Slow-release material for stabilizing and treating barium slag and stabilizing and treating method for barium slag

A slow-release material and stabilization technology, which is applied in the field of slow-release materials for the stabilization and treatment of barium slag, can solve the problem of high sulfate ion concentration, achieve the effect of reducing sulfate ion concentration, significant effect, and high exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

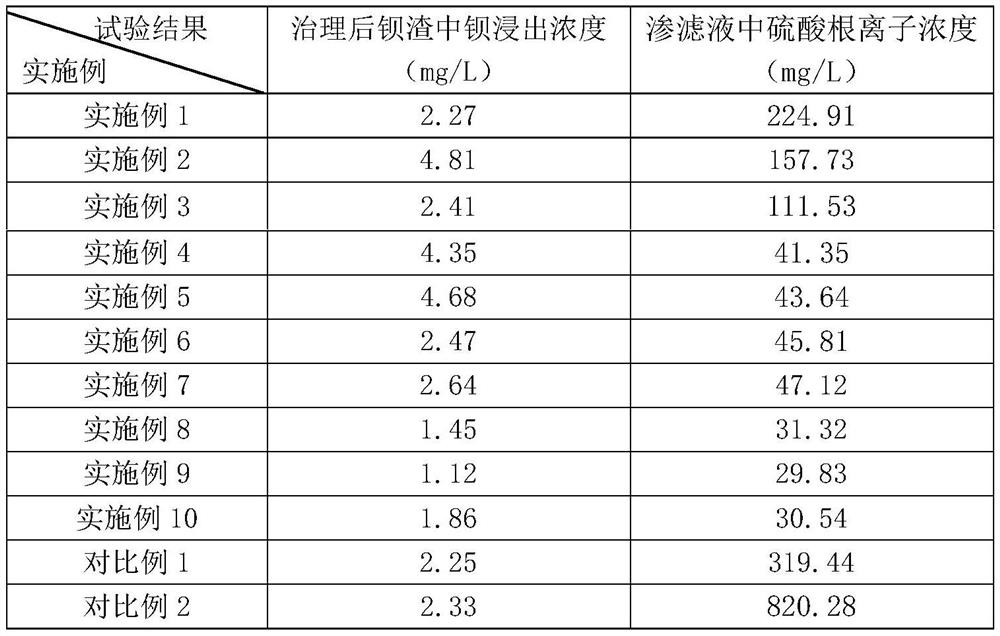

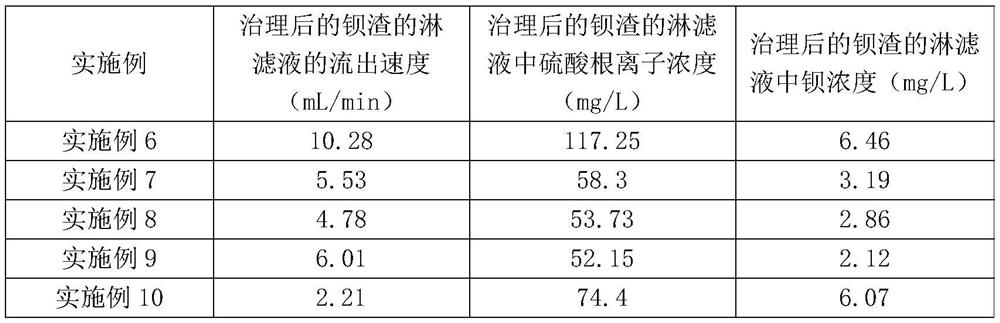

Embodiment 1

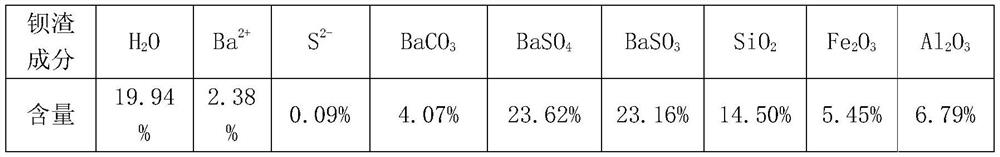

[0036] This embodiment provides a slow-release material for stabilizing and treating barium slag, and its raw material composition is:

[0037] Sodium sulfate 60g, magnesium aluminum hydrotalcite model HT-22 30g.

[0038] The preparation method of the slow-release material for stabilizing and treating barium slag is as follows: uniformly mix 60 g of sodium sulfate and 30 g of magnesium aluminum hydrotalcite.

[0039] The application method of the slow-release material for the above-mentioned stabilization and control of barium slag is as follows:

[0040] Sample preparation: take the barium slag, and measure the moisture content of the air-dried barium slag by the drying-gravimetric method; obtain the above-mentioned slow-release material for stabilizing and treating the barium slag at the same time; It is better than barium slag.

[0041] Treatment: Add slow-release materials to the barium slag, so that the total molar amount of sulfate radicals in the added slow-release ma...

Embodiment 2

[0043] This embodiment provides a slow-release material for stabilizing and treating barium slag, and its raw material composition is:

[0044] Sodium sulfate 50g, model 50g of magnesium aluminum hydrotalcite of HT-22.

[0045] The preparation method of the above-mentioned slow-release material for stabilizing and treating barium slag is as follows: uniformly mixing 50 g of sodium sulfate and 50 g of magnesium aluminum hydrotalcite.

[0046]The application method of the slow-release material for the above-mentioned stabilization and control of barium slag is as follows:

[0047] Sample preparation: take the barium slag, and measure the moisture content of the air-dried barium slag by the drying-gravimetric method; obtain the above-mentioned slow-release material for stabilizing and treating the barium slag at the same time; It is better than barium slag.

[0048] Treatment: Add slow-release materials to the barium slag, so that the molar concentration of sulfate radicals in ...

Embodiment 3

[0050] This example provides a slow-release material for stabilizing and treating barium slag. The only difference from Example 1 is that the sulfate used is calcium sulfate.

[0051] The preparation method of the slow-release material for stabilizing and treating barium slag is as follows: uniformly mix 60 g of calcium sulfate and 30 g of magnesium aluminum hydrotalcite.

[0052] The application method of the slow-release material for the above-mentioned stabilization and control of barium slag is as follows:

[0053] Sample preparation: take the barium slag, and measure the moisture content of the air-dried barium slag by the drying-gravimetric method; obtain the above-mentioned slow-release material for stabilizing and treating the barium slag at the same time; It is better than barium slag.

[0054] Treatment: Add slow-release materials to the barium slag, so that the molar concentration of sulfate radicals in the barium slag after adding the slow-release materials is 1.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com