Root subtree vertical and horizontal pre-scheduling same-equipment process sorting comprehensive scheduling method

A technology of equipment procedures and scheduling methods, which is applied in instruments, manufacturing computing systems, data processing applications, etc., and can solve the problems of insufficiently compact processing process and different vertical and horizontal characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

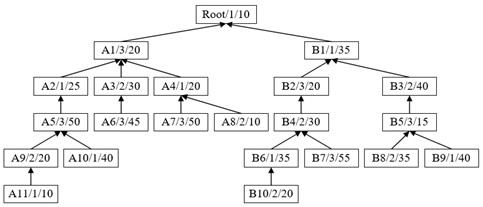

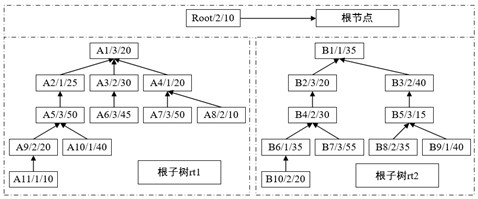

[0038] A comprehensive scheduling method based on vertical and horizontal pre-scheduling of root and sub-trees, which is widely used in practical applications; first, the complex product process tree is split into several root sub-trees; then each root sub-tree is traversed to solve the root sub-tree Tree aspect ratio, analyze the vertical and horizontal characteristics of each root subtree, so as to obtain the root subtree priority, solve the horizontal competition relationship of the root subtree equipment process in the fusion process; finally use the root subtree equipment process pre-start time and equipment process start processing time All equipment processes in the root subtree are fused and scheduled.

Embodiment 2

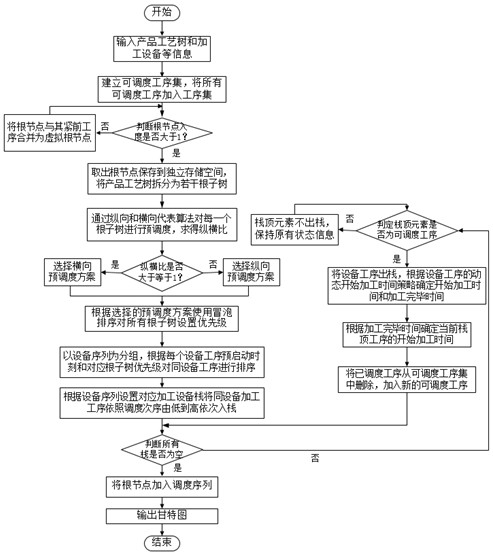

[0040] The above-mentioned root-subtree vertical and horizontal pre-scheduling comprehensive scheduling method for the same equipment process sequence, the specific implementation steps of the scheduling method are as follows:

[0041] Step 1: Perform data information processing on the complex product model to form a standardized comprehensive scheduling process tree model; establish a schedulable process set, and add all schedulable processes in the product process tree to the schedulable process set;

[0042] Step 2: According to the simplified preprocessing principle and process tree decomposition method, take out the root node and save it in an independent storage space, and split the product process tree into several root subtrees to form a root subtree;

[0043] Step 3: Obtain the completion time of vertical pre-scheduling and horizontal pre-scheduling for each root sub-tree in the root sub-tree set, use the pre-scheduling results to obtain the aspect ratio of the root su...

Embodiment 3

[0055] The same equipment processes are sorted at the time before and after pre-starting, and the same equipment processes of the optimal vertical and horizontal pre-scheduling schemes of all root subtrees are sorted in ascending order of starting processing time from small to large.

[0056] The dynamic start processing time strategy of the equipment process determines the initial start processing time of the stack top process according to the final processing completion time of the scheduled process of the same equipment, if the processing completion time of the process immediately before the stack top process process tree is greater than the initial If the start processing time of the stack top process is updated, the start processing time of the stack top process is equal to the processing completion time of the immediately preceding process in the process tree, otherwise the start process time of the stack top process is not updated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com