Greenhouse cleaning machine

A technology for cleaning machines and greenhouses, which is applied to cleaning methods and utensils, cleaning methods using tools, and cleaning methods using liquids, etc. The effect of high practicality and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

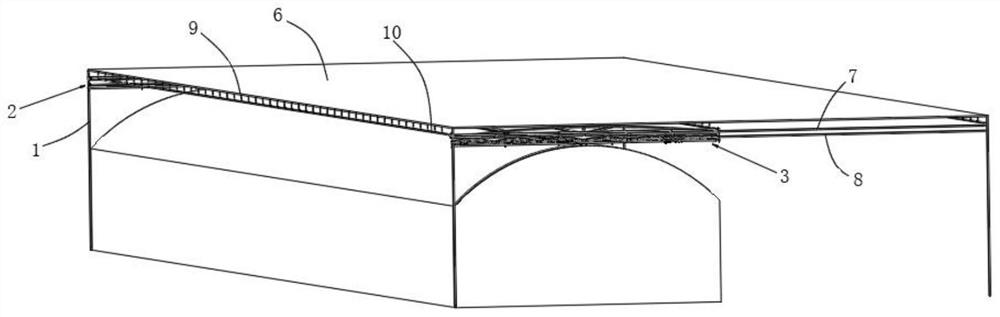

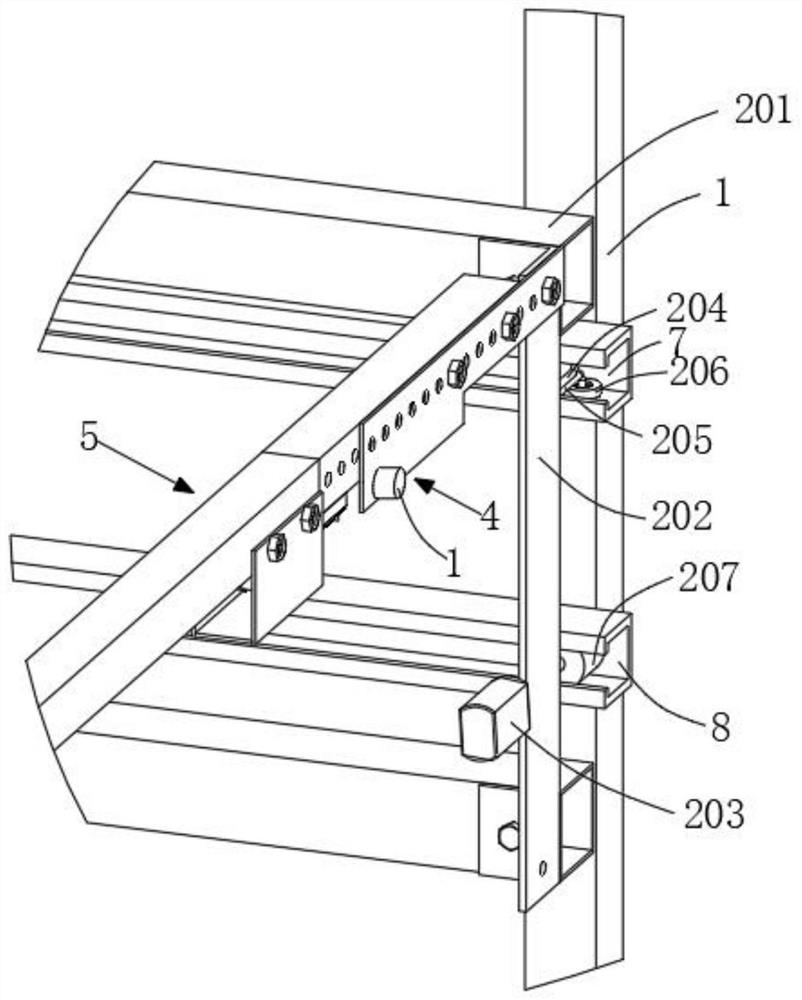

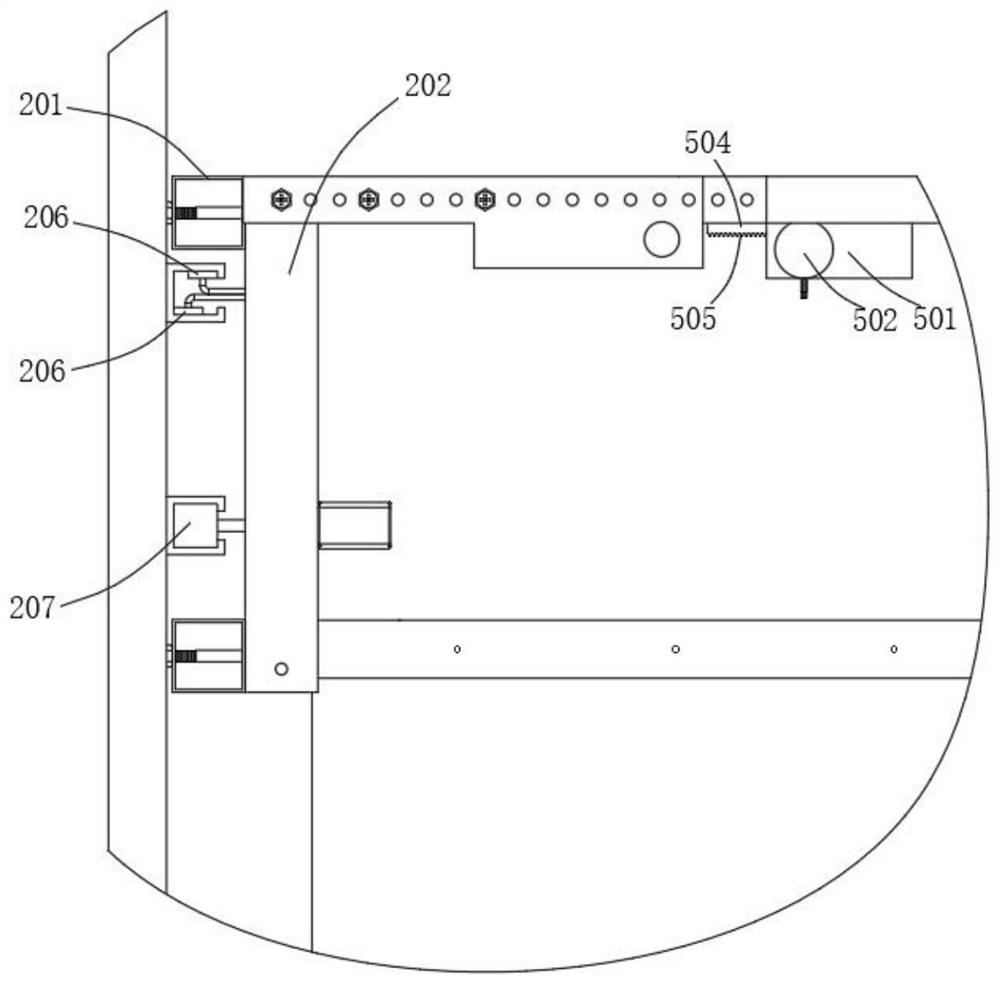

[0026] Embodiment: greenhouse cleaning machine, as attached figure 1 As shown, it includes columns 1 arranged around the greenhouse, and the columns 1 are jointly provided with a top plate 6. Between the columns 1 on the front and rear sides of the greenhouse, there are horizontal guide rails 7 and driving guide rails 8 parallel to each other. The horizontal guide rails 7 and the driving guide rails 8 is jointly provided with transverse movement mechanism 2; figure 2 As shown, the lower surface of the top plate 6 is provided with a plurality of sets of fixed columns 9, and each set of fixed columns 9 is provided with a vertical guide rail 10 perpendicular to the transverse guide rail 7, and a mobile scrubbing mechanism is jointly provided on the two longitudinal guide rails 10 3. A water spray pipe 11 located at the top of the shed is provided below the mobile scrubbing mechanism 3, and the width of the lateral movement mechanism 2 corresponds to the width of the mobile scrub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com