one speed ratio that cannot be set by the continuously variable transmission. In the vehicle power transmission device, a forward-reverse switching mechanism is arranged along the same axis as an axis of the input shaft, a first clutch mechanism and a brake mechanism are provided, a second clutch mechanism is provided in a first torque transmission path that is routed from the input shaft to the output shaft via the continuously variable transmission, a third clutch mechanism is provided in a second torque transmission path that is routed from the output element to the output shaft via the gear train.

Owner:AISIN CORP

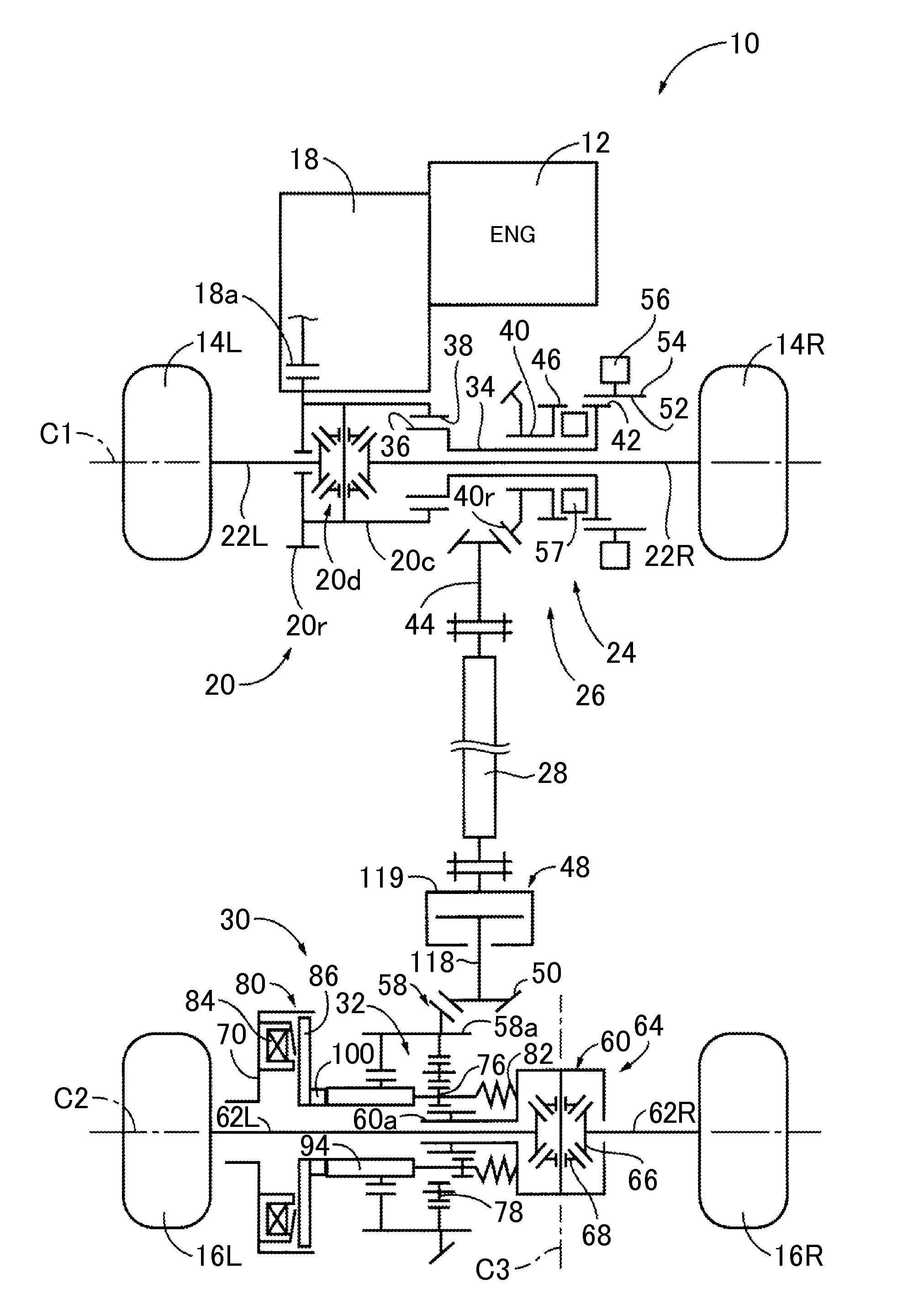

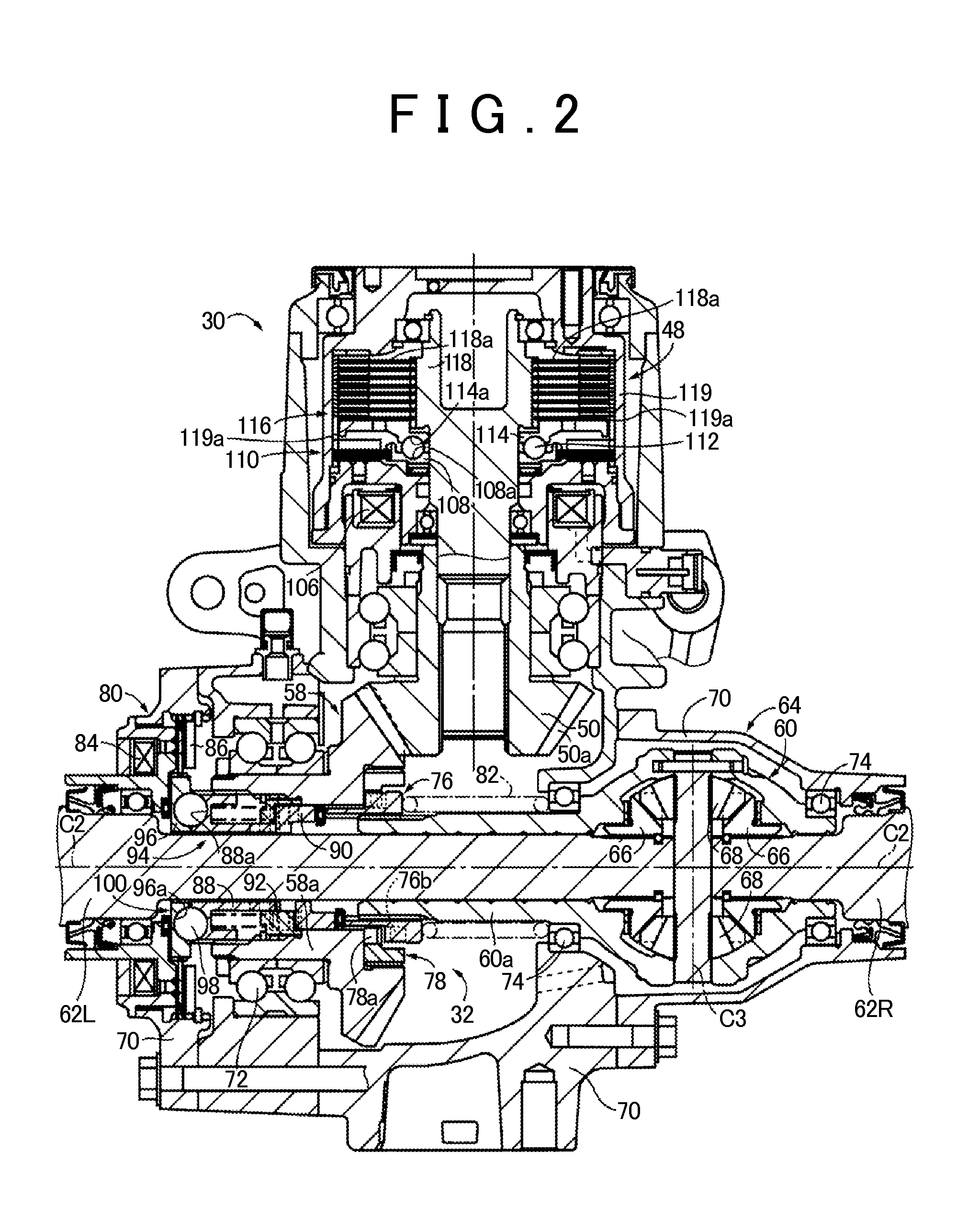

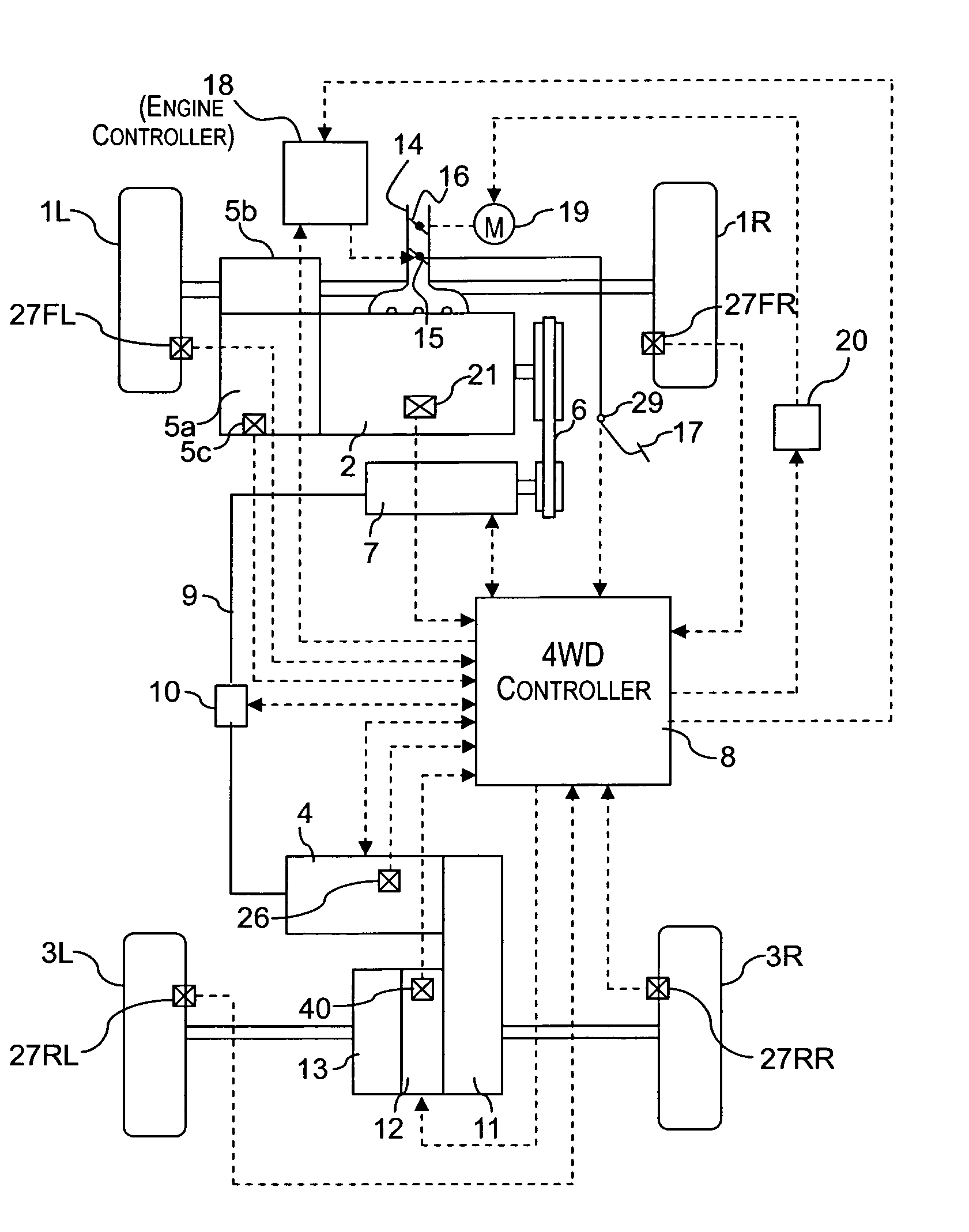

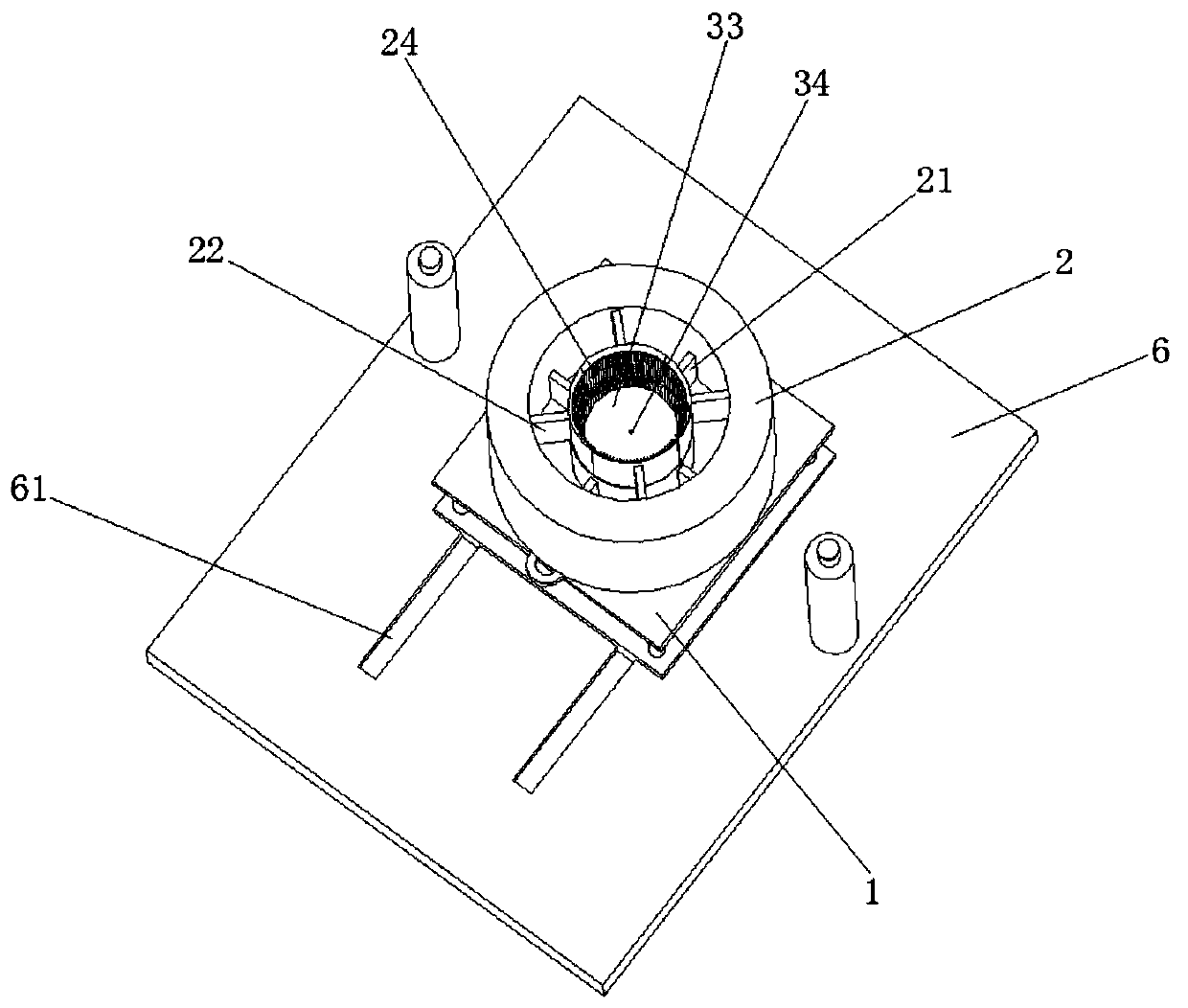

Auxiliary drive wheel-side differential unit for four-wheel drive vehicle

ActiveUS20150165901A1Prevent stateReduce in sizeMagnetically actuated clutchesInterengaging clutchesPropellerFour-wheel drive

A movable sleeve of a second clutch is provided between a cylindrical ring gear and a cylindrical shaft of a differential case of a differential gear unit. In a disconnect mode in which a propeller shaft is disconnected from rear wheels, the cylindrical ring gear is disconnected from the differential case by the movable sleeve of the second clutch. Thus, in the disconnect mode, a fully differential state of the differential gear unit is prevented.

Owner:JTEKT CORP

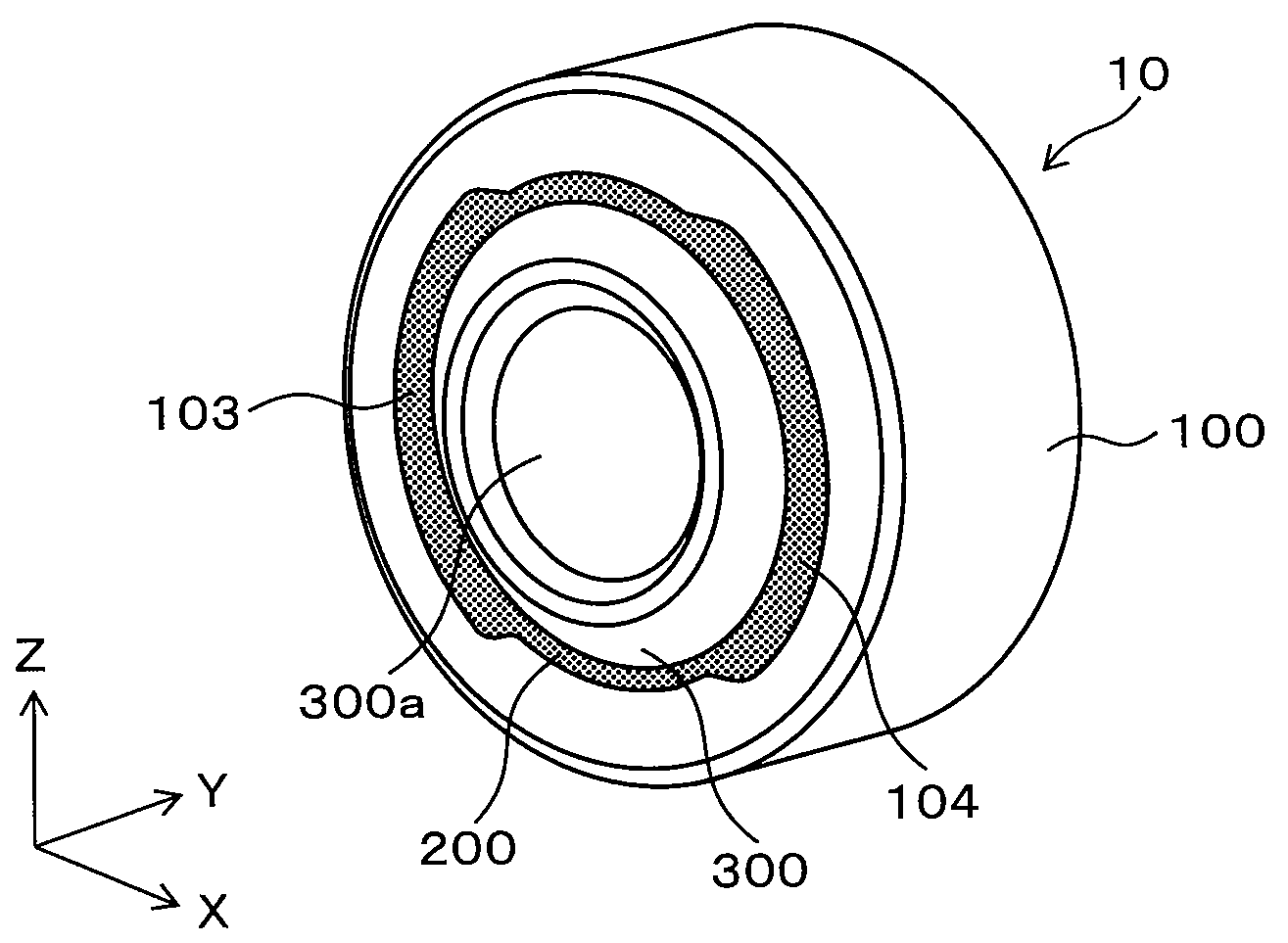

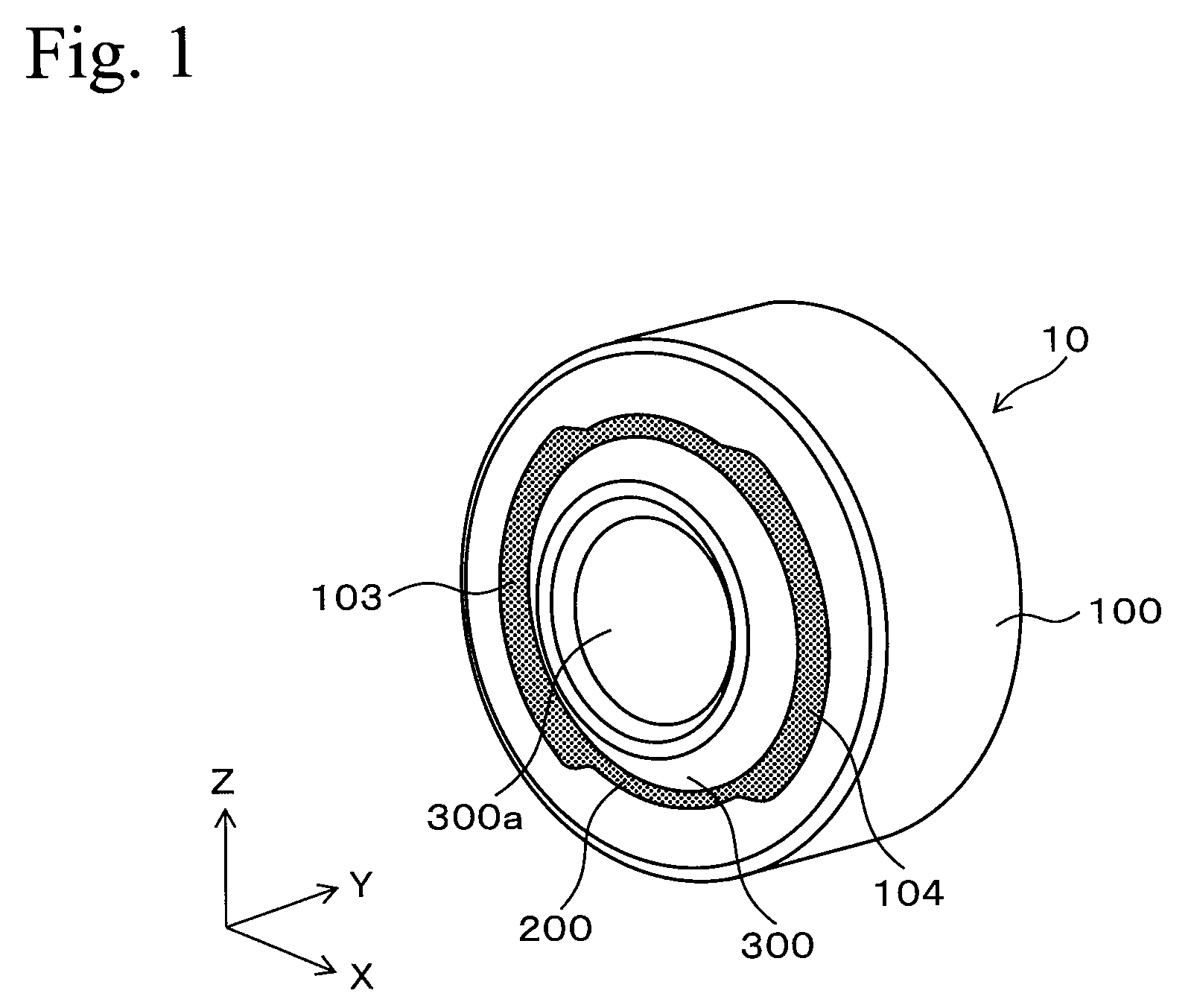

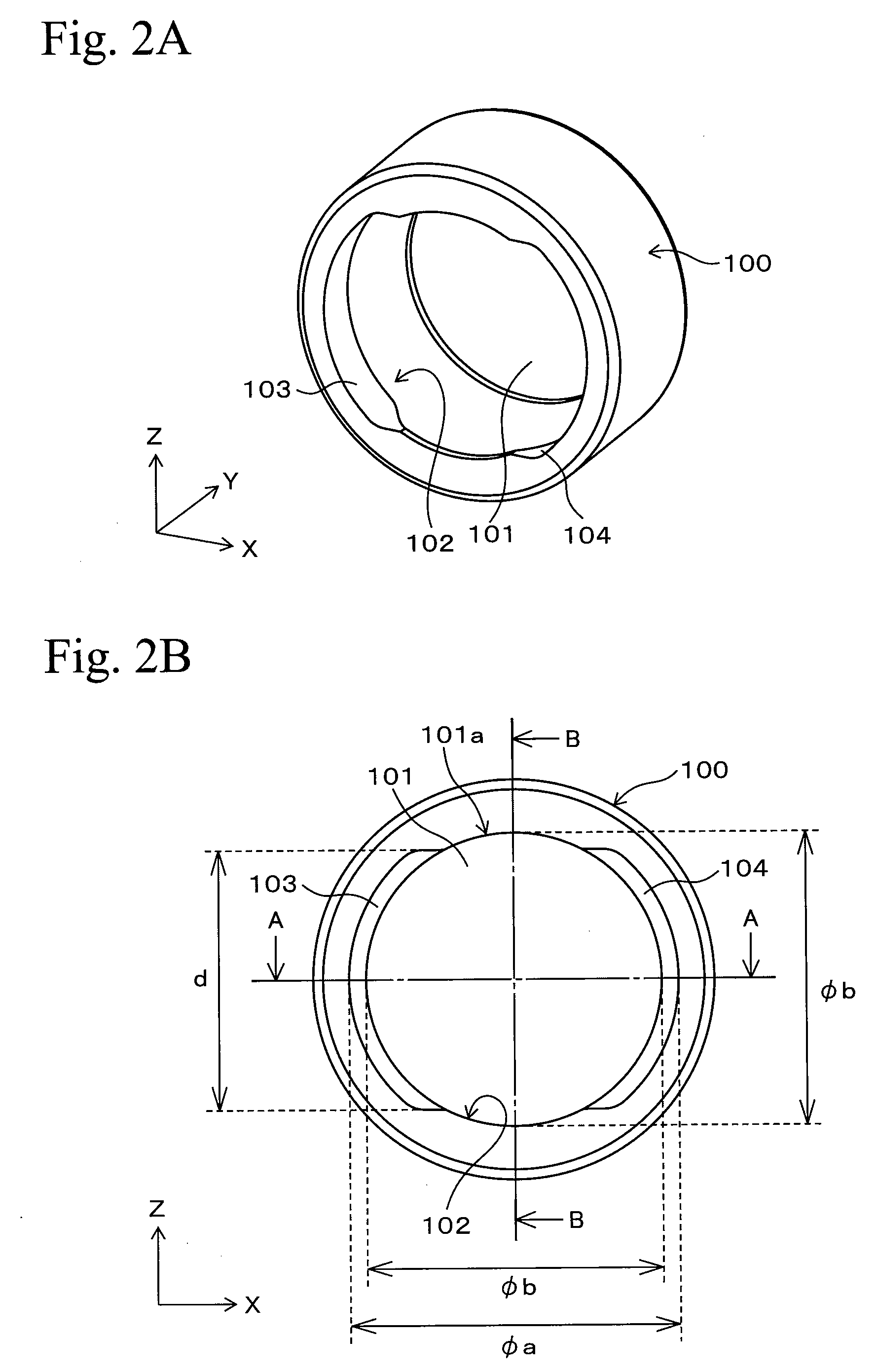

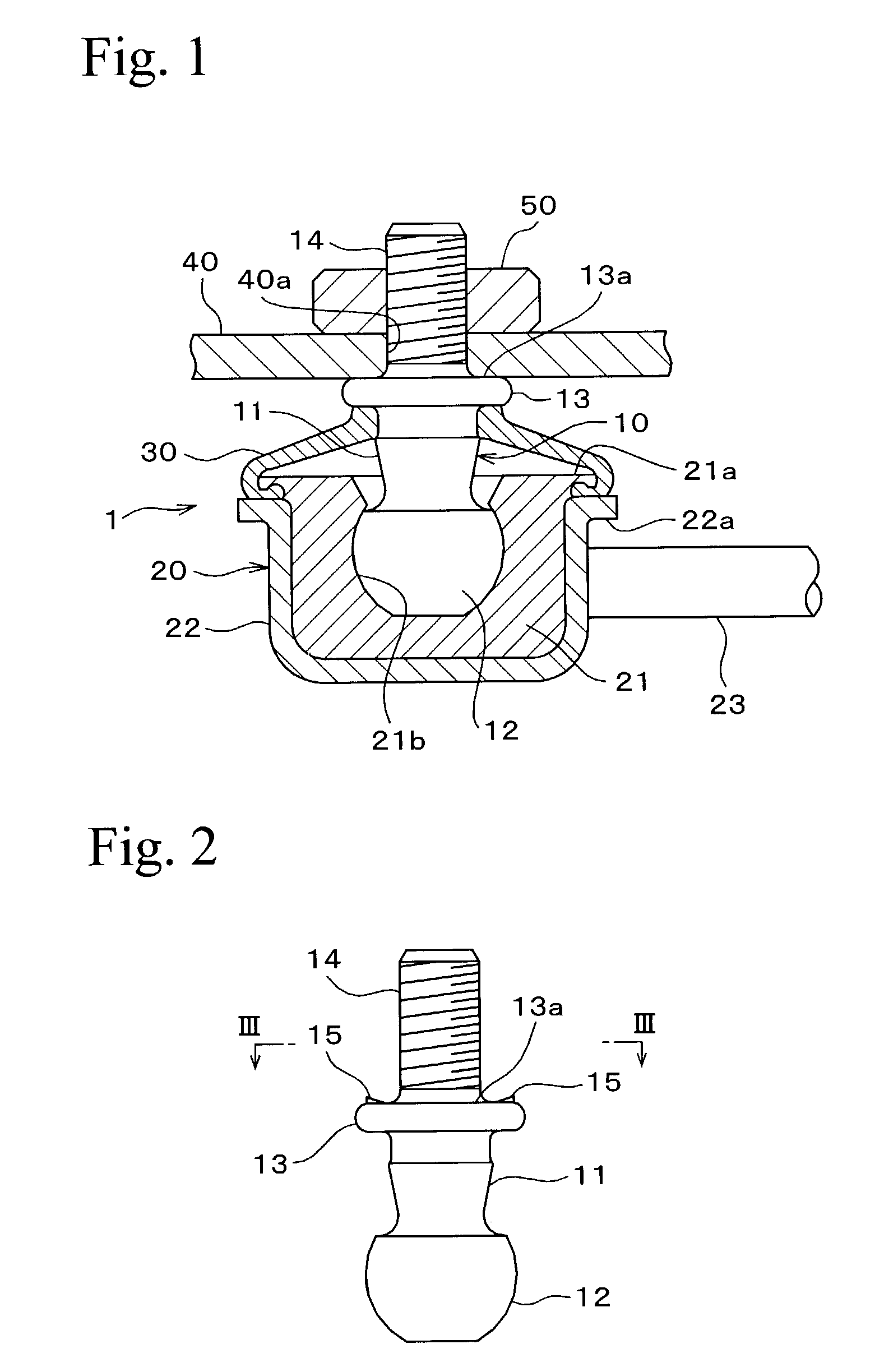

Spherical bearing with resin liner and rod end bearing

InactiveUS20090080818A1Large inner diameterDesign freedomRolling contact bearingsShaftsSpherical bearingEngineering

A spherical bearing with resin liner comprises an inner ring, an outer ring, an opening portion, a notched portion, and a resin liner portion. The inner ring has a convex spherical outer surface and a shape in which opposing end portions of a sphere are cut off, and the outer ring has a concave inner surface which faces the outer surface of the inner ring having a predetermined clearance therebetween. The opening portion is provided at the outer ring and has an inner diameter smaller than the outer diameter of the inner ring, and the opening portion communicates with a space surrounded by the inner surface of the outer ring. The notched portion is provided at an edge of the opening portion for inserting the inner ring into the outer ring, and the resin liner portion continuously fills the clearance and the notched portion.

Owner:MINEBEA CO LTD

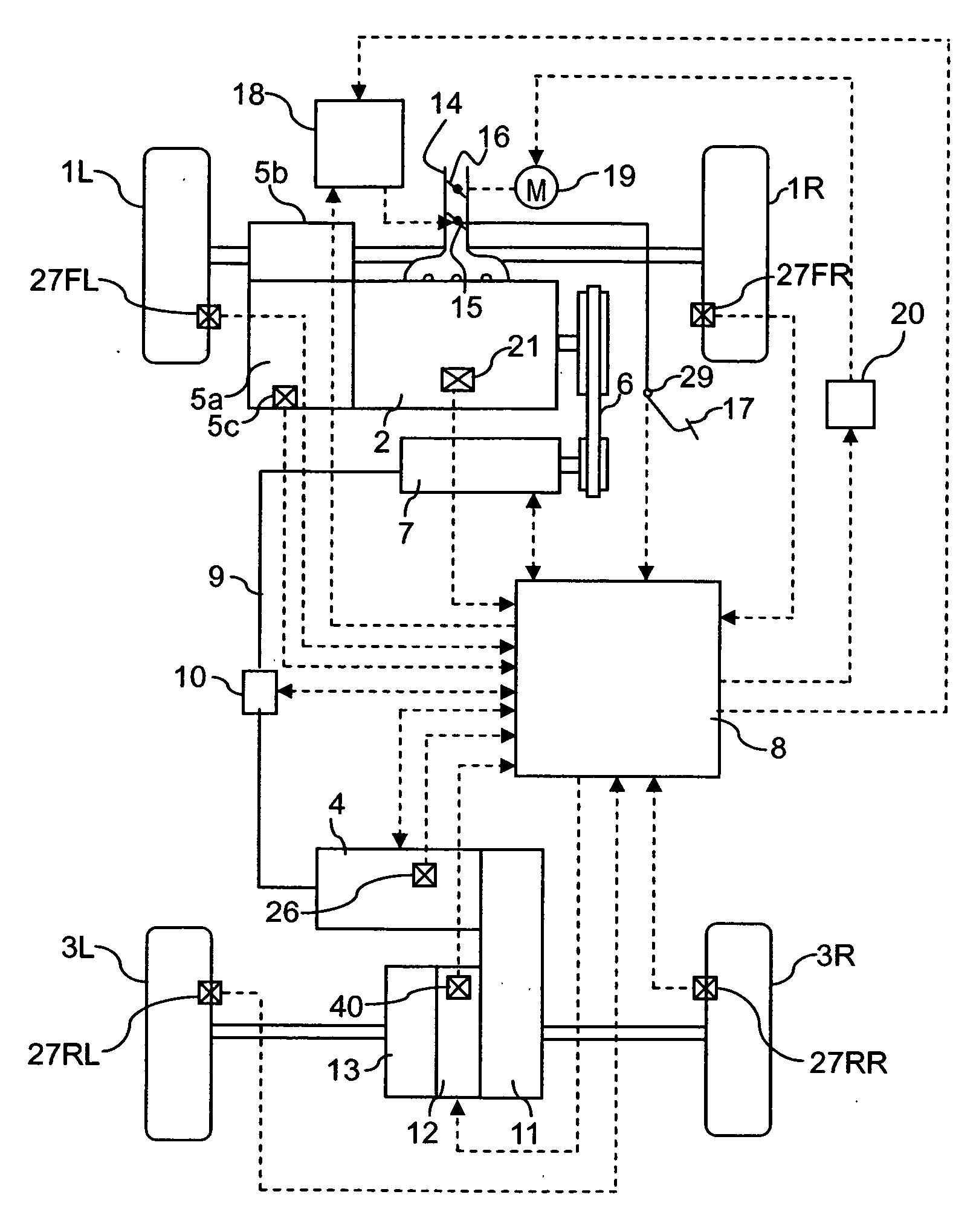

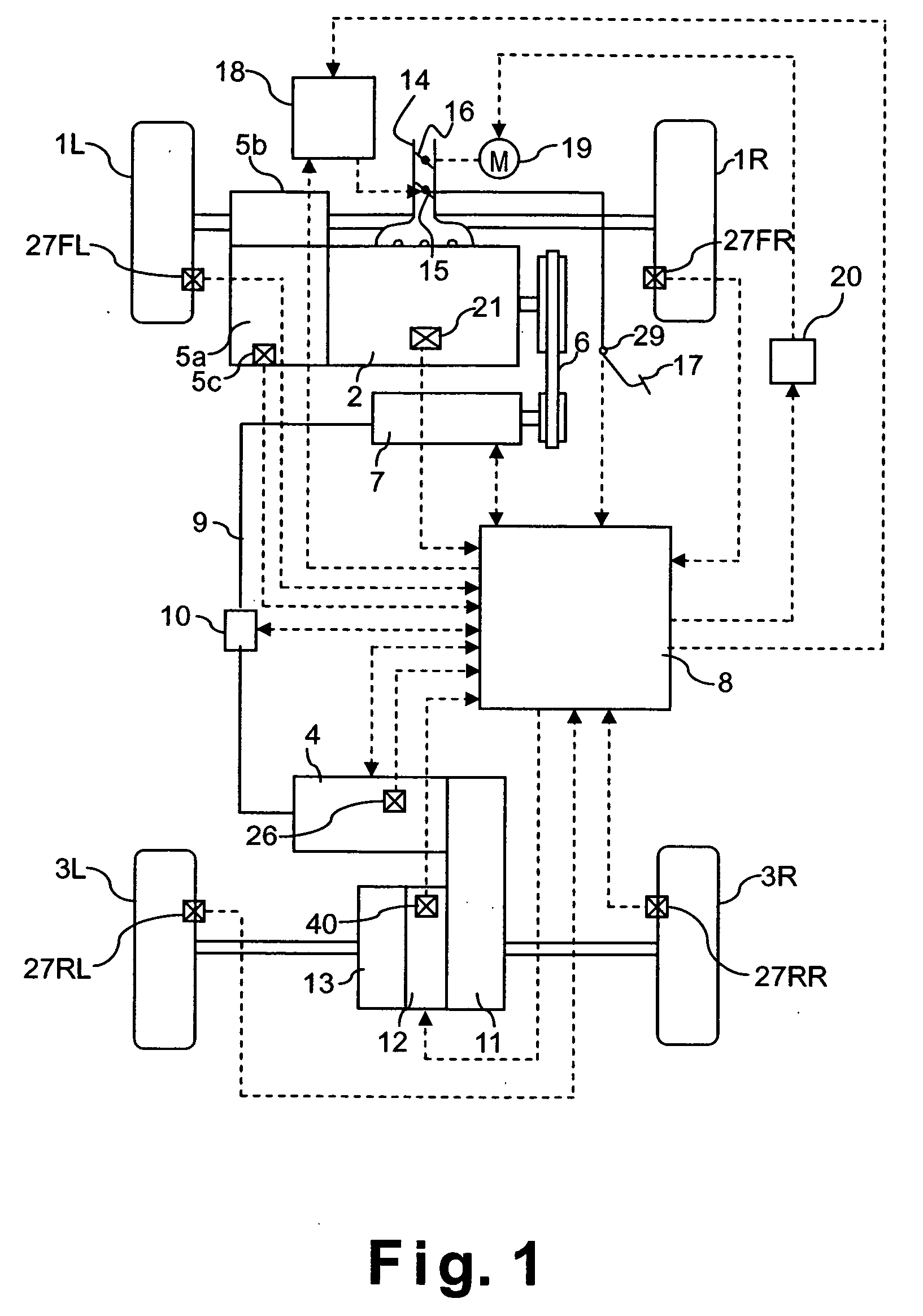

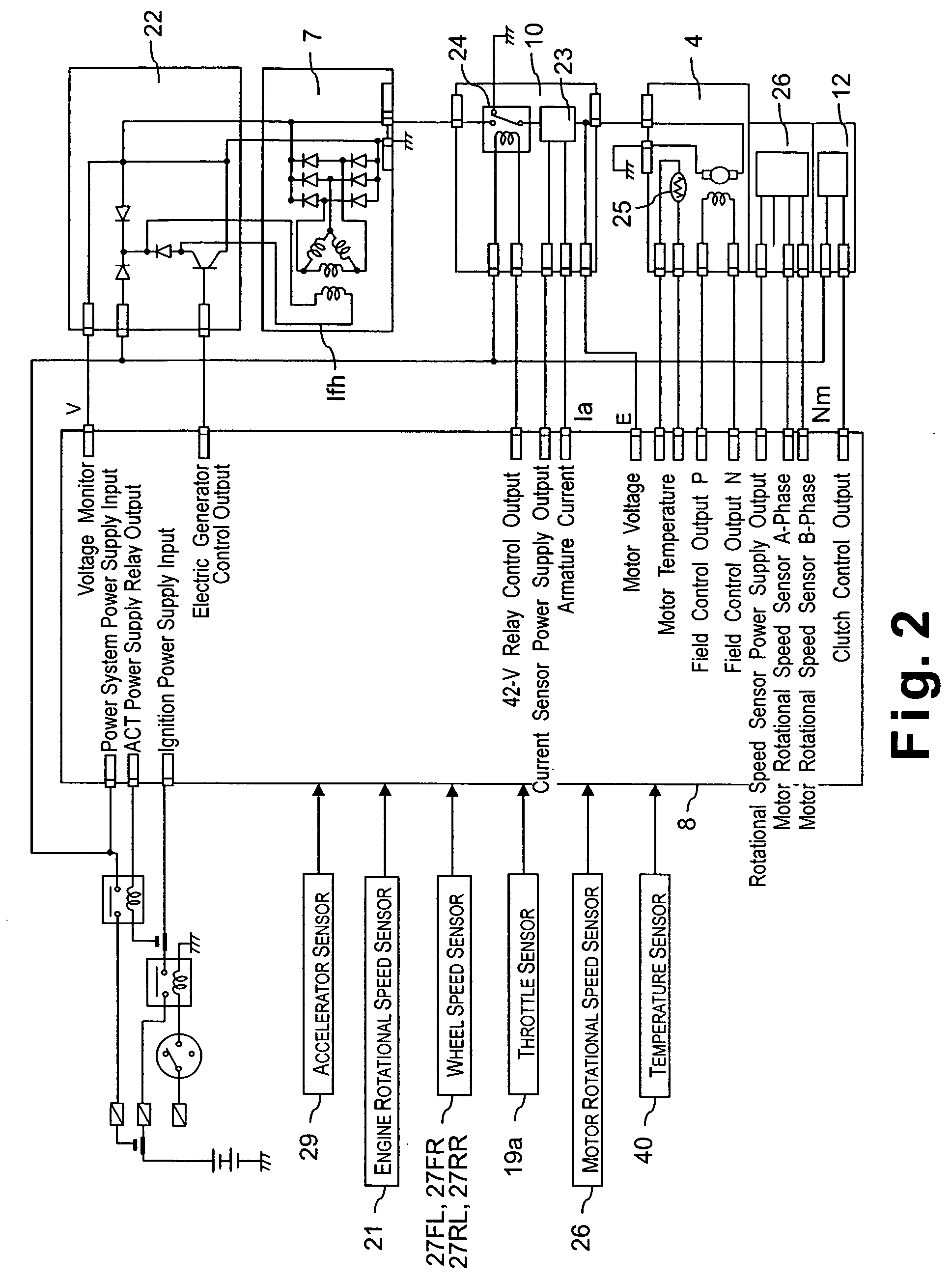

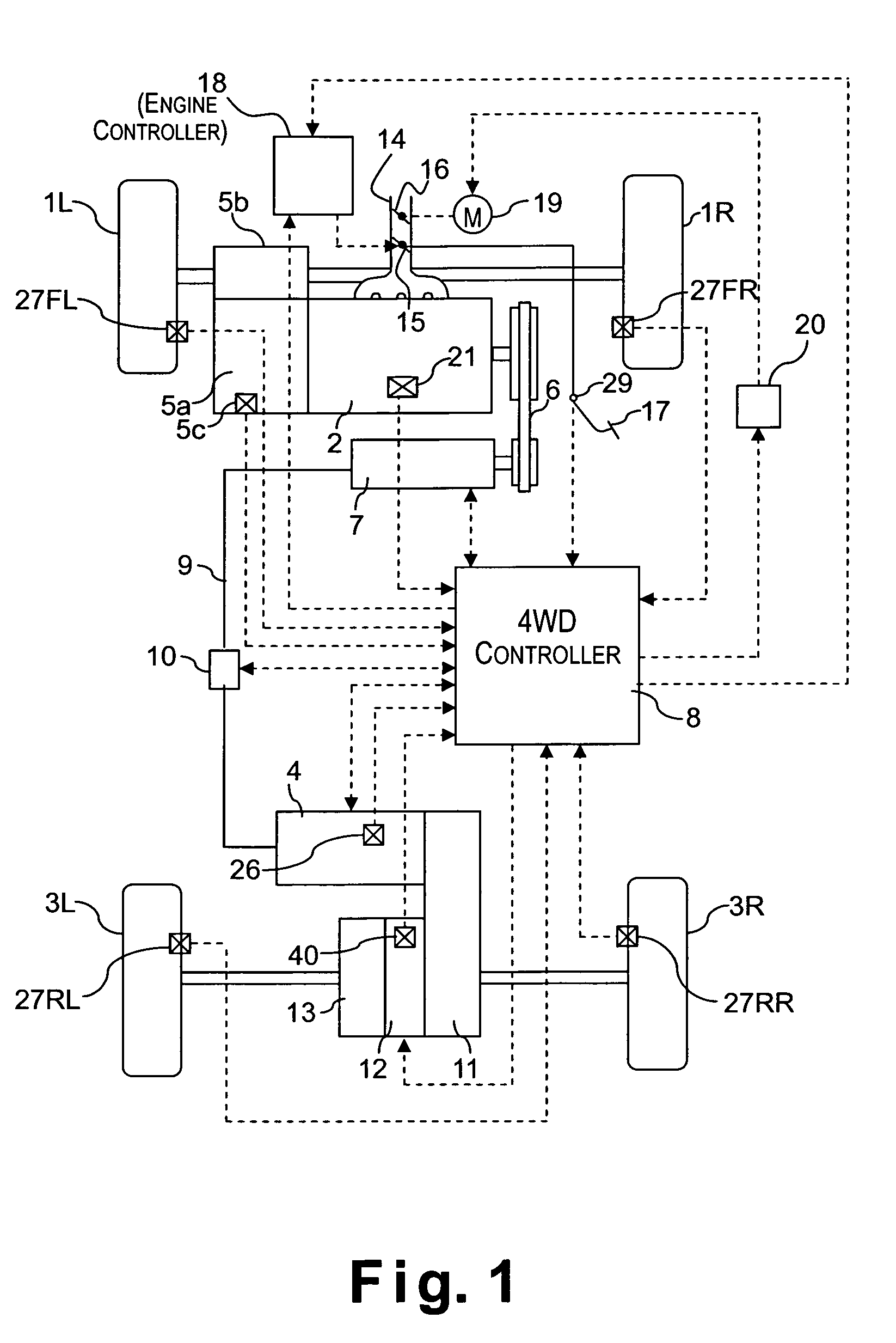

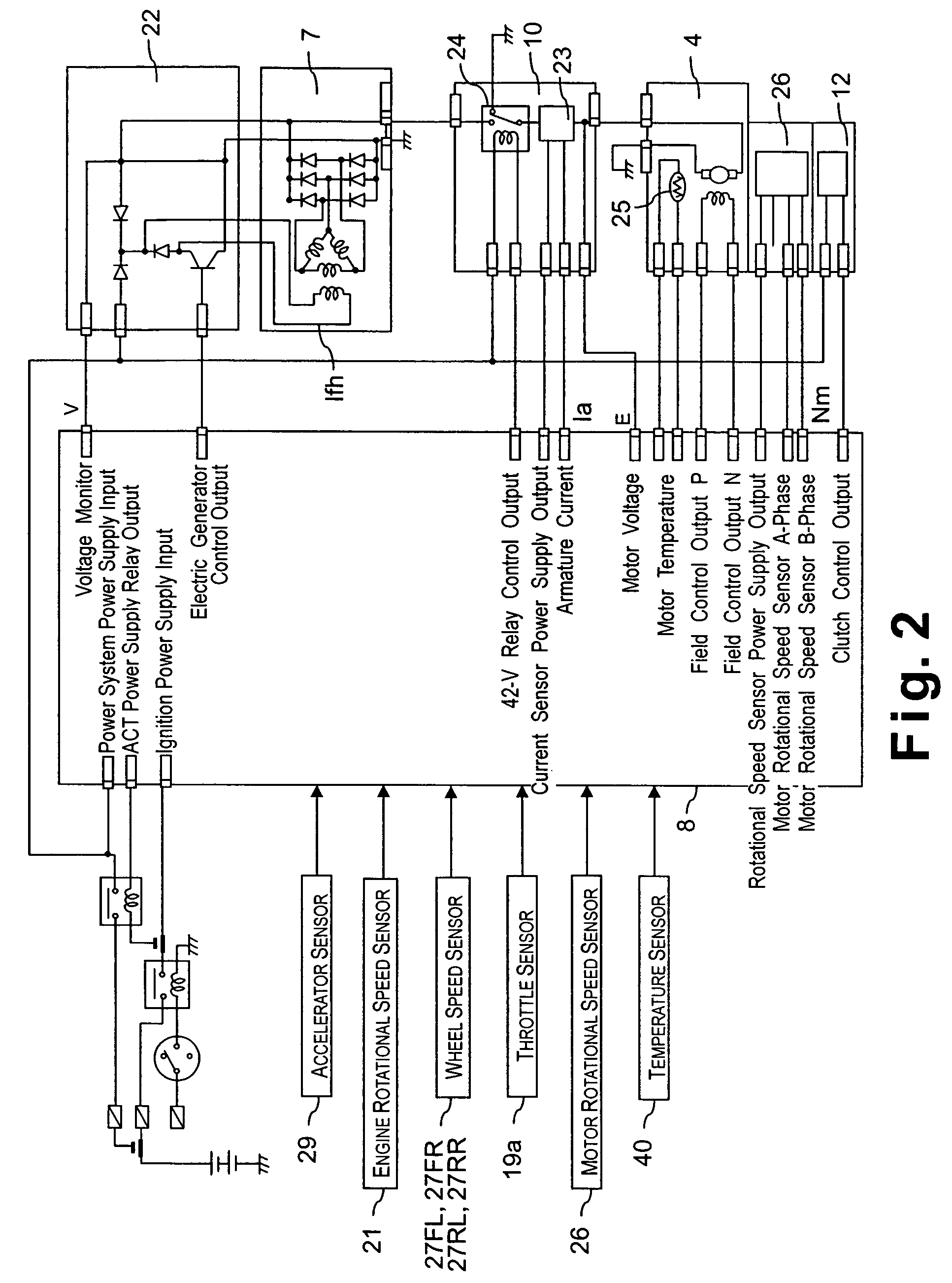

Vehicle drive force control apparatus

ActiveUS20050093496A1Enlarge regionAvoid synchronous rotationClutchesDc motor stoppersVehicle drivingControl theory

A vehicle driving force control apparatus is configured to prevent co-rotation of the motor caused by rotation of a pair of wheels when a clutch connecting the wheels and the motor is released (disconnected). When the clutch is released, the motor is braked by short circuiting the armature. The motor is then braked again by setting the field current of the motor to 0 when the rotational speed of the motor reaches 0. After the clutch is released, a braking-direction field current is applied to the motor in accordance with the decreasing rotational speed of the motor such that the braking force is decreased as the rotational speed of the motor decreases.

Owner:NISSAN MOTOR CO LTD

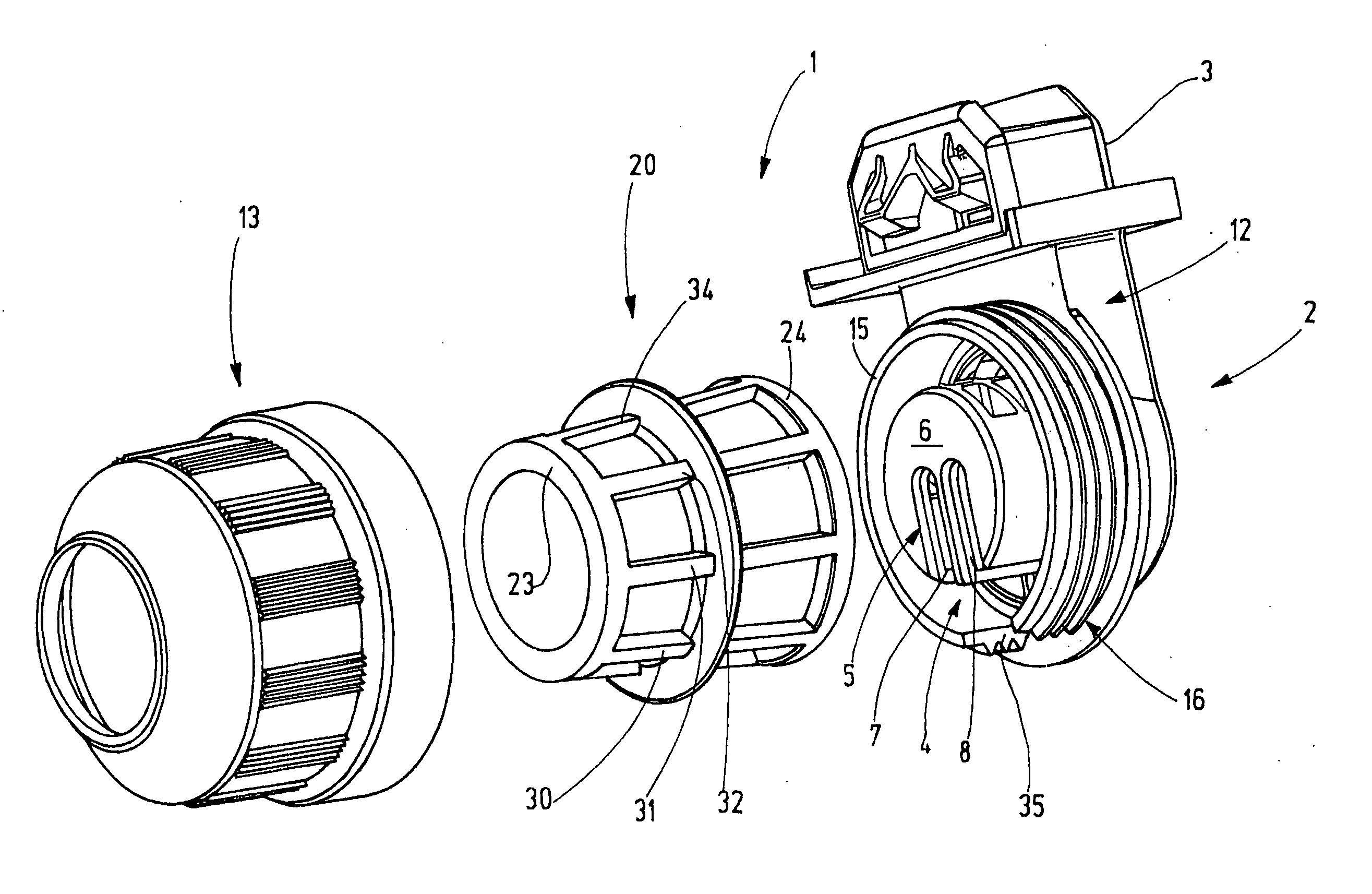

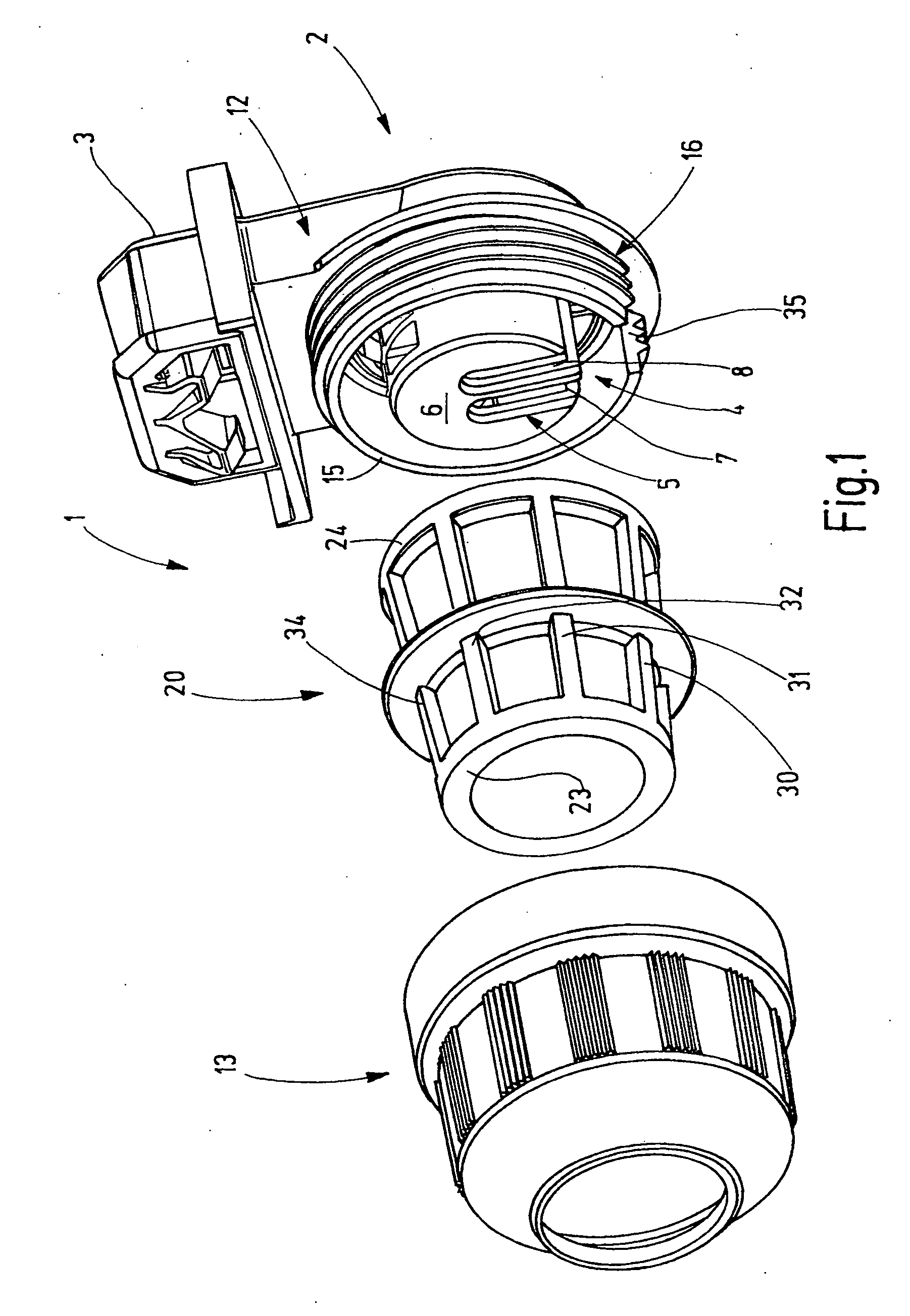

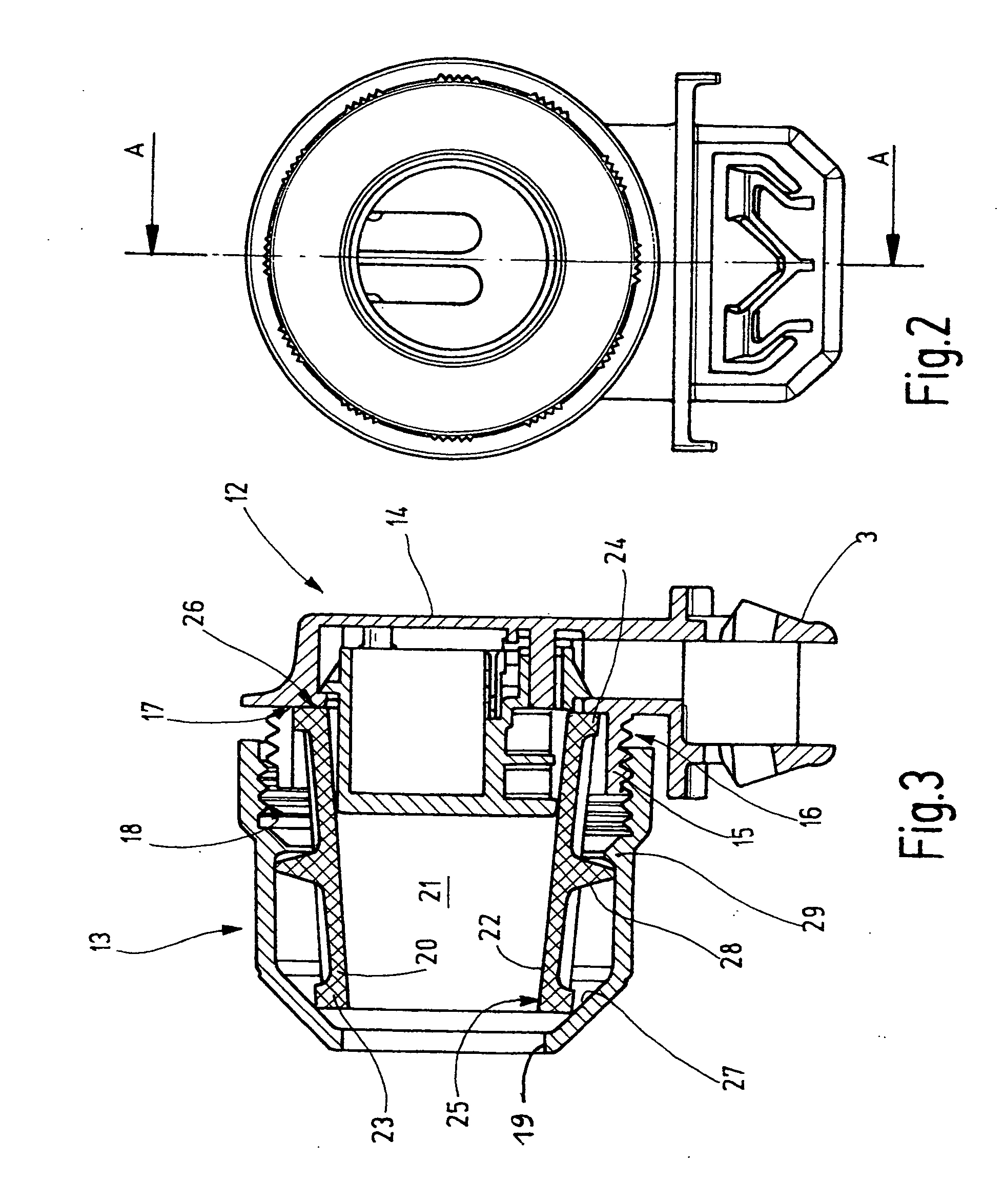

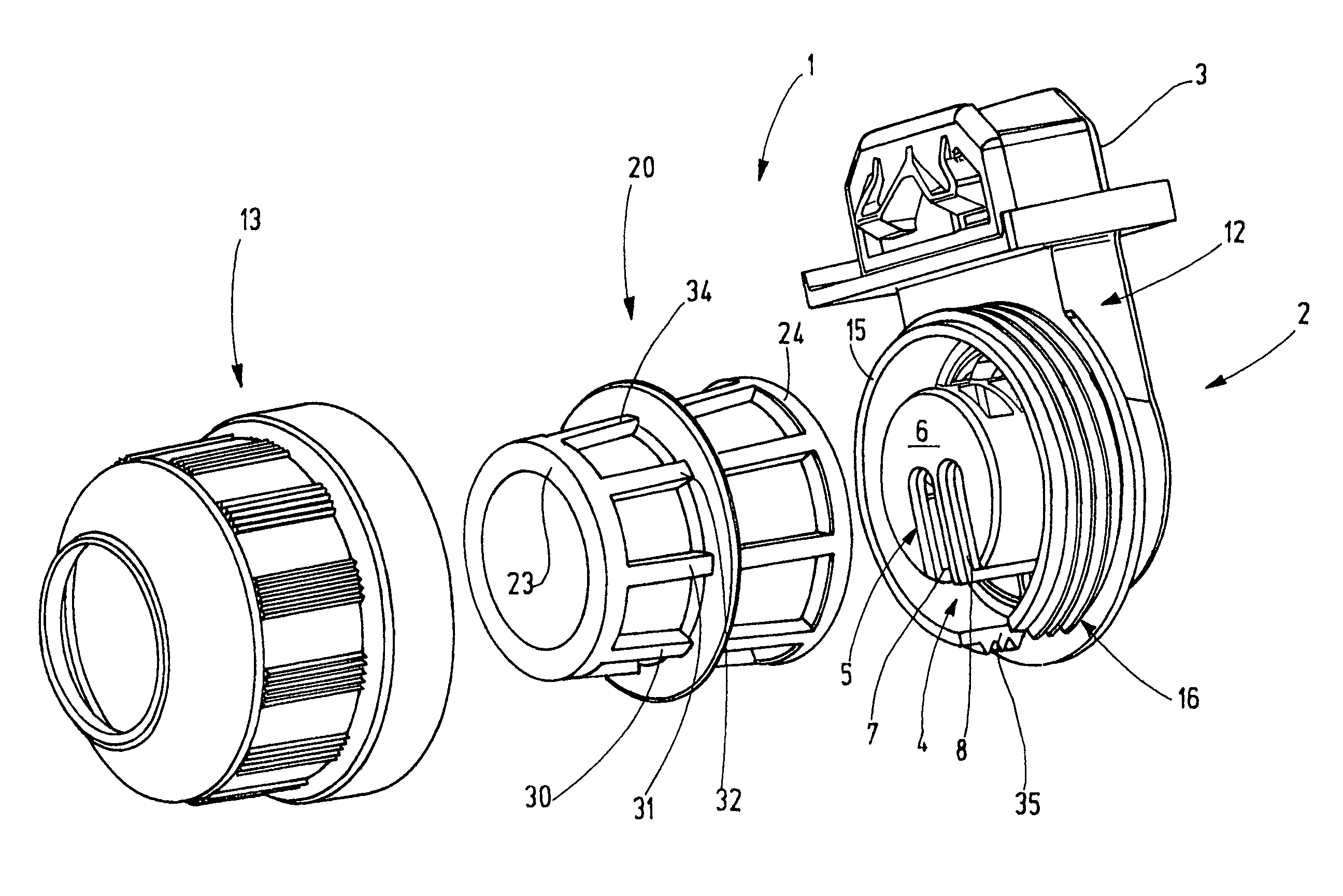

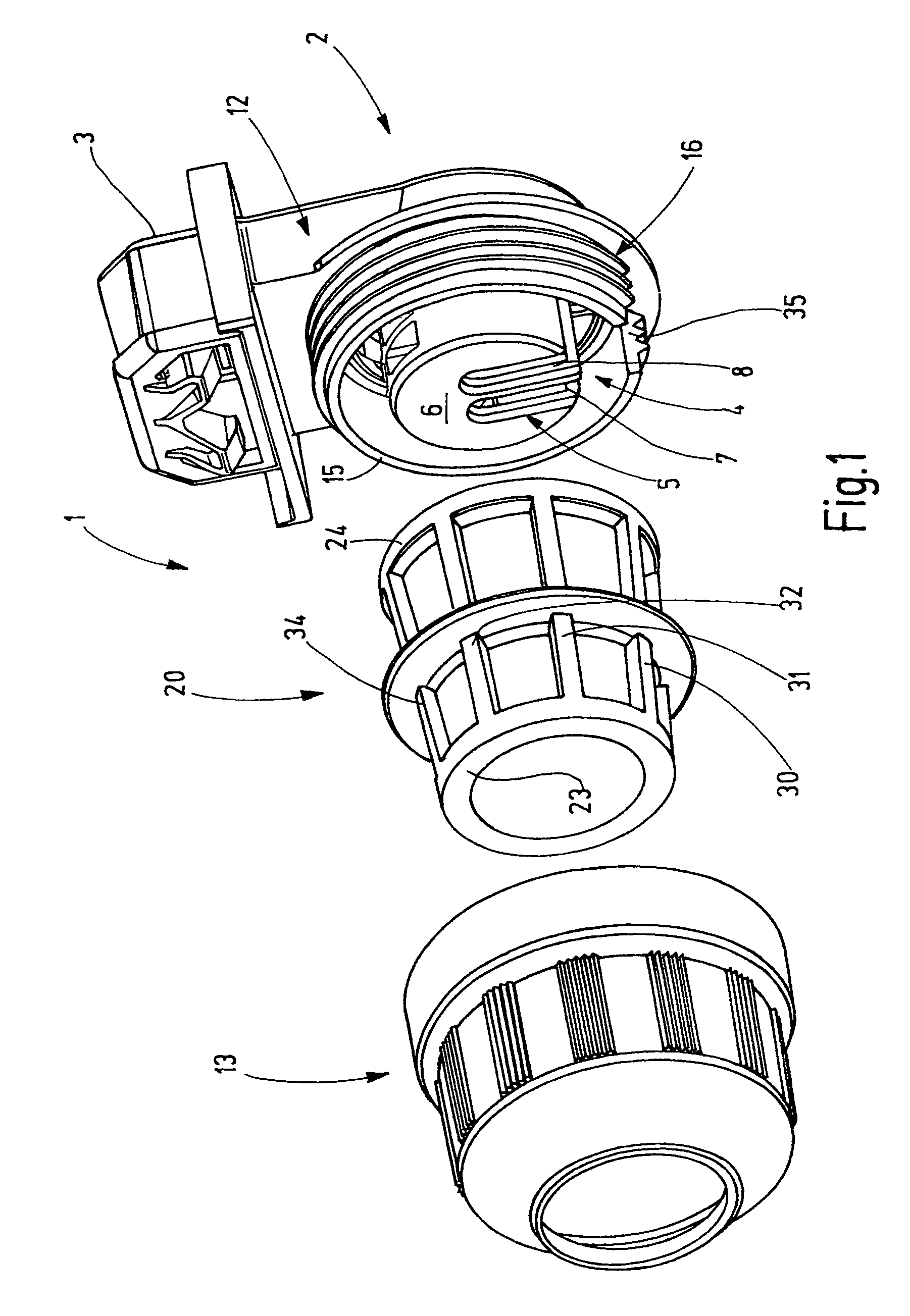

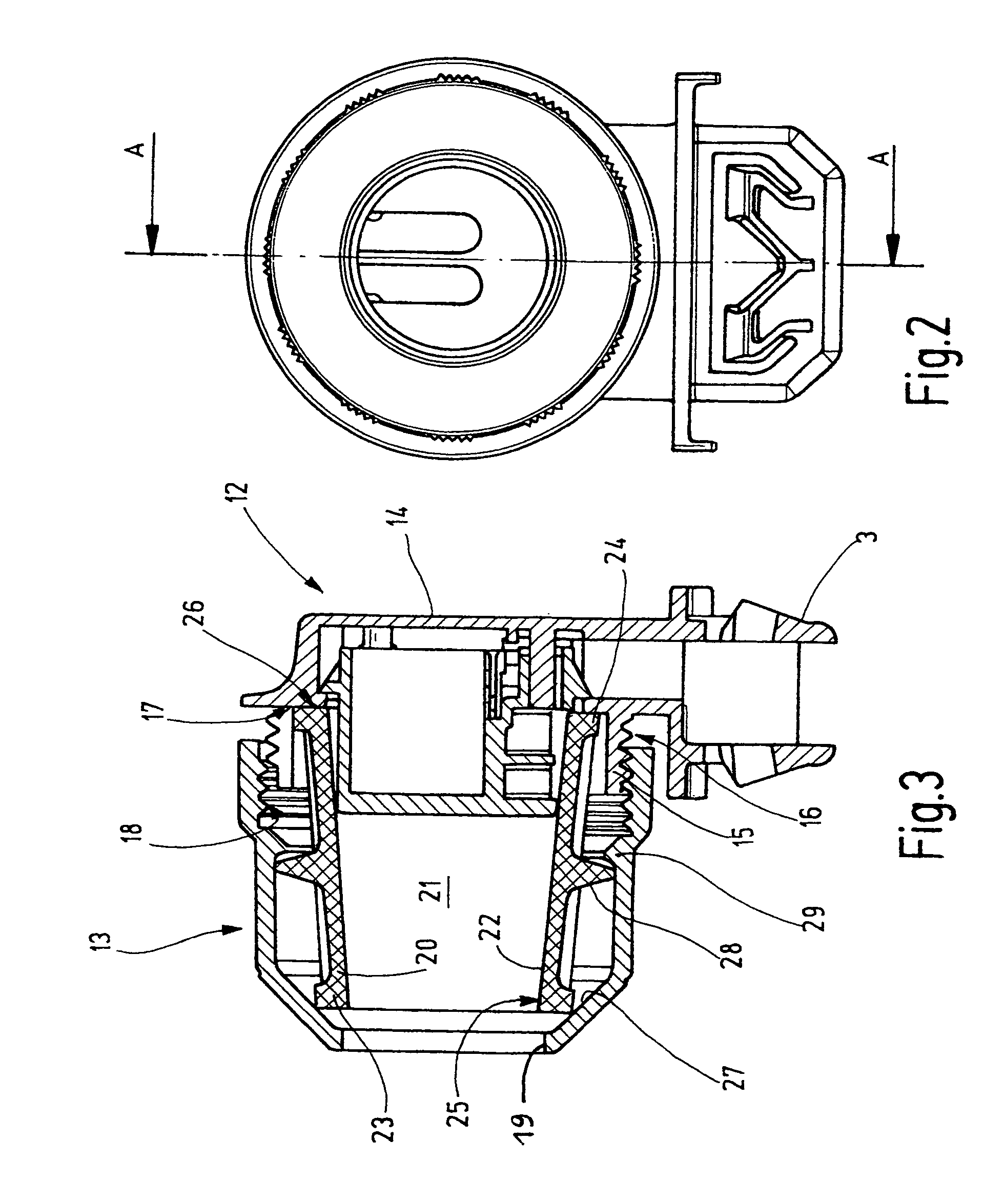

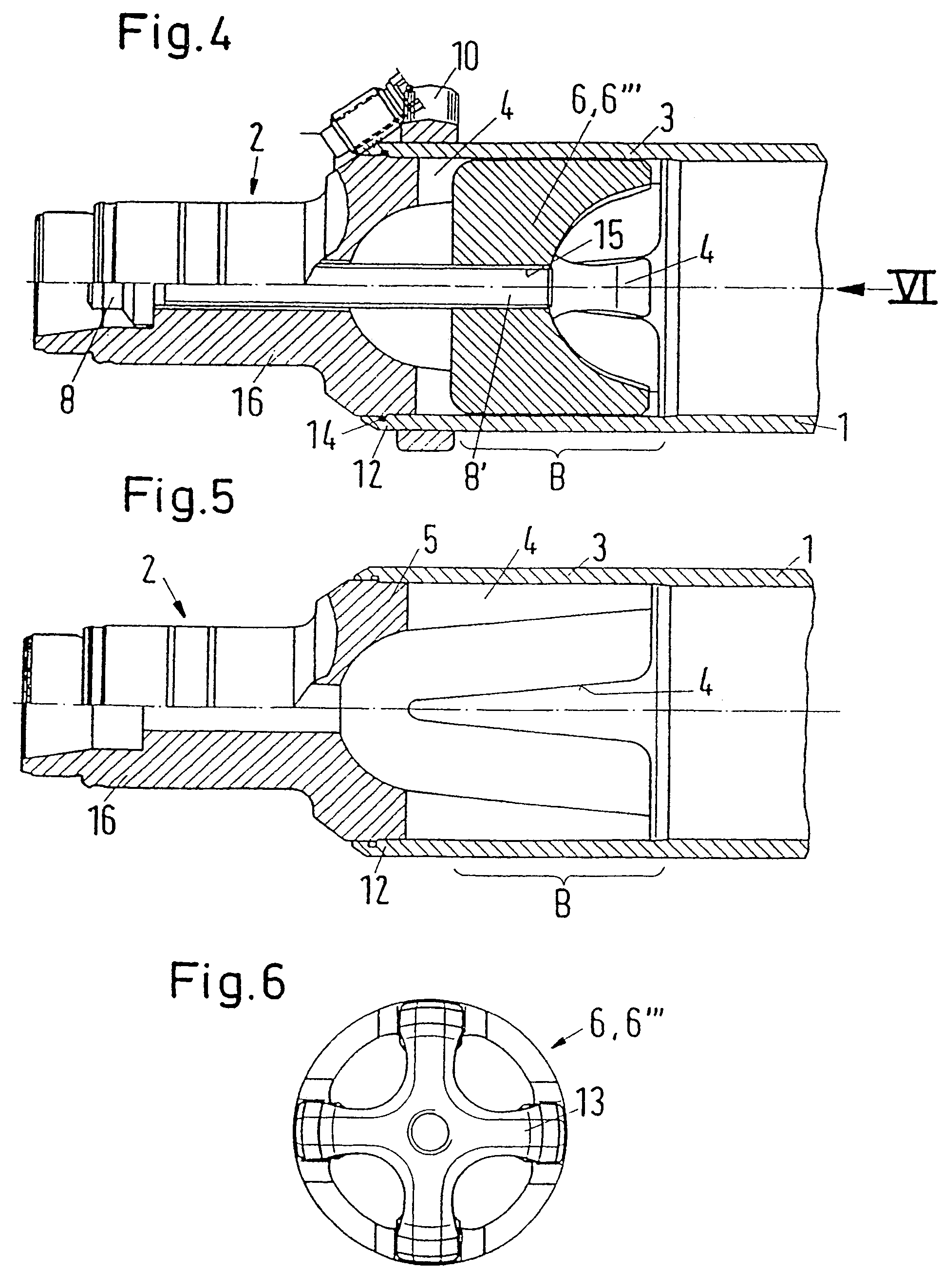

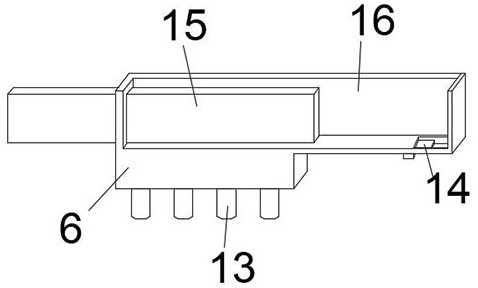

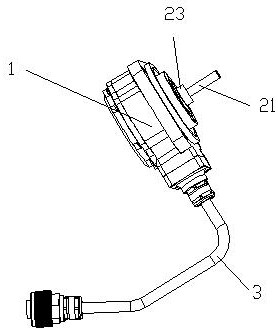

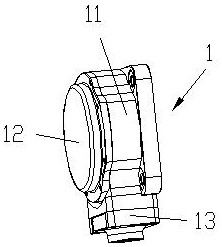

Sealed lamp socket

InactiveUS20070117466A1Improve protectionEasy to manufactureElectric discharge tubesTwo-part coupling devicesElastomerConical forms

A novel lamp socket finding application with a type of increased protection, has a housing part (13) in which a one-piece elastomer sealing sleeve (20) is preferably rotatably held. The sealing sleeve (20) is at its lamp-side end preferably slightly radially compressible, while it is stiffer in the axial direction. As a result, it yields inward when axially pressed by the frustoconical inner side of the housing part (13). The one-piece construction of the sealing sleeve (20) from a single material, on the one hand, ensures a simple manufacture and, on the other hand, prevents a faulty mounting caused by slipped seals or the like.

Owner:VOSSLOH-SCHWABE

Vehicle drive force control apparatus

ActiveUS7095196B2Enlarge regionAvoid synchronous rotationClutchesDc motor stoppersEngineeringVehicle driving

A vehicle driving force control apparatus is configured to prevent co-rotation of the motor caused by rotation of a pair of wheels when a clutch connecting the wheels and the motor is released (disconnected). When the clutch is released, the motor is braked by short circuiting the armature. The motor is then braked again by setting the field current of the motor to 0 when the rotational speed of the motor reaches 0. After the clutch is released, a braking-direction field current is applied to the motor in accordance with the decreasing rotational speed of the motor such that the braking force is decreased as the rotational speed of the motor decreases.

Owner:NISSAN MOTOR CO LTD

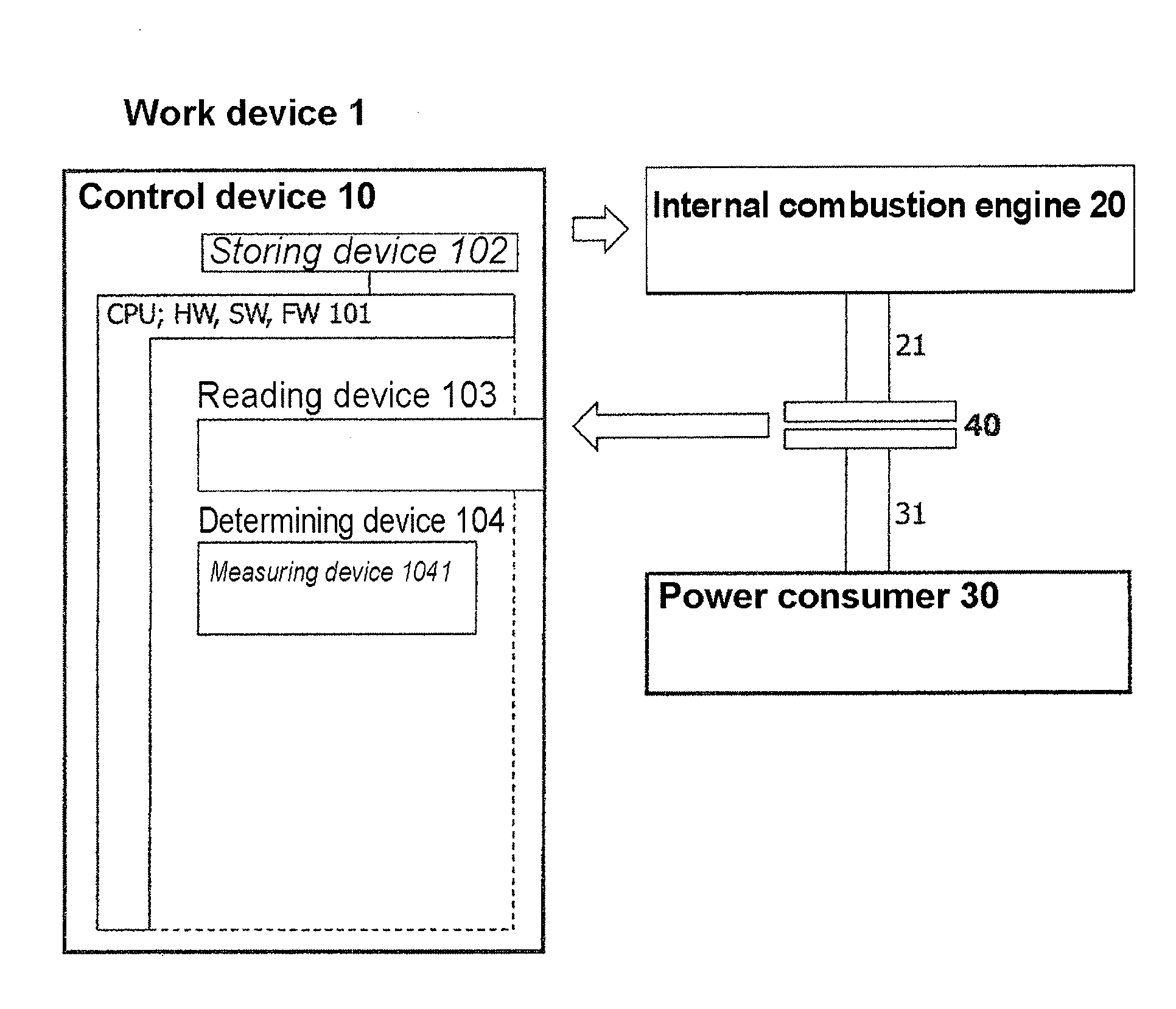

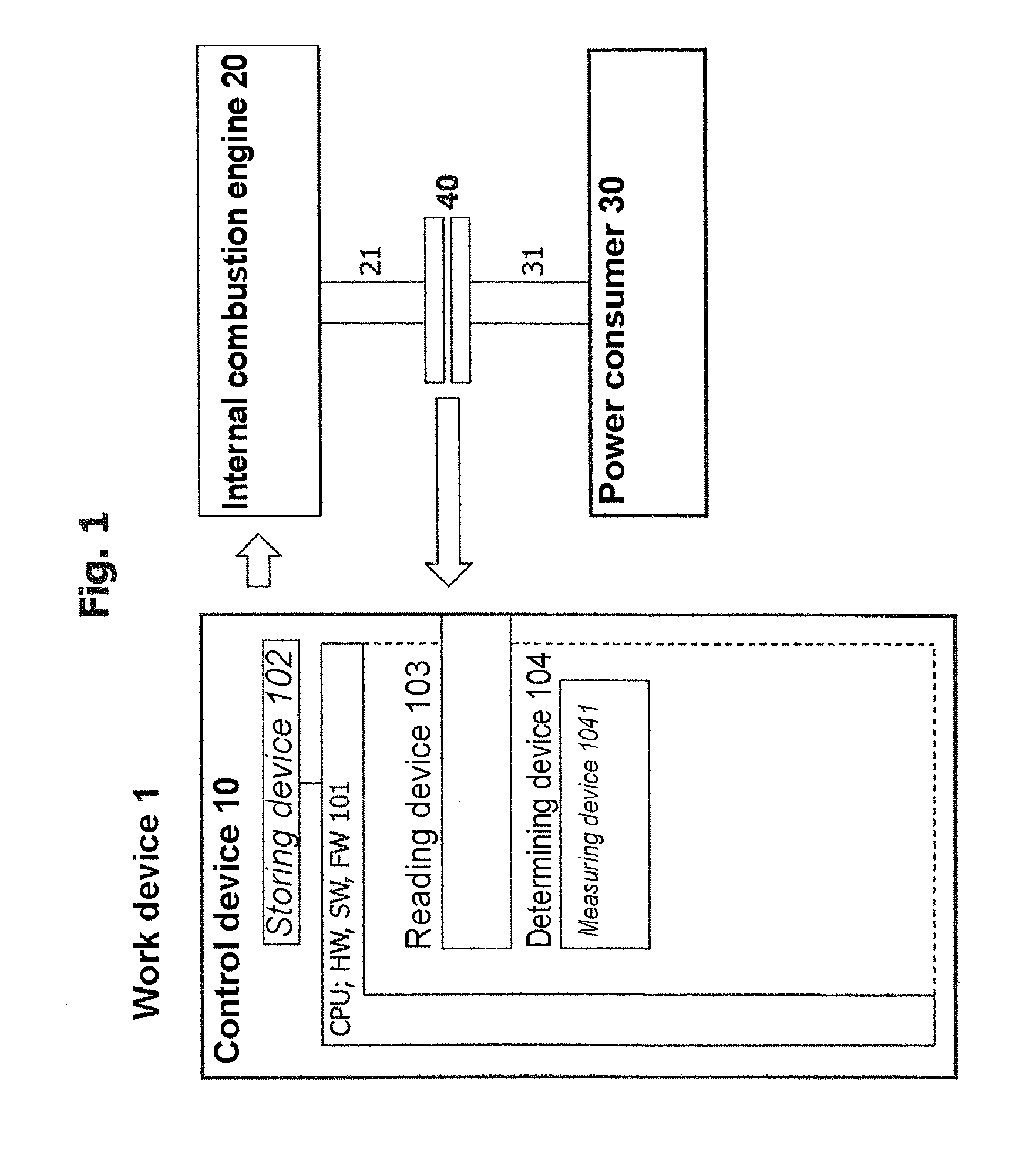

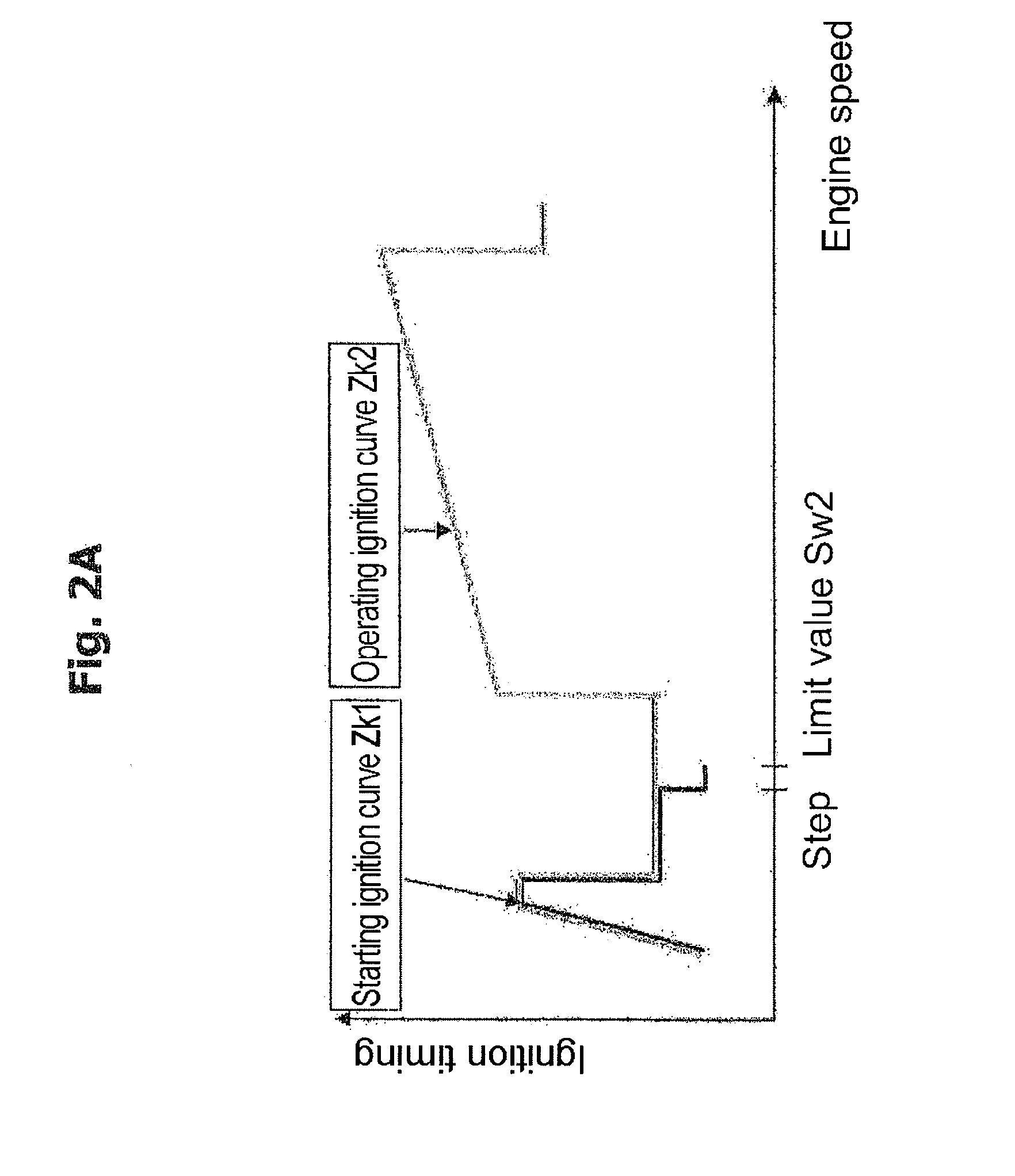

Method and device for controlling the operation of an internal combustion engine of a portable work device

InactiveUS20150345460A1Easy to controlImprove securityAnalogue computers for vehiclesPower operated startersExternal combustion engineInternal combustion engine

The invention relates to a method and a control device for operating an internal combustion engine of a portable work device, said method having the following method steps: a) storing a starting ignition curve for specifying an ignition time after a startup time of the internal combustion engine and an operating ignition curve for specifying the ignition time in a speed range assigned to the nominal operation of the internal combustion engine, b) reading the current engine speed, c) reading at least one time value which indicates the time that has elapsed since a reference time, wherein the reference time can relate to the startup time of the internal combustion engine, and d) determining and / or initiating a switchover process from the starting ignition curve to the operating ignition curve on the basis of the current engine speed and the time value.

Owner:MAKITA CORP +1

Sealed lamp socket

InactiveUS7338302B2Easy to manufactureImprove protectionElectric discharge tubesTwo-part coupling devicesElastomerConical forms

A novel lamp socket finding application with a type of increased protection, has a housing part (13) in which a one-piece elastomer sealing sleeve (20) is preferably rotatably held. The sealing sleeve (20) is at its lamp-side end preferably slightly radially compressible, while it is stiffer in the axial direction. As a result, it yields inward when axially pressed by the frustoconical inner side of the housing part (13). The one-piece construction of the sealing sleeve (20) from a single material, on the one hand, ensures a simple manufacture and, on the other hand, prevents a faulty mounting caused by slipped seals or the like.

Owner:VOSSLOH SCHWABE DEUT GMBH

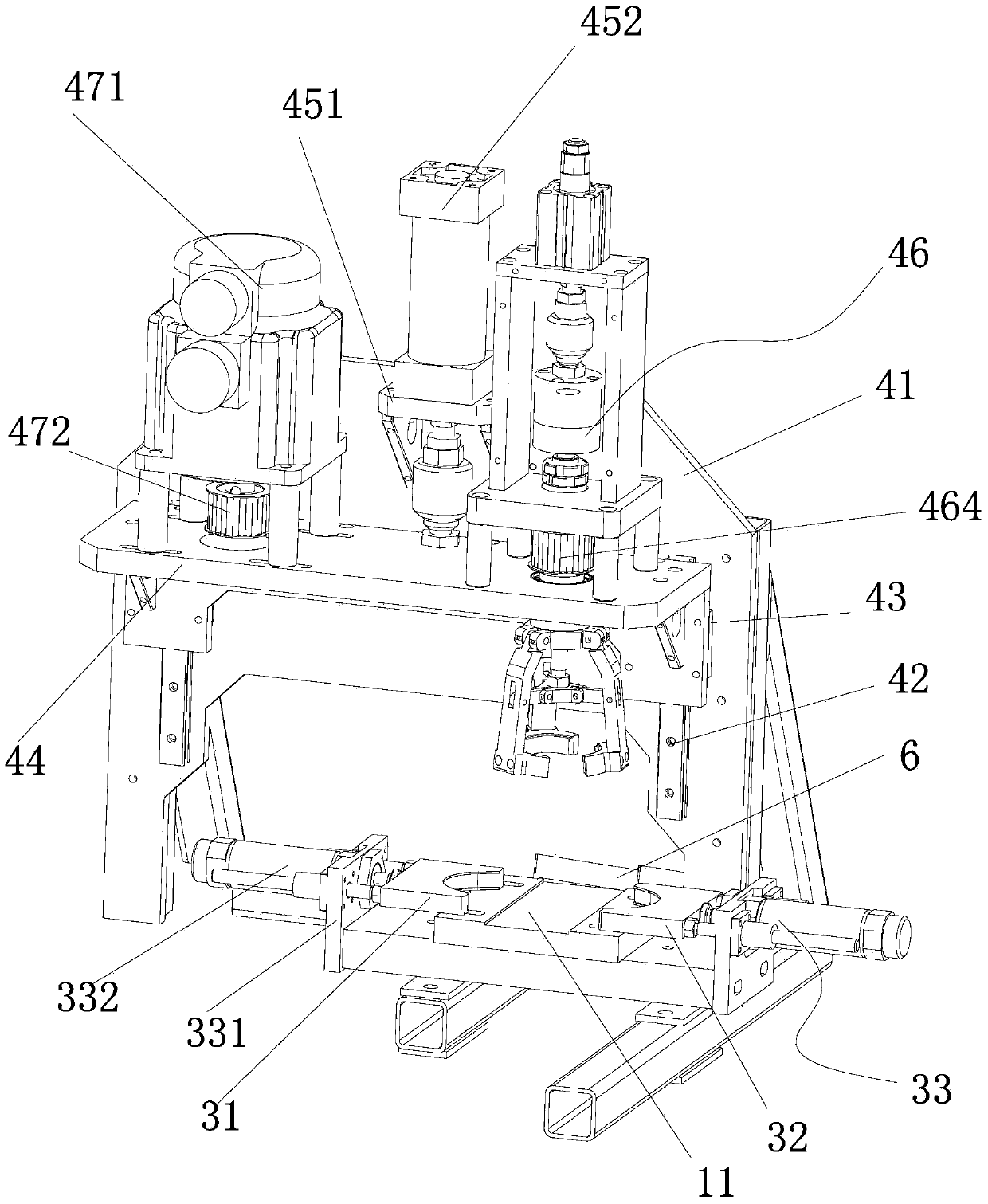

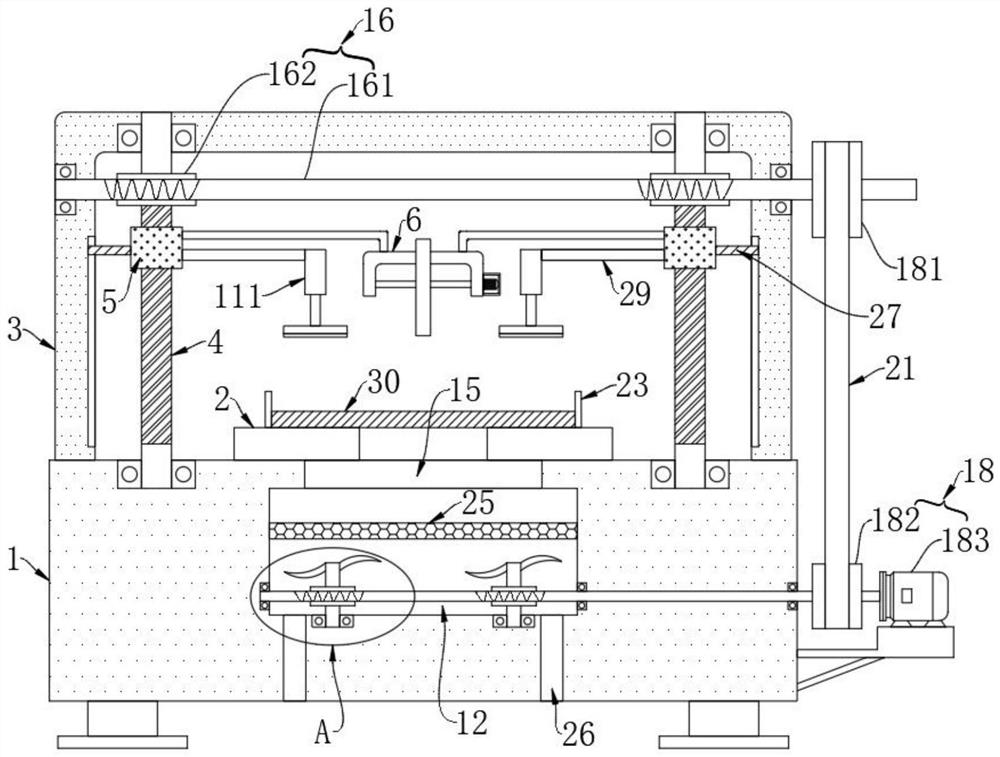

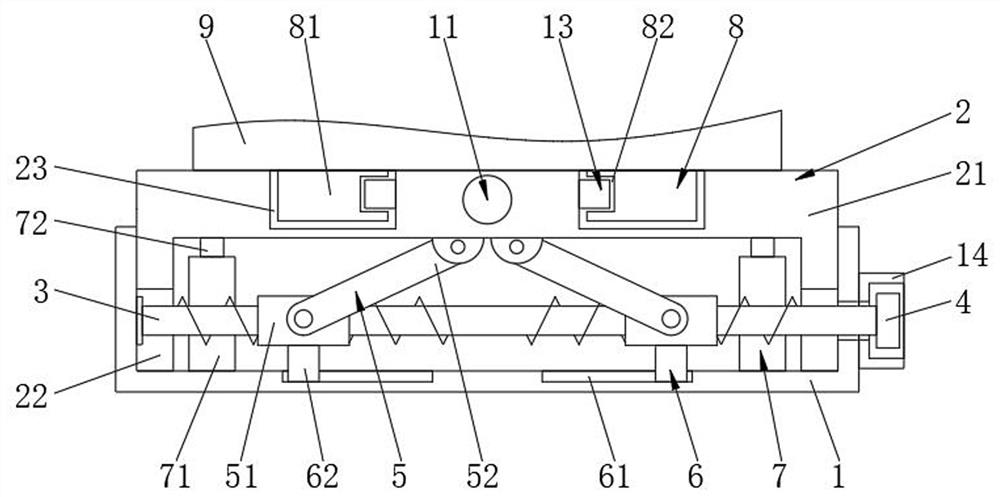

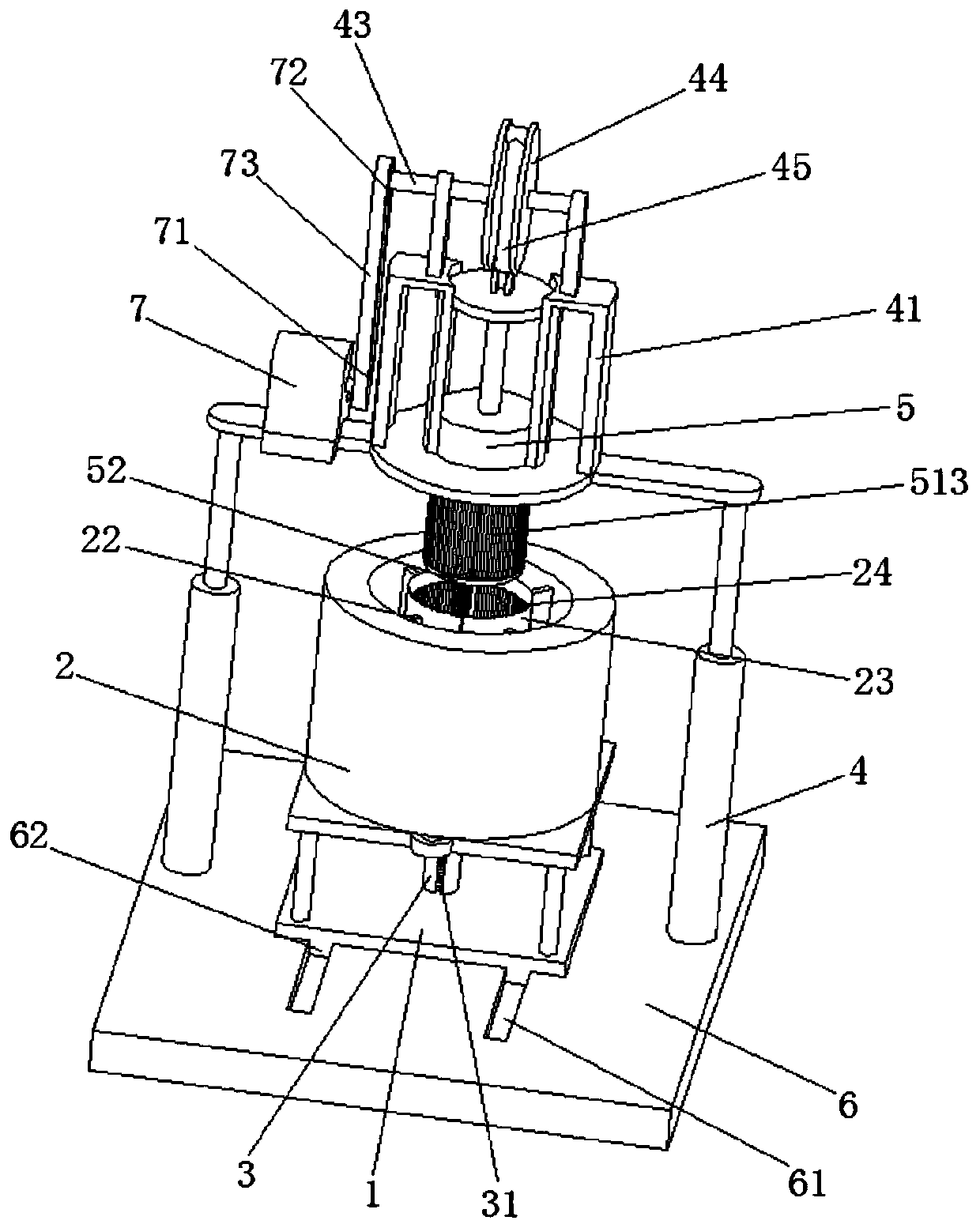

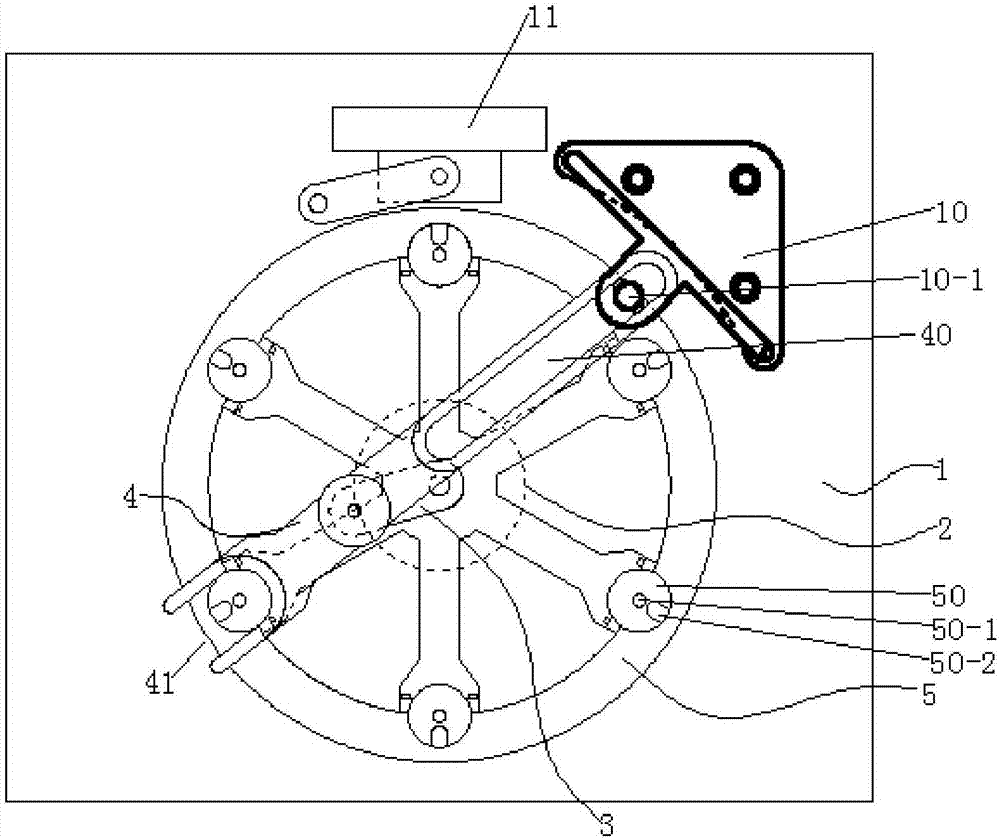

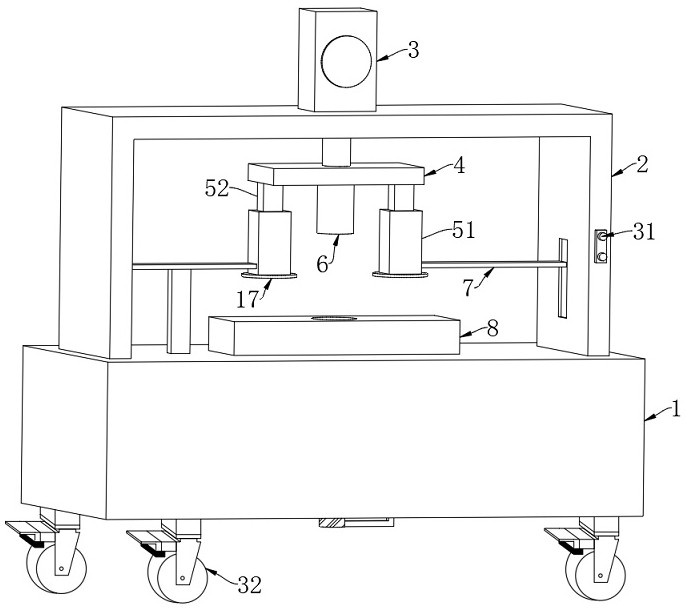

Precision processing device of formed electric motor alloy shell

ActiveCN111376134AGuaranteed precisionQuality improvementEdge grinding machinesGrinding carriagesEngineeringAlloy

The invention relates to the field of casting processing, in particular to a precision processing device of a formed electric motor alloy shell. The precision processing device of the formed electricmotor alloy shell comprises a bracket, the top of the bracket is fixedly connected with a fixed slot, first telescopic frames are symmetrically inserted on the inner side of the fixed slot, second telescopic frames are symmetrically inserted on the inner side, located above the first telescopic frames, of the fixed slot, and the first telescopic frames and the second telescopic frames are arrangedin a staggered mode. One ends of the first telescopic frames and the second telescopic frames are fixedly connected with clamping plates, the sides of the clamping plates are fixedly connected with aplurality of first scraping strips, one ends of the first telescopic frames and the second telescopic frames inserted in the fixed slot are fixedly connected with first springs, a telescopic groove is fixedly connected to the bracket and located at the bottom of the fixed slot, a second spring is inserted in the telescopic groove, and a telescopic rod is inserted in the telescopic groove and located at the top of the second spring. The precision processing device of the formed electric motor alloy shell has simple structure, precise treatment can be carried out on the inner wall and the outerwall of the electric motor alloy shell at the same time, and the precision processing device of the formed electric motor alloy shell is suitable for popularization.

Owner:CHANGZHOU LEKVA ELECTRONICS CO LTD

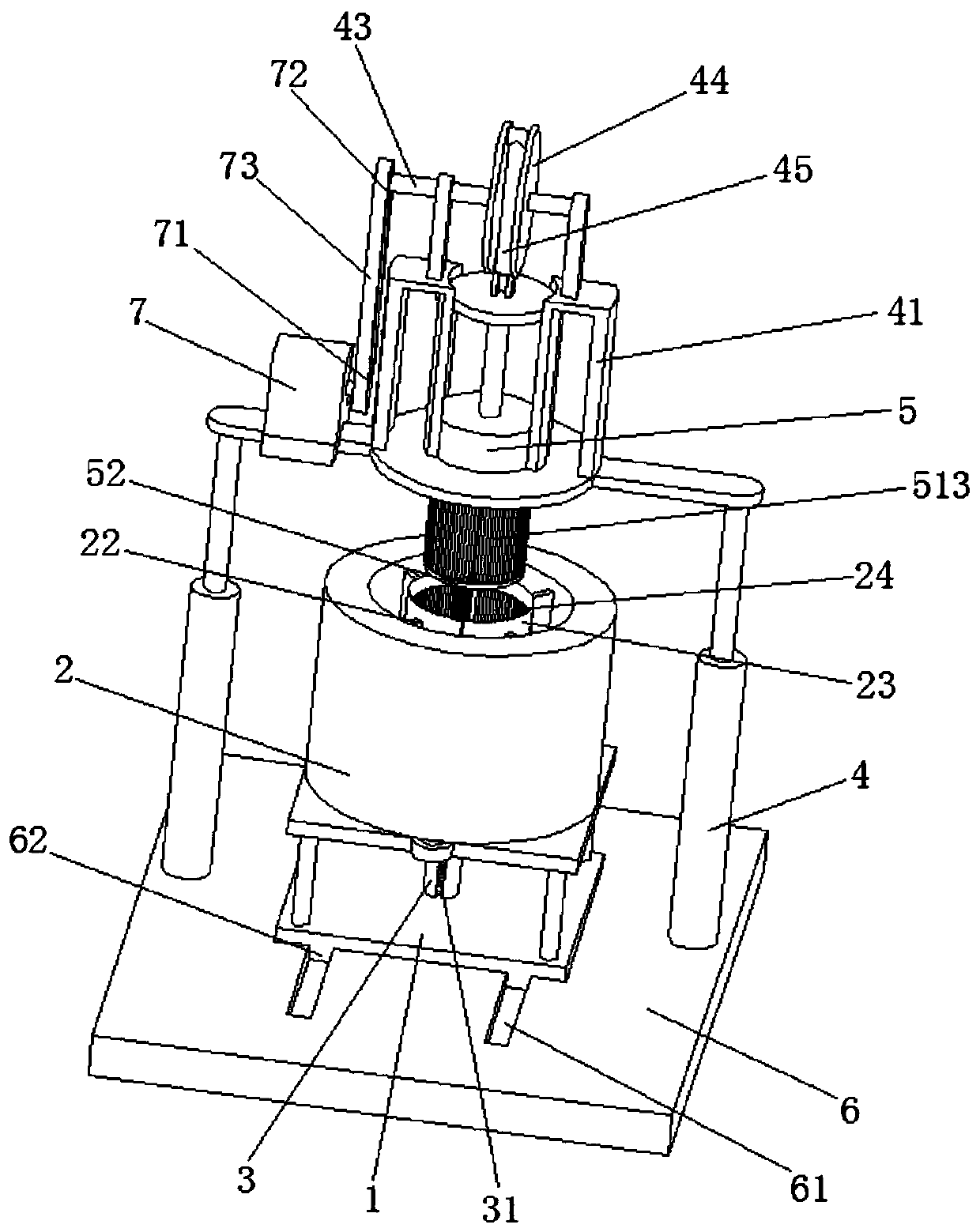

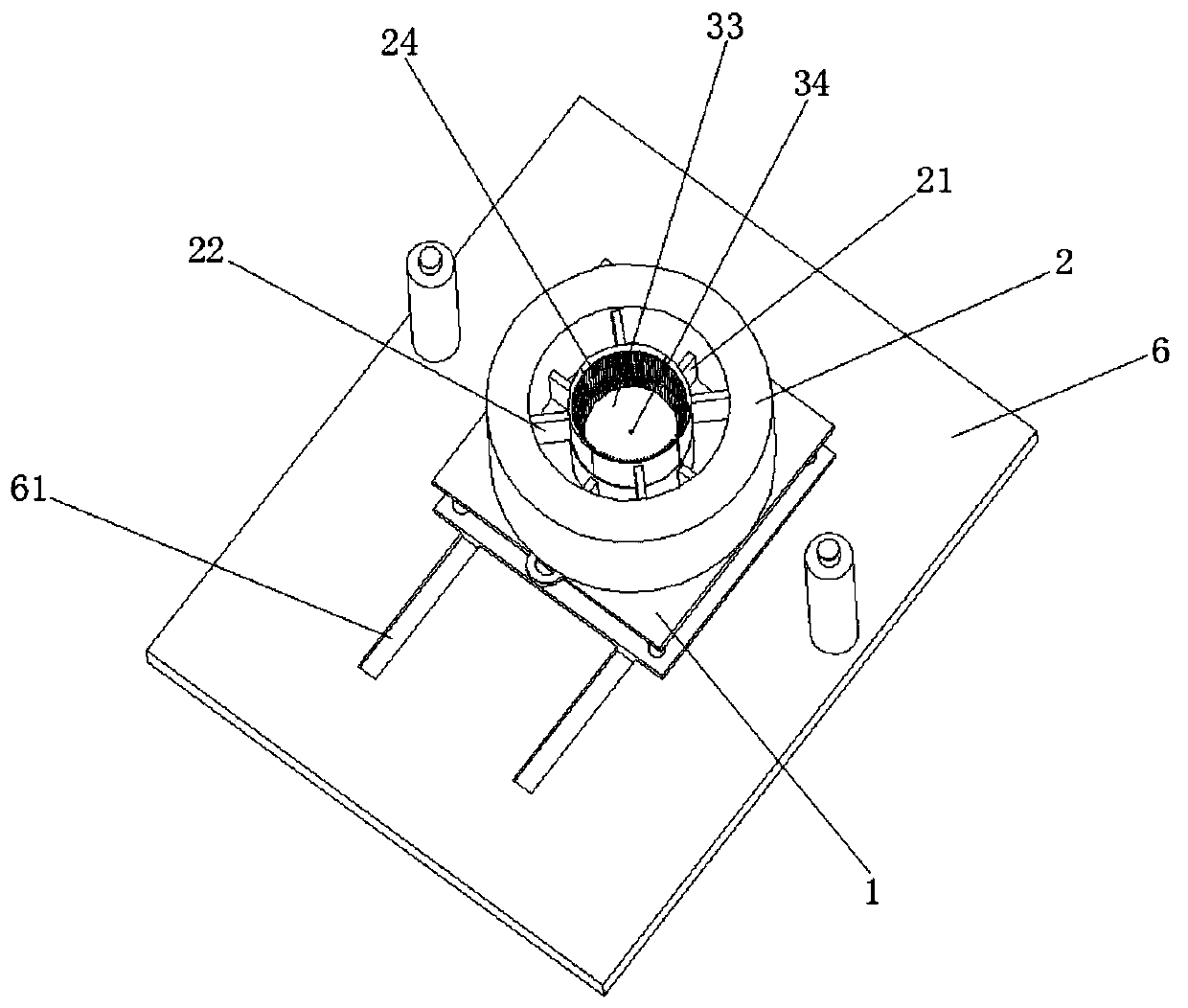

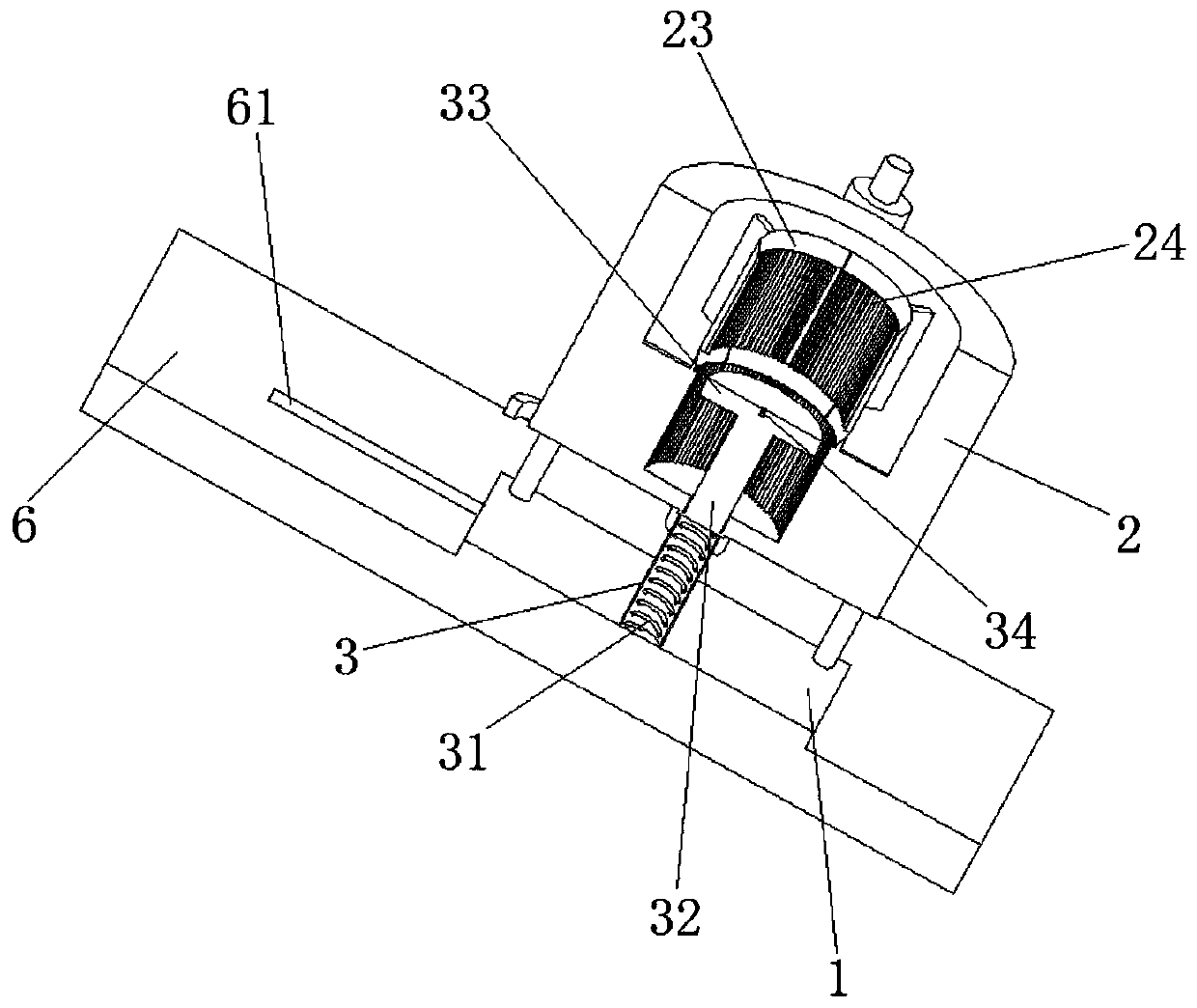

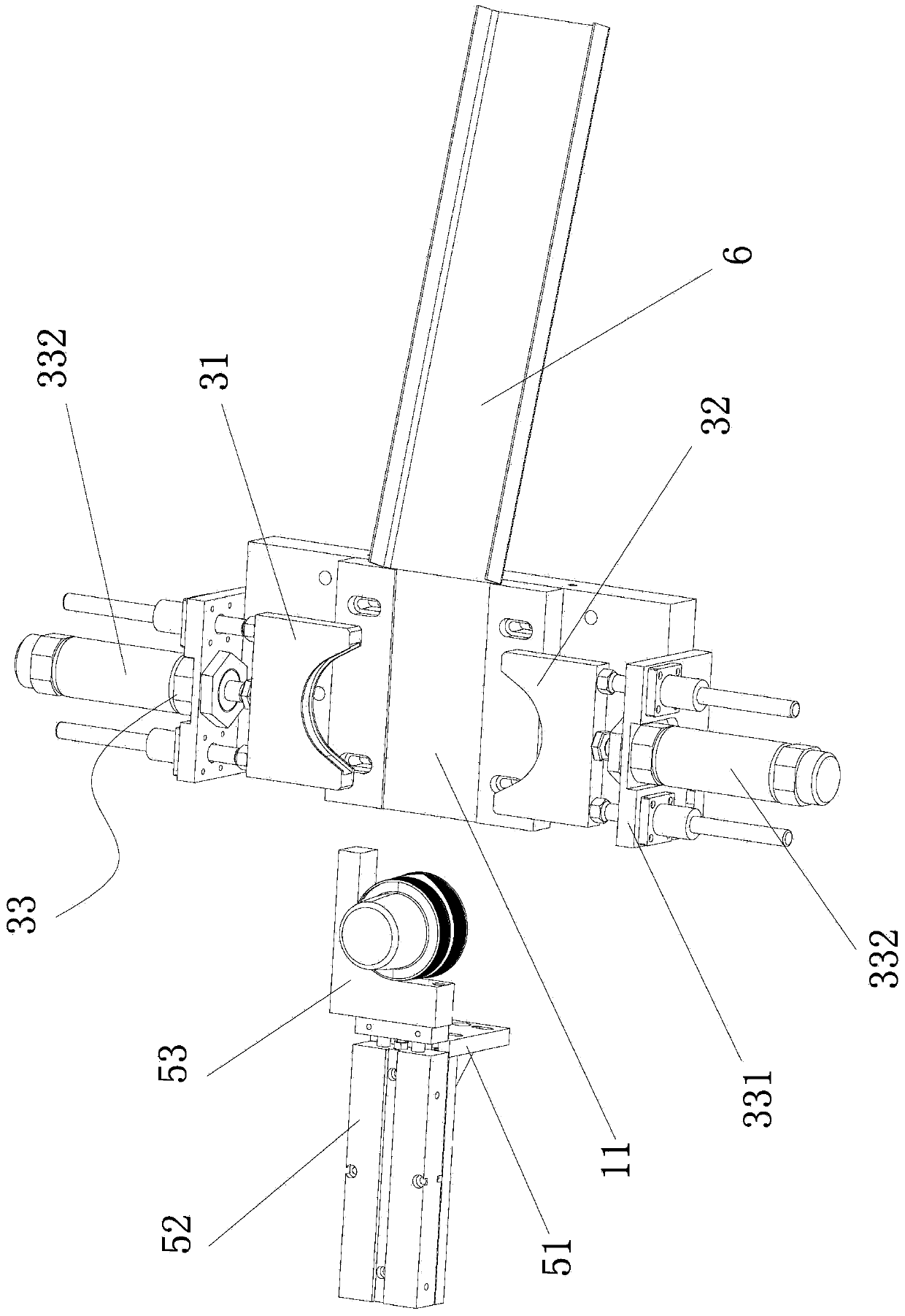

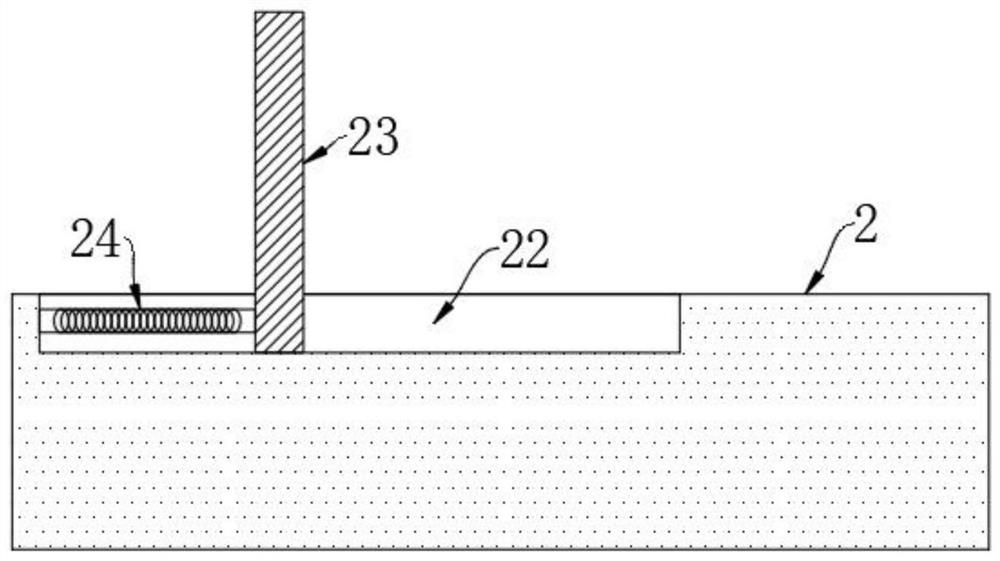

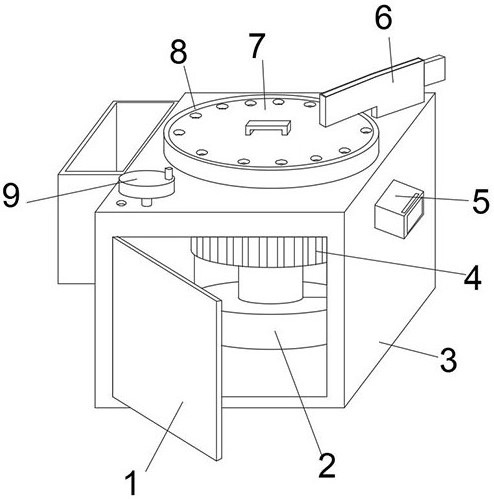

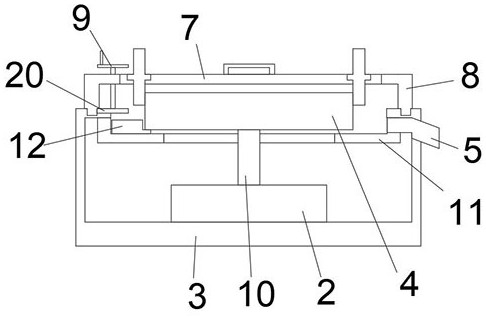

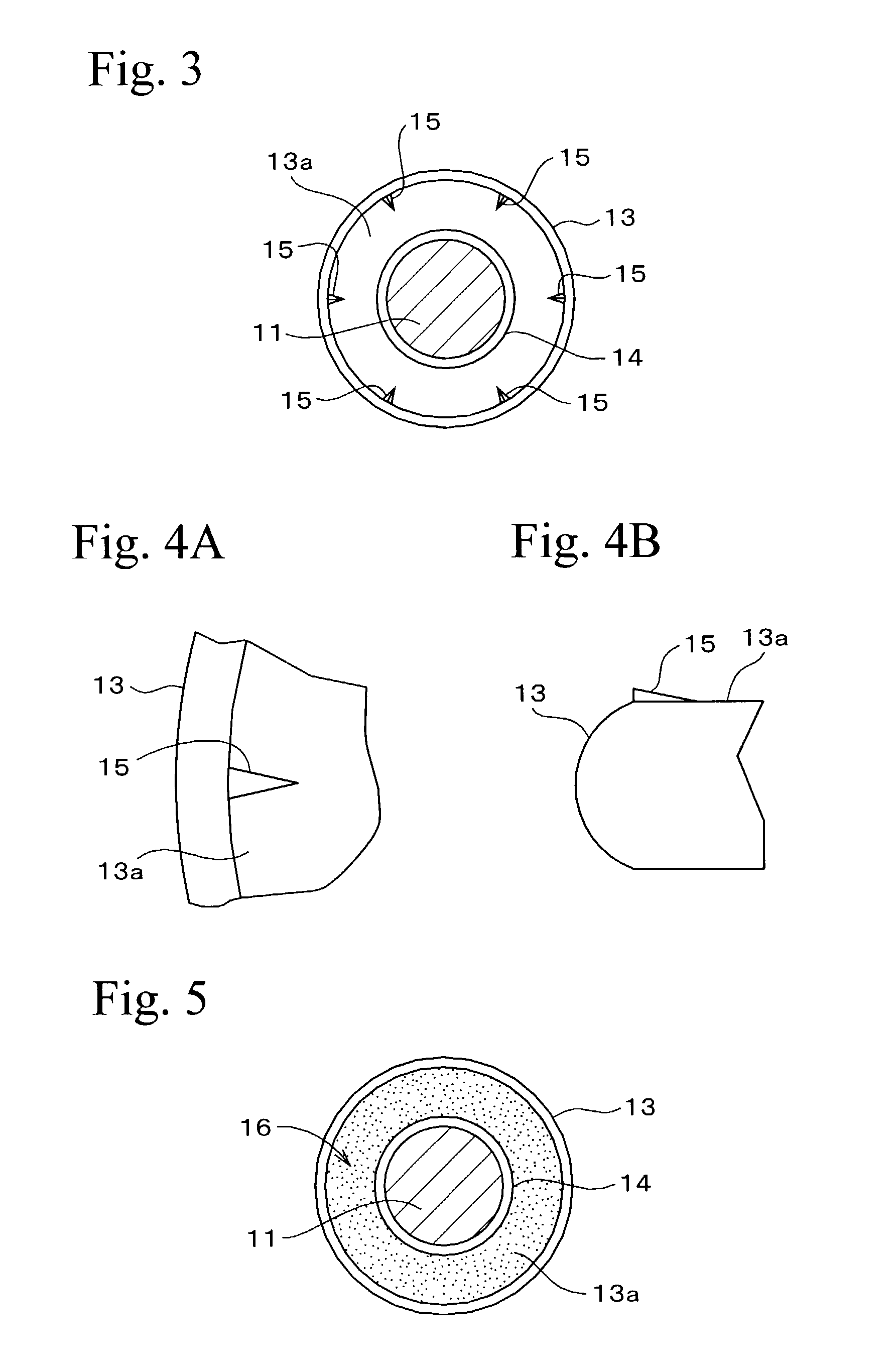

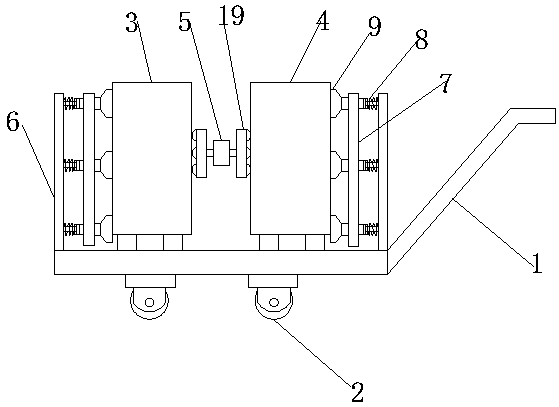

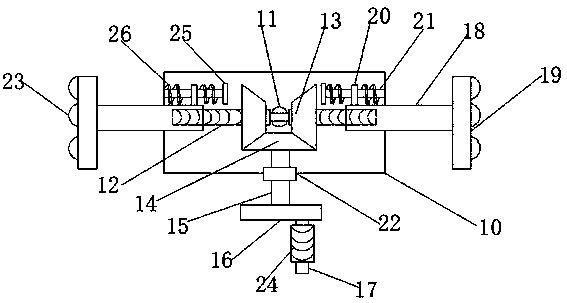

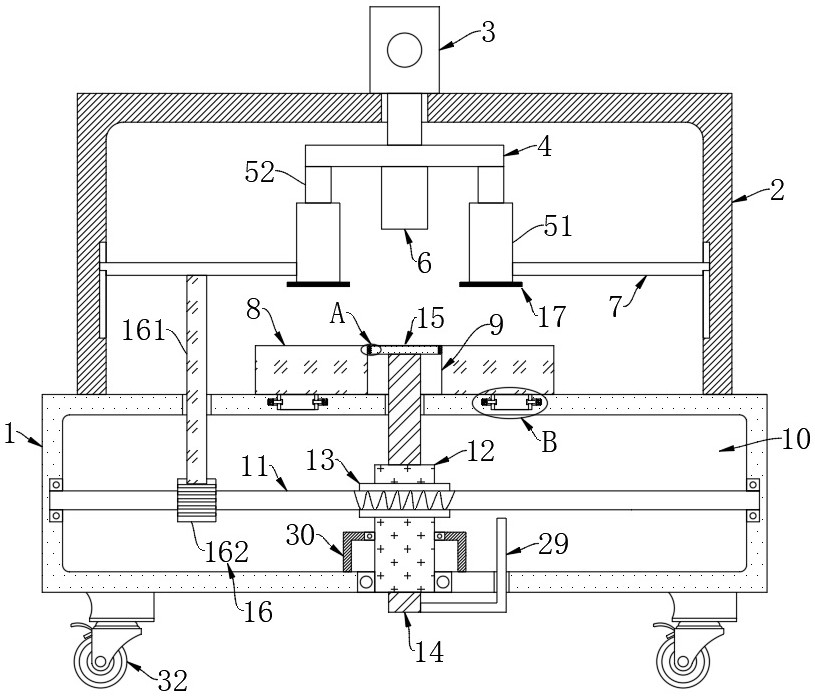

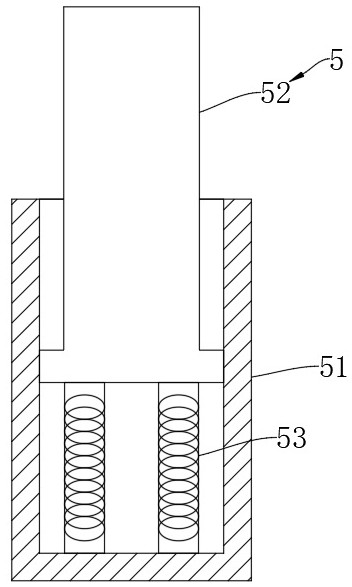

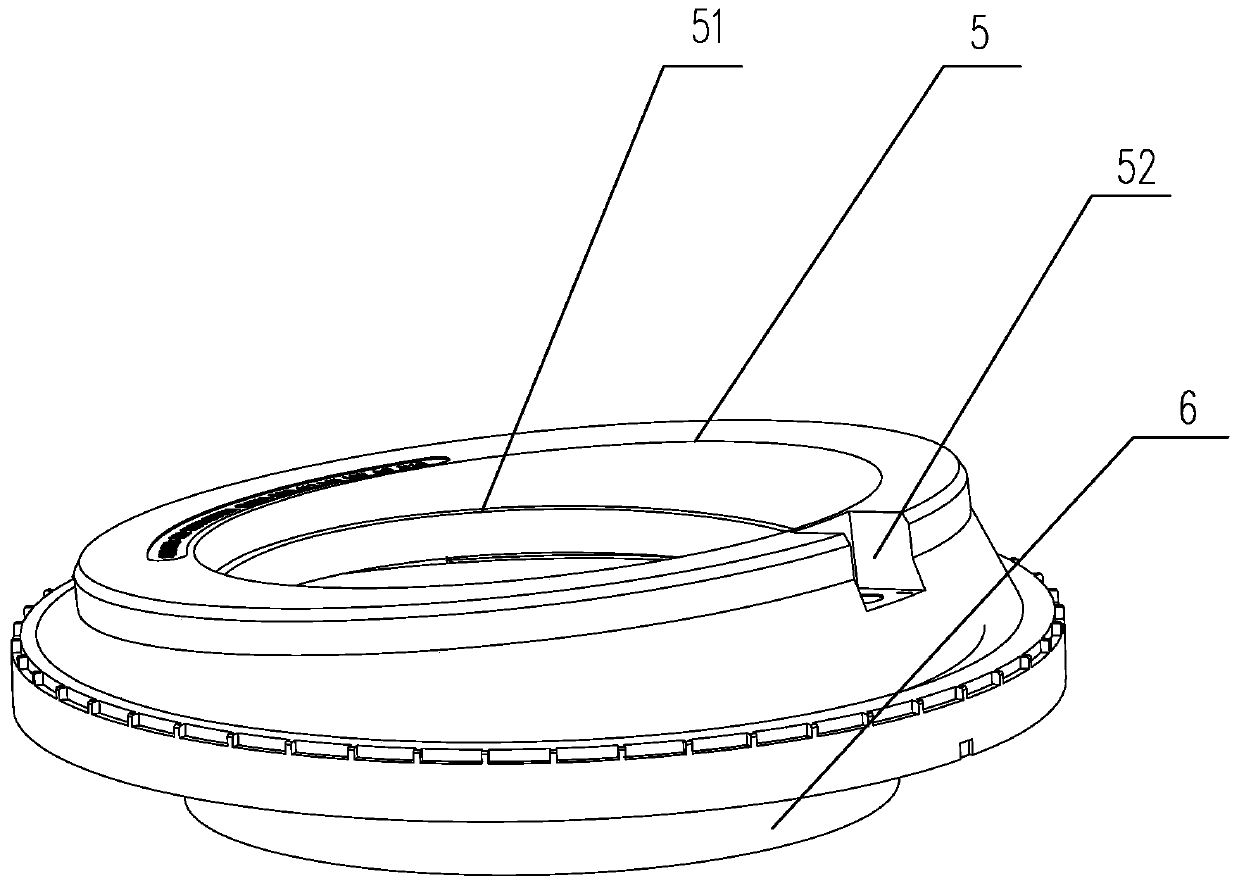

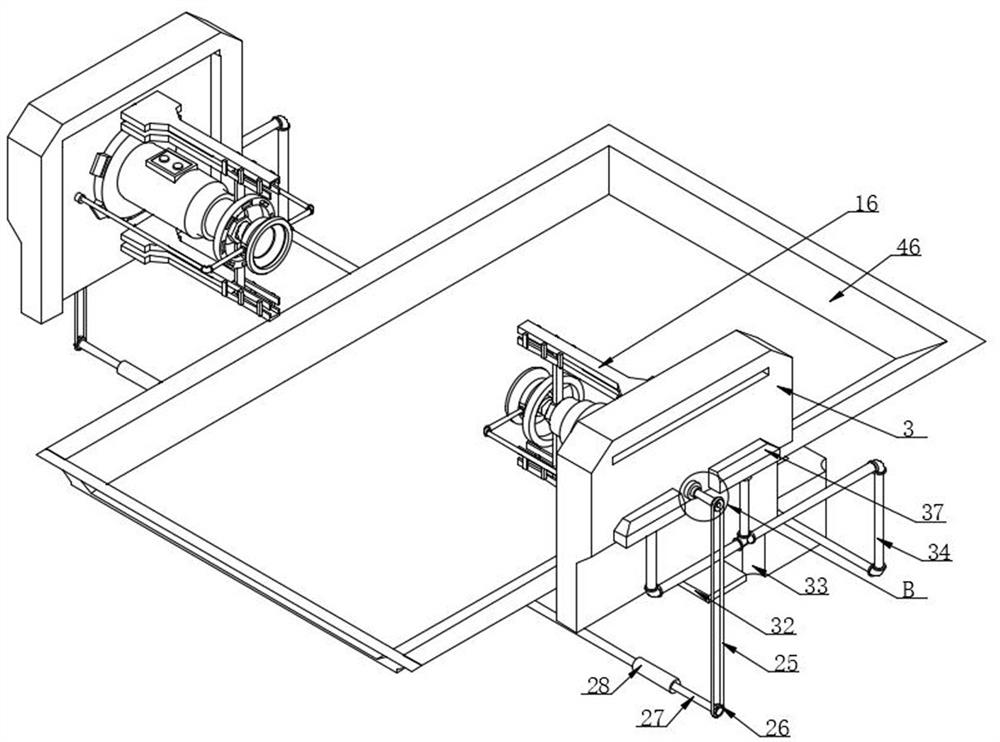

Plastic cap holding linkage clamping rotary capping machine

The invention discloses a plastic cap holding linkage clamping rotary capping machine. The plastic cap holding linkage clamping rotary capping machine comprises a machine base, wherein the machine base is provided with a conveyor belt, and the plastic cap holding linkage clamping rotary capping machine is characterized in that a holding mechanism which can hold and fix lower caps is arranged on the machine base on one side of the conveyor belt, a material pushing mechanism which can send plastic caps on the conveyor belt into the holding mechanism is arranged on the machine base on the other side of the conveyor belt, and the plastic cap holding linkage clamping rotary capping machine which can hold upper caps and screw the upper caps on the lower caps is arranged on the machine base on one side of the holding mechanism. The invention aims at overcoming the shortcomings of the prior art and providing the plastic cap holding linkage clamping rotary capping machine with the advantages of simple structure, long service life and low production cost.

Owner:中粮包装(广州)塑胶有限公司

Ball Joint

InactiveUS20060193680A1Improve sealingImprove wear resistanceCouplings for rigid shaftsPivotal connectionsEngineeringBall joint

Owner:SOMIC ISHIKAWA INC

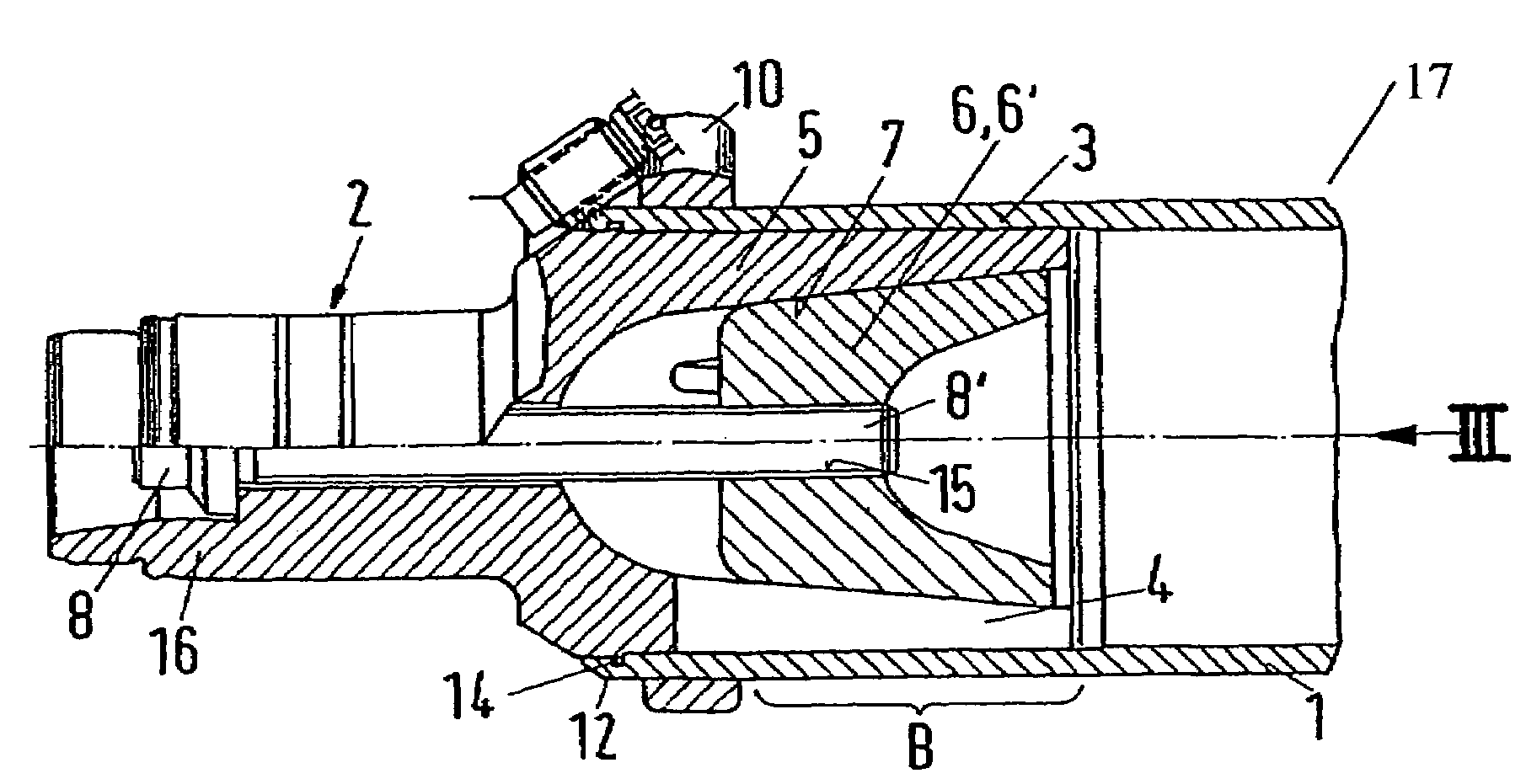

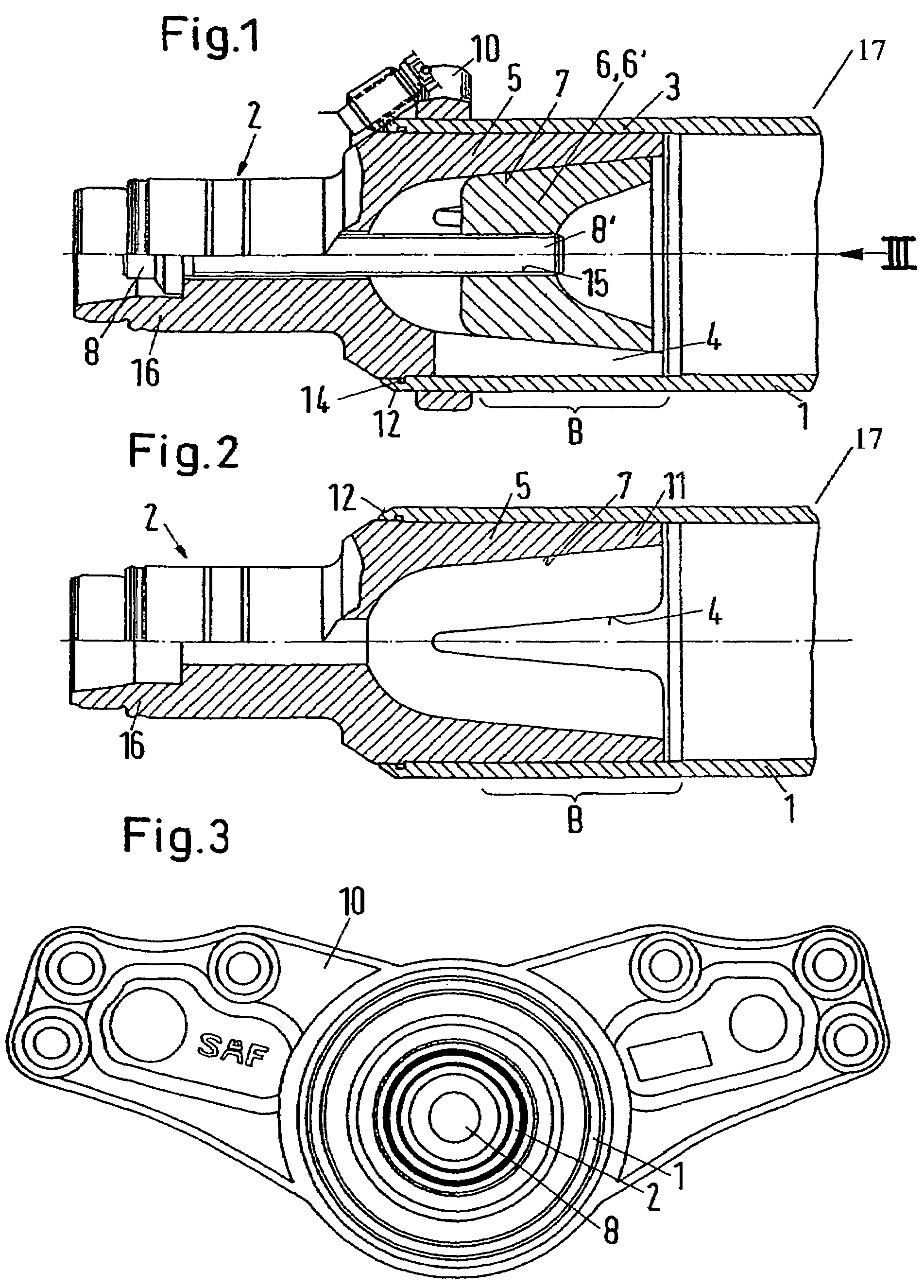

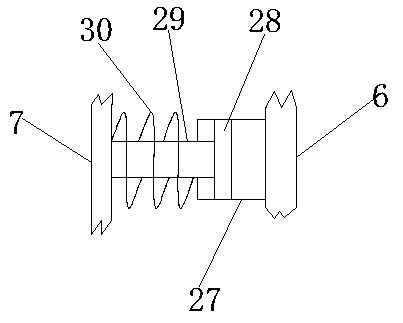

Axle journal mounted to axle tube and method of assembly

InactiveUS7484813B2Secure absorption of radial expansion forceReliable functionSuspensionsWheel manufactureEngineeringMechanical engineering

The invention concerns a method for mounting a wheel on an axle housing in the form of an axle tube (1) for vehicles, in particular commercial vehicles, whereby the wheel is fixed e.g. with wheel bolts to a wheel hub, rotating on the axle journal (2) of the axle tube (1). The axle journal (2) is clamped on to an end section (3) of the axle tube (1) as a separate component. For simplicity of manufacture and assembly combined with functional durability it is proposed that the end section (3) of the axle tube (1) is cylindrical on the inside and that the axle stub (2) fits into the end section (3) of the axle tube (1) with an externally corresponding cylindrical connecting section (5). Further, the end section (3) of the axle tube (1) is radially clamped on to the connecting section (5) of the axle stub (2) by at least one clamping piece (6) that is adjustable in an axial direction to the end (12) of the axle tube (1) by a threaded bolt (8).

Owner:SAF HOLLAND GMBH

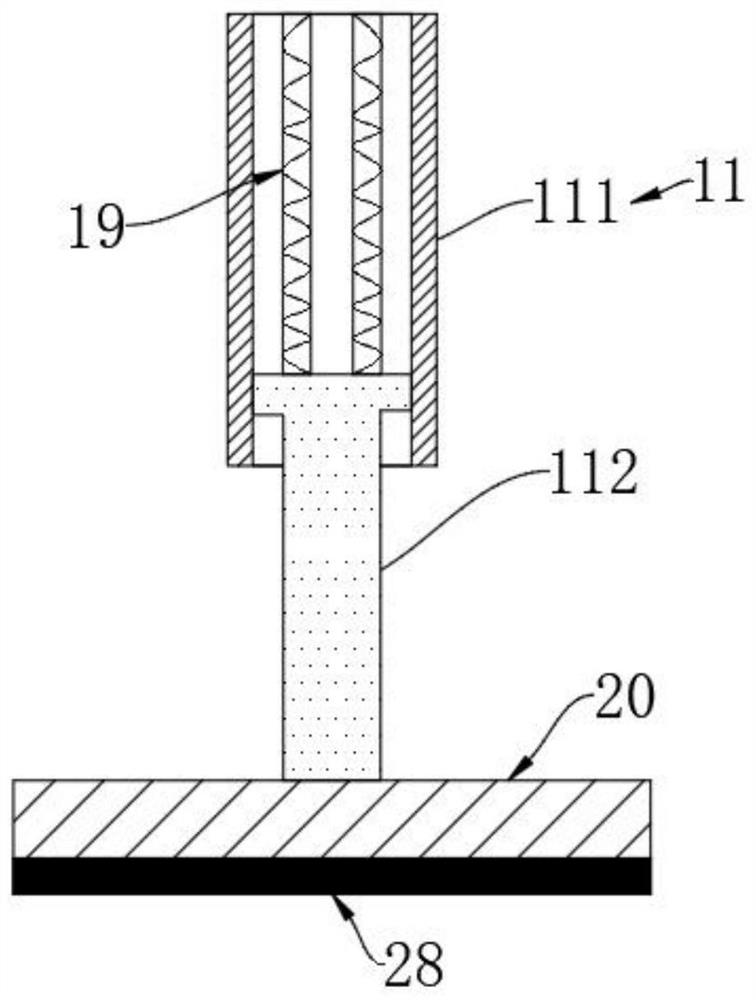

Plate cutting device capable of achieving automatic stabilization and self-cleaning

PendingCN112792925ALow costAvoid pollutionProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringFan blade

The invention belongs to the field of plate processing, and particularly relates to a plate cutting device capable of achieving automatic stabilization and self-cleaning. The plate cutting device comprises a workbench, two symmetrically-arranged placement blocks are fixedly connected to the workbench, a support is fixedly connected to the workbench, two symmetrically-arranged reciprocating lead screws are rotatably connected to a portion between the support and the workbench, sleeves are connected to the reciprocating lead screws in a threaded manner, and a frame is fixedly connected to a position between the two sleeves. According to the plate cutting device capable of achieving automatic stabilization and self-cleaning, through cooperation of a first linkage mechanism, a second linkage mechanism and a driving mechanism, a cutting knife and a pressing plate can be matched with air suction fan blades to synchronously work, and therefore it is guaranteed that the pressing plate presses a wood board in the cutting process, the wood board is kept stable, and manpower consumption is avoided; and meanwhile, in the cutting process, chippings generated by air suction of the air suction fan blades can be utilized, and therefore the situation that the chippings fly randomly and pollute the surrounding environment is avoided.

Owner:李炀炀

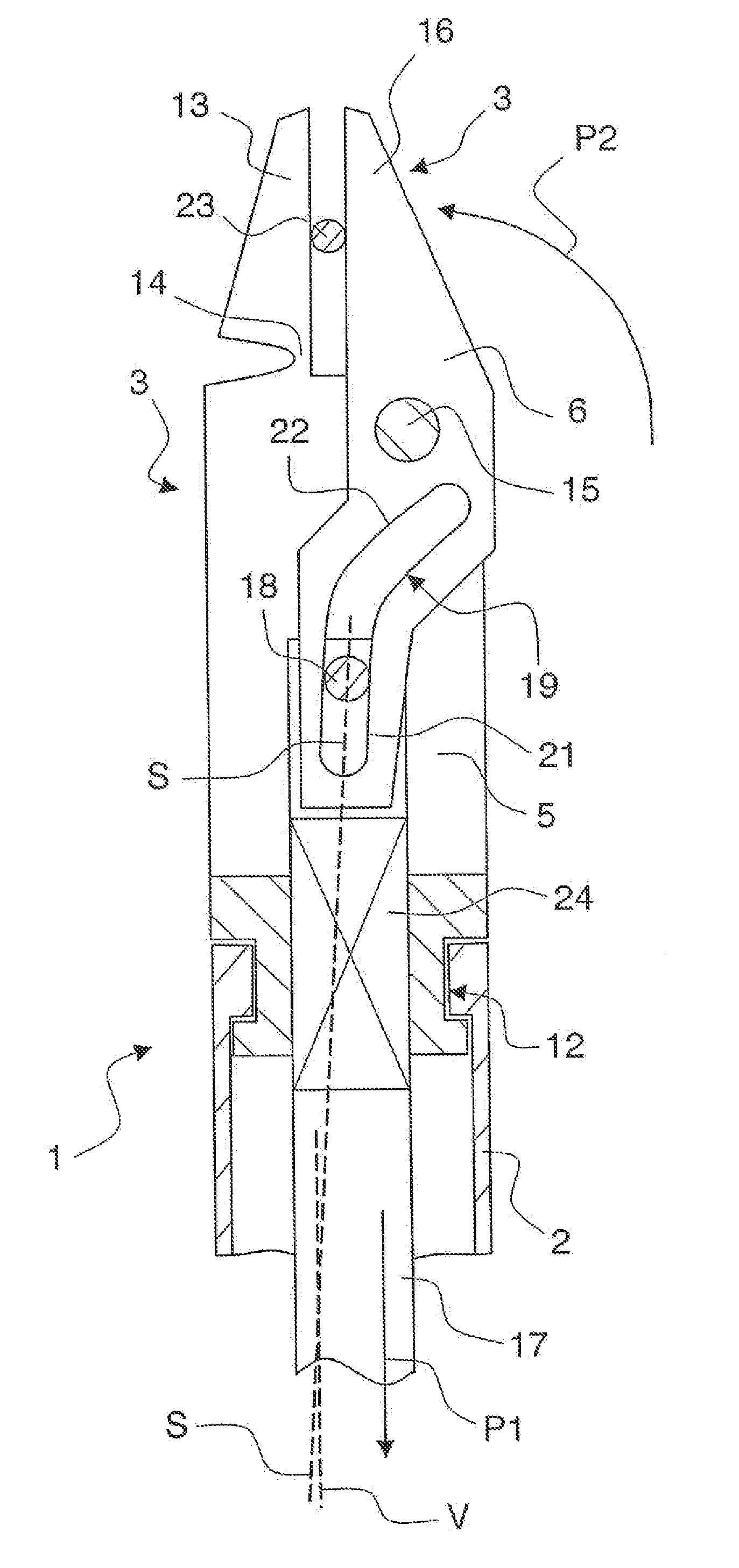

Surgical forceps having engagement in a groove

InactiveUS20120232580A1Enhancing possible usSmooth rotationSurgical needlesSurgical forcepsForcepsSelf locking

Surgical forceps are provided having an elongated shaft which at its distal end bears a forceps jaw having two jaw parts which are movable relative to one another, and at its proximal end bears an actuating handle which by means of a longitudinally displaceable actuating rod that passes through the shaft controls the relative motion of the jaw parts via the engagement of at least one cam on the forceps jaw or on the actuating rod in a groove which is inclined at an angle with respect to the direction of displacement of the actuating rod on the shaft or on the forceps jaw. The groove is provided, at least in one section, with an angle of inclination which is smaller than the angle of inclination up to which self-locking in the groove occurs.

Owner:OLYMPUS WINTER & IBE

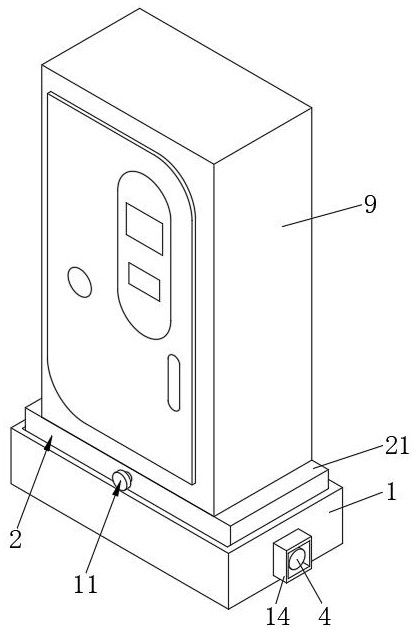

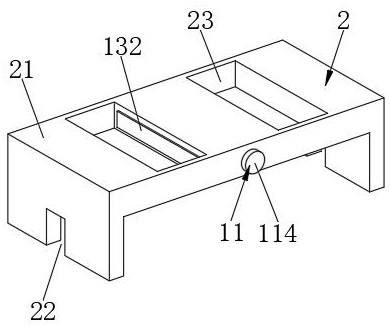

New energy automobile charging pile mounting structure

InactiveCN112319285AEasy to installEasy to prevent standing waterCharging stationsElectric vehicle charging technologyElectrical and Electronics engineeringNew energy

The invention discloses a new energy automobile charging pile mounting structure, and the structure comprises a mounting base and a charging pile body; a placement mechanism is arranged in an inner cavity of the mounting base, a bidirectional threaded rod is movably connected to the left side of the inner cavity of the mounting base through a bearing, and opposite threads are arranged on the surface of the bidirectional threaded rod. The two mounting blocks are placed in the inner cavities of the two mounting grooves correspondingly, the second knob is rotated, the second knob finally drives the second wedge block to enter the inner cavity of the strip-shaped groove to lock the two mounting blocks, and the first knob and the first knob are rotated to finally drive the mounting frame and the charging pile body to ascend, so that the purposes of convenient mounting and water accumulation prevention are achieved; the new energy automobile charging pile installation structure has the advantages of being convenient to install and capable of preventing water accumulation, cement does not need to be adopted for pouring, the function of rapid disassembly and assembly is achieved, the lifting height of the charging pile can be conveniently controlled according to the installation position, and the charging pile is not prone to being soaked by accumulated water.

Owner:郭连坤

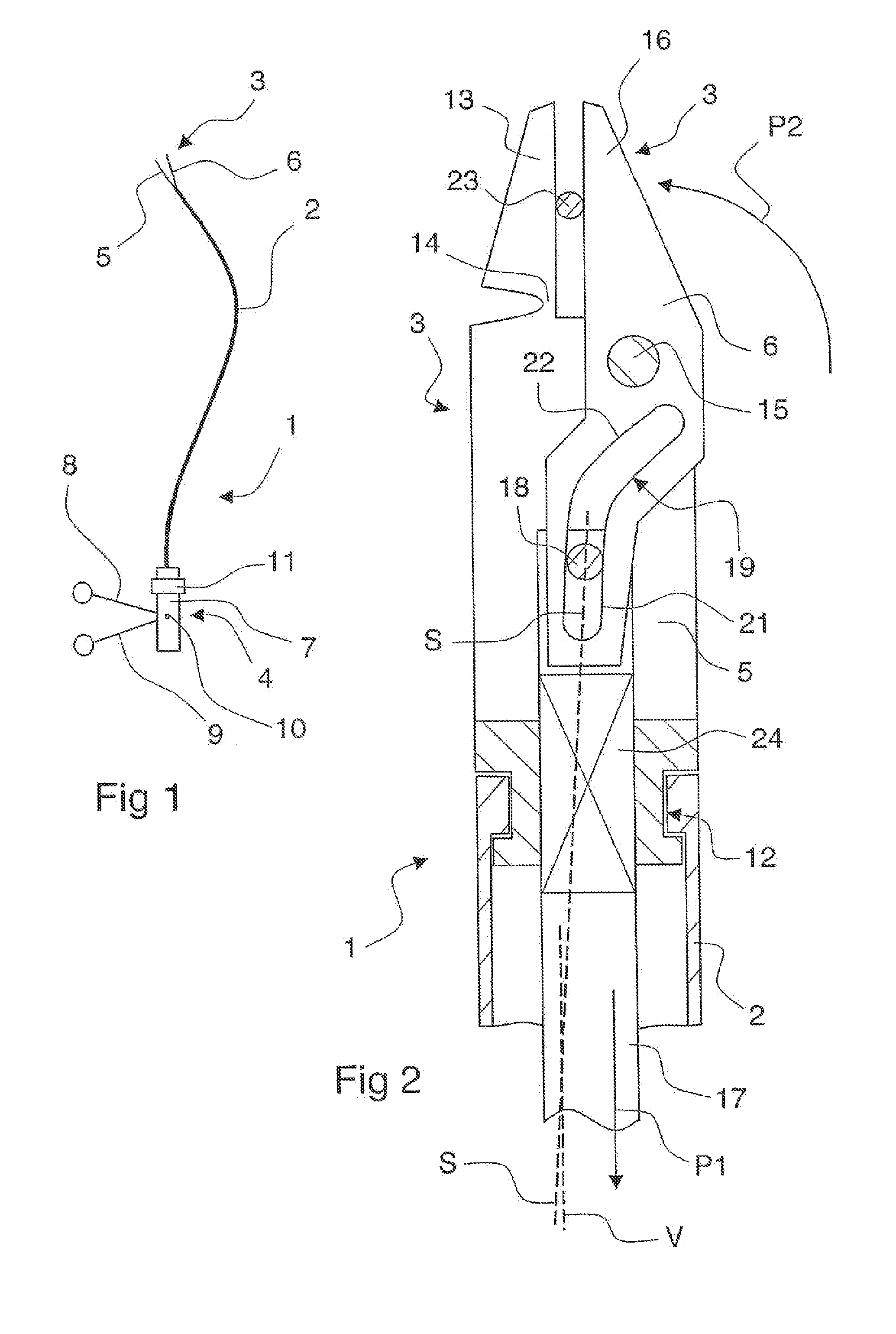

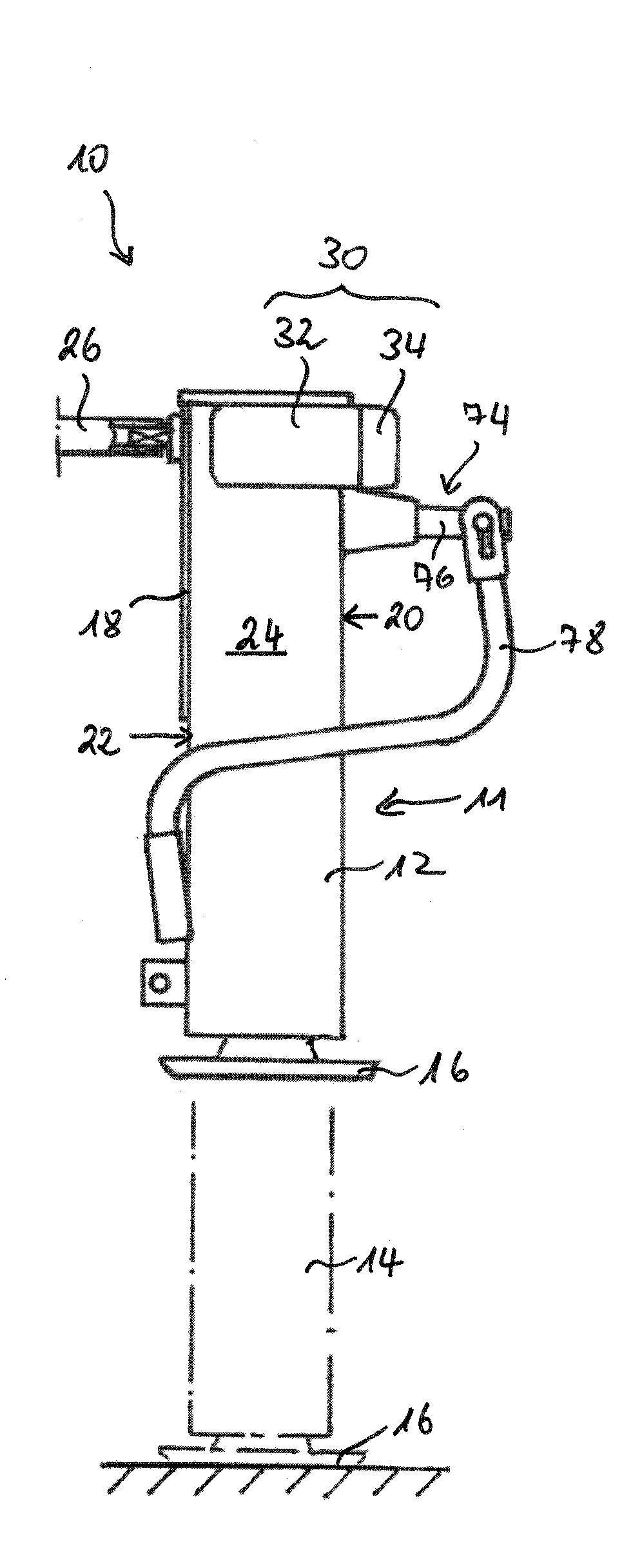

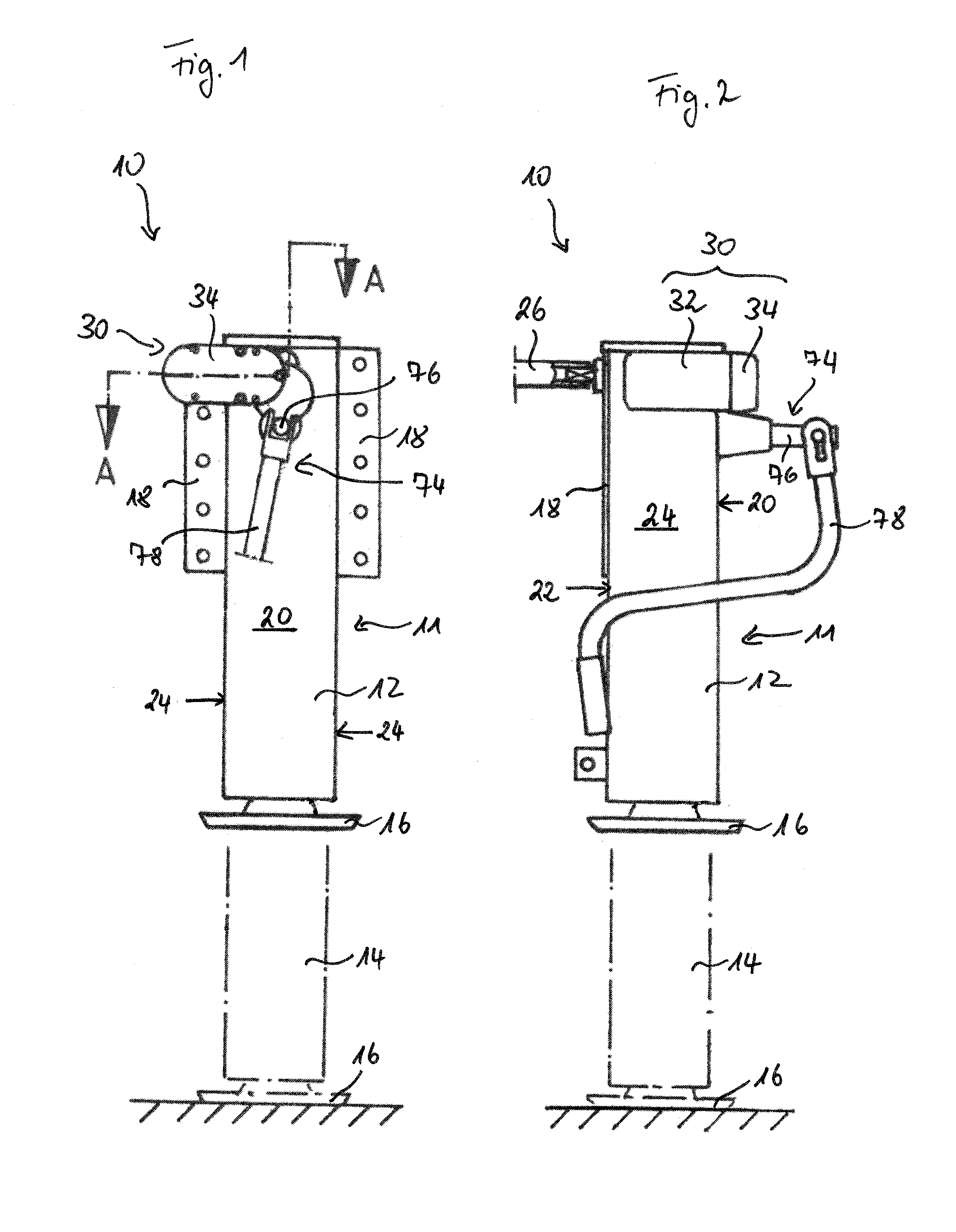

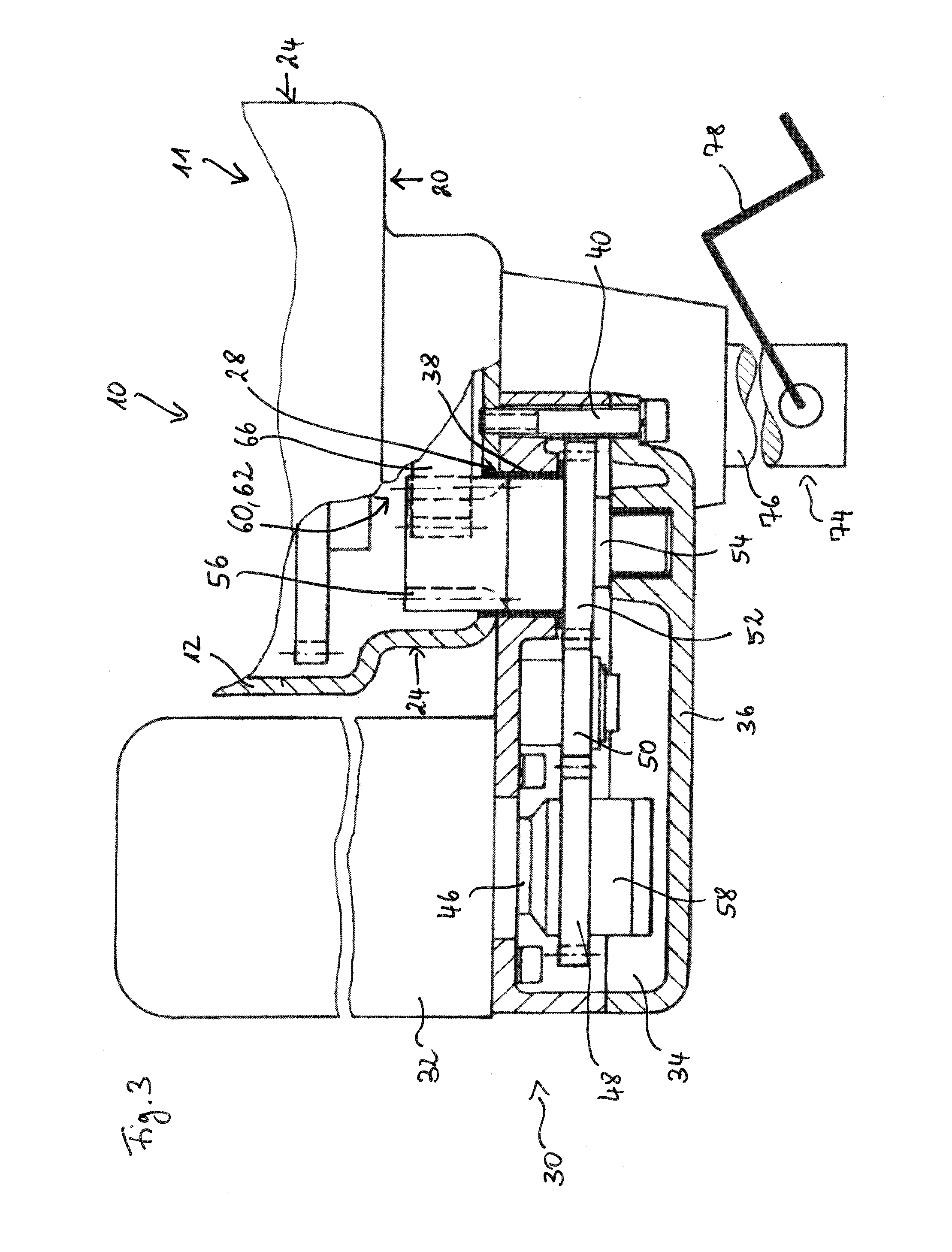

Height-Adjustable Support For a Vehicle

ActiveUS20160264107A1Easy accessAvoid damageVehicle fittings for liftingLifting devicesMotor shaftEngineering

A height-adjustable support for a vehicle having an outer support pipe, an inner support pipe displaceably supported in the outer support pipe and deployable out of and retractable into the outer support pipe by a drive spindle, a gear unit arranged in the outer support pipe and a drive unit for driving the gear unit for moving the inner support pipe relative to the outer support pipe, wherein the drive unit has a motor arranged outside the cross section of the outer support pipe and a transmission unit, wherein a rotation axis defined by a motor shaft extends outside the outer support pipe and the transmission unit is configured to transmit a torque from the motor shaft to the gear unit, and wherein the transmission unit has a housing and a drive pinion protruding out of the housing and engaging the gear unit.

Owner:SAF HOLLAND GMBH

Vehicle power transmission device

ActiveUS9523417B2Easy to reduce in sizeIncreased durabilityGearingTransmission elementsTorque transmissionGear train

Owner:AISIN CORP

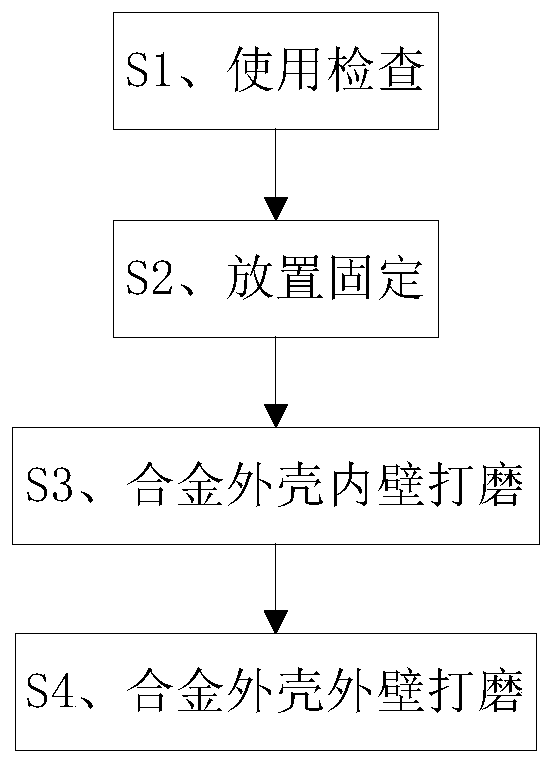

Precision treatment process after molding of alloy shell of electric motor

ActiveCN111390692AGuaranteed precisionQuality improvementEdge grinding machinesGrinding drivesAlloyMaterials science

The invention relates to a precision treatment process after the molding of an alloy shell of an electric motor. The precision treatment process is mainly completed in cooperation with an after-molding precision treatment device for the alloy shell of the electric motor. The after-molding precision treatment device for the alloy shell of the electric motor comprises a bracket, wherein the top of bracket is fixedly connected to a fixing groove; the inner side of the fixing groove is symmetrically provided with No. 1 telescopic racks in an insertion manner; No. 2 telescopic racks are symmetrically arranged on the inner side of the fixing groove and above the No. 1 telescopic racks in the insertion manner; the No. 1 telescopic racks and the No. 2 telescopic racks are all arranged in a staggering manner; certain ends of the No. 1 telescopic racks and the No. 2 telescopic racks are all fixedly connected to clamp plates; certain sides of the clamp plates are all fixedly connected to a plurality of No. 1 scraping strips; and certain ends, arranged in the fixing groove in the insertion manner, of the No. 1 telescopic racks and the No. 2 telescopic racks are all fixedly connected to No. 1 springs. The after-molding precision treatment device is simple in structure, can be used for performing precision treatment on the inner and outer walls of the alloy shell of the electric motor at thesame time, and is suitable to popularize.

Owner:湖南锐毅马达制造有限公司

Auxiliary drive wheel-side differential unit for four-wheel drive vehicle

ActiveUS9695885B2Prevent stateAvoid synchronous rotationMagnetically actuated clutchesInterengaging clutchesDrive wheelPropeller

A movable sleeve of a second clutch is provided between a cylindrical ring gear and a cylindrical shaft of a differential case of a differential gear unit. In a disconnect mode in which a propeller shaft is disconnected from rear wheels, the cylindrical ring gear is disconnected from the differential case by the movable sleeve of the second clutch. Thus, in the disconnect mode, a fully differential state of the differential gear unit is prevented.

Owner:JTEKT CORP

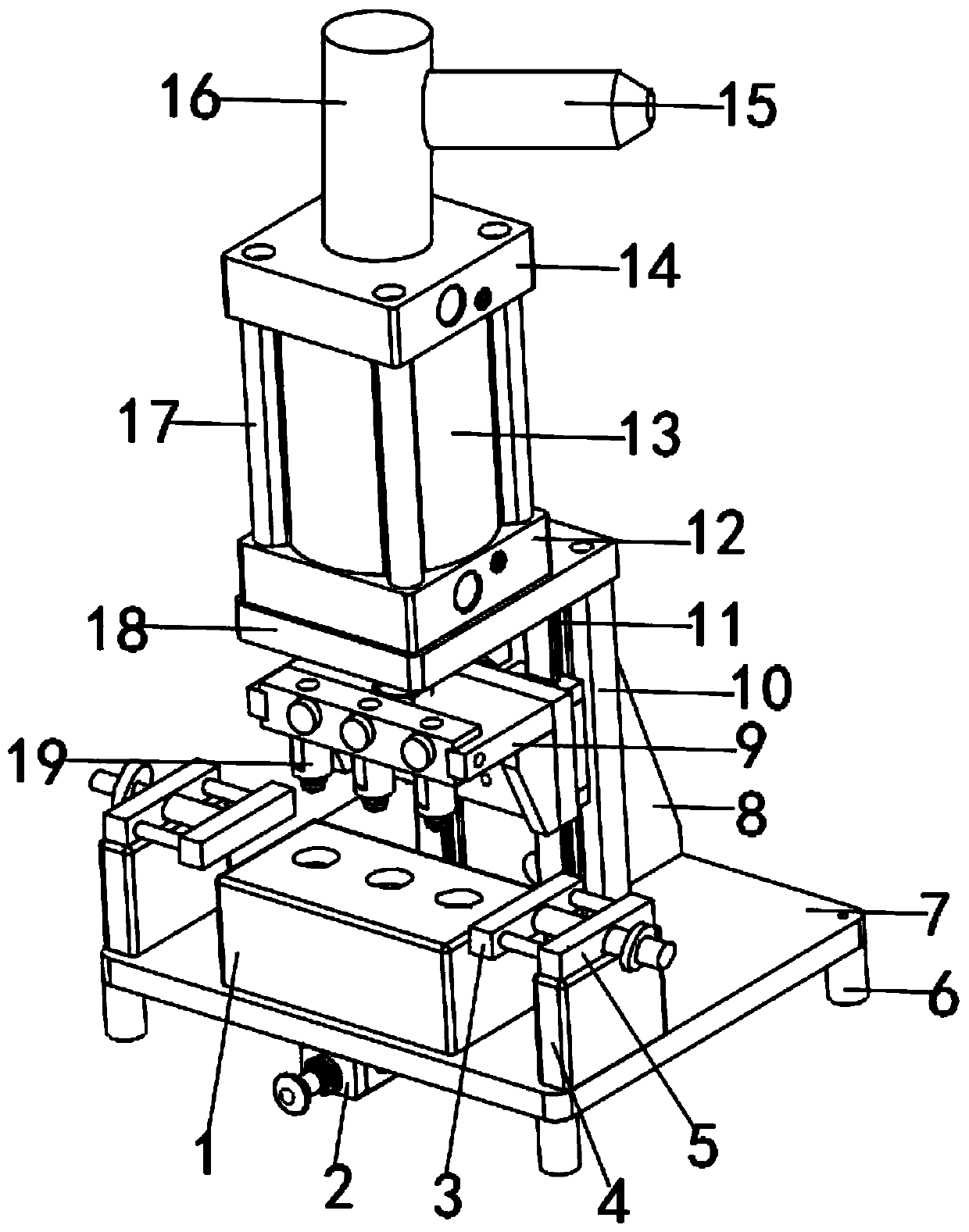

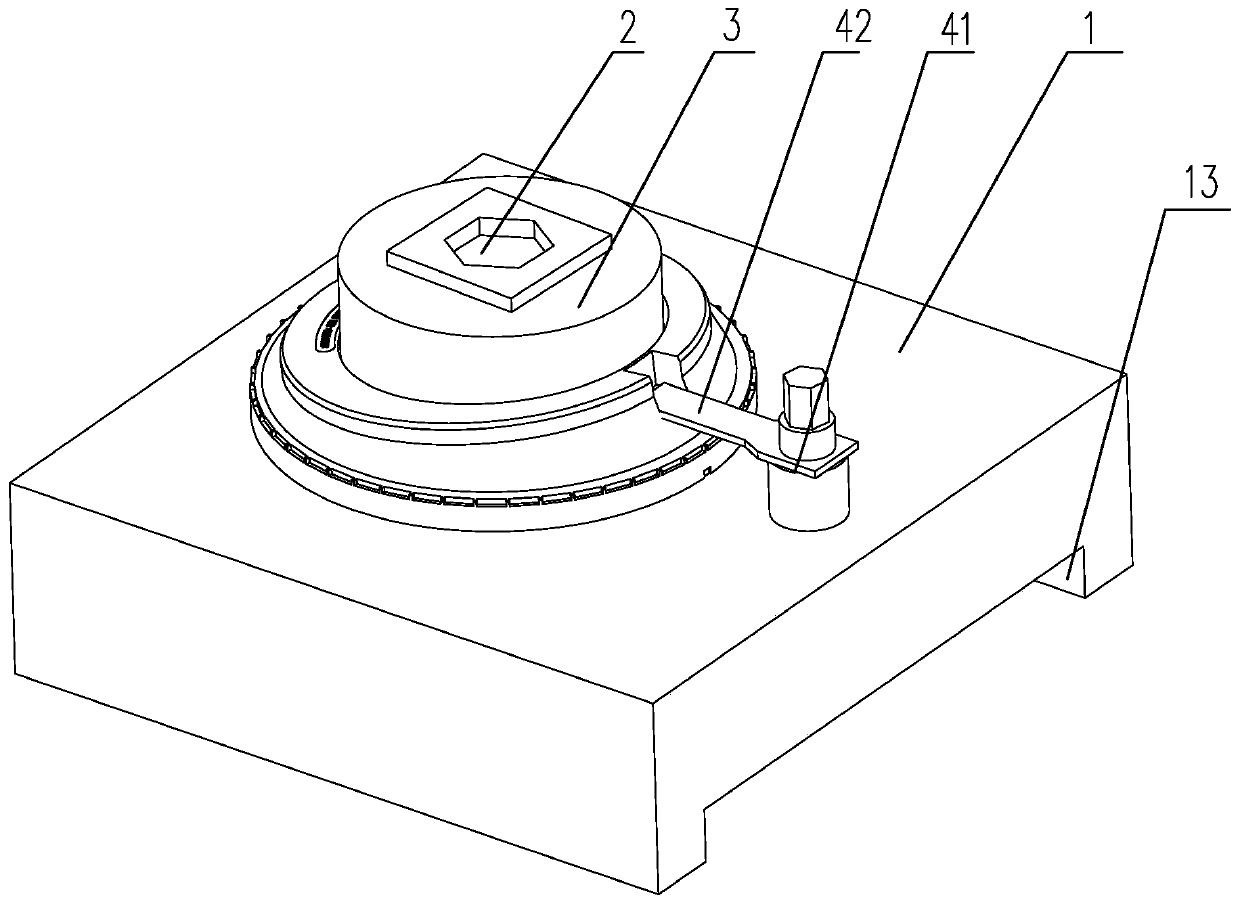

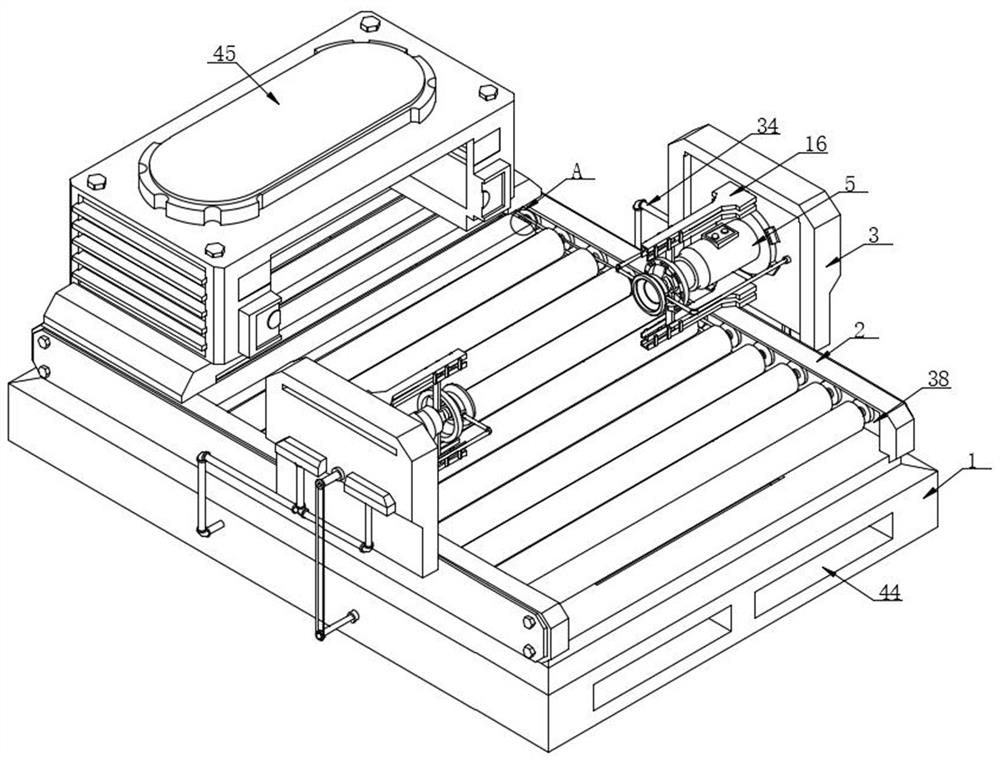

Surface grinding equipment for stud bolt processing

ActiveCN113319698BPlay a fixed roleAvoid synchronous rotationGrinding drivesGrinding machinesEngineeringSurface grinding

The invention discloses surface grinding equipment based on double-head bolt processing, and the invention belongs to the technical field of bolt processing. It includes a fixed base and a grinding disc. The grinding disc is movably installed on the upper part of the fixed base. A rotating collar is movably installed in the middle of the outer surface of the upper end of the fixed base, and the inner side of the rotating collar is fixedly socketed. To install the splicing chuck of the stud bolt, the upper part of the fixed base close to the side of the rotating collar is movably installed with a driving hand wheel for driving the rotating collar to rotate; when the stud bolt is ground, the grinding disc is driven by the motor Rotate, so that the grinding disc can complete the grinding operation of multiple sets of stud bolts at the same time, and when the grinding disc rotates, the user can insert the positioning rod of the driving hand wheel into the circular slot on the fixed base, It can fix the rotating collar and use the setting of the splicing chuck to complete the grinding operation of multiple stud bolts at one time, improving its work efficiency.

Owner:烟台佑利技术有限公司

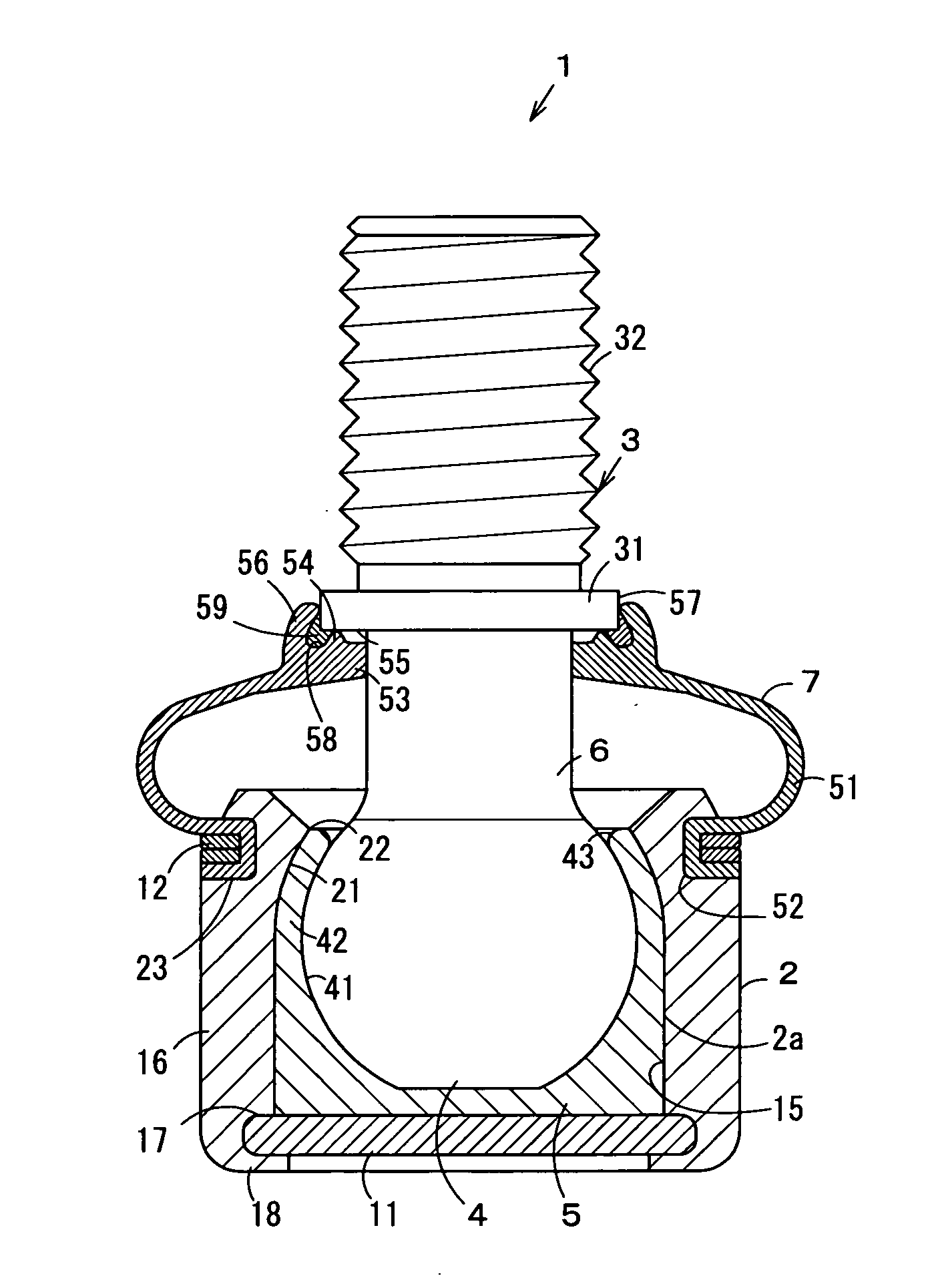

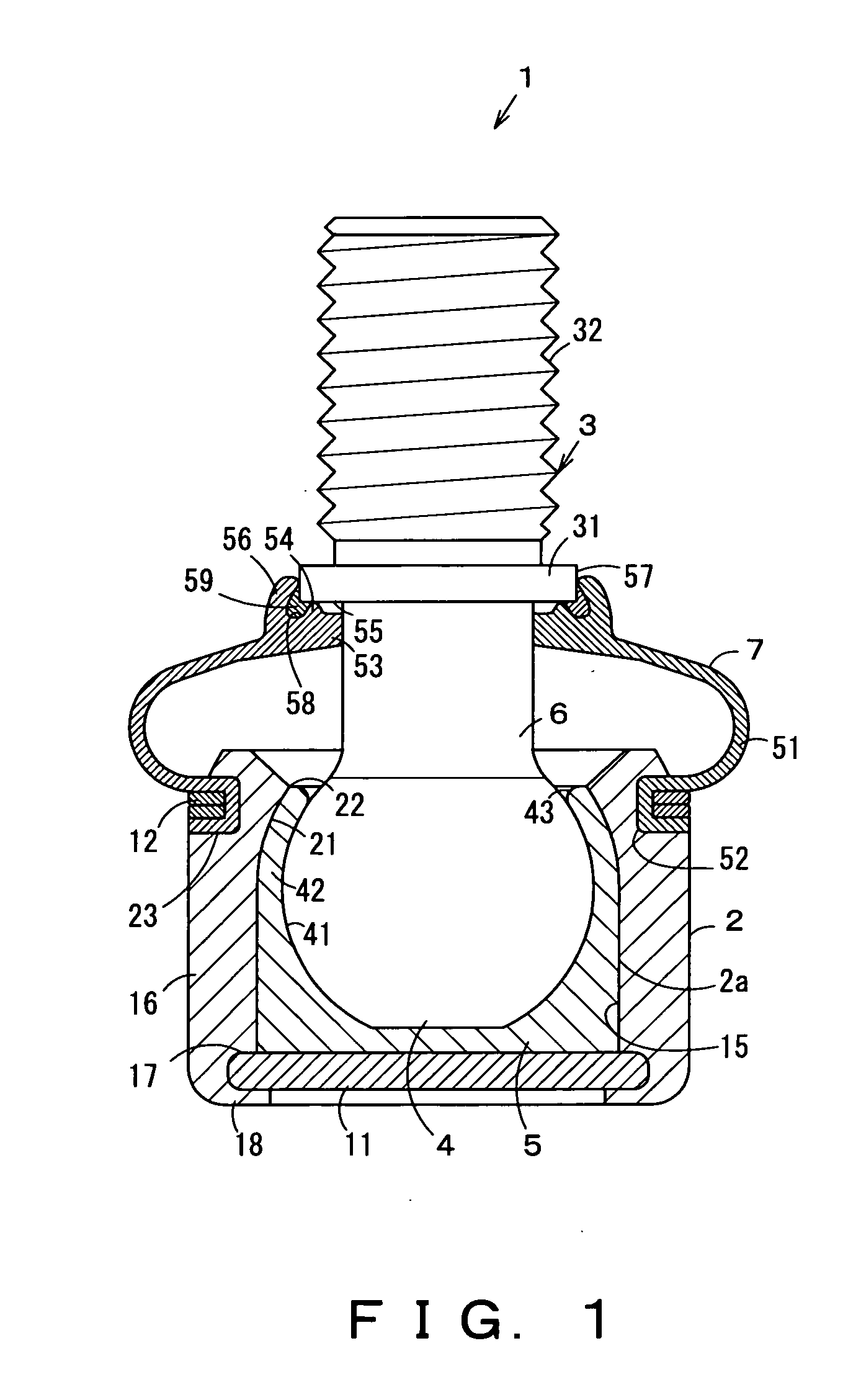

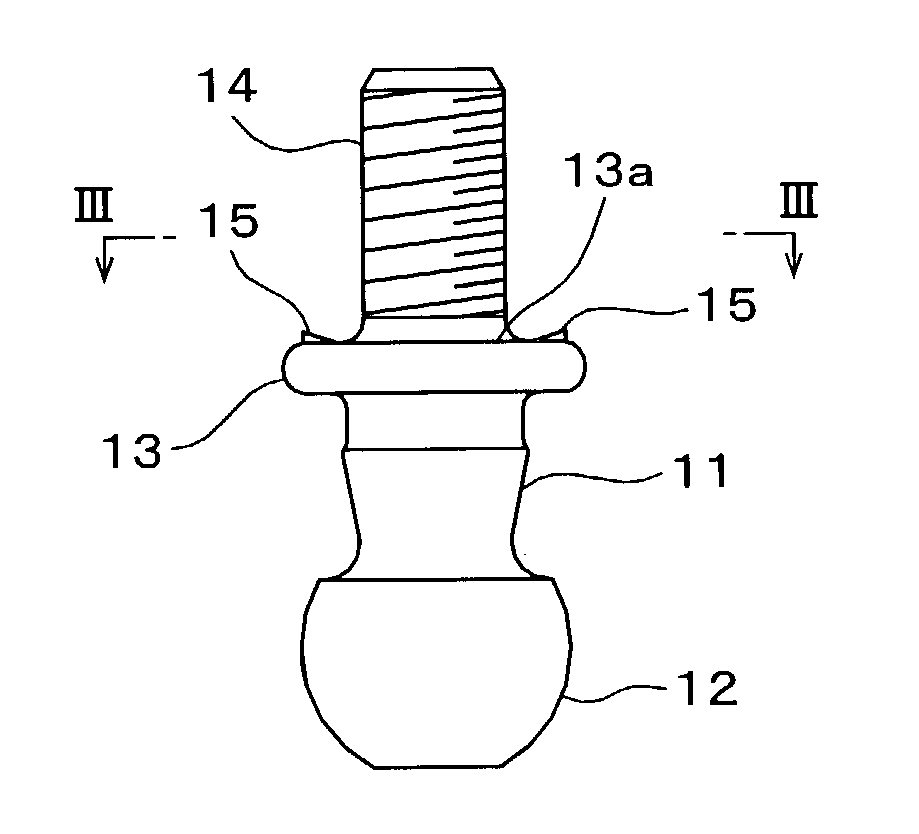

Ball joint

ActiveUS8142097B2Avoid synchronous rotationEasy to installSuspensionsCouplings for rigid shaftsBall joint

A ball joint comprises a ball stud having a stud portion at a middle thereof, a ball portion and a screw portion at opposite sides of the stud portion, and a seat surface portion facing the screw portion between the respective portions, and a bearing member into which the ball portion is slidably fitted so as to universally pivotably-support the ball stud, so that the stud portion is inserted through a mounting member, and a nut is screwed with the screw portion projected from the mounting member, and the seat surface portion abuts and is fastened to the mounting member by fastening the nut to the mounting member. The seat surface portion abutting the mounting member is subjected to a co-rotation preventing process which prevents the ball stud from co-rotating along with the nut when the nut is fastened.

Owner:NHK SPRING CO LTD

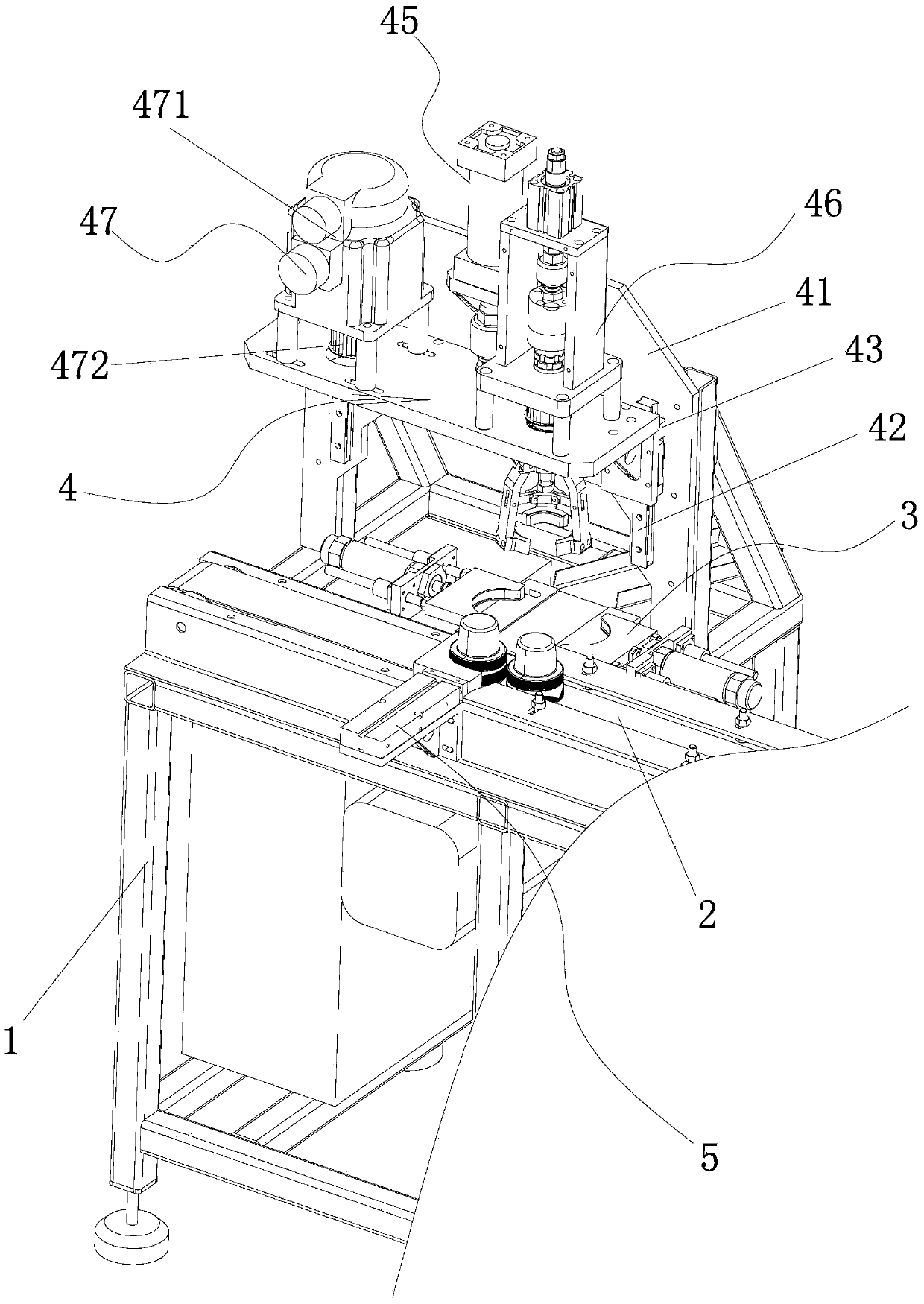

Stepping tapping device for ear tag injection molded part

ActiveCN107999897AImprove coherenceStepping wire implementationPrecision positioning equipmentThread cutting feeding devicesEar tagEngineering

The invention discloses a stepping tapping device for an ear tag injection molded part. The stepping tapping device comprises a base plate, a motor, a rocker, a driving rod and a turntable frame; a limiting guide support is arranged at the corner of the base plate; a guide column is arranged on the limiting guide support; a pneumatic tapping machine is arranged in the middle of the edge of the base plate; the motor is connected to the lower end of the base plate through bolts; one end of the rocker is connected to an output shaft of the motor, and the other end of the rocker is hinged to the lower part of the drive rod; a long groove is formed in the driving rod and can slide under the limit of the guide column; and the turntable frame is connected to the base plate in a rotating mode. Thestepping tapping device has the advantages that the stepping tapping operation can be carried out after a male ear tag body is subjected to injection molding, the tapping efficiency is high, the thread consistency is good, and the adjustment of changing the thickness of a tag pole of the male ear tag body can be facilitated.

Owner:HEBEI BOCHEN HUSBANDRY TECH CO LTD

Device for correcting position of part for winding coating machine and working method thereof

PendingCN110747443AAvoid synchronous rotationHigh flexibilityVacuum evaporation coatingSputtering coatingButt jointIndustrial engineering

The invention discloses a device for correcting the position of a part for a winding coating machine and a working method thereof. The device comprises a butt joint baseplate, a lifting clamping seatand a butt joint fixture, wherein a fixing base is fixedly arranged on the outer surface of the upper end of the butt joint baseplate; fixed supporting plates are fixedly arranged at the two sides, close to the fixing base, of the outer surface of the upper end of the butt joint baseplate; butt joint clamping seats are fixedly arranged on the outer surfaces of the upper ends of the fixed supporting plates; a moving clamping strip is movably arranged at one side of each butt joint clamping seat; two groups of expansion links are fixedly arranged on the outer surface of the upper end of each moving clamping strip; the inner surfaces of the inner sides of the butt joint clamping seats are movably in sleeve connection with threaded rods; and the butt joint clamping seats and the moving clamping strips are in butt joint and fixed through the threaded rods. The device for correcting the position of the part for the winding coating machine has a regulating type fixed structure, so that the range of application of the device is widened; and meanwhile the device has a sliding type regulation structure, so that the flexibility of the device in use is improved.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

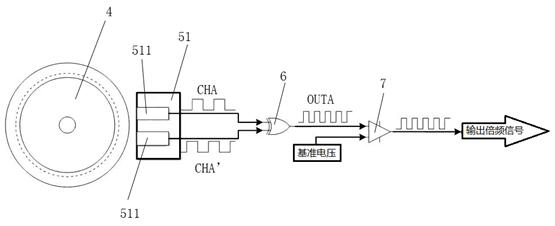

Frequency multiplication method for Hall speed sensor at shaft end

PendingCN113325192AGuaranteed Duty CycleEasy to identifyDevices using electric/magnetic meansHall elementPhase difference

The invention relates to a frequency multiplication method for a Hall speed sensor at a shaft end. According to the method, two square wave signals having the same frequency and output by two Hall elements pass through an exclusive-OR gate to obtain a frequency-multiplied square wave signal; and since the two Hall elements are arranged on the outer periphery of a gear and the projection distance of a connecting line between induction points of the two Hall elements in the rotation direction of the gear is m pi / 4, a phase difference between the two square wave signals with the same frequency is 90 degrees, and the duty ratio of square wave signals obtained after frequency multiplication is 50%, wherein m is the modulus of the gear. According to the invention, the positions of the two Hall elements on the outer periphery of the gear are reasonably arranged, so the phase difference between the two paths of square wave signals with the same frequency before frequency multiplication is 90 degrees, the duty ratio of the square wave signal after frequency multiplication is ensured to be 50%, and high-level time and low-level time in output signals reach the maximum and are thus better identified.

Owner:HUNAN XIANGYI RAILROAD LOCOMOTIVE ELECTRICAL EQUIP

Gas self-service payment machine which is convenient for multiple transports

InactiveCN109131498AImprove firmnessAvoid collisionComplete banking machinesAutomatic teller machinesEngineeringSelf-service

The invention discloses a gas self-service payment machine which is convenient for multiple transports, including a trolley, one side of the trolley is provided with a roller, a first self-service toll machine body and a second self-service toll machine body are respectively arranged on the side of the pushcart away from the roller, a support and fixing device is arrange between that first self-service payment machine body and the second self-service payment machine body, the first self-service toll machine body and the second self-service toll machine body are provided with a fixing plate ona side away from the supporting fixing device, the fixing plate is fixedly connected with the trolley, one side of the fixing plate is provided with a support plate, the support plate and the fixing plate are connected with each other through a shock absorbing device, and a plurality of suction disks are arranged on the side of the support plate far away from the shock absorbing device. The invention has the advantages of realizing multiple transports, avoiding multiple transports, greatly saving time, greatly reducing the labor amount of workers, simple structure, and convenient carrying andusing.

Owner:合肥浮点信息科技有限公司

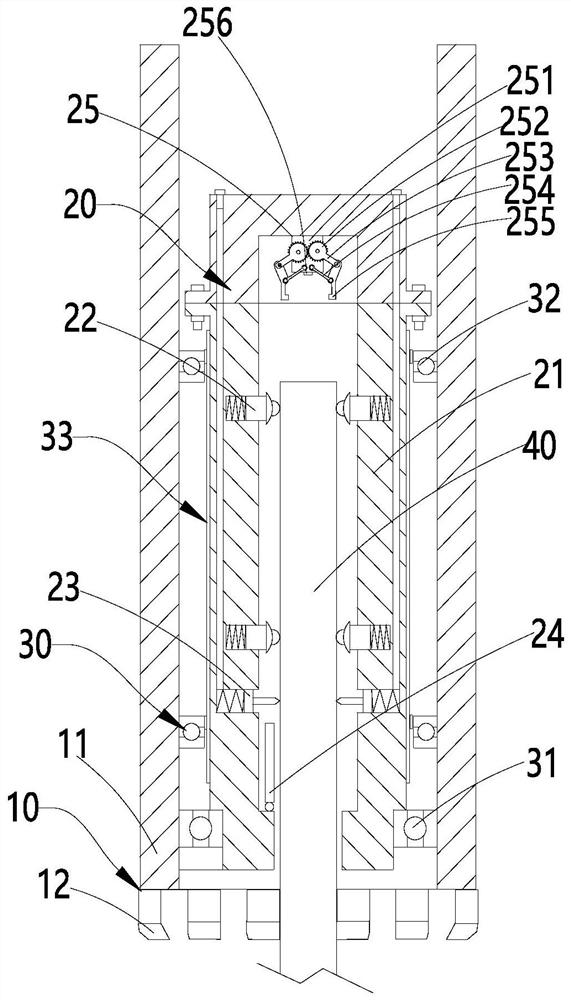

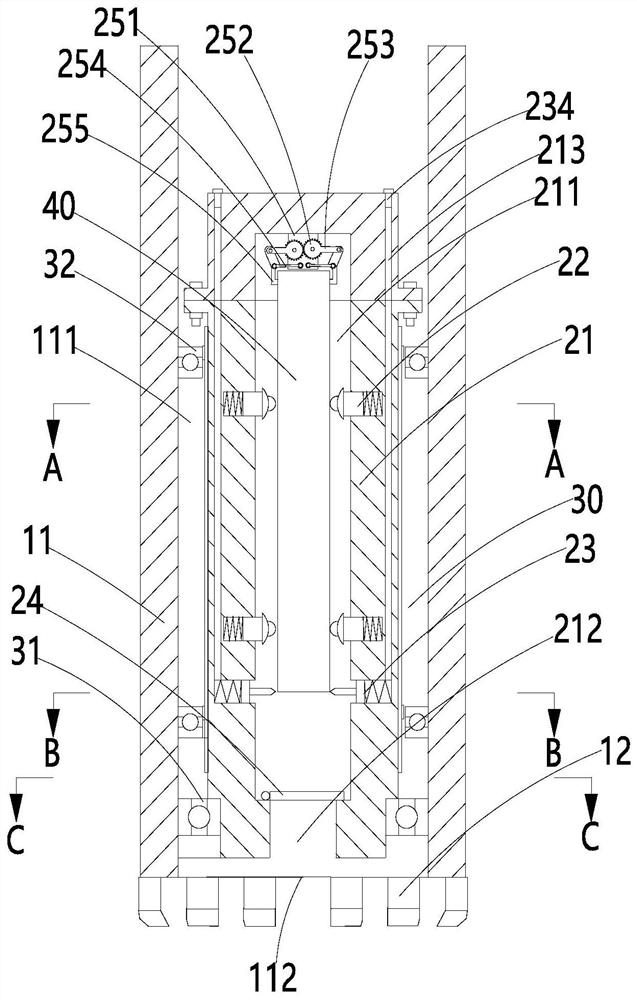

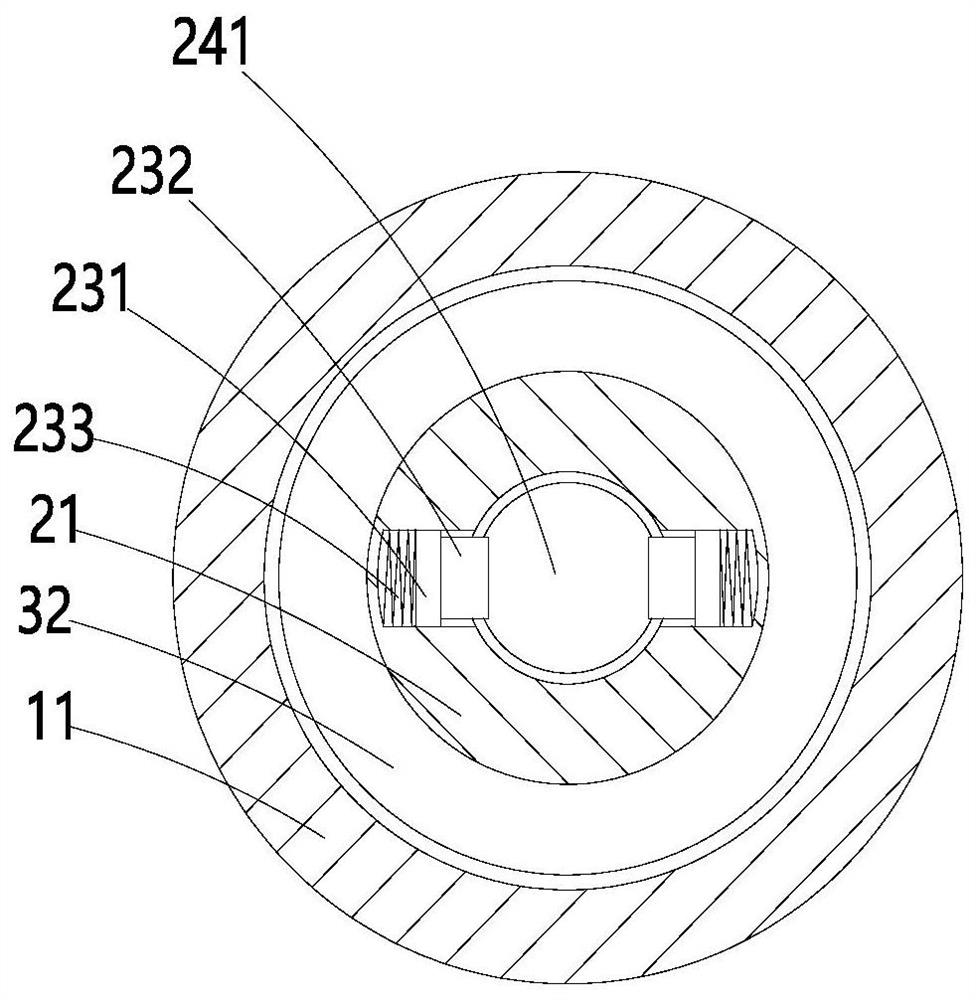

Pressure-maintaining coring device

The invention provides a pressure-maintaining coring device. The pressure-maintaining coring device comprises an outer pipe unit, an inner pipe unit and an anti-twist-off assembly, wherein the outer pipe unit comprises an outer cylinder and a drill bit; a first containing cavity is formed in the outer cylinder. The inner pipe unit comprises an inner cylinder, a shock-proof assembly, a cut-off assembly, a sealing assembly and a clamping assembly. The shock-proof assembly is used for abutting against the outer wall of the rock core entering the second containing cavity so as to eliminate the vibration effect of the inner cylinder on the rock core. And the cutting assembly is used for cutting the rock core entering the second accommodating cavity. And the sealing assembly is used for automatically closing after the cutting assembly cuts the rock core and drives the cut rock core to move upwards in the inner cylinder, so as to seal the second accommodating cavity. The clamping assembly is used for clamping the rock core in the second containing cavity after the rock core is cut. The anti-twist-off assembly is used for eliminating twisting force transmitted from the outer cylinder to the inner cylinder. The pressure-maintaining coring device provided by the invention can effectively protect a rock core, can effectively reflect a real underground condition, and is good in pressure-maintaining coring effect and relatively high in practicability.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Stainless steel plate stamping equipment

InactiveCN113399550AAvoid cumbersomeAvoid lossPerforating toolsShaping safety devicesGear wheelEngineering

The invention belongs to the field of stamping, and particularly relates to stainless steel plate stamping equipment which comprises a workbench, a support is fixedly connected to the workbench, an air cylinder is arranged on the support, the output end of the air cylinder is fixedly connected with a pressing plate, and two buffering mechanisms and a stamping head are fixedly connected to the pressing plate. Sliding rods are fixedly connected to the two buffering mechanisms correspondingly, and the sliding rods are slidably connected with the support. Through cooperation of a toothed bar and a gear, a worm can be matched with up-and-down movement of a stamping head to achieve forward and reverse rotation, under cooperation of a worm gear, a threaded sleeve can be matched with movement of the stamping head to rotate, then a threaded rod can drive a push plate to be matched with automatic sliding in the stamping process, and after stamping is finished, the push plate can be matched with return of the stamping head, the waste materials are automatically pushed out of a receding hole, and tedious manual taking and labor loss are avoided.

Owner:郑晓芳

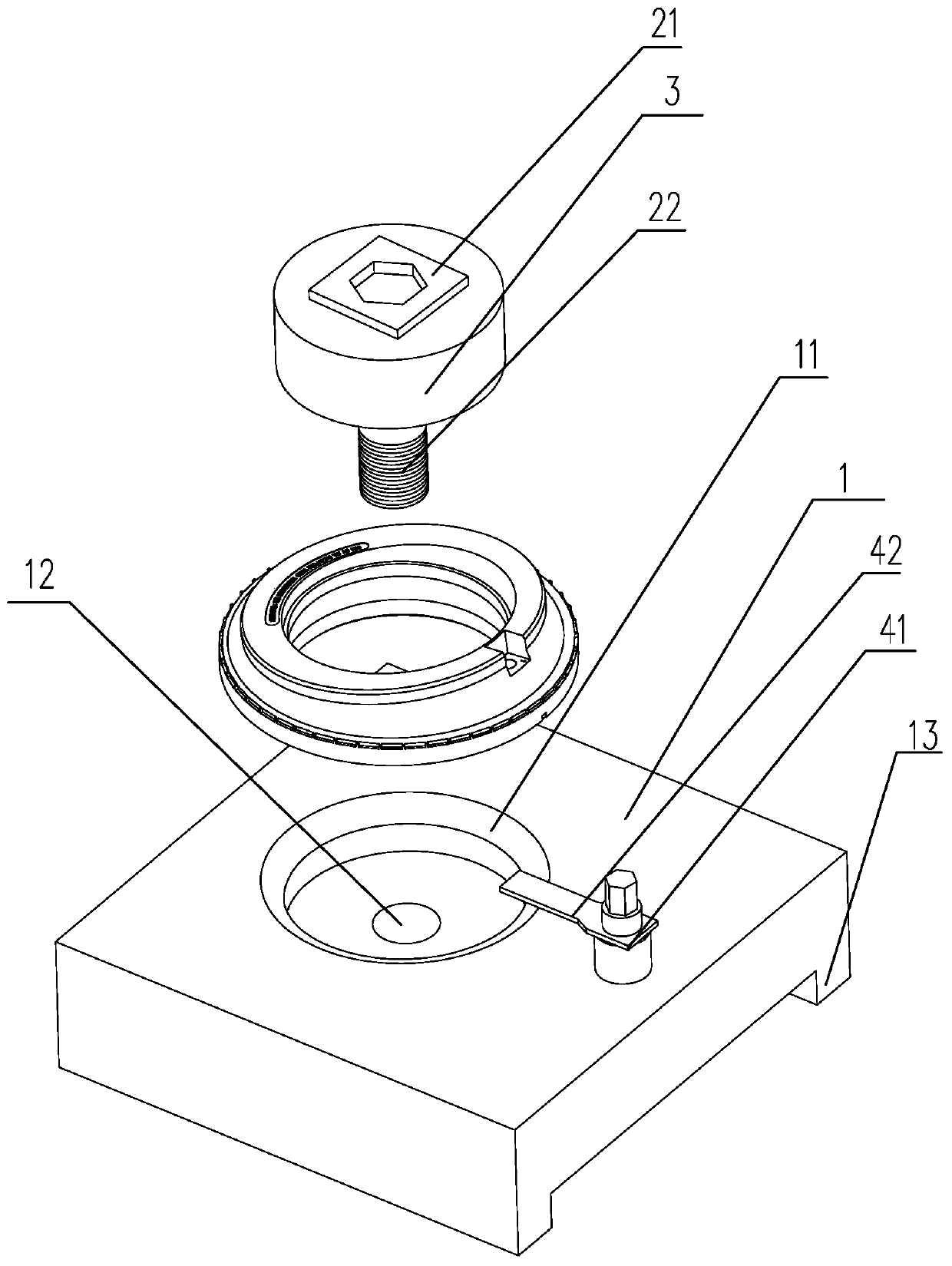

Shock absorber bearing load simulation test device

ActiveCN110726554AEffective simulation testEffective realizationMachine bearings testingSet screwScrew thread

The invention discloses a shock absorber bearing load simulation test device. The shock absorber bearing load simulation test device comprises a base, wherein a mounting groove for mounting a to-be-tested bearing is formed in the base; a positioning hole is formed in the bottom surface of the mounting groove; a positioning screw is in threaded fit with the positioning hole; a positioning disc is arranged on the positioning screw in the circumferential direction; the positioning disc is propped against a step on the inner wall of the outer ring of the to-be-tested bearing to position the to-be-tested bearing; the end part of the positioning screw is connected with a torque meter; and a positioning piece for limiting the rotation of the to-be-tested bearing is further arranged on one side ofthe mounting groove on the base. The shock absorber bearing load simulation test device can effectively perform a simulation test on the shock absorber bearing load, and meanwhile, does not affect the measurement of the flatness and the position degree of an inclined surface.

Owner:C&U CO LTD +1

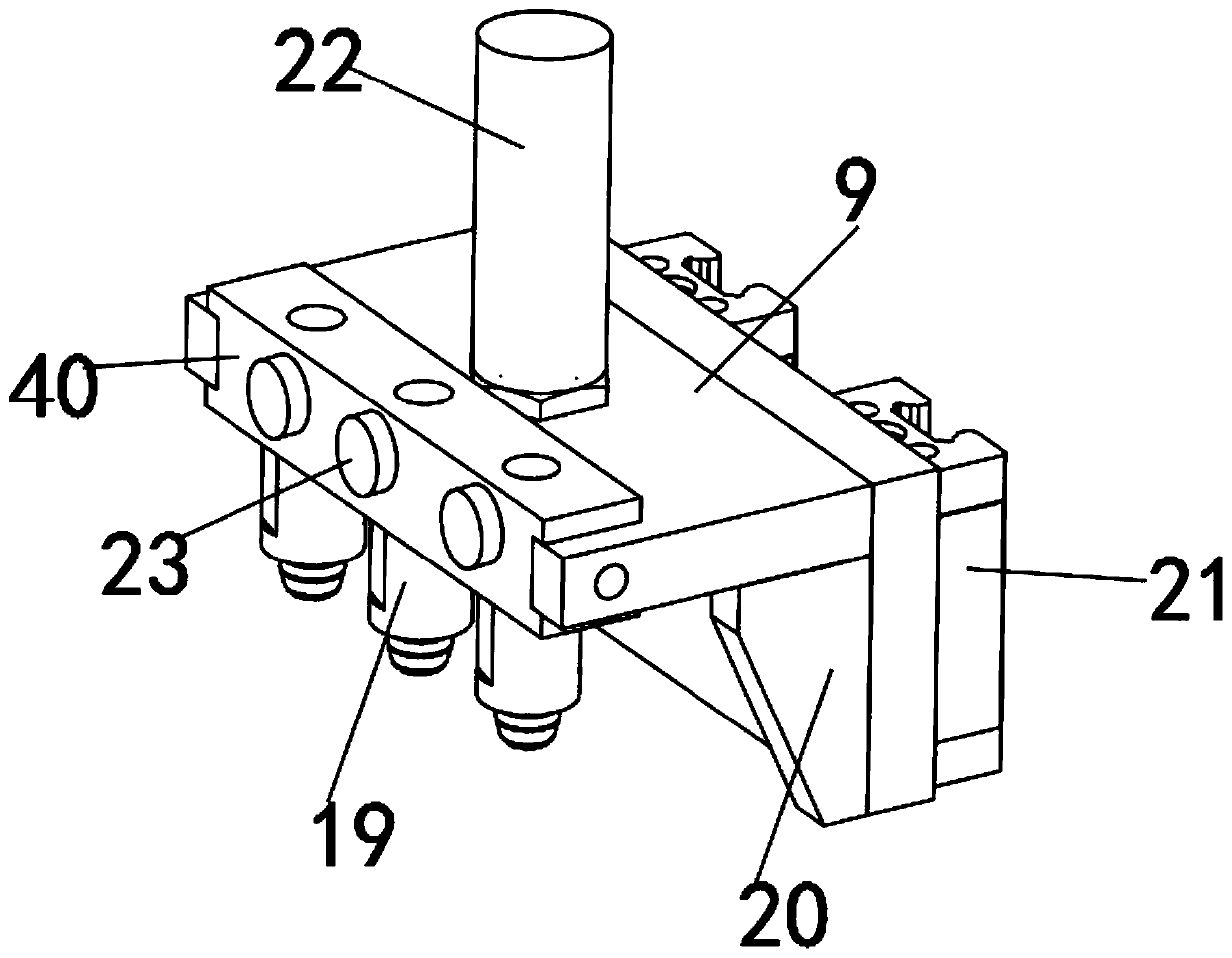

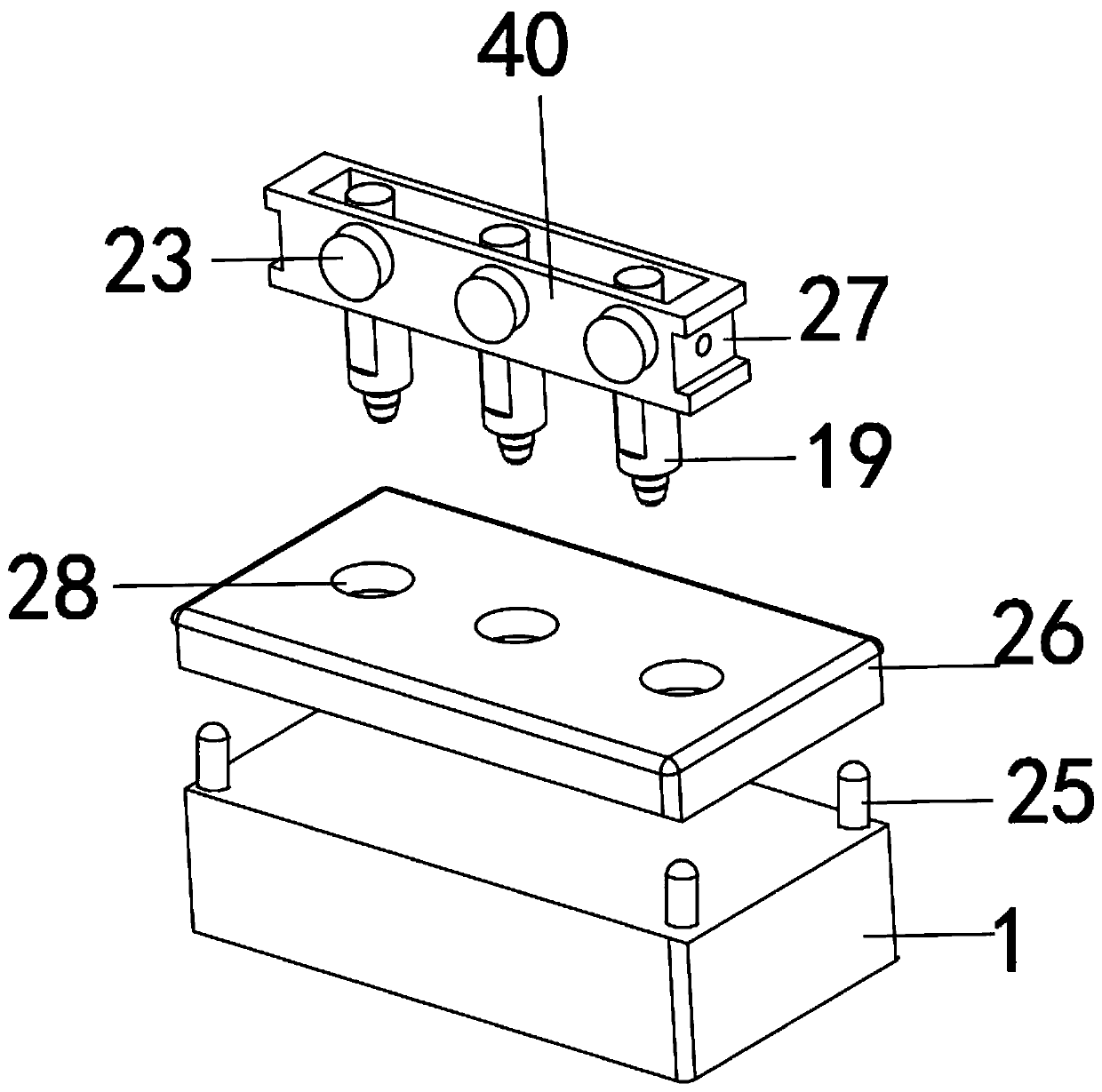

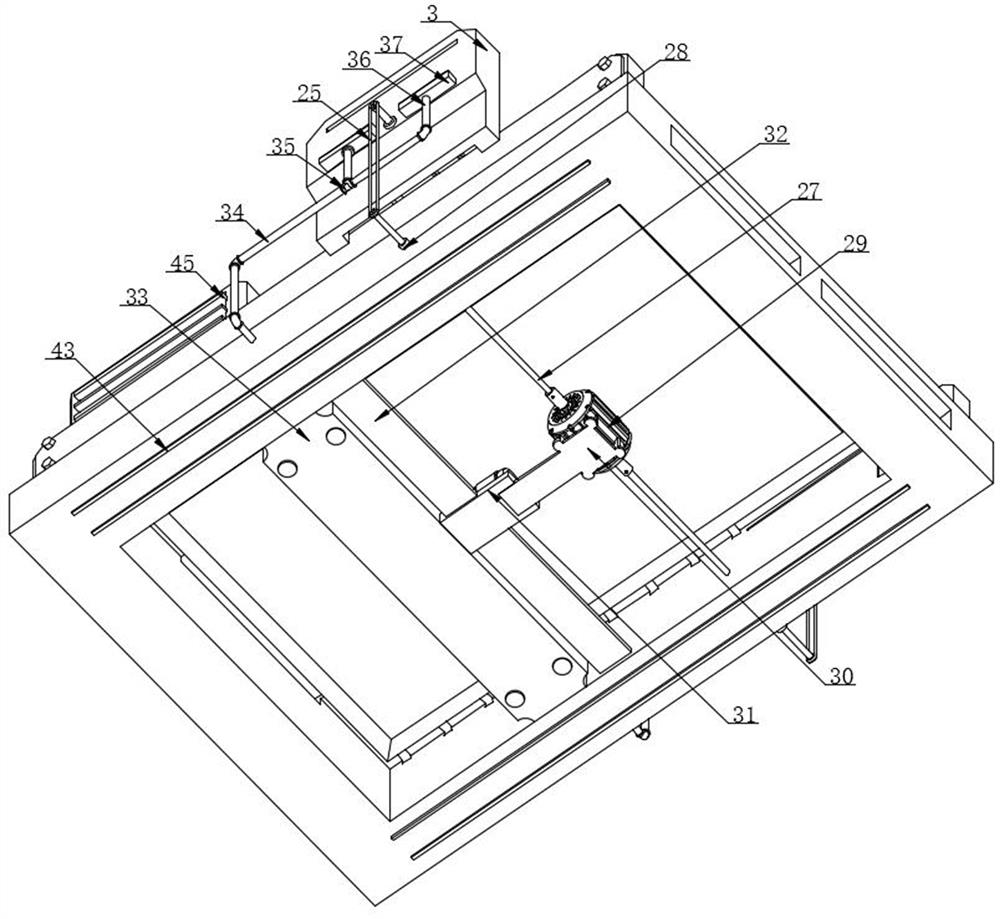

Multifunctional assembly equipment for DTRO and CDRO flow guide discs

InactiveCN114770106AGuaranteed assembly effectImprove fault toleranceAssembly machinesEngineeringDISC assembly

The invention discloses DTRO + CDRO flow guide disc multifunctional assembling equipment, and particularly relates to the technical field of flow guide disc assembly.The DTRO + CDRO flow guide disc multifunctional assembling equipment comprises a base, the upper surface of the base is fixedly connected with the lower surface of a conveying frame, and the upper surface of the conveying frame is fixedly connected with two fixing frames; the opposite faces of the two fixing frames are fixedly connected with the faces, away from each other, of the two positioning discs correspondingly, and the opposite faces of the two positioning discs are fixedly connected with the faces, away from each other, of the two sleeves correspondingly. By arranging the first lead screw, the limiting plate and the positioning suction cup, after the sealing ring is pushed into the mounting groove, an adsorption ring can rotate along with the sealing ring, the situation that the sealing ring is difficult to mount when being in a staggered state is avoided, the flow guide disc assembling effect of the assembling equipment is guaranteed, the fault tolerance rate of the assembling equipment during flow guide disc assembling is increased, and the assembling efficiency is improved. And the flow guide disc does not need to be turned over, so that the operation cost of the assembly equipment is reduced, the production efficiency is guaranteed, and meanwhile, the assembly difficulty is reduced.

Owner:烟台施泰美纳矿业设备有限公司 +1

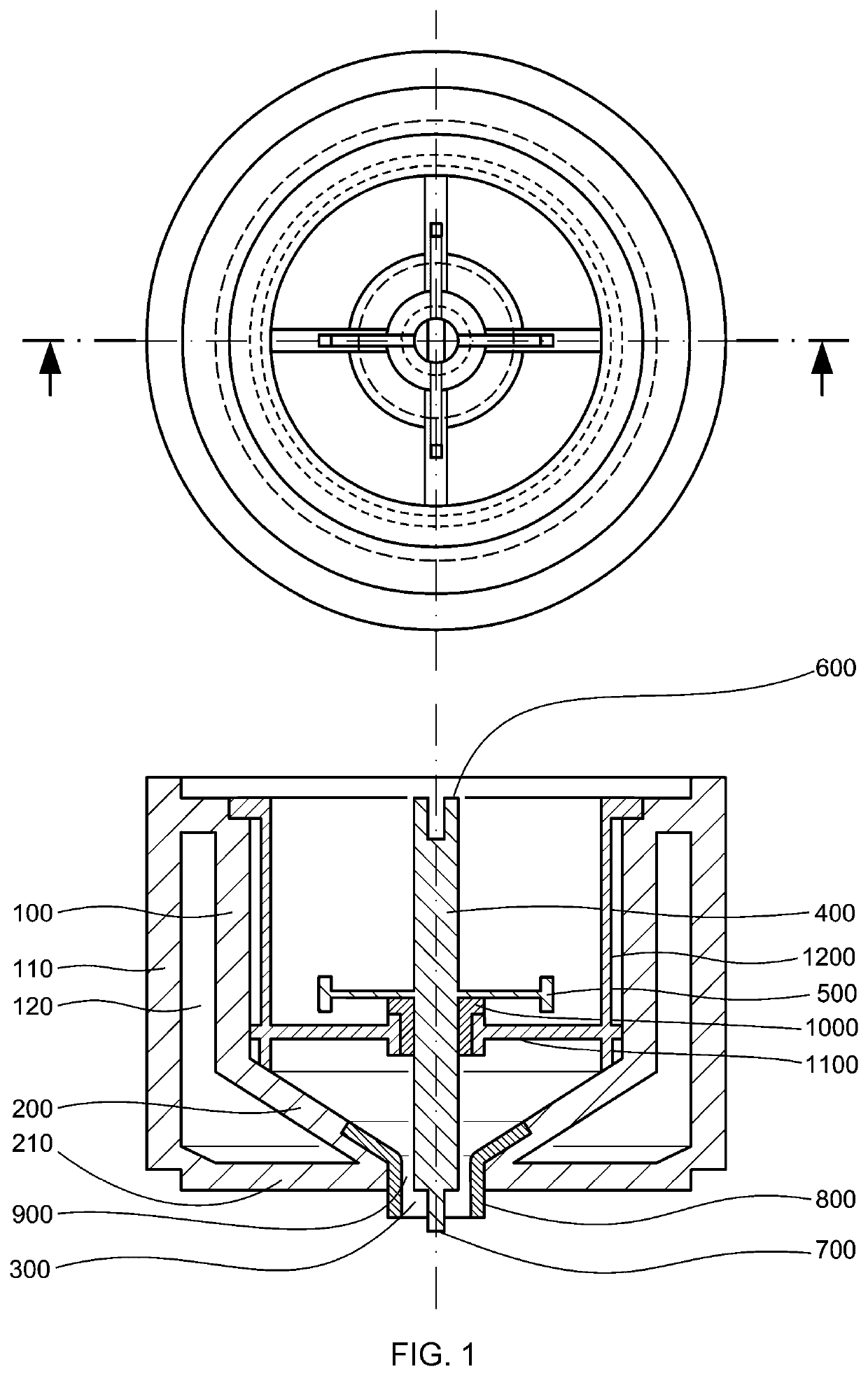

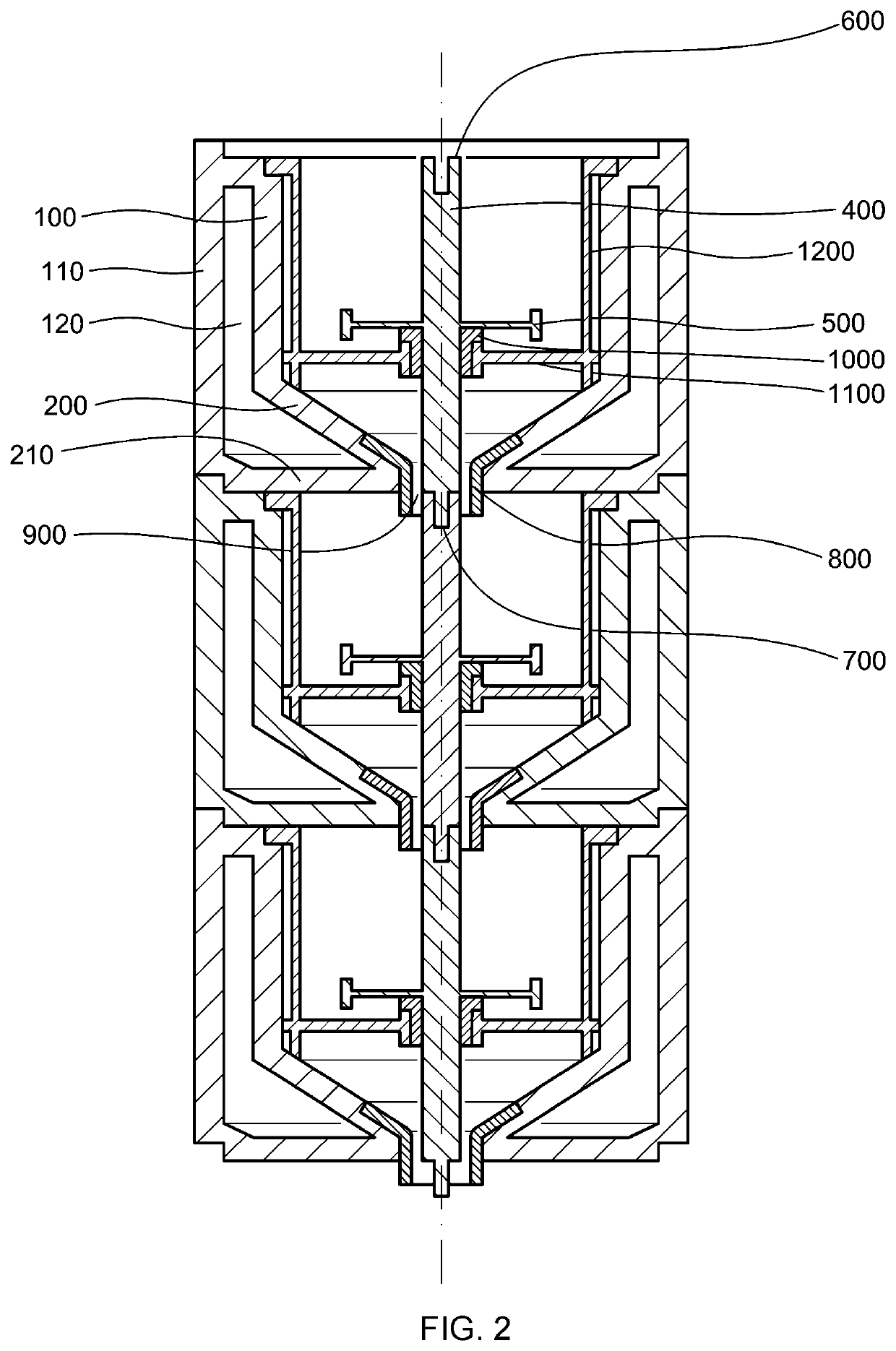

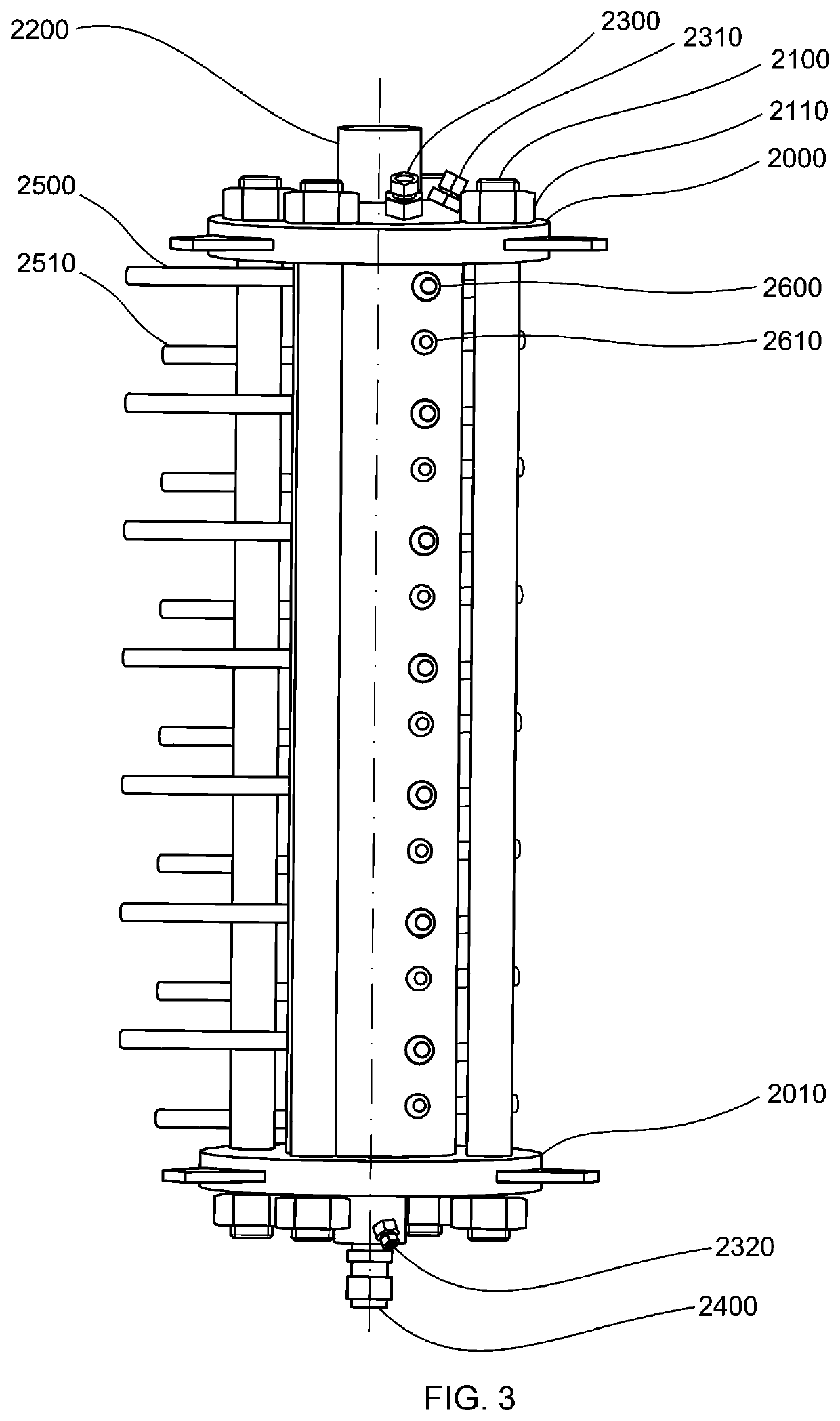

Reaction chamber for a chemical reactor, and chemical reactor constructed therefrom

ActiveUS11033874B2Large specific surface areaAdapt quicklyChemical/physical/physico-chemical stationary reactorsChemical reactorEngineering

Owner:SUZHOU SKYWELL HEALTHCARE INFORMATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com