Stainless steel plate stamping equipment

A technology for stamping equipment and stainless steel plates, applied in the field of stamping, can solve the problems such as easy jamming of scraps in the give-away holes, difficulty in picking up the stuck scraps, lowering work efficiency, etc., to avoid hard contact, convenient disassembly and replacement, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

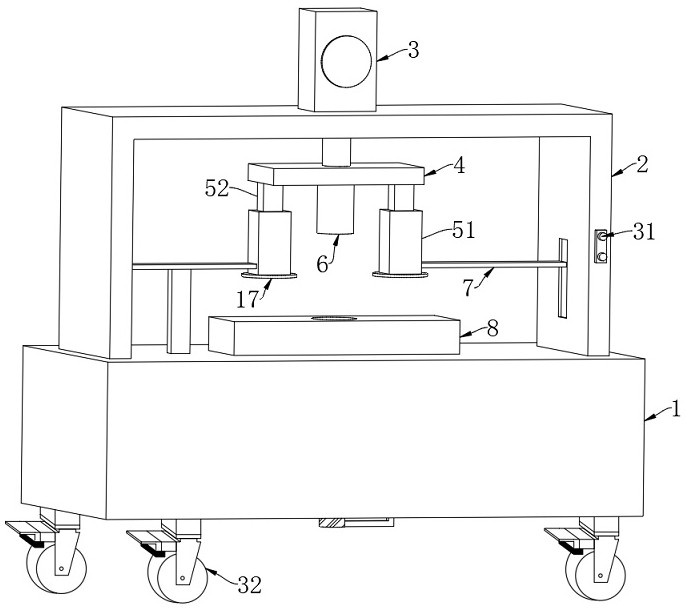

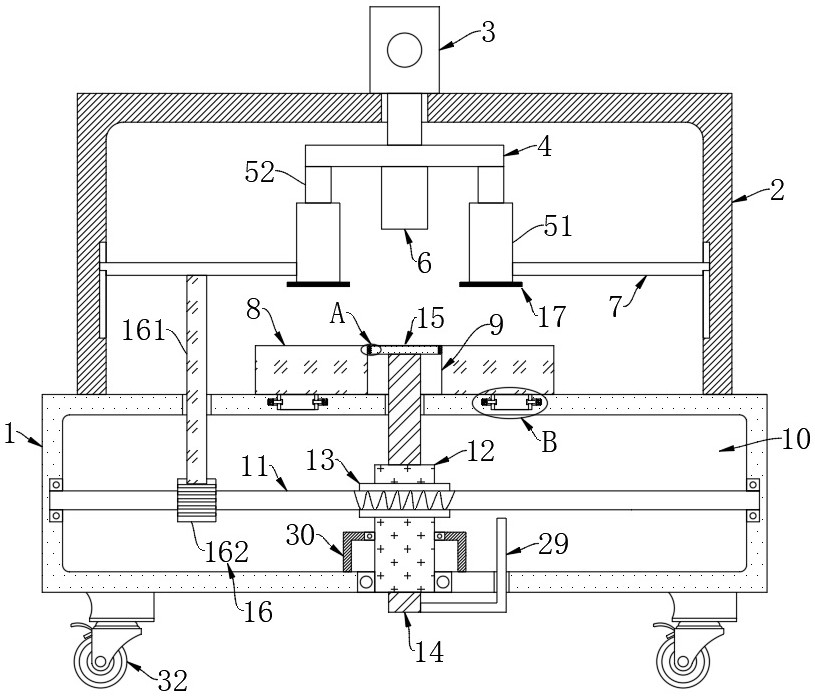

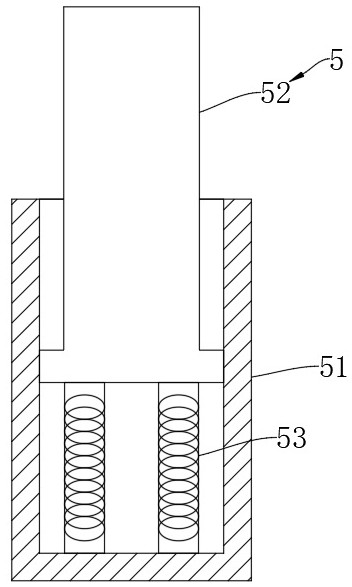

[0030] Such as Figure 1-5 As shown, a stainless steel plate punching equipment includes a workbench 1, a plurality of universal wheels 32 are fixedly connected to the lower end of the workbench 1, and the universal wheels 32 can be self-locking, and the setting of the universal wheels 32 is convenient for the staff to move In the whole device, a bracket 2 is fixedly connected to the workbench 1, and a cylinder 3 is arranged on the bracket 2, and a pressure plate 4 is fixedly connected to the output end of the cylinder 3, and two buffer mechanisms 5 and a punching head 6 are fixedly connected to the pressure plate 4, The buffer mechanism 5 includes a hollow seat 51, a support seat 52 and a buffer spring 53. The support seat 52 is fixedly connected to the pressing plate 4, and the hollow seat 51 is slidably connected to the support seat 52. Between the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com