Conveying line material box separating device

A separation device and conveying line technology, applied in the field of logistics and warehousing, can solve the problems of increasing operators, easy accumulation, congestion, unfavorable application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

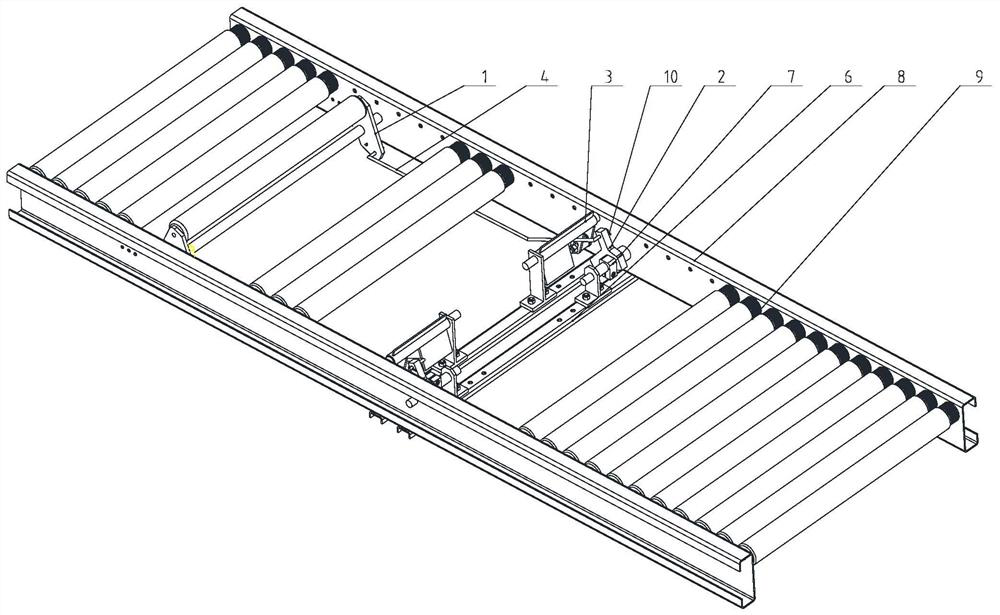

[0031] Example 1, such as Figure 1 to Figure 4 As shown, the material box separation device proposed in this application can be applied to the roller conveyor line 9. The material box separation device includes a roller pressure spring assembly 1 arranged in sequence along the conveying direction and installed on the conveyor line body 8, and a limit stop assembly. 3 and swing assembly 2;

[0032] Wherein, a pull rod 4 is connected between the roller pressing assembly 1 and the swing assembly 2, and a spring 5 is connected between the fuselage 8 and the roller pressing assembly 1;

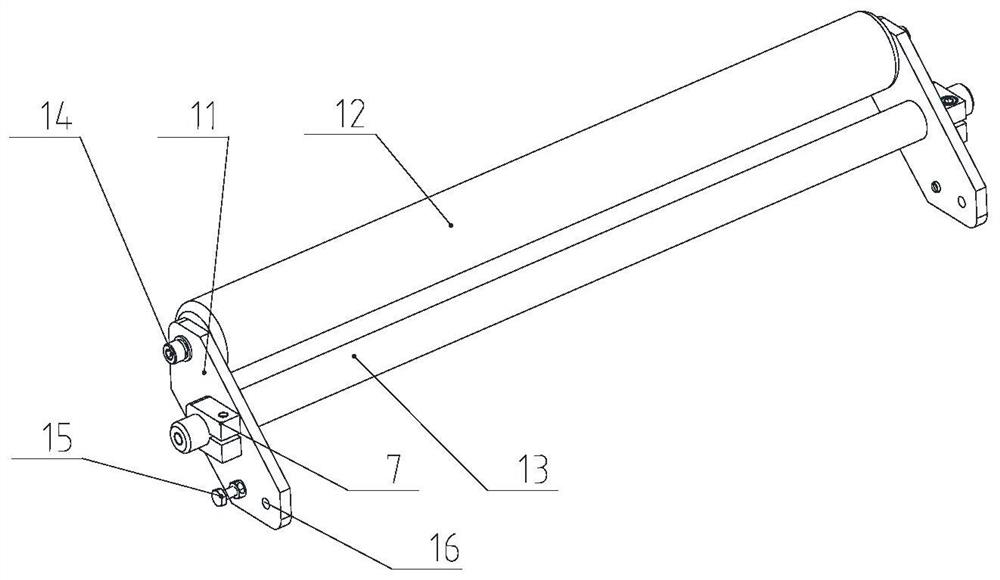

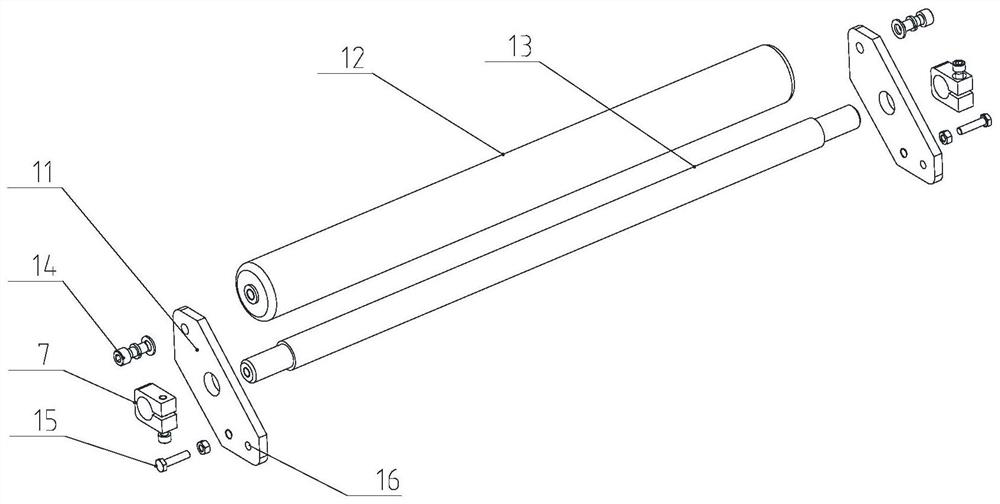

[0033] As shown in FIG. 2 , the roller pressing assembly 1 has a set of roller fixing plates 11, and the two ends of the pressing roller 12 and the roller swing shaft 13 are connected to the roller fixing plates 11 through respectively;

[0034] At the shaft end of the pressing roller 12, it is installed and fixed in the positioning hole of the roller fixing plate 11 through the locking bolt 14; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com