Fruit and vegetable peeling device

A fruit and vegetable, sliding installation technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problems of peeling and processing of different fruits and vegetables or different shapes of fruits and vegetables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

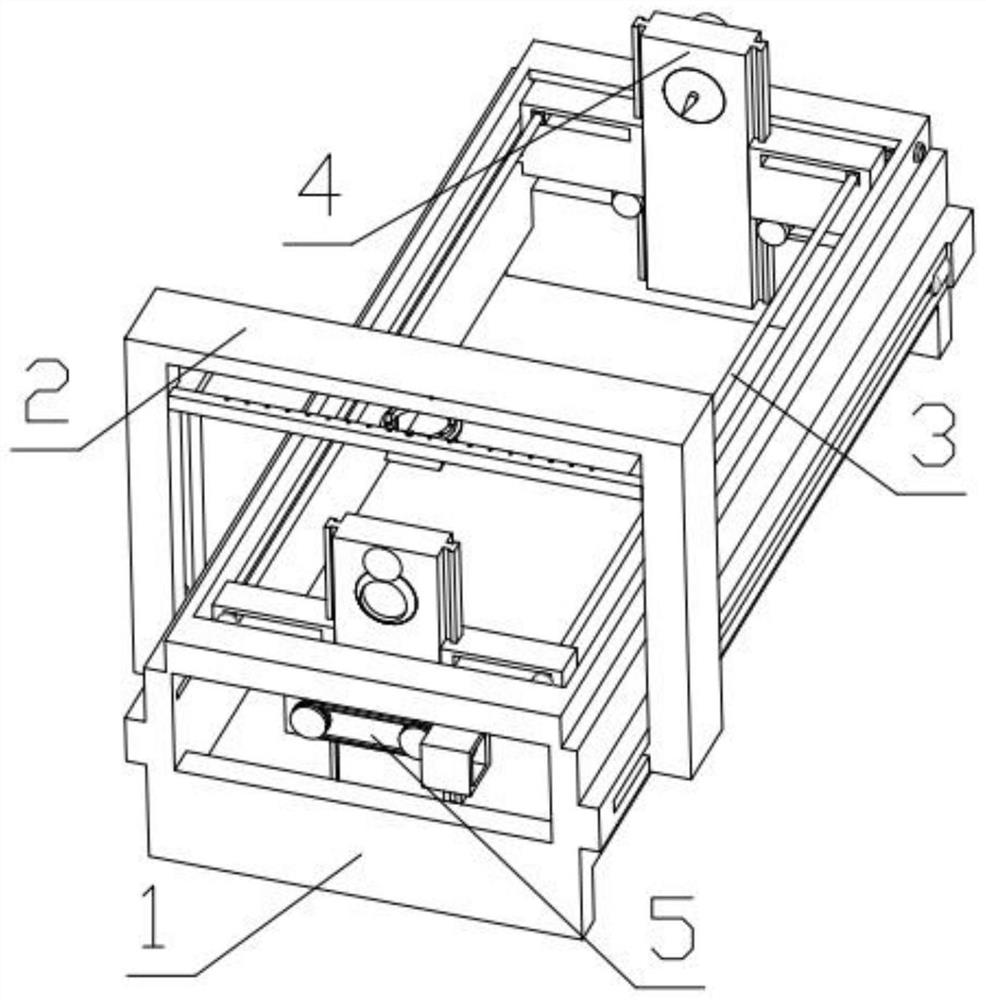

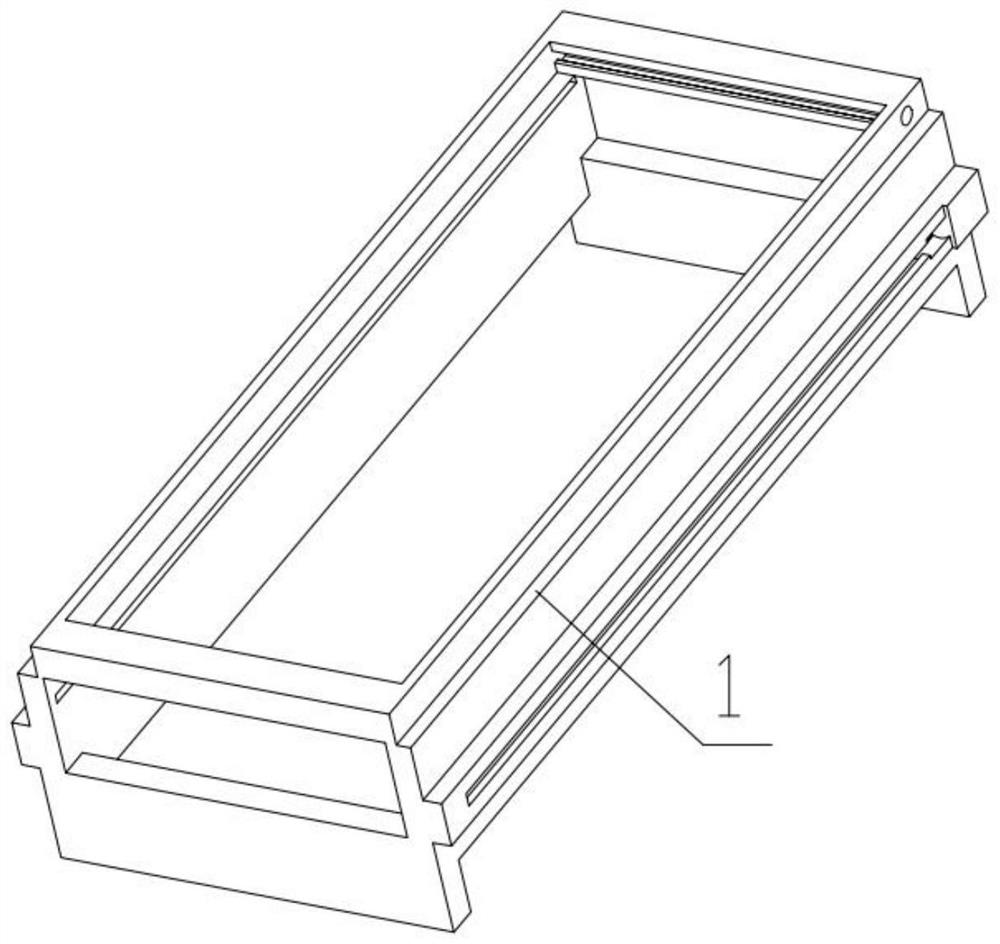

[0036] Combine below Figure 1-17Description of this embodiment, a fruit and vegetable peeling device, including a base frame 1, a peeling mechanism 2, a displacement mechanism 3, a rotation mechanism 4 and a height adjustment mechanism 5, the peeling mechanism 2 is fixedly installed on the base frame 1, The displacement mechanism 3 is fixedly installed on the base frame 1, the height adjustment mechanism 5 is slidably installed in the groove provided on the base frame 1, the height adjustment mechanism 5 is screwed with the displacement mechanism 3, and the rotation mechanism 4 is slidably installed on the height adjustment mechanism 5 In the provided groove, the rotating mechanism 4 is engaged with the height adjusting mechanism 5 .

specific Embodiment approach 2

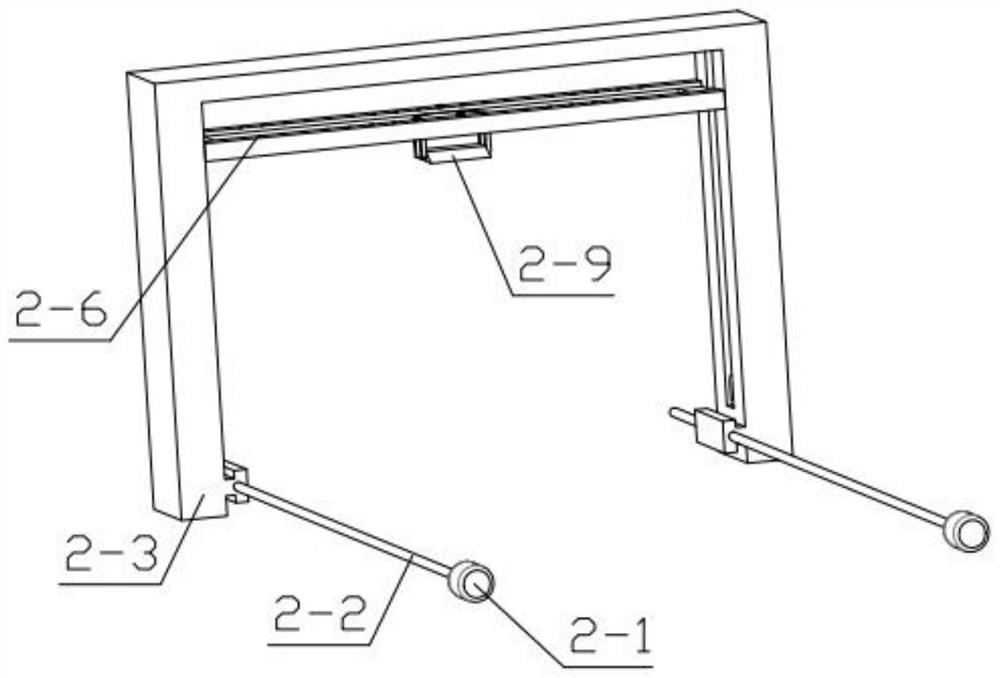

[0038] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain embodiment one, described peeling mechanism 2 comprises first motor 2-1, outer threaded rod 2-2, U-shaped frame 2-3, second motor 2-4 , vertical threaded rod 2-5, positioning frame 2-6, positioning screw 2-7, positioning ring 2-8, double-sided peeling knife 2-9, the first motor 2-1 is fixedly installed on the base frame 1, The output end of the first motor 2-1 is fixedly installed with an outer threaded rod 2-2, and the other end of the outer threaded rod 2-2 is rotatably installed in the groove provided on the base frame 1, and the U-shaped frame 2-3 is slidably installed on the In the groove provided on the base frame 1, the outer threaded rod 2-2 is threadedly connected with the U-shaped frame 2-3, and the second motor 2-4 is fixedly installed on the U-shaped frame 2-3, and the second motor 2-4 The output end is fixedly installed with a vertical threaded rod 2-5, and the other ...

specific Embodiment approach 3

[0040] Combine below Figure 1-17 Describe this embodiment, this embodiment will further explain the first embodiment, the displacement mechanism 3 includes a third motor 3-1, a driving sprocket 3-2, a T-shaped sliding foot 3-3, a two-way threaded rod 3 -4, long chain 3-5, two-way threaded rod two 3-6, the fourth motor 3-7, T-shaped sliding foot two 3-8, the third motor 3-1 is fixedly installed in the through hole that base frame 1 is provided with Inside, the output end of the third motor 3-1 is fixedly installed with driving sprocket 3-2, and driving sprocket 3-2 is meshed with long chain 3-5, and driving sprocket 3-2 and two-way threaded rod one 3-4 Fixed connection, two-way threaded rod-3-4 rotation installed in the groove provided on the base frame 1, two-way threaded rod-3-4 and T-shaped sliding foot-3-3 threaded connection, T-shaped sliding foot-3-3 Fixedly connected with the two-way threaded rod two 3-6, the other end of the two-way threaded rod two 3-6 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com