Surface grinding equipment for stud bolt processing

A stud bolt, grinding technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

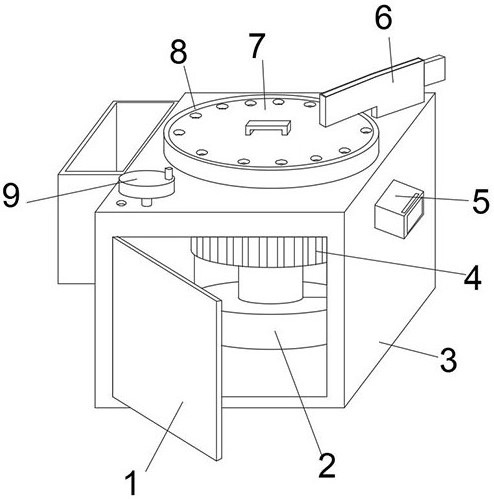

Embodiment 1

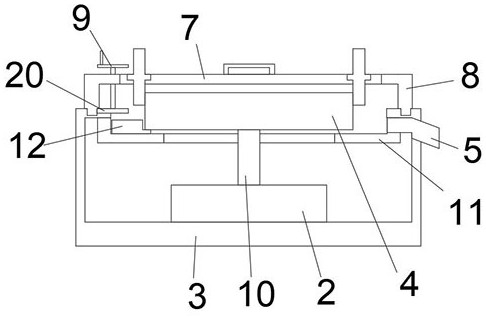

[0037] The upper annular distribution of the splicing chuck 7 has a plurality of round holes for mounting the double-head bolts, and the splicing chuck 7 and the rotary collar 8 are fixed by two sets of docking snaps 17, using the circle on the splicing chuck 7. The holes can be installed in one time, and the inserted double-bolts are passed through the side of the grinding disc 4 in the side of the grinding plate 4, and when the double bolt is polished, the grinding disc is driven when the bolt bolt is polished. 4 Rotate so that the grinding disc 4 can simultaneously complete the grinding operation of the multi-set double bolt.

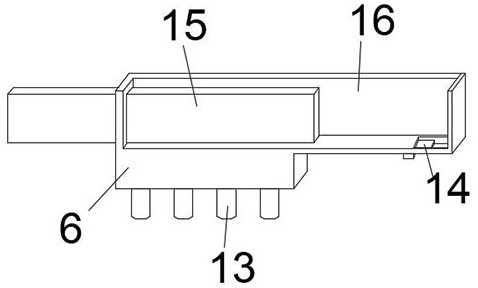

[0038] An end activity is attached to one end of the feed cassette 6, and the inner side of the feed cassette 6 is provided with a receiving groove 16, and the bottom position of the other end of the feed cassette 6 is provided with a tank. When the feed cassette 6 is used, the user passes Place a row of double-head bolts inside the receiving tank 16 of ...

Embodiment 2

[0040] The bottom of the feed cassette 6 is provided with a fixed bolt 13, and the other end of the feed cassette 6 is located in the inside of the discharge slot. The push-pull buckle 14 is attached, and the user can adjust the size of the tank by pushing the push-pull buckle 14. The adjustable discharge slot can be used with a lower end of the rotating collar 8, and the rotary collar 8 and the first pick-up disk 18 are provided with an annular card slot between the lower ends of the rotating collar 8. The setting of the card slot can be mounted on the upper portion of the fixed base 3, and can drive the rotation jacket 8 using the first tootooth 8 to complete the rotation operation.

[0041] The inner active sleeve of the drive hand wheel 9 is attached to the positioning rod 21, and the lower portion of the driving hand wheel 9 is fixedly mounted, and the driving hand wheel 9 and the third tooth plate 20 are connected by the rotor, the third tooth disc 20 The side activity is at...

Embodiment 3

[0043] The inner side of the fixed base 3 is fixed to the lower surface of the grinding disc 4, and the outer surface of the fixed base 3 penetrates the tapered slag nozzle 5, which is generated when the double bolt grinding operation is operated. The metal dust will fall into the slagm 11, and the metal dust is collected by the slagm 11, while opening the slag mouth 5 can discharge the metal dust.

[0044] The lower portion of the grinding plate 4 has a combined blade 12, and the side outer surface of the combined blade 12 is a curved structure, and when the grinding device is slag, the user can install the combined scraper 12. At the lower portion of the grinding plate 4, the combined blade 12 is driven by the grinding plate 4 to slowly rotate, so that the combined blade 12 can discharge the metal dust on the slim disk 11 from the slag mouth 5.

[0045] One end surface of the combination blade 12 is fixedly mounted, and the upper portion of the splicing block 23 is fixedly mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com