Preparation method of instant cellulose ether

A cellulose ether, instant technology, applied in the field of preparation and application of instant cellulose ether, can solve the problems of easy clumping and dispersion effect, cellulose ether is not easy to dissolve, etc., and achieve the effect of fast dispersion and fast dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

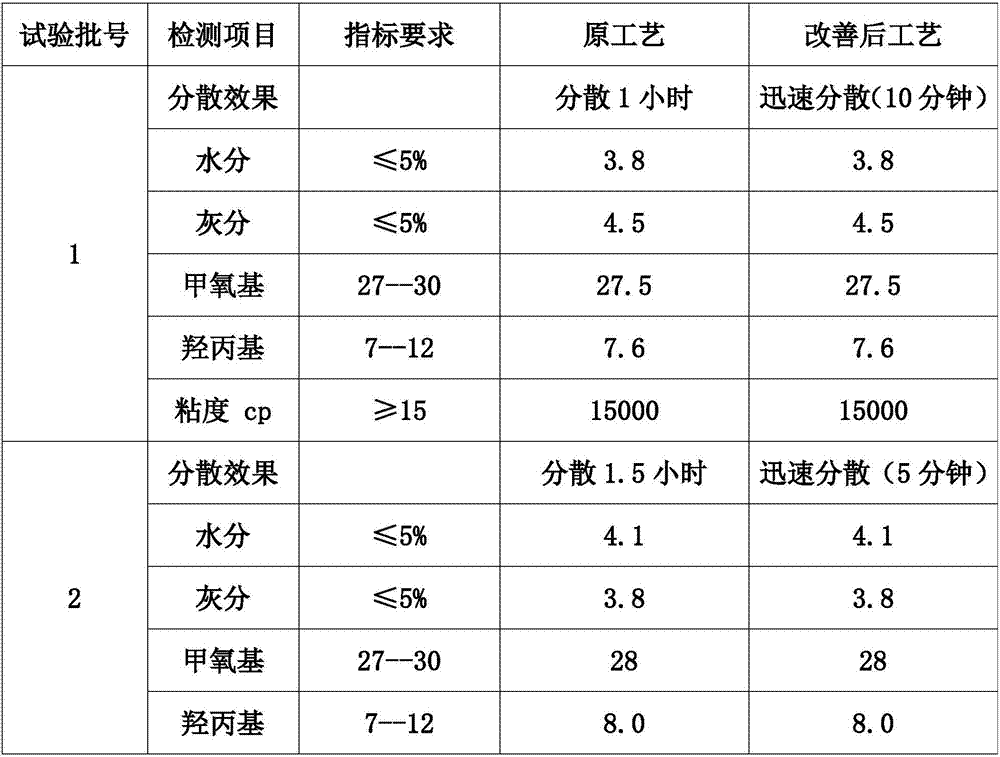

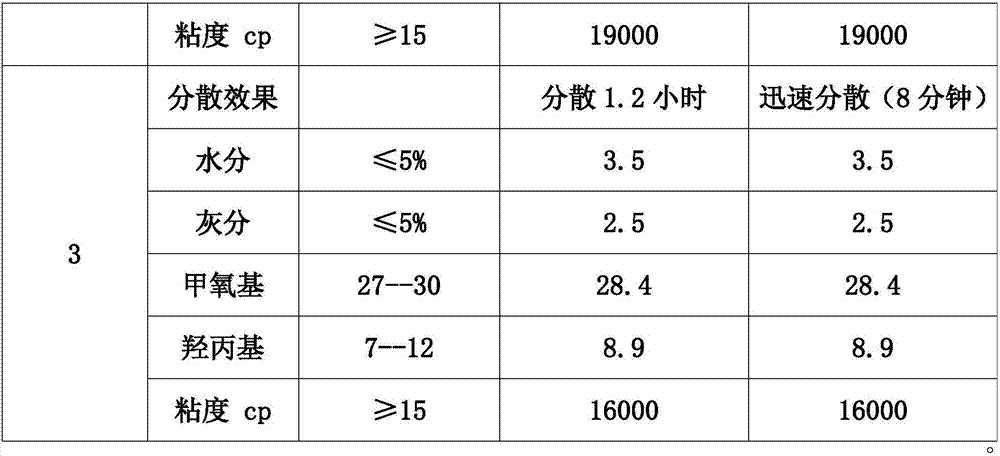

Examples

Embodiment Construction

[0010] The technical scheme of the present invention will be further described below in conjunction with detailed processes.

[0011] Pump the reaction solvent medium (toluene 87%, isopropanol 13%) into the reaction kettle, put sodium hydroxide into the kettle, heat up to 70°C, dissolve the alkali, then cool down to 25-30°C, and put Refined cotton powder is alkalized for 2 hours at 25-30°C to produce sodium cellulose. After the alkalization is completed, add etherifying agents such as propylene oxide and methyl chloride, and react at a constant temperature of 25-30°C for 30 Minutes to make the etherification agent fully stir evenly, then raise the temperature to 54±1°C, react at constant temperature for 1 hour, then immediately raise the temperature to 80°C, react at constant temperature for 2 hours, the reaction is completed, cool down to 50°C and add a certain amount of acetic acid to neutralize and adjust The pH value is between 5-7, and then the material is pressed into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com