A batch-by-batch input experiment design method based on d-optimal design

It is a technology of batch-by-batch investment and experimental design. It is applied in the fields of calculation, instrumentation, electrical and digital data processing, etc., and can solve the problems that cannot be changed, and the number of experiments cannot be flexibly adjusted according to actual needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The following aircraft central wing plate is taken as an example, and in conjunction with the accompanying drawings, the present invention will be described in further detail.

[0063] The rear panel of the central wing of the aircraft is composed of a large number of aluminum alloy rib arches, which is a typical aluminum alloy thin-walled part. Aluminum alloy thin-walled parts have a wide range of applications, but due to their poor local strength, they are recognized as difficult-to-process products by all walks of life in the industry. The quality problems that often appear are mainly unqualified surface roughness.

[0064] In order to directly control the surface roughness quality in the production process, it is necessary to find the optimal cutting parameters, and the goal is to minimize the surface roughness y.

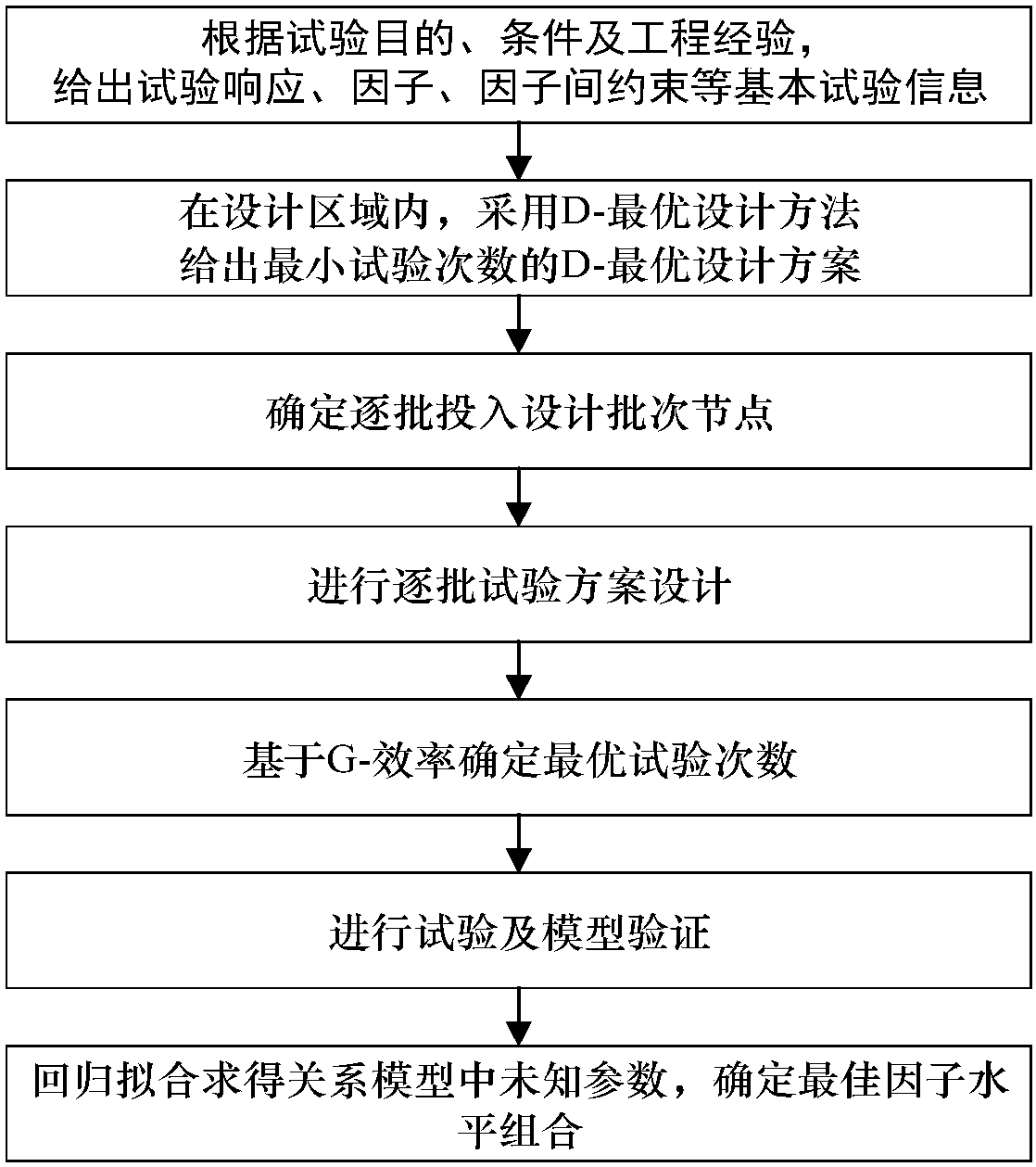

[0065] A kind of batch-by-batch input test design method based on D-optimal design of the present invention, see figure 1 As shown, its specific imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com