Vacuum section flow adjustable plasticizing section pin exhaust extruder

A vented extruder and adjustable technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of inability to adjust the area of the shear groove, poor applicability, blocking the air outlet of the vacuum machine, etc. Achieve the effect of avoiding incomplete plasticization, high applicability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

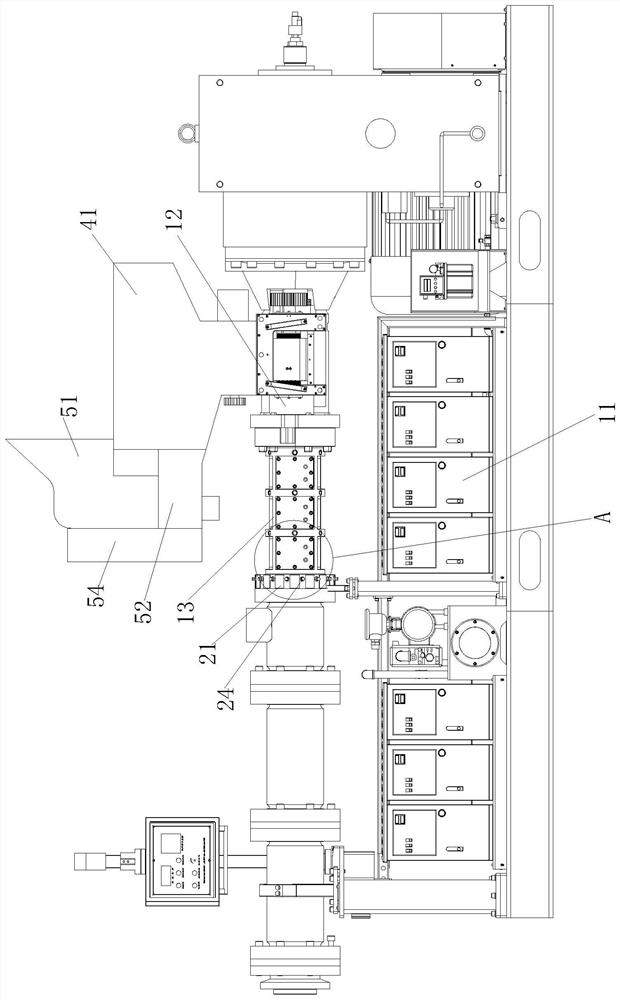

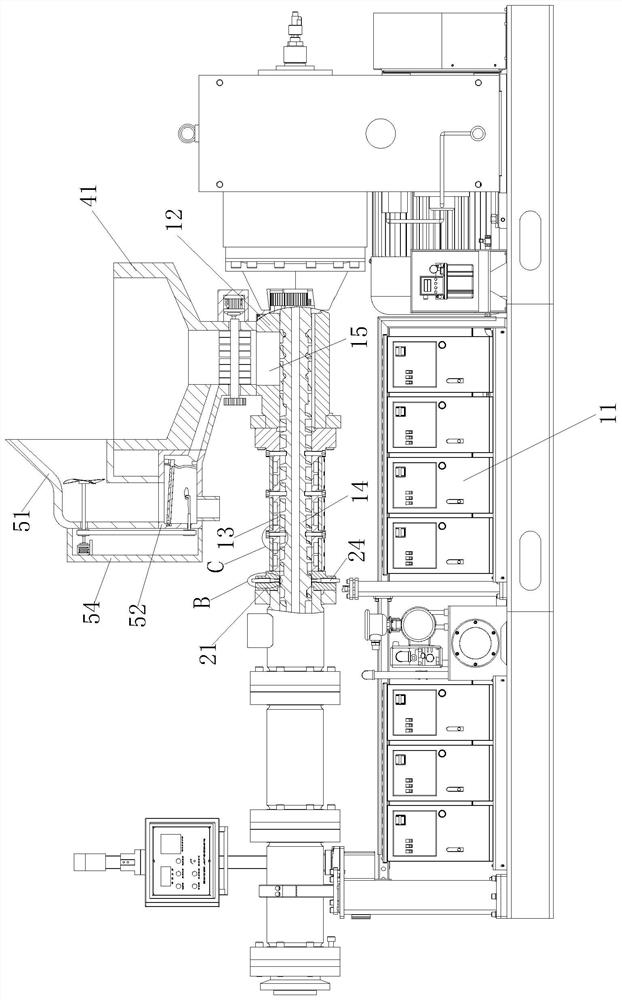

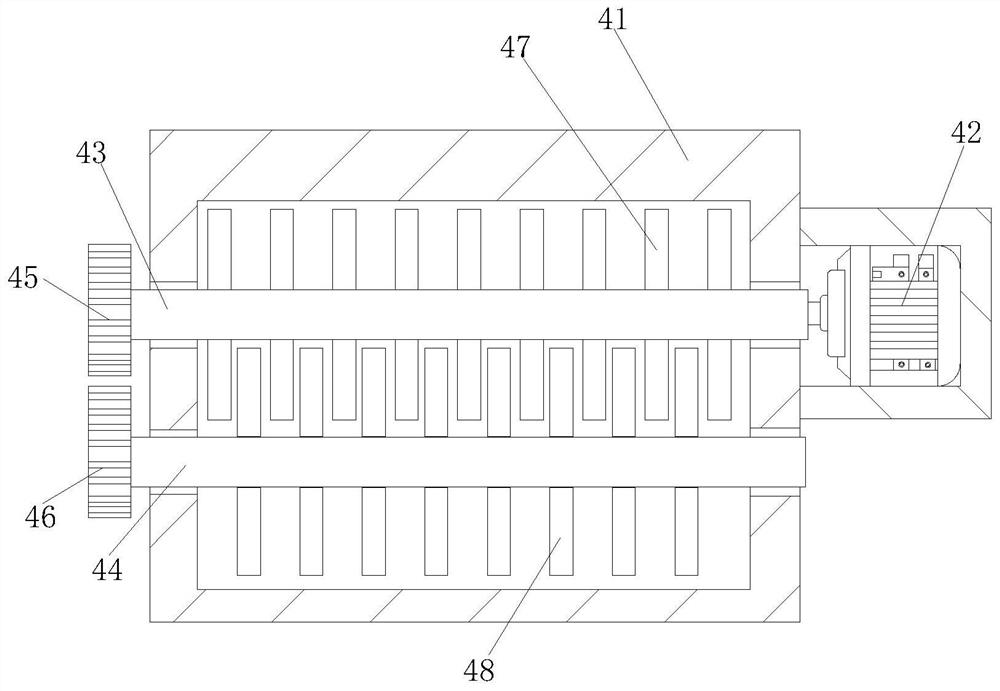

[0028] see Figure 1-9As shown, a vacuum section flow adjustable plasticizing section pin exhaust extruder includes a frame 11, a first housing 12, a second housing 13, a screw 14, an exhaust assembly and a plasticizing assembly; The first housing 12 is installed on the top of the frame 11; the top of the first housing 12 is provided with a feeding trough 15; the second housing 13 is fixed on the side of the first housing 12; the screw 14 is located on Inside the first housing 12 and the second housing 13; the end of the screw 14 is installed in the first housing 12; the exhaust assembly is arranged on the side of the second housing 13 away from the first housing 12; The plasticizing assembly is arranged on the surface of the second housing 13; the side of the exhaust assembly away from the second housing 13 is equipped with an air extraction device; the side of the air extraction device is equipped with an extrusion device; the exhaust The assembly includes an adjustment rin...

Embodiment 2

[0035] see Figure 10 As shown in Comparative Example 1, as another embodiment of the present invention, a mesh shield 8 is fixed at the top opening of the suction shell 51; during use, mosquitoes and foreign objects can be avoided through the mesh shield 8 into the suction shell 51.

[0036] Working principle, the liquid pipeline is fixedly connected with the infusion hole 34 and the liquid outlet hole 35, a motor is installed on the first housing 12, and a gear is fixedly connected with the screw rod 14 and the output end of the motor; Drive the screw 14 to rotate, the material is poured into the first shell 12 through the feeding trough 15, and the material is transported to the second shell 13 through the screw 14, the high-temperature liquid enters the annular cavity 31 through the infusion hole 34, and then the liquid passes through the The liquid outlet hole 35 flows out, and the high-temperature liquid is used to heat the second shell 13, thereby heating the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com