Building round pipe end forming device

A molding device and construction technology, applied in the direction of molding tools, metal processing equipment, manufacturing tools, etc., can solve the problems of high processing cost and equipment investment cost, slow efficiency, and non-environmental protection, and achieve low cost, simple and convenient processing, The effect of quick change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

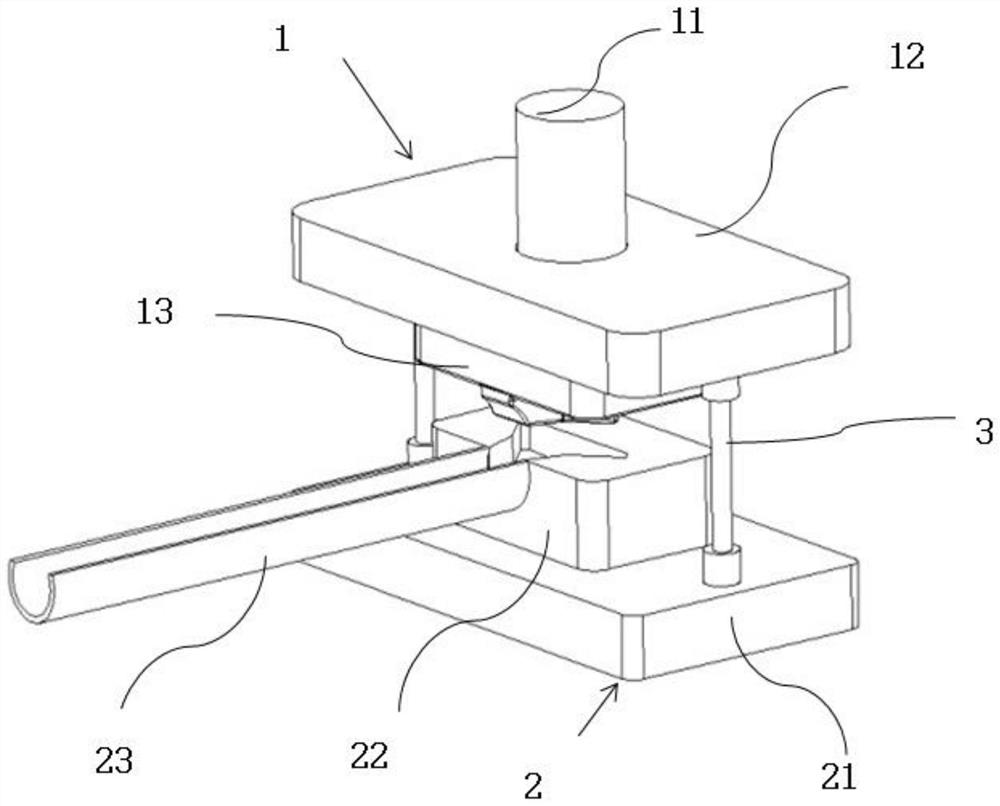

[0033] Such as figure 1 As shown, a round pipe end forming device for construction, the die handle 11 is fixed in the die handle hole of a small press through a splint, the end forming punch 13 is fixed in the upper die base 12 by pressing bolts, the die handle 11 , upper mold base 12, forming punch 13 constitute upper mold together. The lower mold base 21 is fixed on the small press workbench by splints, the end forming die 22 is fixed on the lower die base 21 by pressing bolts, the end forming die 22 and the positioning channel 23 jointly constitute the lower die.

[0034] When the end of the round pipe is formed for the first time, the round pipe enters above the die 22 through the positioning channel 23, and the end forming punch moves down with the slider of the press, and is guided and positioned by the forming guide post 3, and the end of the round pipe is formed. The end forming strength is good, the efficiency is fast, and the appearance is excellent.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap